N.B.

The lobe is huge and comparable to the dimensions of the horn.

I have not received a site plan requested from the OP.

At the frequencies of interest, the intensity and arrival time difference cues are at their vanishing points. For basically the same reasons we cannot detect the individual frames of a video program. WHG

As can be seen from David McBean's diagrams, the thing that's been missing in this debate using proof-by-pictures is the listener's distance from the horn and other clues to dimensions. If we take the image of sonic desolation outside the 6dB trace, just how many feet are we talking about?

What is now helpful is the actual dimensions in feet or meters of the coverage lobe. And to see that image overlaid on the sketches of the yard and seating (or tubbing*) locations.

The lobe is huge and comparable to the dimensions of the horn.

I have not received a site plan requested from the OP.

Quite a hoot reading the physicist's view of hearing perception. Or the golden ears (and bodily proprioception) of others.

At the frequencies of interest, the intensity and arrival time difference cues are at their vanishing points. For basically the same reasons we cannot detect the individual frames of a video program. WHG

Last edited:

I have not received a site plan requested from the OP.

Post #768 shows the general site layout.

Property is large. Listening area can be very close to the horns, or far away - or anywhere between. (I have no preference). I own earth moving equipment, so the ground profile is a variable I can change.

Originally I was going to build two stereo horns, 60 feet apart, and sit way back from the horns. I was talked out of doing this, due to comb-filtering - now I'm looking at building the bass horns side-by-side, with a more narrow stereo main separation. I anticipate sitting close to the bass horns. This is why I don't need high SPL. There are about 35 homes within 1 mile of my house to the south - which is why I'm pointing my horns to the north. I am well aware that the very bottom octaves will easily make their way south, regardless if I point my horns to the north.

This is an outdoor home-audio horn system.

Reducing the size of the horns is not a design requirement. (I'd rather have two half-space stereo horns, than two quarter-space stereo horns). If I'm sitting close to a 32 foot wide x 14 foot tall horn, is a little bit of beaming between 100 Hz, and my crossover point (which will likely be somewhere between 120 and 150 Hz) - will it be a pronounced problem?

Last edited:

Didn't read all the 1022 post. So sorry if it has been already discussed.

Low end content got recorded harmonics + amp/cab harmonics.

Harmonics are of higher frequency => so directivity is important for harmonics.

So if a low end is recorded to the left, we can somewhat get some localisation effect from his harmonics.

At the same it, with only one center sub way, harmonics generated from driver are now exclusively on center channel, whereas those registered are still only on the left.

Low end content got recorded harmonics + amp/cab harmonics.

Harmonics are of higher frequency => so directivity is important for harmonics.

So if a low end is recorded to the left, we can somewhat get some localisation effect from his harmonics.

At the same it, with only one center sub way, harmonics generated from driver are now exclusively on center channel, whereas those registered are still only on the left.

Pass

It is apparent that my efforts won’t be needed here as the design is already frozen. Beaming is, and has been, a bogus issue for the wave lengths in question here. The sizes you are contemplating represent marked acoustic overkill. Simulation of Inlow's 16 Hz. bass horn [1] clearly demonstrates this. Note that driver displacement is inversely proportional to signal [f]^2. This means that driver excursion requirements grow rapidly the lower you go in frequency. Secondly because the system is outdoors, there is no room gain to help out. The overtones and harmonics issue raised here for signals below 80 Hz is amazing, and never the less inaudible, provided the system drive signals are properly conditioned (DSP front end and dedicated power amps assumed).

Also the structure(s) must deal with the elements for water runoff, moisture envision, wind up-lift loads, and snow loads. Besides cost, placement and structural load issues, these considerations make smaller better.

WHG

[1] DIY 16hz sub bass horn - The Paper Horn by Inlow Sound

Post #768 shows the general site layout.

Property is large. Listening area can be very close to the horns, or far away - or anywhere between. (I have no preference). I own earth moving equipment, so the ground profile is a variable I can change.

Originally I was going to build two stereo horns, 60 feet apart, and sit way back from the horns. I was talked out of doing this, due to comb-filtering - now I'm looking at building the bass horns side-by-side, with a more narrow stereo main separation. I anticipate sitting close to the bass horns. This is why I don't need high SPL. There are about 35 homes within 1 mile of my house to the south - which is why I'm pointing my horns to the north. I am well aware that the very bottom octaves will easily make their way south, regardless if I point my horns to the north.

This is an outdoor home-audio horn system.

Reducing the size of the horns is not a design requirement. (I'd rather have two half-space stereo horns, than two quarter-space stereo horns). If I'm sitting close to a 32 foot wide x 14 foot tall horn, is a little bit of beaming between 100 Hz, and my crossover point (which will likely be somewhere between 120 and 150 Hz) - will it be a pronounced problem?

It is apparent that my efforts won’t be needed here as the design is already frozen. Beaming is, and has been, a bogus issue for the wave lengths in question here. The sizes you are contemplating represent marked acoustic overkill. Simulation of Inlow's 16 Hz. bass horn [1] clearly demonstrates this. Note that driver displacement is inversely proportional to signal [f]^2. This means that driver excursion requirements grow rapidly the lower you go in frequency. Secondly because the system is outdoors, there is no room gain to help out. The overtones and harmonics issue raised here for signals below 80 Hz is amazing, and never the less inaudible, provided the system drive signals are properly conditioned (DSP front end and dedicated power amps assumed).

Also the structure(s) must deal with the elements for water runoff, moisture envision, wind up-lift loads, and snow loads. Besides cost, placement and structural load issues, these considerations make smaller better.

WHG

[1] DIY 16hz sub bass horn - The Paper Horn by Inlow Sound

Last edited:

I would not be soliciting your design recommendations, if my plans were already frozen.It is apparent that my efforts won’t be needed here as the design is already frozen - - - Also the structure(s) must deal with the elements for water runoff, moisture envision, wind up-lift loads, and snow loads. Besides cost, placement and structural load issues, these considerations make smaller better.

Regarding snow-loads, wind-loads, seismic-loads, moisture control, etc - designing a reinforced concrete structure in accordance with ACI-318 requirements, is well within my technical purview. Where I am lacking in knowledge however, is the acoustic portion of my horn design.

William,1)It is apparent that my efforts won’t be needed here as the design is already frozen.

2)Beaming is, and has been, a bogus issue for the wave lengths in question here. 3)The sizes you are contemplating represent marked acoustic overkill. Simulation of Inlow's 16 Hz. bass horn [1] clearly demonstrates this.

4)Also the structure(s) must deal with the elements for water runoff, moisture envision, wind up-lift loads, and snow loads. Besides cost, placement and structural load issues, these considerations make smaller better.

1) Or cast in four concrete monuments...

2) If David McBean's simulation in post 1017 is correct, and based on my experience with large bass horns, it "looks" about right to me, the 15' bass horn would be only 83.4 degrees at 100 Hz, 7.6 degrees less than the 90 degree mid and high horns used in typical horn systems.

For the low mid horns to have a similar beam-width at the crossover point, they will also have to be quite large. There is nothing wrong with a gradually expanding pattern at progressively lower frequencies, but the "waist-banding" at 100 Hz the huge horn will produce is definitely not a "hi-fi aspiration".

3) Yes, they do.

4) Agreed.

Cheers,

Art

Attachments

Eric,Where I am lacking in knowledge however, is the acoustic portion of my horn design.

I would suggest you re-read my answers to your quest for knowledge on the acoustic portion of your horn system design from prior to the point where your thread degenerated in to a troll fest.

If you do at some point actually begin to learn the requisite knowledge, you will understand the frustration of the "content providers" who see you asking the same questions over and over, then ignore advice, after you had been given all the advice you needed in the first 30 posts or so.

For a design to have a desired outcome, it must meet the "acoustic goals" you deem important.

None of us can decide what your "acoustic goals" are, (or will be) you must state them clearly to reach them.

Just as when making a design before building a bridge, you need to determine what every design aspect contributes before you can connect point "A" to point "B".

This is an example of 10 design criteria that were all met by my most recent horn design for use above 80 Hz:

Had any commercially available design existed that met all 10 design criteria, I would have bought, rather than built it myself.

1) Flat and smooth frequency response to assure "what goes in is what comes out".

2) High output response to below 100 Hz so sub-woofers do not need to be co-located with the main speakers, which are generally elevated. At frequencies below 100 Hz sound output (unless from a large array) is near omni-directional, so the apparent sound image location does not wander between the sub(s) and main speaker location as it would with the higher acoustical crossover point a speaker with less low frequency output would require.

3) Smooth phase response, necessary for good transient response.

4) Wide dynamic range, the capability of reproducing levels equivalent to instruments such as brass and percussion which can peak in the 125-130 dB SPL (sound pressure level) range at one meter.

5) Low harmonic and amplitude modulation distortion at all SPL levels that will be reproduced. Quite a bit of even order HD can be tolerated, as musically it is simply doubling octaves, while odd order HD is much less tolerable, as it can change the composition, introducing notes not in the original. AM distortion, often (mistakenly) called "Doppler distortion" occurs when a driver's excursion exceeds the linear range of operation, which causes a change in level (amplitude) of the higher frequencies at the same rate (modulation) of lower frequencies. The effect is quite pronounced, making voices sound like they are gargling, and the onset is rather rapid after Xmax (the limit of linear excursion) is exceeded. Clean output at high SPL requires larger drivers with greater Xmax than would satisfy reproduction at less than "live" levels.

6) Low thermal compression during demanding musical passages. At high drive levels loudspeaker voice coils heat up, causing their impedance to rise. Amplifiers, being voltage sources, deliver less power at higher impedance, hence louder average signal results in less output than it would before the voice coil heated. As well as the thermal compression issues, large temperature rises result in a number of other driver parameter changes which can result in a drastically changed frequency response, especially when using passive crossovers.

7) Even SPL over a large coverage area. The low humidity here in the high desert causes high frequency air absorption losses (in addition to the usual 6 dB per doubling of distance loss) to be 10 dB or more worse than in humid environments. To make up for those losses requires as much as 10 times more HF power, making points 4, 5, & 6 more difficult to achieve.

8) Constant directivity (even polar response) with a well defined 90 x 40 degree coverage pattern over a wide frequency range, necessary for each listener to hear the same response. Well defined coverage "edges" are needed to keep reproduced sound out of unwanted areas to reduce reverberation and acoustical feedback caused when stage microphones "hear", and re-amplify the main speaker's output.

9) In addition to the above audio criteria, working in smaller venues (sometimes without additional set up help) and advancing arthritis in my left wrist (getting old sucks) require compact size and light weight, which made achieving the above criteria far more challenging.

10) Power is often limited in smaller venues, making high efficiency a necessity to achieve criteria 1-6, and energy efficiency is just plain good for the planet.

Eric, only you can determine when you will master the requisite acoustic knowledge needed to build a great sounding system.

As your "mission" is a bit more evolved now than it was as stated, you may want to edit that post if you decide what your audio goals are. You can also use the OP to link to post numbers, though that gets dicey when posts are deleted..

Have fun,

Good Luck!

Art

Last edited:

Unless you've actually heard a pair of outdoor 15-Hz straight exponential stereo bass horns, cast in rigid concrete, how can you say for sure that my design is an acoustic overkill? Overkill implies a point of diminishing returns. Full-size straight exponential bass horns have very appreciable returns - in that the horn’s high-impedance throat will couple to the low-impedance air, with a high degree of mechanical efficiency. I want to experience this phenomenon - - - in my backyard. Will smaller horns work? Sure - with less efficiency, and with greater input power, and with less impedance matching, etc. It’s called an "ideal" horn - not an "overkill" horn.The sizes you are contemplating represent marked acoustic overkill.

The majority of time when I’m listing to my system, the volume will be set to a position where you could talk to the person next to you without yelling. This is not loud. . . I.E. just because my horns are big, does not mean they must be loud. This is a backyard stereo system. . . . . Occasionally I will turn the volume up - thus I need a reasonable amount of dynamic headroom.

Last edited:

The reasons for the horizontal boundaries are:

Floor: Not interested in directing acoustic energy into the ground

Roof: Implements the area expansion required for optimized driver loading.

Not concerned about vertical pattern control here.

A lot of this has been said before. The OP asked about this in post 149, but doesn't seem to have taken the answers on board, e.g:

I would make it [...] flat on the ground.

And later:

I'd make the side walls straight - or at least straight at the mouth. Most of the curve would be in the top wall. Vertical coverage angle could be any angle, it wouldn't really matter. In this application, you'd have to climb a tree to critique the vertical dispersion.

It's a long thread, and these old ideas are being churned up for a second, third, or tenth go around, and:

at 1000 posts, the OP has not done a single measurement or listening test.

Eric -

What are you willing to spend (not even counting your own labour time) on this total system to enhance your backyard?

How about a clear statement of your maximum budget so all the folks who spent so much time posting can judge if this exercise was just a fool's errand initiated by a guy who thinks it's fun to be the centre of attention or for real.

Might be costing $20,000 or who knows? I think you are bluffing or at best, indifferent to realities.

Ben

What are you willing to spend (not even counting your own labour time) on this total system to enhance your backyard?

How about a clear statement of your maximum budget so all the folks who spent so much time posting can judge if this exercise was just a fool's errand initiated by a guy who thinks it's fun to be the centre of attention or for real.

Might be costing $20,000 or who knows? I think you are bluffing or at best, indifferent to realities.

Ben

Last edited:

Ben,Eric -

What are you willing to spend (not even counting your own labour time) on this total system to enhance your backyard?

How about a clear statement of your maximum budget so all the folks who spent so much time posting can judge if this exercise was just a fool's errand initiated by a guy who thinks it's fun to be the centre of attention or for real.

Might be costing $20,000 or who knows? I think you are bluffing or at best, indifferent to realities.

Ben

Eric thus far has been unwilling to spend any labour towards reviewing any data, or considering professional consultation on a an acoustic design he indicated he was out of his depth (submariner joke

) on in his own thread.

) on in his own thread.I would doubt Eric could produce his "museo de concrete" for a mere $20,000 (USD) if his time is valued at a fraction of what has been expended in this "biggest, hardest", horny thread. But we have all Ben willing participants to flagrant abuses in the past, so our sado/masochistic tendencies should not be held to "close to" our (respective) (war) chests.

But I have faith that Eric is not bluffing or indifferent to realities, since we drive the same year and model car- though he still did not say if his was the color red.. so much yet to learn..

Cheers, Eh?

Art "Hoser" Welter

Getting it for Free

If the same fact is presented by a variety posters, then it may be considered credible and worthy of further independent investigation.

I will not sift through the post plethora before making a recommendation. WHG

A lot of this has been said before. The OP asked about this in post 149, but doesn't seem to have taken the answers on board, e.g:

And later:

It's a long thread, and these old ideas are being churned up for a second, third, or tenth go around, and:

If the same fact is presented by a variety posters, then it may be considered credible and worthy of further independent investigation.

I will not sift through the post plethora before making a recommendation. WHG

Last edited:

I will not sift through the post plethora before making a recommendation. WHG

Aye.

I just thought I'd bring this up since you were expressing concerns about the use of your time - you may be better off waiting for the OP to do some dabbling and measurements of his own.

e.g. Entropy455 talked of doing some prototype plywood horns. I bet if he actually makes these, he will refine his ideas about what matters / how best to do the bass horns.

I am going to build two identical 150-hz horns (simple plywood construction – nothing fancy)

[...]

I’m a Pepsi Challenge type of guy. I normally won’t write off a product, until after I’ve made my own evaluation.

That was a month ago.

Kelly's Heros

Why should I help you if the reward for doing so is as exemplified here? Once a horn's dimensions become comparable to the wavelength of lowest frequency to be passed, making it larger puts you on a path of diminishing returns. All well designed horns of a given geometry will exhibit the same upper band transformation efficiency. The lowest notes of a pipe organ are 8 and 16Hz. They are felt more than they are heard.

WHG

Oddball says: "Too many negative waves!"Unless you've actually heard a pair of outdoor 15-Hz straight exponential stereo bass horns, cast in rigid concrete, how can you say for sure that my design is an acoustic overkill? Overkill implies a point of diminishing returns. Full-size straight exponential bass horns have very appreciable returns - in that the horn’s high-impedance throat will couple to the low-impedance air, with a high degree of mechanical efficiency. I want to experience this phenomenon - - - in my backyard. Will smaller horns work? Sure - with less efficiency, and with greater input power, and with less impedance matching, etc. It’s called an "ideal" horn - not an "overkill" horn.

>snip<

Why should I help you if the reward for doing so is as exemplified here? Once a horn's dimensions become comparable to the wavelength of lowest frequency to be passed, making it larger puts you on a path of diminishing returns. All well designed horns of a given geometry will exhibit the same upper band transformation efficiency. The lowest notes of a pipe organ are 8 and 16Hz. They are felt more than they are heard.

WHG

Re #2

The sub-bass horn design I was working on does not have intrinsic pattern control, or waist banding issues well above the recommended c/o frequency of 80 Hz. Each of the three segments are dedicated to reproducing signals of left center and right channels respectively. Thus, in the overlap region with the mid-bass horns there are no insurmountable issues as well. At the that low end of the pass band common signaling is expected. WHG

William,

>snip<

2) If David McBean's simulation in post 1017 is correct, and based on my experience with large bass horns, it "looks" about right to me, the 15' bass horn would be only 83.4 degrees at 100 Hz, 7.6 degrees less than the 90 degree mid and high horns used in typical horn systems.

For the low mid horns to have a similar beam-width at the crossover point, they will also have to be quite large. There is nothing wrong with a gradually expanding pattern at progressively lower frequencies, but the "waist-banding" at 100 Hz the huge horn will produce is definitely not a "hi-fi aspiration".

>snip<

Cheers,

Art

The sub-bass horn design I was working on does not have intrinsic pattern control, or waist banding issues well above the recommended c/o frequency of 80 Hz. Each of the three segments are dedicated to reproducing signals of left center and right channels respectively. Thus, in the overlap region with the mid-bass horns there are no insurmountable issues as well. At the that low end of the pass band common signaling is expected. WHG

A lot of this has been said before. The OP asked about this in post 149, but doesn't seem to have taken the answers on board

Interesting comment hollowboy - the acoustic coupling of the horn’s impedance curve with the half-space plane occurs when the horn is within 1/4 wavelength of the half-space plane. While I openly admit this half-space horn coupling concept was difficult for me to grasp initially, however I’ve got an understanding now. Question - where am I failing to incorporate this lesson within my current plan? What have I failed to take onboard? Do you think I need to design a full-space horn, then literally cut it in half down the center axis, and joint it with the half-space plane? I.E. can you please be more constructive with your constructive criticism?

Why should I help you if the reward for doing so is as exemplified here? Once a horn's dimensions become comparable to the wavelength of lowest frequency to be passed, making it larger puts you on a path of diminishing returns. All well designed horns of a given geometry will exhibit the same upper band transformation efficiency. The lowest notes of a pipe organ are 8 and 16Hz. They are felt more than they are heard.

No one is twisting your arm to help me. I am well aware that 16 Hz is felt, and not heard. I am not sure what point you are trying to make about diminishing returns. Are you implying my horns are too big? They are properly sized half-space stereo bass horns, with a 15 Hz cutoff frequency – positioned side-by-side to minimize comb-filtering. So where’s the big flaw in my approach? And I thought you were going to provide a sketch or something – for recommended ‘conceptual’ horn geometry/design? I am not expecting you (or anyone) to calculate bending inertia, size & place rebar, calculate bending deflections, and bending stresses – i.e. the structural aspects are my area of expertise.

What are you willing to spend (not even counting your own labour time) on this total system to enhance your backyard?

I estimate the horns will cost me roughly 8 grand in concrete and 3.3 grand in rebar. Add another 50% in concrete & rebar for the horn retaining wall and horn foundation (abutment). I already have plenty of power – several MA-3600VZ amps, MA-5000VZ, a few DC-300-2A amps, etc. I own an excavator, bulldozer, track loader, and 10 ton truck – thus my labor costs are low (and my time is free, because this is my hobby). I’ll need to purchase other items - signal processors (digital crossovers, digital delays), wood for the forms, drivers, etc. Projects usually end up costing twice what's expected, and that's ok. . . .

Last edited:

Entropy455 talked of doing some prototype plywood horns. I bet if he actually makes these, he will refine his ideas about what matters / how best to do the bass horns - - - that was a month ago.

Are you implying that I'm behind schedule?

More importantly - are you implying that I'm way off the mark regarding what matters in outdoor concrete bass horn system design? Can you please elaborate, or speculate, as to what I should ultimately think that matters?

Hi Bill,

Your proposed design should work very well indeed .

.

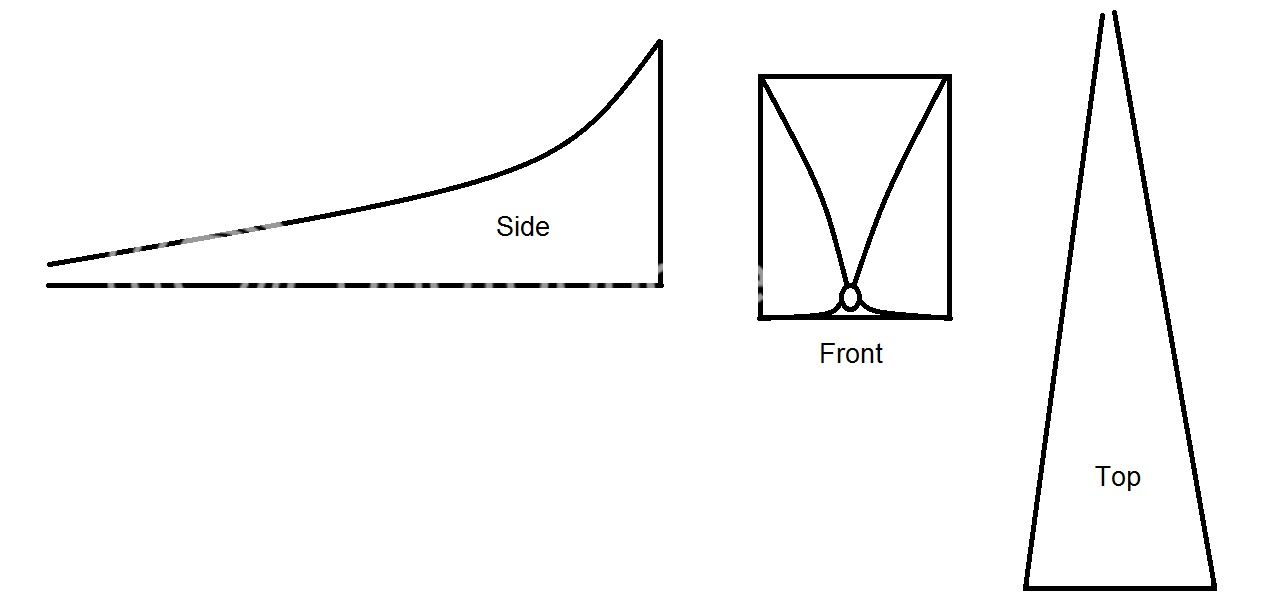

By using T = 0.6 and having in effect a "conical" expansion in the horizontal plane, I assume this means that the initial roof flare near the throat will be negative, to maintain the correct overall hyperbolic-exponential cross-sectional area expansion rate. Is this correct?

Many thanks. I look forward to seeing further details of your proposed design in due course.

Kind regards,

David

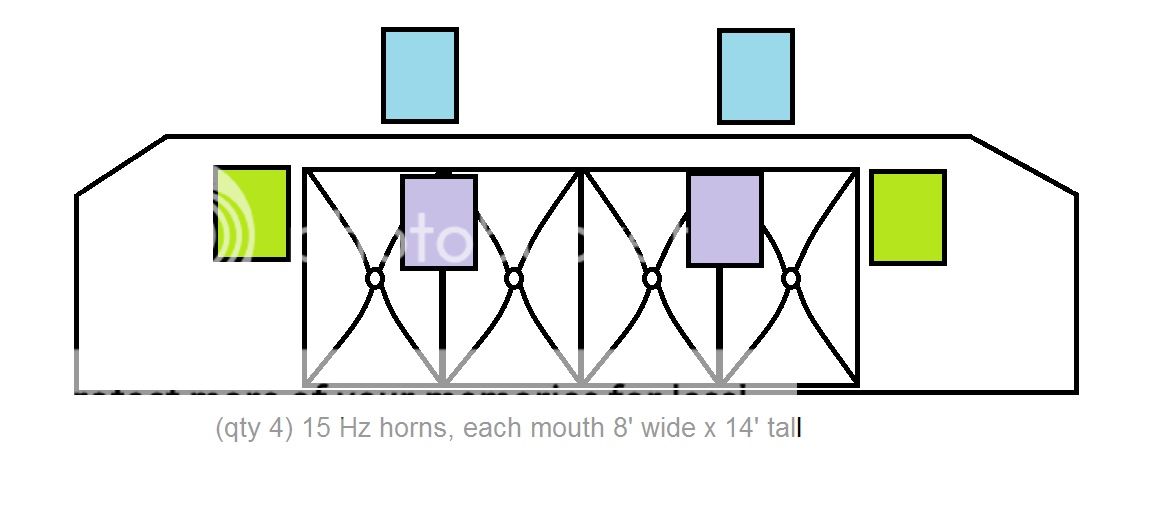

I am using four radially dispersed straight stem walls in the vertical plane and a flat floor and curvilinear roof to form the other two horn boundaries. The horn so formed has three 9' x 9' cells radiating into essentially a 1/4 space domain. Each cell is driven by two vertically stacked long-throw, 18" drivers. (Candidate: IST/UXL-18)

Throat diameter for each driver: 14". Horn length = 25'

The area expansion, remains at [T] = 0.6 for a [Fc] = 15Hz to start.

Your proposed design should work very well indeed

By using T = 0.6 and having in effect a "conical" expansion in the horizontal plane, I assume this means that the initial roof flare near the throat will be negative, to maintain the correct overall hyperbolic-exponential cross-sectional area expansion rate. Is this correct?

When I figure how to pour the roof and throat transitions from concrete I will release the design.

Many thanks. I look forward to seeing further details of your proposed design in due course.

Kind regards,

David

Here's a sketch (not to scale), showing my stereo bass horn proposal. The two left horns are a half-space left channel, and right horns are right. The horns are built into a large retaining wall.

If I place the mains in the location shown in green, I'll have better far-field stereo separation, however I could have some lobing issues at the bass-horn's crossover frequency. Another thing I like about the green location, is that I can cast pockets into the wall for the mains - to keep them out of the elements also - perhaps even put a small door on them (the bass horns will specifically not have a door). The blue location is somewhat centrally located above each stereo bass channel. The purple location is basically an elevated position out in front of the horns.

Constructive feedback . . . .. please???

By using T = 0.6 and having in effect a "conical" expansion in the horizontal plane, I assume this means that the initial roof flare near the throat will be negative, to maintain the correct overall hyperbolic-exponential cross-sectional area expansion rate. Is this correct?

I think he means something like this? I must admit, a flat bottom with straight side-walls would be VERY easy to cast. However the top of the horn is going to be a serious pain. If I am to incorporate a flat surface (for ease of construction), ideally it would be the top of the horn - as the top of the horn is a reinforced slab in bending-tension, simply supported on ends (in other words, the top of the horn must be cast thick, and with lots of rebar). . . . I look forward to seeing his design proposal nonetheless. . . .

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question