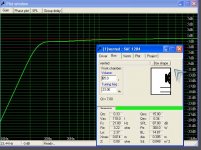

I have an SAE 1204 and Apex Sr amp that I bought from ApexJr.com. I am almost ready to build my powered sub and need some help reviewing my specs and plans before I actually start any cutting. Here is the plot from WinISD.

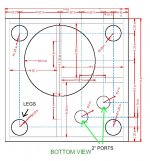

I am planning on using some plans from Adire Audio's Shiva ported enclosure plans. Instead of the one port they use I was planning on using two like in the next picture. Will this cause me any problems? Should I position them differently? If everything looks ok, I would like the go ahead so I could start the build ASAP. Please let me know. Thanks.

I am planning on using some plans from Adire Audio's Shiva ported enclosure plans. Instead of the one port they use I was planning on using two like in the next picture. Will this cause me any problems? Should I position them differently? If everything looks ok, I would like the go ahead so I could start the build ASAP. Please let me know. Thanks.

Attachments

I see that your sub has both the cone and the ports facing downward.

Are you certain that it is a good idea for your subwoofer to be facing down? These long excursion subs like the SAE 1204 might be a good deal more subject to sag than other woofers.

One member called up the company for a subwoofer he had, (I don't know if it is SAE or not), and asked if it was all right to have the cone downfiring. He was assured it was.

Two years later, the cone was sagging.

Peerless specifically recommends against downward or upward firing subs, and their drivers do not have the excursion of the SAE even. So I hope you get away with a downward firing, long excursion woofer.

Nothing wrong with having the ports downfiring, however.

I see the two ports are 4" diameter. That is good. You might try ading flares for even smoother operation, but it might not be necessary.

Are you certain that it is a good idea for your subwoofer to be facing down? These long excursion subs like the SAE 1204 might be a good deal more subject to sag than other woofers.

One member called up the company for a subwoofer he had, (I don't know if it is SAE or not), and asked if it was all right to have the cone downfiring. He was assured it was.

Two years later, the cone was sagging.

Peerless specifically recommends against downward or upward firing subs, and their drivers do not have the excursion of the SAE even. So I hope you get away with a downward firing, long excursion woofer.

Nothing wrong with having the ports downfiring, however.

I see the two ports are 4" diameter. That is good. You might try ading flares for even smoother operation, but it might not be necessary.

kelticwizard said:

I see the two ports are 4" diameter. That is good. You might try ading flares for even smoother operation, but it might not be necessary.

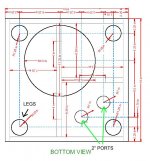

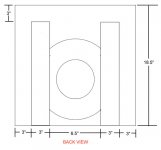

First off, my bad about the ports. They are actually 2" diameter. WinISD says that I can use (2) 2" ports that are each 8.99" long to give a Vent mach of 11.1 Here is the new pic. I can't edit the other one so here is the new one.

And about the downfiring sub. Maybe this isn't a good idea. I wasn't sure, I just saw that the plans looked good. Does anyone know if this is bad for sure? I will change my plans definitely if this is not a good idea. I am open to all suggestions as this is my first powered sub/speaker build. I built some BR1's but that was cake because the cabinets were already made. Please let me know about the downfiring sub. Thanks all.

-Ed

Attachments

Nice to see that the bracing doesn't run down the centre of the box.... i'd mount the driver on the side for the same reasons KW states... i'd also tune it for more droop on the bottom. With the response you've modeled it is going to have a big peak as room gain kicks in.

dave

dave

planet10 said:Nice to see that the bracing doesn't run down the centre of the box.... i'd mount the driver on the side for the same reasons KW states... i'd also tune it for more droop on the bottom. With the response you've modeled it is going to have a big peak as room gain kicks in.

dave

Could you explain a little more. Do you mean I should make the tuning frequency lower? Should I drop it to something like 18 or 20Hz? I would like to keep the volume at 85L. Please let me know. I will definitely be changing my plans now to be a forward firing sub. Can I just make the bottom the front as it is a cube? Does having the ports and driver on the same side matter? Thanks for everyone's help so far.

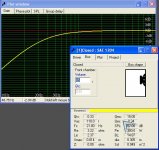

85L sealed enclosure

I would like some good low end. I listen to Home Theatre and music, but more Home Theatre than music. Right now I'm using BR1's and I need some low end. I do not mind building a sealed or ported. I just would like something that sounds good. I'm open for any suggestions. Also, if it would be better to make a smaller enclosure than that's fine too. I just would like a max of 85-95 liters. Thanks again.

I would like some good low end. I listen to Home Theatre and music, but more Home Theatre than music. Right now I'm using BR1's and I need some low end. I do not mind building a sealed or ported. I just would like something that sounds good. I'm open for any suggestions. Also, if it would be better to make a smaller enclosure than that's fine too. I just would like a max of 85-95 liters. Thanks again.

Attachments

Let's see, 85l BR or an 85l sealed box? Sounds like the best of both worlds to me. Build the box with the ports. Listen with the ports plug or not depending on how you're feeling at the time.

Although I'm partial to BR designs, your sealed curve looks pretty good. BTW, my vote is to mount the driver on the side as KW indicated.

Anyone up for some M&M

From north of 8 Mile Road,

Although I'm partial to BR designs, your sealed curve looks pretty good. BTW, my vote is to mount the driver on the side as KW indicated.

Anyone up for some M&M

From north of 8 Mile Road,

AudioIsFun said:

Can I just make the bottom the front as it is a cube?

Well, the legs might look a little funny sticking out the front. I'd put them on the bottom.

AudioIsFun said:Does having the ports and driver on the same side matter?

No. However, although I have not built a sub with downfiring ports yet, I have communicated with people who say that mounting the ports downward is a truly great way to build a ported box, especially a sub. The output gets coupled to the room and comes out very smoothly and powerfully.

Now for some bad news. I do not think two 2 inch diameter ports are adequate. Added together, they have the same cross-sectional area as one 3" port. A 3" port is adequate for a 10" woofer perhaps, but not a super long throw 12 inch. Use at least two 3" ports, and put flares on the ends, (available Madisound or Parts Express), because a port flared on both ends is supposed to be the equivalent of a port with twice the cross-sectional area. Not twice the diameter-twice the cross-sectional area. So a flared 3" dia port is equivalent to an unflared 4" diameter port.

Your SAE 1204 moves a lot of air, and requires a lot of space to accommodate that large bass output rushing out the port.

I would tune the box to at least 20 Hz or below, to account for room gain.

Two 3" diameter ports of 30" length, (better use some elbows), will take up about 7 liters of space. Add about 4 liters for the driver, and you have about 10 liters to deal with that will not be counted toward box volume. So your 85 liter box is actually 75 liters. Actually, the difference between 75 and 85 liters is not that much-or you can add a little extra space if you want.

Two 3" diameter ports of 30 inches tune an 85 liter box to 20 Hz. They will be 22" if you tune to 23 Hz.

Come to think of it, I think Stryke has a design of it's own that calls for three 3" ports. I think BAM was building it. I'll check. I think two 3" flared ports will be adequate, though.

Two 3" diameter ports of 30 inches tune an 85 liter box to 20 Hz. They will be 22" if you tune to 23 Hz.

Come to think of it, I think Stryke has a design of it's own that calls for three 3" ports. I think BAM was building it. I'll check. I think two 3" flared ports will be adequate, though.

Here is the thread. BAM's project is a little bit smaller than yours, though.

http://www.diyaudio.com/forums/showthread.php?threadid=25072&highlight=

Incidentally, I do think that having the ports firing downwards probably means that you can build the ports of a somewhat smaller diameter. Can't verify that, though.

To sum up, if I were building this I would increase the box size only slightly to accommodate the 10 extra liters, (really, that is very small), have the woofer firing frontward and have two 3" ports firing downward. That is how I would do it.

http://www.diyaudio.com/forums/showthread.php?threadid=25072&highlight=

Incidentally, I do think that having the ports firing downwards probably means that you can build the ports of a somewhat smaller diameter. Can't verify that, though.

To sum up, if I were building this I would increase the box size only slightly to accommodate the 10 extra liters, (really, that is very small), have the woofer firing frontward and have two 3" ports firing downward. That is how I would do it.

The 85L sealed looks pretty good to me... Still has an F10 @ 20 Hz. Match that up with room gain and you'll have good bass.... when you add in the ApexSr 6 dB of boost at 30 Hz you still might have too much. I'd be looking at wiring in a bass boost defeat switch and seeing if i could get the thing to roll off earlier & slower -- keeping the same size box, you'd have to go aperiodic -- which jives with Roddy's suggestion, because an aperiodic could be considered a leaky sealed box -- stuff the ports with foam, instead of just plugged.

dave

dave

kelticwizard said:Two 3" diameter ports of 30" length, (better use some elbows), will take up about 7 liters of space. Add about 4 liters for the driver, and you have about 10 liters to deal with that will not be counted toward box volume. So your 85 liter box is actually 75 liters. Actually, the difference between 75 and 85 liters is not that much-or you can add a little extra space if you want.

Two 3" diameter ports of 30 inches tune an 85 liter box to 20 Hz. They will be 22" if you tune to 23 Hz.

Come to think of it, I think Stryke has a design of it's own that calls for three 3" ports. I think BAM was building it. I'll check. I think two 3" flared ports will be adequate, though.

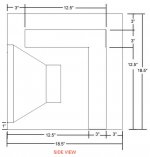

Ok so I'm going to use some new plans for a 95 L enclosure to account for the extra 10L of the driver and tubes. Here are the new diagrams. They are not exactly to scale, but I tried to make it close. I need these plans revised again if you guys could give them a look. Now for another question. I see flared ports by Madisound and Partsexpress but they are too short. I can buy elbows from HomeDepot but I still need more 3" tubing. I know I can buy 3" PVC from HomeDepot also, but don't they sell them in like 10feet+ things of tube? I only need like 4 feet, if that. I was thinking I could buy these flared ports, 3" x 11-1/2" PORT TUBE DUAL FLARED , and then cut them in half, couple them to some cut 3" PVC, if I can acquire some, and then to the elbow. I would use the bracing in the middle to help brace the port as I think it will be top heavy. Does anyone know how much 3" PVC at a hardware store costs? Please look over my plans and let me know about the materials for the port I need. Thanks again for everyones help.

-Ed

P.S. How far do the ports have to be from the inside walls? I thought I read somewhere that they had to be at least 3" from any inside wall? Please let me know so I can position these ports better if needed.

*The outer square is of the internal dimensions in both pics.

Attachments

AudioIsFun:

Your guess is as good as mine as to where to get 3" diameter PVC pipe in less than long lengths. I don't think it is all that expensive, though.

You can run the vent along an interior wall if you want, with one important provision. The opening of the port should be free of any stuffing and somewhat away from the wall. Actually, you can put the opening along a wall, without stuffing in the immediate vicinity, but it does lower the tuning somewhat-not sure how much, just a little. The important thing to keep in mind is that the port must be unobstructed by stuffing-you want free flow.

Since you are going to have flares on both ends, if you run the vent along the wall, you will have to turn the vent inward in order to make room for the flare.

One suggestion I would make is that if you want to brace the long vent, use a muffler clamp to attach the PVC pipe to whatever brace you wish to make. Makes things easy.

Your guess is as good as mine as to where to get 3" diameter PVC pipe in less than long lengths. I don't think it is all that expensive, though.

You can run the vent along an interior wall if you want, with one important provision. The opening of the port should be free of any stuffing and somewhat away from the wall. Actually, you can put the opening along a wall, without stuffing in the immediate vicinity, but it does lower the tuning somewhat-not sure how much, just a little. The important thing to keep in mind is that the port must be unobstructed by stuffing-you want free flow.

Since you are going to have flares on both ends, if you run the vent along the wall, you will have to turn the vent inward in order to make room for the flare.

One suggestion I would make is that if you want to brace the long vent, use a muffler clamp to attach the PVC pipe to whatever brace you wish to make. Makes things easy.

BAM said:Post up the T/S parameters you have for the SAE1204 and I'll come up with something for your driver.

T/S Parameters:

(VC's in parallel)

FS 21 Hz

Qms 15

Qes 0.342

Qts 0.334

Vas 110L Liters

Cms .32 mm/N

Mms 177 grams

Sd 492 cm2

Rms 1.565 Kg/S

Physical Dimensions:

A= 12.32" B=11.07" C=5.63" D=6.15" E=2.50" F=.32"

Here is the website I got the info from. Apex Jr

Thanks a lot for helping me. I really appreciate it. Thanks to everyone for helping me. I will post pics when I have a chance to actually build the sub. I am still acquiring some tools that I need, and I have lots of midterms around now. Hopefully I'll have some time next week. Thanks again.

-Ed

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Need these sub plans reviewed before I start the build