Those readings were from outside the car, inside the VLF could be another 40 dB higher.Blizzardbuffalo,

The references you posted do have footnotes tying them to NIOSH and OSHA, both use dBA, not dB SPL.

The "quickly closing a door reached 49.07db(A) at 28Hz " would read about 40 dB higher (89.07) read without weighting.

Funny study, thanks for the link.

Art

... If they are using a weighting scale, they do not mention it.

(Almost) every country uses IEC 61672-1:2003. It mandates A weighting.

For the US, NIOSH 98-126 specifies A weighting.

Last edited:

what is your budget? I built one of these http://www.diyaudio.com/forums/subwoofers/143714-lab12-tapped-horn.html for an interactive new media bull poop installation when I was in college. It will reasonably hit 16 hz and lower if you are careful. however its quite impractical afterwards, too low for a pa sub, great for a theater. its BIG. Building it wasn't too bad but if you've never used a table saw before it might be a tad ambitious. you might be better off with a dual 18 and careful management with a max msp patch since most speaker management dsp wont go below 20hz.

You, sir, are speaking my language. I built a pair of PA's for myself using a tapered horn very similar to the technique pictured in your build (which was very well done, I might add).

My current most likely option, depending on wood costs, is to do something like this. I've been a bit intimidated though, because of the gigantic proportions needed to reach 10 Hz. If you say your build got down to 16 Hz reasonably well, I'm sure a little adjustment could get me down a bit farther and I am willing to compromise.

I was actually planning to compose mostly with Max/MSP, actually. However, I don't quite understand what you mean when you mention using a patch to manage dsp? Could you explain a bit further?

Hi,

if you want to go low, you need to go big. I have an idea for a dual LAB-12 big box horn that might suffice, and depending on your wood costs could be <800$. But it's a 3000l monster - floor to ceiling height, over 1m^2 cross section, and probably about 10 (!) sheets of plywood to build. But it would do 120db from 10Hz and up if properly corner loaded.

I doubt you can get much more than that at your budget using traditional drivers - low frequencies eat cone excursion for breakfast, and unless you can control it with proper horn loading, you'll run out soon. And horn loading at this frequency requires vast truck-length horns - think 20 thousand liters or more. Probably not in the money/time budget to build

Wow, that is a behemoth of a build. This was what I was worried about, though you're right, there's really not much of a way around it using traditional drivers. I've looked at other methods including that rotary woofer, but mostly everything is either conceptually outside of my ability or fiscally outside my ability.

I am pretty sure that I will have to compromise and make my targe frequency above 10hz. I was thinking perhaps somewhere between 12 and 16. Things are a bit more manageable in that area. Do you have plans for that build, btw?

Think outside of the box:

ACP&D Limited - How servo hydraulic amplifiers work

Woodward | Hydraulic Amplifier

I don't know about cost, but it is another way.

This is a really really cool idea. I suppose I would have to attach it to some extremely large diaphragm, though?

The LabSub design rolls off at below Fc, about 32 Hz.My current most likely option, depending on wood costs, is to do something like this. I've been a bit intimidated though, because of the gigantic proportions needed to reach 10 Hz. If you say your build got down to 16 Hz reasonably well, I'm sure a little adjustment could get me down a bit farther and I am willing to compromise.

In room, cabin gain can make up for some of the roll off.

Tom Danley gave away the Labsub (Live Audio Board) sub design when he came up with tapped horns. The Emminence Lab 12, designed for the Labsub, also works very well in low tuned tapped horns.

A tapped horn can go far lower per size than a front loaded horn, it does not depend on a huge mouth to go low and loud.

This is evident in that the Gjallerhorn is not much larger than the LabSub, but goes considerably lower and louder.

Art

Wow, that is a behemoth of a build. This was what I was worried about, though you're right, there's really not much of a way around it using traditional drivers. I've looked at other methods including that rotary woofer, but mostly everything is either conceptually outside of my ability or fiscally outside my ability.

I am pretty sure that I will have to compromise and make my targe frequency above 10hz. I was thinking perhaps somewhere between 12 and 16. Things are a bit more manageable in that area. Do you have plans for that build, btw?

Nothing I have physical buildable plans for yet, just an idea in my head with some corresponding hornresp simulations. But basically picture something like the Lab12 Tapped Horn linked previously, just double the height, width and depth, and add in a second driver to fill up the double width. it definitely needs to be at least a 4-path fold horn, or else you won't get the ~10m path length you will need for infrasonic output.

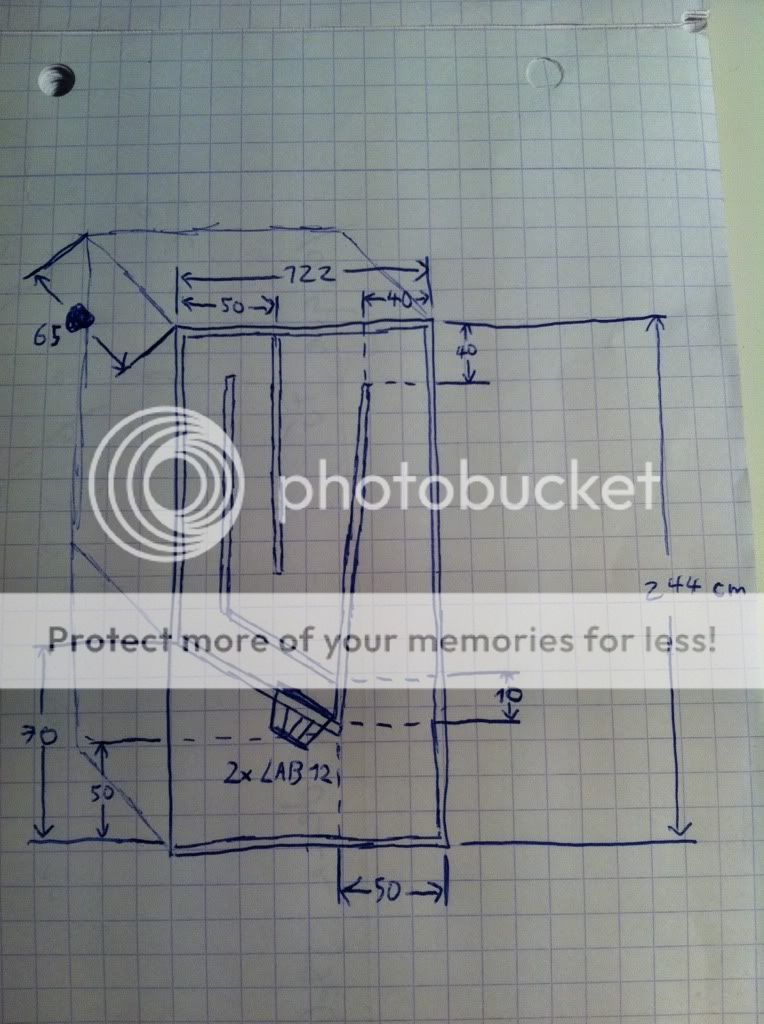

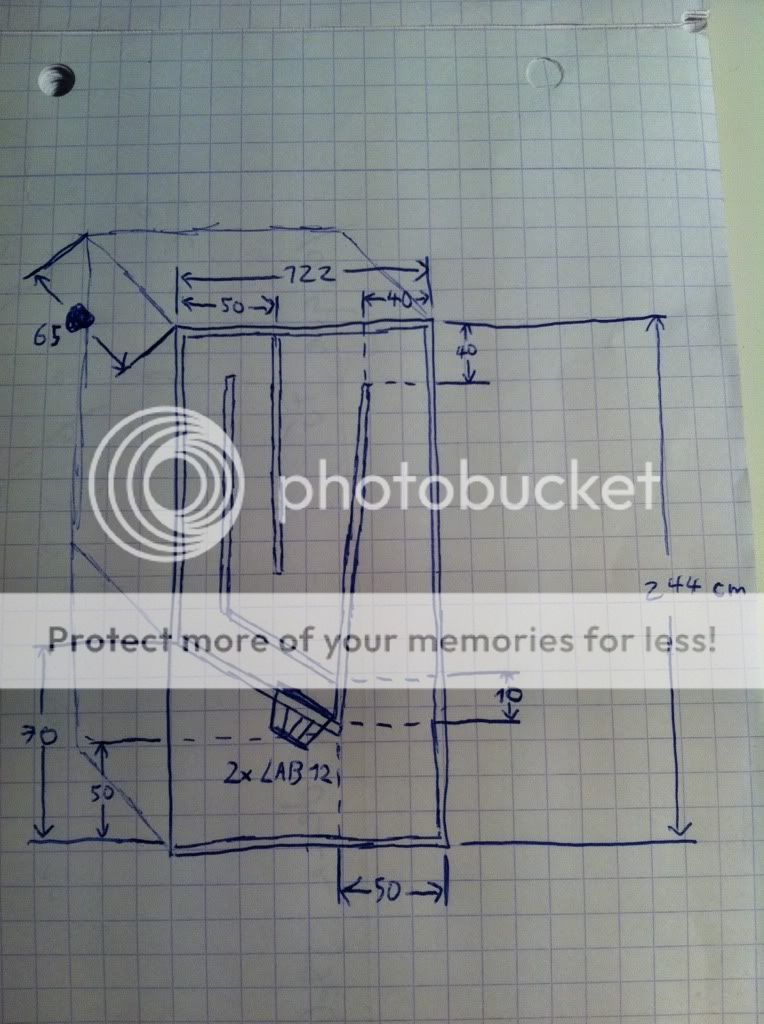

I should be working on a presentation right now, which is why I'd much rather doodle subwoofers on my notepad - here's a quick sketch of something I have in mind:

This one is sketched with efficient usage of 4x8 foot sheets of plywood in mind - I'm assuming you are based in USA like your flag suggests, and this is the size of wood available to you. The two biggest sides are 4x8 foot sheets, and the internal width of the horn is 2 feet. My markings on the doodle are metric though - all in cm. Should be buildable using 5 sheets for the box, plus maybe 1 whole extra sheet (or any scrap wood you have) for bracing - a big box like this is going to need to be very well braced.

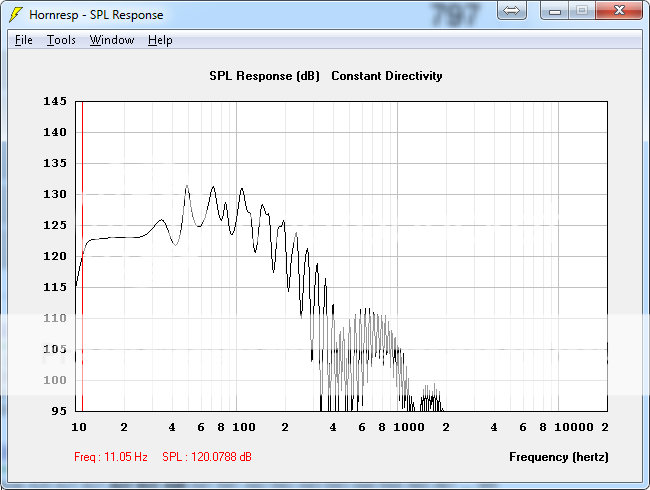

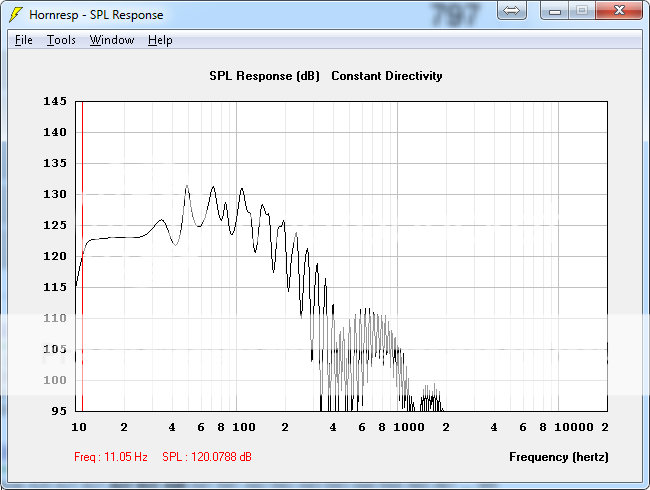

Here's how hornresp simulates the output, at maximum (100Watts / 3Ohm) with the box placed in a rigid room corner:

This one is sketched with efficient usage of 4x8 foot sheets of plywood in mind - I'm assuming you are based in USA like your flag suggests, and this is the size of wood available to you. The two biggest sides are 4x8 foot sheets, and the internal width of the horn is 2 feet. My markings on the doodle are metric though - all in cm. Should be buildable using 5 sheets for the box, plus maybe 1 whole extra sheet (or any scrap wood you have) for bracing - a big box like this is going to need to be very well braced.

Here's how hornresp simulates the output, at maximum (100Watts / 3Ohm) with the box placed in a rigid room corner:

Good work James!Here's how hornresp simulates the output, at maximum (100Watts / 3Ohm) with the box placed in a rigid room corner:

Does only 100 watts make the drivers hit Xmax (13mm)?

One note, though a 2 food depth is great for wood use, the Lab 12s are 12.25" and would either need to be put at a bit of an angle, or a divot chiseled (or routed) out at the top and bottom of the speaker mounting location.

For a cabinet that big, I'd want to put at least four or even eight 12", 129, 136 dB at 15 Hz in room...

Don't try it full tilt boogie in a plaster and lath constructed house unless you plan to rebuild

Art

Good work James!

Does only 100 watts make the drivers hit Xmax (13mm)?

One note, though a 2 food depth is great for wood use, the Lab 12s are 12.25" and would either need to be put at a bit of an angle, or a divot chiseled (or routed) out at the top and bottom of the speaker mounting location.

For a cabinet that big, I'd want to put at least four or even eight 12", 129, 136 dB at 15 Hz in room...

Don't try it full tilt boogie in a plaster and lath constructed house unless you plan to rebuild.

Art

Hey Art,

yep, 100W already hits xmax, it's amazing how much drivers will flop around at low frequencies like that. I'd much rather put something like the TC Sounds Pro 5100 in a horn that size, but seeing as that alone is over OP's budget..... better hope he has access to cheap lumber

I know about the width issue, my proposed solution is to stagger the drivers somewhat, like the circles in the % sign.

Additionally I would route a few circular spacers from some spare wood so that the further forward driver can be mounted upside down. This will equalize the path length through the horn a bit, and also reduce distortion with the woofers operating push-pull. And at this sort of low frequency, any distortion reduction will be much needed - even with that, I wonder how much THD will be in a system like this - low enough for it to even be worthwhile?

Where's the music, Fella ?

I take it you can't compose and record this "Infra-music", until you have the loudspeaker built? So I'm curious, musical instrument speakers are usually called "Producers", and Hi-Fi "Re-Producers"! Shouldn't you be looking at a PA forum?

Also, will you allow us to have a recording of your "Infra-music", please? I'd love to hear my sub playing a tune other than a bass-line or rumbles and explosions!!

Good luck

I take it you can't compose and record this "Infra-music", until you have the loudspeaker built? So I'm curious, musical instrument speakers are usually called "Producers", and Hi-Fi "Re-Producers"! Shouldn't you be looking at a PA forum?

Also, will you allow us to have a recording of your "Infra-music", please? I'd love to hear my sub playing a tune other than a bass-line or rumbles and explosions!!

Good luck

I measured the distortion of dual Lab 12s in my Keystone TH with about 400 watts per cone, it was still pretty clean. At 100 watts, I'd think your design would not have much distortion at all, and the even order distortion components would be perceived as part of the music.Hey Art,

yep, 100W already hits xmax, it's amazing how much drivers will flop around at low frequencies like that. I'd much rather put something like the TC Sounds Pro 5100 in a horn that size, but seeing as that alone is over OP's budget..... better hope he has access to cheap lumber

. This will equalize the path length through the horn a bit, and also reduce distortion with the woofers operating push-pull. And at this sort of low frequency, any distortion reduction will be much needed - even with that, I wonder how much THD will be in a system like this - low enough for it to even be worthwhile?

PP reduces even order distortion, leaving odd order (not so musical) distortion.

With Lab 12s, the vent noise at high excursion in a TH is quite easily heard, I would think it would be more objectionable than the second harmonic distortion it would reduce. For this experiment, having the magnets towards the throat would probably be better.

The TC Epic 12" has a lot more excursion than the Lab12, for not much more money, with a monster excursion limited cabinet like you have designed, definitely worth it.

Art

The music could be composed on headphones, which have response as low as the OP plans to go.I take it you can't compose and record this "Infra-music", until you have the loudspeaker built?

Headphones don't provide the tactile sensation of a sub operating at the same level, so some adjustments will need to be made for the sub(s) that ultimately is built or rented.

Changing the sub from the composition room to a playback venue will require further adjustment.

I measured the distortion of dual Lab 12s in my Keystone TH with about 400 watts per cone, it was still pretty clean. At 100 watts, I'd think your design would not have much distortion at all, and the even order distortion components would be perceived as part of the music.

PP reduces even order distortion, leaving odd order (not so musical) distortion.

With Lab 12s, the vent noise at high excursion in a TH is quite easily heard, I would think it would be more objectionable than the second harmonic distortion it would reduce. For this experiment, having the magnets towards the throat would probably be better.

The TC Epic 12" has a lot more excursion than the Lab12, for not much more money, with a monster excursion limited cabinet like you have designed, definitely worth it.

Art

Thanks, I knew there was a TC Sounds subwoofer with a lot more excursion than the Lab, but for some reason I only saw the LMS-R 12, which is a lot more expensive.

The Epic 12" would probably be a worthwhile upgrade for this cab.

these guys did 160dB at 16Hz...

http://www.youtube.com/watch?v=FdNultZ4QT8

http://www.youtube.com/watch?v=FdNultZ4QT8

Last edited:

The Mythbusters 161 dB car engine powered cone was funny, but not musical.these guys did 160dB at 16Hz...

MythBusters subwoofer - YouTube

The OP needs musical sound in a space (presumably) larger than a two seat car.

Yes, Rice-Kellogg drivers are little motors and go to DC. But at a fraction of a wave-length, the radiation resistance is miniscule. Why are some people thinking that is the right way to shake the air?

Lot of confusion about dB scales. For some purposes, you want to talk about what people mean by "equal loudness for me," very for use very roughly as speech intelligibility, or maybe to assess some kinds of industrial noise damage, and that is when to use dBA (at least as far as the curve has been plotted with human testing).

But if you are talking about force or ear-drum impingement or some psycho-physical measures, dBA has no special significance.

Ben

Lot of confusion about dB scales. For some purposes, you want to talk about what people mean by "equal loudness for me," very for use very roughly as speech intelligibility, or maybe to assess some kinds of industrial noise damage, and that is when to use dBA (at least as far as the curve has been plotted with human testing).

But if you are talking about force or ear-drum impingement or some psycho-physical measures, dBA has no special significance.

Ben

Last edited:

I'm not sure exactly what you want to do, or what kind of study you want. While your power requirements are high, you don't need as much speed so in many infrasonic designs weight is not as much of an issue.

Be careful of some tactile transducers which are actually out-of-balance rotary motors which vibrate but NOT AT THE ACTUAL FREQUENCY APPLIED. They change speed with the volume of bass, but are definitely not musical.

Tapped horns are a possibility, but the speaker driver can be a problem; you may need to dope down or even fiberglass the cone to add mass and strength. You can assure linear motion by using something like two sets of bifold doors at right angles to each other. Hinged sheets of plywood...

There are some better options. Some use mechanical or fluidic ampilfication, which allows you to use thousands of horsepower from chemical combustion engines or huge electrical motors driven by your local nuclear or coal electircal plant, without requiring enormous audio amplifiers. Others are just very efficient, requiring that you rent a few hundred-thousand watts of power amplifiers.

The most powerful and economical devices are not reproducers of complicated changing audio waveforms, but produce or generate sounds themselves, more like instruments than speakers. The most powerful use other main sources of power, not an amplifier (though an amplifier may provide control). These include the very large recirculating wind tunnel with diversion vane designs that Danley built. The audio output can be huge, if the wind tunnel blowers are powered by large enough motors or engines. The diversion vane can be driven and controlled several ways, including mechanical crank or cam as an "infrasonic siren" generator, or via an electric motor or electric linear motor as an infrasonic speaker. You can consider using the linear actuator motors that drive the seek arms in old huge disk drives, for instance the DEC PDP-11 drives. Big deep magnets drive a long hinged arm, all very lightweight to move quickly. If you can find a source of several, they can also drive cones and horn-loaded cones or tapped-horn-loaded cones. Usually such systems require some sort of feedback mechanism so the lienar motor also appllies braking forces.

Very very long organ pipes can be built from large fiberglass and plastic sewer pipe at reasonable cost and make really substantial low-frequency output if driven by a large high-power blower. Here harnessing resonance is the key, both in the pipe and in the room. Consider renting a diesel air compressor trailer, one of the really big ones on a semi-trailer for sandblasting large buildings and bridges. Of course, each generally makes only one note.

Another viable alternative would be the discontinued Danley "Intersonics" brand of rotary-drive subwoofer, or one of the many homemade clones and variations. These were driven by 4-pole commutated DC rotary motors which responded well to conventional amplifiers. The rotary shaft drives belts to cones that are horn-loaded; the belt is pre-loaded in tension via something like a fiberglass spring. Often two belts are used, wound on the motor shaft and exiting in opposite directions so that forces on the motor's rotary shaft bearings are balanced. They are extremely extremely efficient and LOUD despite the fact that all the power comes from the amplifier. There's no wasteful voice coil overhang resistance outside the magnetic gap; Danley used to compare it to a "commutated" voice-coil in trying to explain its efficiency. Close tolerances due to rotary barings helps too. You generally start with surplus capstan motors from large mainframe disk drives.

Other efficient drivers for very low frequncies use "moving-metal". The voice coil includes a moving iron magnetic structore, so that the magnetic field that is generated by the portion of the voice coil that is outside the magnetic gap is still coupled to the stationary magnetic structure. Most Hartley sub drivers fall into this "moving iron" category, and also have rather large cones (and prices).

The Thigpen is a very interesting design, but to really have sufficient output it needs to be significantly scaled up until it's rather dangerous, and to be in a baffle and low-pass tunnel to minimize blade noise. To understand it, you can study variable-pitch aircraft propellers, but you will need to vary from no pitch at all to significant pitch. It is another true mechanical amplifier, using a small control motor signal (which varies the blade pitch) to control the work output from the huge power of the main engine and flywheel. The fan spins at a relatively constant and somewhat irrelevant speed, but the blade pitch is modulated at audio frequency. There are many design vairations, from mechanical linkage arms off of a slip-ring (kind of like a clutch throwout bearing) which is reminiscent of variable-pitch aircraft props, to systems that put the modulation motors on the rotating mechanism and get power to those small servo motors via brushes or non-contact coils etc. If you could move the "pitch" lever on a turbo-prop plane at audio frequencies, you'd have a thousand-horsepower subwoofer.

Then there's all kinds of more direct infrasonic sources which allow for some limited degree of control suitable for only certain kinds of study. For instance, it is difficult to predict when lightning will strike and provide a suitable low-frequency spike. But a stick of dynamite in a crater lake can be triggered electrically with great accuracy.

He's a busy guy, but you need to talk to Tom Danley and/or study his designs on the old "bass list".

Be careful of some tactile transducers which are actually out-of-balance rotary motors which vibrate but NOT AT THE ACTUAL FREQUENCY APPLIED. They change speed with the volume of bass, but are definitely not musical.

Tapped horns are a possibility, but the speaker driver can be a problem; you may need to dope down or even fiberglass the cone to add mass and strength. You can assure linear motion by using something like two sets of bifold doors at right angles to each other. Hinged sheets of plywood...

There are some better options. Some use mechanical or fluidic ampilfication, which allows you to use thousands of horsepower from chemical combustion engines or huge electrical motors driven by your local nuclear or coal electircal plant, without requiring enormous audio amplifiers. Others are just very efficient, requiring that you rent a few hundred-thousand watts of power amplifiers.

The most powerful and economical devices are not reproducers of complicated changing audio waveforms, but produce or generate sounds themselves, more like instruments than speakers. The most powerful use other main sources of power, not an amplifier (though an amplifier may provide control). These include the very large recirculating wind tunnel with diversion vane designs that Danley built. The audio output can be huge, if the wind tunnel blowers are powered by large enough motors or engines. The diversion vane can be driven and controlled several ways, including mechanical crank or cam as an "infrasonic siren" generator, or via an electric motor or electric linear motor as an infrasonic speaker. You can consider using the linear actuator motors that drive the seek arms in old huge disk drives, for instance the DEC PDP-11 drives. Big deep magnets drive a long hinged arm, all very lightweight to move quickly. If you can find a source of several, they can also drive cones and horn-loaded cones or tapped-horn-loaded cones. Usually such systems require some sort of feedback mechanism so the lienar motor also appllies braking forces.

Very very long organ pipes can be built from large fiberglass and plastic sewer pipe at reasonable cost and make really substantial low-frequency output if driven by a large high-power blower. Here harnessing resonance is the key, both in the pipe and in the room. Consider renting a diesel air compressor trailer, one of the really big ones on a semi-trailer for sandblasting large buildings and bridges. Of course, each generally makes only one note.

Another viable alternative would be the discontinued Danley "Intersonics" brand of rotary-drive subwoofer, or one of the many homemade clones and variations. These were driven by 4-pole commutated DC rotary motors which responded well to conventional amplifiers. The rotary shaft drives belts to cones that are horn-loaded; the belt is pre-loaded in tension via something like a fiberglass spring. Often two belts are used, wound on the motor shaft and exiting in opposite directions so that forces on the motor's rotary shaft bearings are balanced. They are extremely extremely efficient and LOUD despite the fact that all the power comes from the amplifier. There's no wasteful voice coil overhang resistance outside the magnetic gap; Danley used to compare it to a "commutated" voice-coil in trying to explain its efficiency. Close tolerances due to rotary barings helps too. You generally start with surplus capstan motors from large mainframe disk drives.

Other efficient drivers for very low frequncies use "moving-metal". The voice coil includes a moving iron magnetic structore, so that the magnetic field that is generated by the portion of the voice coil that is outside the magnetic gap is still coupled to the stationary magnetic structure. Most Hartley sub drivers fall into this "moving iron" category, and also have rather large cones (and prices).

The Thigpen is a very interesting design, but to really have sufficient output it needs to be significantly scaled up until it's rather dangerous, and to be in a baffle and low-pass tunnel to minimize blade noise. To understand it, you can study variable-pitch aircraft propellers, but you will need to vary from no pitch at all to significant pitch. It is another true mechanical amplifier, using a small control motor signal (which varies the blade pitch) to control the work output from the huge power of the main engine and flywheel. The fan spins at a relatively constant and somewhat irrelevant speed, but the blade pitch is modulated at audio frequency. There are many design vairations, from mechanical linkage arms off of a slip-ring (kind of like a clutch throwout bearing) which is reminiscent of variable-pitch aircraft props, to systems that put the modulation motors on the rotating mechanism and get power to those small servo motors via brushes or non-contact coils etc. If you could move the "pitch" lever on a turbo-prop plane at audio frequencies, you'd have a thousand-horsepower subwoofer.

Then there's all kinds of more direct infrasonic sources which allow for some limited degree of control suitable for only certain kinds of study. For instance, it is difficult to predict when lightning will strike and provide a suitable low-frequency spike. But a stick of dynamite in a crater lake can be triggered electrically with great accuracy.

He's a busy guy, but you need to talk to Tom Danley and/or study his designs on the old "bass list".

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Infrasonic Speaker - Need advice for undergrad thesis project