Just a little background on my DIY skills...almost non-existent...regardless of my diy skills...

I would like to build a sonotube subwoofer enclosure for a 12" sub to replace my current sub (was sunfire true sub mkii...now it is temporarily the bic f12)...my budget is probably around $350 (i know it is not too much...but I am hoping I can do something decent with it)...i would like to move up to a 15" sub but space is an issue as shown below...i want to place the sub in the same location as the bic f12 pictured below...there is nothing really stopping me from placing the sonotube sub in the corner...but even the slightest localization of the sub will bother me...

Question 1...is the list below a fairly complete list of materials needed to complete the project...

- 12" subwoofer (most likely the Dayton Audio DVC310-88...but more on this later)

- 12" diameter sonotube (question on this topic below)

- Amplifier (most likely the Bash 300W Digital Plate Amp as the sub is rated at 350 - close enough)

- PVC for port

- 3/4" MDF

- Terminal Plate or Binding Posts

- Spekaer Mounting Kit

- Damping Material

- Finishing Materials (will figure this out later)

- Wood Glue

- Clamps

- Table Saw

- Dremel (my router alternative)

Question 2....Will 14" sonotube diameter be a better option with a 12" sub due to the necessity of the enclosure's base legs and the enclosure will not have to be as tall?

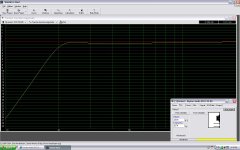

Question 3...I chose the Dayton Audio DVC310-88 due to the decent excursion and frequency response plot in WINISD (can be seen below)...will this sub be a good choice for a sonotube design...

--- DVC310-88 ---

Power Handling (RMS) 350 Watts

Power Handling (max) 700 Watts

Impedance 8 ohms

Frequency Response 20 to 450 Hz

Sensitivity 87.4 dB 1W/1m

Voice Coil Diameter 2"

Magnet Weight 112 oz.

Resonant Frequency (Fs) 22.2 Hz

DC Resistance (Re) 2.8 ohms

Voice Coil Inductance (Le) 1.76 mH

Mechanical Q (Qms) 8.69

Electromagnetic Q (Qes) 0.40

Total Q (Qts) 0.38

Compliance Equivalent Volume (Vas) 4.25 ft.³

Mechanical Compliance of Suspension (Cms) 0.20 mm/N

BL Product (BL) 15.85 Tm

Diaphragm Mass Inc. Airload (Mms) 259.3g

Maximum Linear Excursion (Xmax) 15.1 mm

Surface Area of Cone (Sd) 502.7 cm²

Question 4...I am fairly certain the answer to this question is "NO" but i will ask nonetheless...should the port volume be subtracted the from the total internal volume of the enclosure...by that i mean if the design requires a 3.2 ft^3 enclosure with a 4" port of length 10.5"...should i add the volume of the port to the total internal volume of the enclosure > 3.2 ft^3 + (3.14 * .33^2 * .875 = .299 ft^3) = 3.499 ft^3

Question 5...What is the general protocol of attaching an end cap to the sonotube?...i believe it is just wood glue between the inner end cap (the smaller end cap) and the inside of the enclosure?...

Question 6...Are screws necessary at all when building a sonotube sub enclosure (aside from mounting the sub to the end cap)?...or is it all just wood glue...

I would like to build a sonotube subwoofer enclosure for a 12" sub to replace my current sub (was sunfire true sub mkii...now it is temporarily the bic f12)...my budget is probably around $350 (i know it is not too much...but I am hoping I can do something decent with it)...i would like to move up to a 15" sub but space is an issue as shown below...i want to place the sub in the same location as the bic f12 pictured below...there is nothing really stopping me from placing the sonotube sub in the corner...but even the slightest localization of the sub will bother me...

Question 1...is the list below a fairly complete list of materials needed to complete the project...

- 12" subwoofer (most likely the Dayton Audio DVC310-88...but more on this later)

- 12" diameter sonotube (question on this topic below)

- Amplifier (most likely the Bash 300W Digital Plate Amp as the sub is rated at 350 - close enough)

- PVC for port

- 3/4" MDF

- Terminal Plate or Binding Posts

- Spekaer Mounting Kit

- Damping Material

- Finishing Materials (will figure this out later)

- Wood Glue

- Clamps

- Table Saw

- Dremel (my router alternative)

Question 2....Will 14" sonotube diameter be a better option with a 12" sub due to the necessity of the enclosure's base legs and the enclosure will not have to be as tall?

Question 3...I chose the Dayton Audio DVC310-88 due to the decent excursion and frequency response plot in WINISD (can be seen below)...will this sub be a good choice for a sonotube design...

--- DVC310-88 ---

Power Handling (RMS) 350 Watts

Power Handling (max) 700 Watts

Impedance 8 ohms

Frequency Response 20 to 450 Hz

Sensitivity 87.4 dB 1W/1m

Voice Coil Diameter 2"

Magnet Weight 112 oz.

Resonant Frequency (Fs) 22.2 Hz

DC Resistance (Re) 2.8 ohms

Voice Coil Inductance (Le) 1.76 mH

Mechanical Q (Qms) 8.69

Electromagnetic Q (Qes) 0.40

Total Q (Qts) 0.38

Compliance Equivalent Volume (Vas) 4.25 ft.³

Mechanical Compliance of Suspension (Cms) 0.20 mm/N

BL Product (BL) 15.85 Tm

Diaphragm Mass Inc. Airload (Mms) 259.3g

Maximum Linear Excursion (Xmax) 15.1 mm

Surface Area of Cone (Sd) 502.7 cm²

Question 4...I am fairly certain the answer to this question is "NO" but i will ask nonetheless...should the port volume be subtracted the from the total internal volume of the enclosure...by that i mean if the design requires a 3.2 ft^3 enclosure with a 4" port of length 10.5"...should i add the volume of the port to the total internal volume of the enclosure > 3.2 ft^3 + (3.14 * .33^2 * .875 = .299 ft^3) = 3.499 ft^3

Question 5...What is the general protocol of attaching an end cap to the sonotube?...i believe it is just wood glue between the inner end cap (the smaller end cap) and the inside of the enclosure?...

Question 6...Are screws necessary at all when building a sonotube sub enclosure (aside from mounting the sub to the end cap)?...or is it all just wood glue...

Attachments

Q1… Per below, it needs a bit of revising IME for best overall performance.

Q2… It’s been decades since I did one, but the 12” concrete formers I bought were 12.25” i.d., so plenty big enough for the 12” drivers I used. The bolt hole pattern on the 310 is narrower though at 11.63”, so even at 12” i.d. it should still allow room for bolt holes.

Going shorter, fatter just makes it more under-damped, requiring more stuffing [sims have the same minimal amount].

Q3…Unfortunately, this driver’s specs indicate that it’s not suited for a down-firing app, so Q2 is just for reference.

Q4… No, the answer is yes; it, any bracing and the driver’s displacement should be subtracted from the tube’s gross volume to find its net volume [Vb] for doing a sim.

Note that a sonotube sub can’t accurately be simmed with a typical vented box program due to the long tube having ¼ WL resonant modes that will damp the vent enough to lower the tuning. Sims done with original MJK MathCad software.

Q5, 6… No screws except for add-ons.

I guess you could just glue it all together, but ideally you’ll be using an inner and outer plate at each end, preferably with through rods to clamp the vented top, bottom baffle and massive floor plate together with flat, lock, washers and nuts.

Of course recess the top and bottom hardware and use decorated cardboard, alum or similar tubes to hide the exposed threaded rod between the baffle and floor plate unless you prefer acorn nuts on top and mounting feet/spikes on the bottom for that industrial chic ‘look’.

Otherwise, cover the top with a decorative plate, which I velcro’d on in case I ever needed to access the hardware. That, or place a large S.O. chosen planter on top to do double duty by mass loading it to the floor.

GM

Q2… It’s been decades since I did one, but the 12” concrete formers I bought were 12.25” i.d., so plenty big enough for the 12” drivers I used. The bolt hole pattern on the 310 is narrower though at 11.63”, so even at 12” i.d. it should still allow room for bolt holes.

Going shorter, fatter just makes it more under-damped, requiring more stuffing [sims have the same minimal amount].

Q3…Unfortunately, this driver’s specs indicate that it’s not suited for a down-firing app, so Q2 is just for reference.

Q4… No, the answer is yes; it, any bracing and the driver’s displacement should be subtracted from the tube’s gross volume to find its net volume [Vb] for doing a sim.

Note that a sonotube sub can’t accurately be simmed with a typical vented box program due to the long tube having ¼ WL resonant modes that will damp the vent enough to lower the tuning. Sims done with original MJK MathCad software.

Q5, 6… No screws except for add-ons.

I guess you could just glue it all together, but ideally you’ll be using an inner and outer plate at each end, preferably with through rods to clamp the vented top, bottom baffle and massive floor plate together with flat, lock, washers and nuts.

Of course recess the top and bottom hardware and use decorated cardboard, alum or similar tubes to hide the exposed threaded rod between the baffle and floor plate unless you prefer acorn nuts on top and mounting feet/spikes on the bottom for that industrial chic ‘look’.

Otherwise, cover the top with a decorative plate, which I velcro’d on in case I ever needed to access the hardware. That, or place a large S.O. chosen planter on top to do double duty by mass loading it to the floor.

GM

Edit: Just noticed the published Vas is bogus if Fs, Cms, Mms is ~accurate, so…………

Vas = ~71.4255 L/2.52237 ft^3

Q3… driver is suitable for down-firing assuming other specs aren't too far off.

The sims use a net ~83.3483 L/2.9434 ft^3 minimally damped and your 4” dia. x 10.5” long vent. Internal height for the 12” sonotube = 46.5”, 14” = 31.92”.

As you can see, they are tuned higher and more under-damped than yours, so a high stuffing density will probably be required and either needs a longer sonotube and/or longer vent to tune it to Fs or below.

GM

Vas = ~71.4255 L/2.52237 ft^3

Q3… driver is suitable for down-firing assuming other specs aren't too far off.

The sims use a net ~83.3483 L/2.9434 ft^3 minimally damped and your 4” dia. x 10.5” long vent. Internal height for the 12” sonotube = 46.5”, 14” = 31.92”.

As you can see, they are tuned higher and more under-damped than yours, so a high stuffing density will probably be required and either needs a longer sonotube and/or longer vent to tune it to Fs or below.

GM

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.