NB: Not sure if this should be in PA Systems or Subwoofers. Mods, feel free to move it if you like.

I'll be using this thread to document my build of 2x THAM15, probably throw a few questions out there, and share some measurements of the finished result. First, though, a quick introduction.

So, I bought a pair of Beyma 15P1200Nd drivers on an impulse. They were almost-half RRP, so what the heck. My first pair went into some old EV Deltamax 2-way cabinets, crossed to the 2" compression driver at 1.2kHz. Sounds lovely, though of course being top speakers, sheer output in the low end is limited.

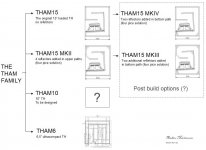

So, some subwoofers are in order. After lots of reading around about high-output designs (ie, avoiding port compression, stuff like that) and trying to roll my own, it looks like the THAM15 is the right thing for the job: extension to 40Hz and plenty of output in a smallish package.

The amplifier of choice is a PV2600, bridged, into the Beyma drivers paralleled. This is how I've run them previously* without issue. I know running bridged into 4ohm isn't a good idea, but the stuff that'll be played has very little sustained power, so I'm not too worried. Conveniently, sims show the drivers nudge past Xmax at full power from the Peavey amp. A good match methinks.

So, first question...

After I saw the free-air video of the 21SW115, I tested the Beyma drivers for wind noises. There's quite a lot of noise coming from the motor vents, especially towards the end of Xmax, and moreso as I head towards Xlim. Does anyone think that'll be a problem?

Somehow I doubt it, since there'll be an awful lot of sound at Xmax, but even so, worth checking.

Video of the free-air run coming soon.

Cheers

Chris

* the first set of Beyma drivers were used in a pair of mis-matched cabinets (one BP6, the other an OD-QWP, neither worked particularly well) for one of the smaller stages in an outdoor music festival. At FOH 15-20ft away from the stage, it was feel-it-in-your-chest loud, and the Peavey amp carried on all day.

I'll be using this thread to document my build of 2x THAM15, probably throw a few questions out there, and share some measurements of the finished result. First, though, a quick introduction.

So, I bought a pair of Beyma 15P1200Nd drivers on an impulse. They were almost-half RRP, so what the heck. My first pair went into some old EV Deltamax 2-way cabinets, crossed to the 2" compression driver at 1.2kHz. Sounds lovely, though of course being top speakers, sheer output in the low end is limited.

So, some subwoofers are in order. After lots of reading around about high-output designs (ie, avoiding port compression, stuff like that) and trying to roll my own, it looks like the THAM15 is the right thing for the job: extension to 40Hz and plenty of output in a smallish package.

The amplifier of choice is a PV2600, bridged, into the Beyma drivers paralleled. This is how I've run them previously* without issue. I know running bridged into 4ohm isn't a good idea, but the stuff that'll be played has very little sustained power, so I'm not too worried. Conveniently, sims show the drivers nudge past Xmax at full power from the Peavey amp. A good match methinks.

So, first question...

After I saw the free-air video of the 21SW115, I tested the Beyma drivers for wind noises. There's quite a lot of noise coming from the motor vents, especially towards the end of Xmax, and moreso as I head towards Xlim. Does anyone think that'll be a problem?

Somehow I doubt it, since there'll be an awful lot of sound at Xmax, but even so, worth checking.

Video of the free-air run coming soon.

Cheers

Chris

* the first set of Beyma drivers were used in a pair of mis-matched cabinets (one BP6, the other an OD-QWP, neither worked particularly well) for one of the smaller stages in an outdoor music festival. At FOH 15-20ft away from the stage, it was feel-it-in-your-chest loud, and the Peavey amp carried on all day.

Sine, not a problem - I know HDD crashes can really screw things up, even with backups in place.

Fresh, I think I'll be building the MkI version. The reflectors are there to improve the >100Hz performance, which, with 15" tops, I'm not too concerned about. I do like the look of the MkII's mouth, though, so might include that. That'd be a Mk1.2, I guess.

Winter and exams are drawing in here, so I can't promise this'll be the fastest of builds. With a bit of luck I'll have some wood cut for next weekend. Maybe. The cutsheets are all provided on Martin's blog, which is rather handy. I'd have to borrow a router for the 45 degree bits, too. The bottom angle is 93 degrees, and all the rest are 90. I suspect I'll get away without cutting the 93 degree angle, and just filling the gap with glue.

Chris

PS - Figured out how I can test motor noise: mount a driver in an existing cabinet, facing inwards, then turn it up. Since the cabinet will reduce excursion dramatically, it should give a reasonable indication of what the THAM15 will be like for noise. The only problem I can see is that the neighbours will be very unhappy with me, but should be fine for a quick test.

Fresh, I think I'll be building the MkI version. The reflectors are there to improve the >100Hz performance, which, with 15" tops, I'm not too concerned about. I do like the look of the MkII's mouth, though, so might include that. That'd be a Mk1.2, I guess.

Winter and exams are drawing in here, so I can't promise this'll be the fastest of builds. With a bit of luck I'll have some wood cut for next weekend. Maybe. The cutsheets are all provided on Martin's blog, which is rather handy. I'd have to borrow a router for the 45 degree bits, too. The bottom angle is 93 degrees, and all the rest are 90. I suspect I'll get away without cutting the 93 degree angle, and just filling the gap with glue.

Chris

PS - Figured out how I can test motor noise: mount a driver in an existing cabinet, facing inwards, then turn it up. Since the cabinet will reduce excursion dramatically, it should give a reasonable indication of what the THAM15 will be like for noise. The only problem I can see is that the neighbours will be very unhappy with me, but should be fine for a quick test.

Piece #1 below looks like it'll need a small cutout to avoid the cone hitting it at high excursions. The driver surround sits almost flat to the front gasket. With 18mm material, it'll take some serious power input to make the cone slap, but if it did, that'd fold the cone immediately. I'll probably take out 10mm or so with a jigsaw. Better save than sorry.

Going to take a video of the free-air excursion now, see what you guys think.

Chris

Going to take a video of the free-air excursion now, see what you guys think.

Chris

Forgive me if I'm wrong, but isn't that measurement almost 2 inches (between baffle and panel 1)?

Those beyma might be nice but I know they don't have 4" p2p excursion capabilities.

Panel 1 is a vertical brace, so it'd be only 18mm away from the driver. Since the Xlim is ~50mm p/p (I've tried this), I'd like to make sure the cone tries to move 7mm into some wood (worst-case, someone throws a crapload of power at it).

Chris

Piece #1 below looks like it'll need a small cutout to avoid the cone hitting it at high excursions. The driver surround sits almost flat to the front gasket. With 18mm material, it'll take some serious power input to make the cone slap, but if it did, that'd fold the cone immediately. I'll probably take out 10mm or so with a jigsaw. Better save than sorry.

Going to take a video of the free-air excursion now, see what you guys think.

Chris

Hello Chris, it does look like a great idea to do a cutout to the brace, I don't think it will hurt anything on the design if you cut a piece of it, like you mentioned, better save than sorry.

Update: tested the 40Hz OD-QWP with the driver facing into the pipe.

The windows, doors and furnature was far more audible than any noises the motor structure might've been making, so I'm going to call it good. This was my laptop feeding into the bridged PV2600. Not quite enough signal into the amp to clip it, but still got the driver boogying.

Chris

The windows, doors and furnature was far more audible than any noises the motor structure might've been making, so I'm going to call it good. This was my laptop feeding into the bridged PV2600. Not quite enough signal into the amp to clip it, but still got the driver boogying.

Chris

Hi,

I think you could make the design a little taller, stretching out the middle section. That'd increase the path length. Whether or not that's a good idea is up to you: Hornresp is your friend.

FWIW, a pair of THAM15s next to each other is just about falling off at 40Hz in open-field space. With wall/corner loading, I'd expect them to dig slightly lower and go considerably louder.

Chris

I think you could make the design a little taller, stretching out the middle section. That'd increase the path length. Whether or not that's a good idea is up to you: Hornresp is your friend.

FWIW, a pair of THAM15s next to each other is just about falling off at 40Hz in open-field space. With wall/corner loading, I'd expect them to dig slightly lower and go considerably louder.

Chris

Hi Y'all,

There is a great thread by Forsman that extends the low end of the THAMxx style enclosures:

http://www.diyaudio.com/forums/subwoofers/224160-thorn-f1-learning-experiance-tapped-horn.html

Always check w/ Hornresp for compatibility w/ your chosen driver.

Regards,

There is a great thread by Forsman that extends the low end of the THAMxx style enclosures:

http://www.diyaudio.com/forums/subwoofers/224160-thorn-f1-learning-experiance-tapped-horn.html

Always check w/ Hornresp for compatibility w/ your chosen driver.

Regards,

Last edited:

Thanks, guys. Streching out the middle section, would that be L23 for a Hornresp novice?

Yes I've seen Forsman's derivative of the THAM12 but it still doesn't hit a clean 40 Hz before falling off. Ideally, I'd like F3 no higher than 35 Hz...

On the topic of Hornresp and being a complete noob at it, how come most of the better-known TH designs cannot take a lot of power before they exceed Xmax? For example, if I input the parameters for a Thorn F1 and check acoustical power graph using the the driver's Xmax and Pe, I get the same result as Forsman's "official graph". However, when I go and check the displacement graph at that power level, Xmax is way exceeded and cannot be reigned in unless I reduce the power available significantly, typically well below 100W....?

Yes I've seen Forsman's derivative of the THAM12 but it still doesn't hit a clean 40 Hz before falling off. Ideally, I'd like F3 no higher than 35 Hz...

On the topic of Hornresp and being a complete noob at it, how come most of the better-known TH designs cannot take a lot of power before they exceed Xmax? For example, if I input the parameters for a Thorn F1 and check acoustical power graph using the the driver's Xmax and Pe, I get the same result as Forsman's "official graph". However, when I go and check the displacement graph at that power level, Xmax is way exceeded and cannot be reigned in unless I reduce the power available significantly, typically well below 100W....?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Building a pair of THAM15 subs