Iám learning to fold some tapped horns, but before i can finish a folded horn i have to figure out which "fold-style" i have to use.

i found out how to fold horns in google sketch up, just make a 2D modell and just fold it, but its not easy to fold it cause some styles work and some not.

I am trying double fold, keystone and to fold it like the MTH30 and some own ideas.

My question is, if its possible to figure out which "fold style" to use before i start modeling in sketch up. Is there a way to calculate this, or can somebody tell me how to know the "folding-style" before doing all the work?

i found out how to fold horns in google sketch up, just make a 2D modell and just fold it, but its not easy to fold it cause some styles work and some not.

I am trying double fold, keystone and to fold it like the MTH30 and some own ideas.

My question is, if its possible to figure out which "fold style" to use before i start modeling in sketch up. Is there a way to calculate this, or can somebody tell me how to know the "folding-style" before doing all the work?

The Keystone and the MTH30 are a very different shape, requiring different fold patterns to achieve the required horn path length.I am trying double fold, keystone and to fold it like the MTH30 and some own ideas.

My question is, if its possible to figure out which "fold style" to use before i start modeling in sketch up. Is there a way to calculate this, or can somebody tell me how to know the "folding-style" before doing all the work?

After determining the horn volume, you need to decide the desired shape and dimensions that work for your applications.

I generally use truck box integers when designing cabinets for portable use.

Since most straight trucks in the USA have a clear 90 inch width (and usually height) integers are 45, 30, 22.5 and 15 inches.

Once the shape and volume are determined, draw out the straight horn on a piece of paper, cut and fold it so it fits in the shape you decided on.

Easy as that

I generally use truck box integers when designing cabinets for portable use. Since most straight trucks in the USA have a clear 90 inch width (and usually height) integers are 45, 30, 22.5 and 15 inches.

This is an excellent idea. Something I learnt AFTER building my POC#2, LOL. Now I'm designing POC #3 to be a bit more transport-friendly.

Once the shape and volume are determined, draw out the straight horn on a piece of paper, cut and fold it so it fits in the shape you decided on.

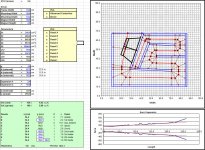

...or if you're spreadsheet-savvy, you could do it in Excel

Attachments

This is an excellent idea. Something I learnt AFTER building my POC#2, LOL. Now I'm designing POC #3 to be a bit more transport-friendly.

...or if you're spreadsheet-savvy, you could do it in Excel

Hi. Brian Steele

I'm interested fold a horn in excel

please share and recommend.

Thank you.

Folding affects the horn response. You can include compensation for folding in your design. The swedish thread Spelglädje under 1000 Hz contains some expermentation data, run it through google translate.

Check out Martinssons designs, they are masterpieces of simplicity. They have only one really difficult angle to cut, the rest are 90, 60 or 45 degrees. You can easily build these with cheap tools. These tapped horns are intended for sound reinforcement.

Check out Martinssons designs, they are masterpieces of simplicity. They have only one really difficult angle to cut, the rest are 90, 60 or 45 degrees. You can easily build these with cheap tools. These tapped horns are intended for sound reinforcement.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- How to fold a Horn