There is a possibility that I will be asked to construct a subwoofer for a room that will be used quite heavily for parties. This means that in this case quantity is somewhat prioritized over quality. This also means that it will be playing a lot of base heavy music.

The budget is rather slim but I've made two suggestions using a Dayton DCS385-4 15" driver and a Monacor SAM-300D 300W amp. As for the box I was thinking a ported rather then sealed for increased volume. The placement won't be ideal either since it will have to stand behind a corner sofa, i.e it will have to be a three sided box. The port will be firing underneath the sofa.

I did some calculations in BB Pro 6 and got two inital alternatives I would like to get some feedback on:

F3 @ 30Hz:

F3 @ 35Hz:

At this stage I would like to point out that I don't have a whole lot of experience with building subwoofers so go easy on me.

The budget is rather slim but I've made two suggestions using a Dayton DCS385-4 15" driver and a Monacor SAM-300D 300W amp. As for the box I was thinking a ported rather then sealed for increased volume. The placement won't be ideal either since it will have to stand behind a corner sofa, i.e it will have to be a three sided box. The port will be firing underneath the sofa.

I did some calculations in BB Pro 6 and got two inital alternatives I would like to get some feedback on:

F3 @ 30Hz:

F3 @ 35Hz:

At this stage I would like to point out that I don't have a whole lot of experience with building subwoofers so go easy on me.

Thanks. Would you advice to put both the cone and port above the sofa?

If possible, yes. But would not face them upwards, where people could spill on them.

A quick sketch with dimensions of what you have to work with would be very helpful here.

How large is the space, and what are the main speakers you have to keep up with?

Last edited:

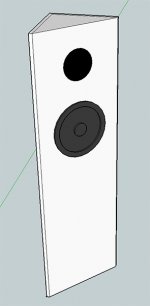

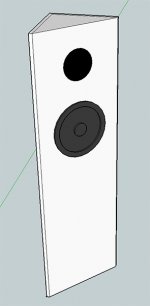

Made a quick 3d sketchup:

The amp would be placed at the bottom of the baffle. The box is now 79" high which would place the port above head level (don't want anyone to get that thing blowing in their neck). Would this be a better placement? Or should I keep the port high and place the cone low with the amp in the middle?

The amp would be placed at the bottom of the baffle. The box is now 79" high which would place the port above head level (don't want anyone to get that thing blowing in their neck). Would this be a better placement? Or should I keep the port high and place the cone low with the amp in the middle?

......should pass right through a sofa.

Disagree. A sofa will absorb a significant amount of sound, which is particularly important for a sub with limited output.

Made a quick 3d sketchup:

View attachment 369693

The amp would be placed at the bottom of the baffle. The box is now 79" high which would place the port above head level (don't want anyone to get that thing blowing in their neck). Would this be a better placement? Or should I keep the port high and place the cone low with the amp in the middle?

I would build it right up to the ceiling and get both the driver and port as close to the ceiling as is practical, for good corner loading. Use a large area port with a 90 degree bend, slot/triangle port if needed, or put the woofer and port on the top face about 2-3" from the ceiling.

I strongly recommend plywood, not mdf.

Last edited:

Not sure how tight your budget is, but you may also want to look at these two drivers:

Dayton Audio DCS450-4 18" Classic Subwoofer 4 Ohm 295-475

Dayton Audio DVC385-88 15" DVC Series Subwoofer 295-190

Dayton Audio DCS450-4 18" Classic Subwoofer 4 Ohm 295-475

Dayton Audio DVC385-88 15" DVC Series Subwoofer 295-190

I can't get good curves with such a big box though. Maybe I'm missing something?I would build it right up to the ceiling and get both the driver and port as close to the ceiling as is practical, for good corner loading. Use a large area port with a 90 degree bend, slot/triangle port if needed, or put the woofer and port on the top face about 2-3" from the ceiling.

I strongly recommend plywood, not mdf.

Why plywood instead of mdf, wouldn't mdf be better at resisting vibrations?

I can't get good curves with such a big box though. Maybe I'm missing something?

Why plywood instead of mdf, wouldn't mdf be better at resisting vibrations?

Too much volume will lead to a lower extension than is desired and lower sensitivity. You should be aiming for maximum output around 30-80 hz, so your initial tunings are about right. Getting it corner loaded is important though for output, so it may make sense to build it up on a riser of unused space if you were to corner load to a ceiling.

All types of plywood are stiffer than the equivalent thickness of MDF. While mdf will damp higher frequency vibrations better, plywood will be stiffer and transmit more bass energy in the box which is particularly important for subwoofers. All good quality pa speakers and subs are built from baltic birch plywood, at considerable expense. The economical alternative to this is cabinet grade poplar, fir or aspen plywood which is available at home depot for about $45 a sheet.

Columbia Forest Products : Veneer Core

If you're worried about higher frequency vibrations, an internal coating of roofing tar will help, but is not particularly needed. I prefer to not stuff the box, since the stuffing will lower extension at the expense of output. Bracing is also important.

Yes in the 75-100hz range (mid-bass) but the five mattresses the bass player used on the windows and doors of the practice space next door did nothing to the low E of his SVT Meatsmoke combo.Disagree. A sofa will absorb a significant amount of sound, which is particularly important for a sub with limited output.

If you have the budget, I would actually suggest 2 12" enclosures instead of 1 15. Reason being, while corner loading will give you the most output, putting the sub in the corner will excite every room mode that exists. This might be nice if the room is small, but if it's a large room for parties, you will likely have nodes due to standing waves and phase cancellations. If you don't care about this, then it's whatever, but if you smooth out the room response with the 2 12s, you will actually end up with more bass everywhere.

This is true but for the wrong reason. Plywood is strong, but most importantly much less massive than MDF. When you need to be moving things around, or flying arrays, this becomes important very quickly. Coloration in pro sound applications is not a major concern as it is in quiet hi-fi listening rooms. Mass, however, is king for low frequencies. Plywood is not a superior building material for low frequencies compared to MDF. It simply has a greater strength/weight ratio.Too much volume will lead to a lower extension than is desired and lower sensitivity. You should be aiming for maximum output around 30-80 hz, so your initial tunings are about right. Getting it corner loaded is important though for output, so it may make sense to build it up on a riser of unused space if you were to corner load to a ceiling.

All types of plywood are stiffer than the equivalent thickness of MDF. While mdf will damp higher frequency vibrations better, plywood will be stiffer and transmit more bass energy in the box which is particularly important for subwoofers. All good quality pa speakers and subs are built from baltic birch plywood, at considerable expense. The economical alternative to this is cabinet grade poplar, fir or aspen plywood which is available at home depot for about $45 a sheet.

Columbia Forest Products : Veneer Core

If you're worried about higher frequency vibrations, an internal coating of roofing tar will help, but is not particularly needed. I prefer to not stuff the box, since the stuffing will lower extension at the expense of output. Bracing is also important.

"Plywood" and "MDF" are generic terms. Within each you can have cheap stuff and high quality. I think the important thing is to brace the cabinet so the walls don't buzz.

And if you can build all the way up to the ceiling, try to use that volume! 2 drivers-the same one you modeled if budget allows, or maybe 2 of something less expensive. More area = same SPL with less cone motion. How wide is the face of this thing?

By the way, I'd be really concerned about fitting big-enough-area ports without the inside end being too near a wall. Be sure to run some air velocity simulations, or someone here can help if you can't.

One of the audio writers some time back actually did a bunch of testing, and got the smoothest bass response using multiple subs stacked in the corner. Tom something? But not Tom Holman...I'm blanking on the name...anyway, in your case an 8' corner tube with 2 cones up near the ceiling would be equivalent.

And if you can build all the way up to the ceiling, try to use that volume! 2 drivers-the same one you modeled if budget allows, or maybe 2 of something less expensive. More area = same SPL with less cone motion. How wide is the face of this thing?

By the way, I'd be really concerned about fitting big-enough-area ports without the inside end being too near a wall. Be sure to run some air velocity simulations, or someone here can help if you can't.

One of the audio writers some time back actually did a bunch of testing, and got the smoothest bass response using multiple subs stacked in the corner. Tom something? But not Tom Holman...I'm blanking on the name...anyway, in your case an 8' corner tube with 2 cones up near the ceiling would be equivalent.

Thanks guys for your help and input. Unfortunately, behind the corner sofa is the only place where a sub can be placed so no chance of having two subs. I'll be in the room tomorrow so I'll take some more accurate measurements and get back to you then.

If anyone wants to do their own calculations to see what you come up with I would really appreciate it. My newest calculations got a Vb of 157.8L, F3 at 30Hz, Fb at 22.24Hz and QL at 6.076 with little damping. With 300W power it would give me a peak of a little over 117dB between 50-80Hz (not including room response).

My newest calculations got a Vb of 157.8L, F3 at 30Hz, Fb at 22.24Hz and QL at 6.076 with little damping. With 300W power it would give me a peak of a little over 117dB between 50-80Hz (not including room response).

Also, how low will the db drob need to be at the Hz where Xmax is crossed as to not need a subsonic filter?

If anyone wants to do their own calculations to see what you come up with I would really appreciate it.

Also, how low will the db drob need to be at the Hz where Xmax is crossed as to not need a subsonic filter?

That's a nice idea but since it won't be in my home and the fact that the back will rarely be dusted, I think I'll take the easy way.

Great, I'll give it a shot.

Haven't got the exact measurements yet but I played around a bit more in Bassbox and when I went from "Vented box" to "Vented box with active HP filter" it went crazy! I filled in 20Hz and put Qx to 2 (would this be a good Qx value?). Now the driver exceeds Xmax as soon as 47Hz! Vent air velocity skyrocketed from 18.7m/s to 37.8m/s @20Hz.

No matter how I dimension the box I can't get the cone displacement to go down to reasonable numbers. What am I doing wrong?

What am I doing wrong?

Great, I'll give it a shot.

Haven't got the exact measurements yet but I played around a bit more in Bassbox and when I went from "Vented box" to "Vented box with active HP filter" it went crazy! I filled in 20Hz and put Qx to 2 (would this be a good Qx value?). Now the driver exceeds Xmax as soon as 47Hz! Vent air velocity skyrocketed from 18.7m/s to 37.8m/s @20Hz.

No matter how I dimension the box I can't get the cone displacement to go down to reasonable numbers.

Plywood is stiffer and lighter than MDF. All things being equal, it is the prefered material to build a (non-sealed) subwoofer from. With any ported or horn subwoofer, the idea is for the sound energy in the box to get out through the port or horn. If the MDF is flexing and absorbing energy, you lose output.

Putting a sub behind a sofa will also lose output into the room.

Building a good speaker or subwoofer is first about the overall design/model, then about how it is implemented. There are a bunch of little details that can either add or subtract from the overall performance. If you sweat all those little details, you can make something very impressive out of modest equipment.

Putting a sub behind a sofa will also lose output into the room.

Building a good speaker or subwoofer is first about the overall design/model, then about how it is implemented. There are a bunch of little details that can either add or subtract from the overall performance. If you sweat all those little details, you can make something very impressive out of modest equipment.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- DIY Subwoofer for music