I posted about this subwoofer project earlier this year with some pictures of the construction and a description of an idea for a closeable port. So I went on a journey to have a Port Valve turned from Oak. Well the guy who was going to do the turning gave up on me so I went and bought a lathe and did it my self. I’m actually glad I got the lathe, beside it being a lot of fun I was able to get the valve just the way I wanted it and the valve seat fits so tight that I will only need a thin gasket to finish the seal, so I’m very happy with the functionality of the entire Vale mechanism, it works very smooth and only a few twists of the knob and the Valve is closed very tight.

Besides the 5 month delay to get an acceptable Port Valve turned the project so far has taken about 300 hours over 4months and cost about $1200 US for each of the 2 Maelstrom 18” Sonotubes. I still have a few details to finish but this one is ready to go into the listening room. Next I will silkscreen the plate behind the Valve knob with a placard that will show the “Open” and “Close” position, and a felt gasket on the valve seat to complete the seal. The prototype worked very well so I’ve already had many hours to listen to a working version of the port valve in a real world situation, and it does work very well to tighten up the bass when the valve is closed, pulse it’s somewhat decorative and functional as a display shelf. Now all I have to do is fix all the rattles in the house that just one of these has brought to my attention. Hopefully early this New Year I will have both subs in the listening room and have the BFD E.Q. set up properly.

Besides the 5 month delay to get an acceptable Port Valve turned the project so far has taken about 300 hours over 4months and cost about $1200 US for each of the 2 Maelstrom 18” Sonotubes. I still have a few details to finish but this one is ready to go into the listening room. Next I will silkscreen the plate behind the Valve knob with a placard that will show the “Open” and “Close” position, and a felt gasket on the valve seat to complete the seal. The prototype worked very well so I’ve already had many hours to listen to a working version of the port valve in a real world situation, and it does work very well to tighten up the bass when the valve is closed, pulse it’s somewhat decorative and functional as a display shelf. Now all I have to do is fix all the rattles in the house that just one of these has brought to my attention. Hopefully early this New Year I will have both subs in the listening room and have the BFD E.Q. set up properly.

Attachments

a 5 angle valve grind might give you better flow

You could also just have a threaded rod at the end of the valve stem and spin it down to close it, but all that spinning is a lot of work!

Are you closing it to try intermediate tunings?In other words does the bass slowly tighten up as you close it?

Also keeps the cats out.

You could also just have a threaded rod at the end of the valve stem and spin it down to close it, but all that spinning is a lot of work!

Are you closing it to try intermediate tunings?In other words does the bass slowly tighten up as you close it?

Also keeps the cats out.

You might need to measure the output using the Richter scale.kingdaddy said:SY,

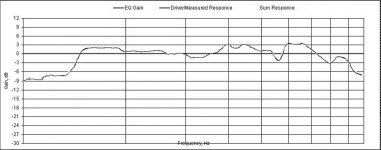

I'll be using Tony Gomez's PEQ program and a Rat Shack SPL meter this week to plot a in-room response. Thanks all for the comments.

Attachments

Variac said:a 5 angle valve grind might give you better flow

You could also just have a threaded rod at the end of the valve stem and spin it down to close it, but all that spinning is a lot of work!

Are you closing it to try intermediate tunings? In other words does the bass slowly tighten up as you close it?

Also keeps the cats out.

Actually the Valve stem is threaded and screws into a 1/2 copper plumbing pipe that is suspended in the middle of the port which is attached to the window crank mechanism.

The Valve must be removable to gain access to the alignment assembly which centers the Valve in the middle of the port opening, but screwing the valve in is not necessary to close the port as the window crank mechanism does all the work with just a few twists of the knob. As for the sound difference it's hade to hear any difference until the port is completely sealed, I thought I might be able to hear it go Aperiodic but so far I can't.

The toughest part of this project was undoubtedly building a guide and alignment mechanism that would not only keep the valve perpendicular or linier to the center of the port during movement but also to keep everything well dampened and quite. I wasted a lot of money trying different materials, but finally ended up with a Kydex (plastic) Valve guide and that rubber dip that you can buy at Home Depot, this took care of any vibrating parts or ringing. It’s surprising that the window crank mechanism has enough holding power to seal the port closed without any help but I’m glad it does other wise this would have gotten even more complex and I was about ready to give up the idea if I had to build one more integrated mechanical mechanism. I think the Diameter of the port helped a lot, I was able to keep the air flow below 17m/s with an 8” diameter and still keep the port resonance above the pass band, and this pressure exerted over such a large area also allows the valve to seal very well when closed.

These 2 Sonotubes will be powered with a Mackie 1400i at 700W per channel and of course a BFD to smooth out the humps. This along with 2 other 12” ACI sealed subs and 4 bass shakers in the couch should take care of the bass department, as it stands I have a total of 9 speakers plus the bass shakers and approximately 3200 watts total power and not a single Passive crossover in my 14’X15’ listening room. Next will be a new Center Channel speaker.

This pic shows an early prototype of the valve closing mechanism without the rubber dampening and Kydex guides.

Attachments

I must correct myself

Variac;

I'll have to correct myself about the bass changing as I close the Port Valve, I just tried some test tones and it is very audible as the port is closing. I can hear the air rushing around the valve seat at about 2" before it’s closed and as the valve is closed it gets very strange sounding right up until it seals closed, then audible Womp! is heard when the air is sealed. Also I noticed the enclosure vibrating considerable more then with the Valve open. This thing might actually prove to be quite fun and enlightening to experiment with. BTW leaving the port barely open sounds terrible, it sound’s completely different (in a good way) when the port is well open or totally closed, but the air rushing sound is not at all musical.

Variac;

I'll have to correct myself about the bass changing as I close the Port Valve, I just tried some test tones and it is very audible as the port is closing. I can hear the air rushing around the valve seat at about 2" before it’s closed and as the valve is closed it gets very strange sounding right up until it seals closed, then audible Womp! is heard when the air is sealed. Also I noticed the enclosure vibrating considerable more then with the Valve open. This thing might actually prove to be quite fun and enlightening to experiment with. BTW leaving the port barely open sounds terrible, it sound’s completely different (in a good way) when the port is well open or totally closed, but the air rushing sound is not at all musical.

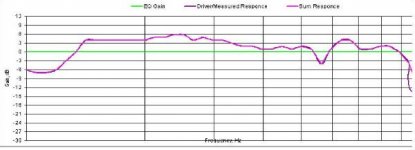

Here is the final correction for both subs sealed (port valves closed). This time I tried to stay away from very narrow filters as much as possible. Tuning for the sealed version was much more difficult that the Ported correction, I'm not sure why.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Finished my Maelstrom Sonotube after almost a year of work

And to your neighbors, be afraid, be very afraid.

And to your neighbors, be afraid, be very afraid.