Depends on what you think is similar.Am I to assume most hand held circular saws have a similar width blade anyway?

Kerf widths from .104 to .125 are common.

With a battery powered saw, look for a thin kerf and a couple spare batteries

ThyDntWntMusic,

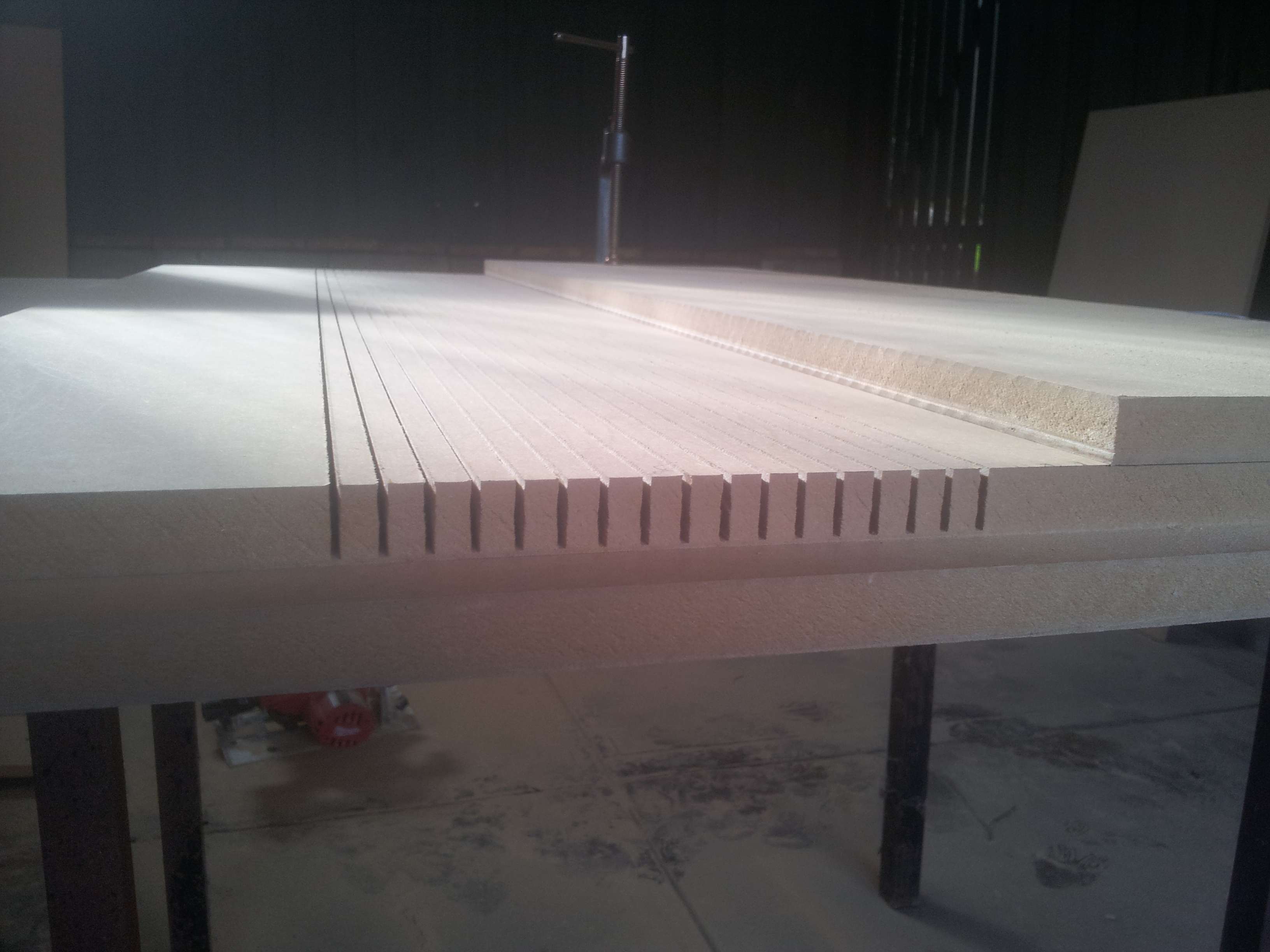

A wider blade with take more power from you portable saw to cut and you will use your battery faster. One thing I will say about the subject of blade width is that the width of the groove will have much to do with how much you can bend the wood as much as how close together you place the grooves. I don't think you should worry to much about the finish of the cut as you will be closing the cut up with the bending and it will be on the inside of the cabinet. You can look at the set of the teeth on the blade and that will also have much to do with the cut width, as much or more than just the thickness of the blade body. Some blades will have a straight set tooth profile and some can have a wide offset to the individual teeth. It also depends on the thickness of the MDF that you will be using in your project which blade you would want to use.

A wider blade with take more power from you portable saw to cut and you will use your battery faster. One thing I will say about the subject of blade width is that the width of the groove will have much to do with how much you can bend the wood as much as how close together you place the grooves. I don't think you should worry to much about the finish of the cut as you will be closing the cut up with the bending and it will be on the inside of the cabinet. You can look at the set of the teeth on the blade and that will also have much to do with the cut width, as much or more than just the thickness of the blade body. Some blades will have a straight set tooth profile and some can have a wide offset to the individual teeth. It also depends on the thickness of the MDF that you will be using in your project which blade you would want to use.

I'm wanting to do more cuts, closer together, to get a smoother bend, hence looking for the thinnest blade possible

Saw has never struggled with anything I've thrown at it, upto 36mm MDF (double layer 18mm)

Battery life isn't of concern either.

Might head to my local hardware store and see what they have available, and go from there.

Thanks!

Saw has never struggled with anything I've thrown at it, upto 36mm MDF (double layer 18mm)

Battery life isn't of concern either.

Might head to my local hardware store and see what they have available, and go from there.

Thanks!

Ok, here's where I'm at.

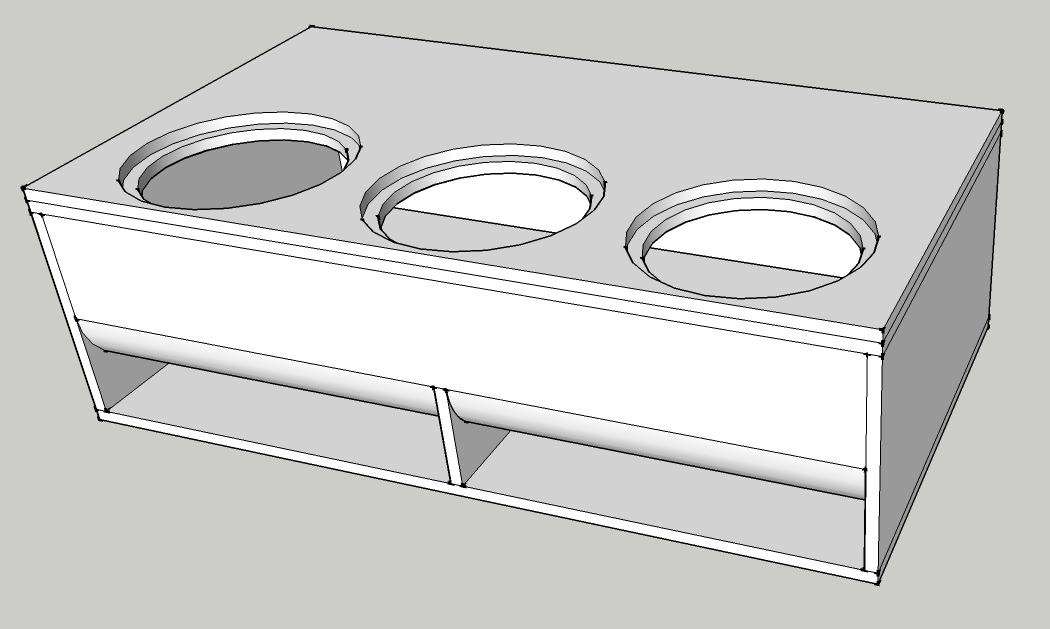

Trying to kerf a 100mm radius (200mm diameter)

Circumference of a 200mm circle is 628mm, so, for a 90 degree bend, the outside of the bend needs to be 157mm.

My first and last cuts are 160mm apart, and I chose to do 16 cuts because it seemed like a nice neat number.... was this a mistake?

I don't seem able to get a 90 degree bend, and the MDF is starting to sound like it will crack.....

thanks!

Trying to kerf a 100mm radius (200mm diameter)

Circumference of a 200mm circle is 628mm, so, for a 90 degree bend, the outside of the bend needs to be 157mm.

My first and last cuts are 160mm apart, and I chose to do 16 cuts because it seemed like a nice neat number.... was this a mistake?

I don't seem able to get a 90 degree bend, and the MDF is starting to sound like it will crack.....

thanks!

Since MDF is nothing but adhesive bonded particles I would think that this would be a fairly poor material to bend no matter the number of kerf cuts. The material is just to brittle for this. I have done this with Birch ply of many different constructions and this didn't give me a problem with bending as long as the cuts were close enough for the bend radius you are after. A suggestion I would make if you are hell bent on bending the mdf is to use an added a veneer layer before you attempt this. It would add a strain relief and reinforce the crack prone substrate. It wouldn't necessarily have to be the final veneer finish but could be an inexpensive wood veneer that you could then bond your final finish onto. It seems that most people that I have seen use this method of construction use multi-ply plywood rather than mdf. If I was doing what you are attempting to do with mdf I would probably glue a large block of mdf to form the corner radius and then machine the radius on the larger block and have a solid corner. With a simple step you could attach the flat sections and glue up a construction with solid corners with either inside and outside radius or just a radius on the outside and a square block on the inside. This would be something you would see more commonly in furniture construction than a bent kerf construction with mdf.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Saw blade for kerfing MDF?