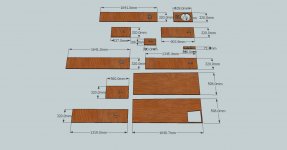

Due to the number of panels and the moderate complexity of the cabinet, its not that easy to see everything in full detail via captured images from GS. Ive posted what I can here, of course Dan I'll send you the actual GS files so you have the full 3D model at your disposal. I assume you have some basic knowledge of how to use Sketchup, although all you really need to be able to do is rotate around the model and zoom in and out.

Attachments

Great, you must be a wizard with GS... It would take me a week to draw that and even then I see things of which I'm not sure how you did it...

One thing though, the vent hole really needs more space.

Alternatively you can put a hole in the side behind the magnet and connect the driver securely to the panel through a duct.

Now you have extra reinforcement in the cabinet and good cooling for the driver.

One thing though, the vent hole really needs more space.

Alternatively you can put a hole in the side behind the magnet and connect the driver securely to the panel through a duct.

Now you have extra reinforcement in the cabinet and good cooling for the driver.

If the driver was fixed from the other side of the baffle then that would gain an additional 43mm (19 for the MDF + 14 for the basket rim thickness), giving more like 50mm or so clearance. Just cross your fingers the driver doesnt ever pack in lol.

Ive done so much modelling with GS making sub boxes I think I'm getting pretty decent at it now, and I can usually put things together in a reasonable time. I still come up against it from time to time though, and still pick up new tricks along the way, but all in all its a great piece of software.

Ive done so much modelling with GS making sub boxes I think I'm getting pretty decent at it now, and I can usually put things together in a reasonable time. I still come up against it from time to time though, and still pick up new tricks along the way, but all in all its a great piece of software.

If the driver was fixed from the other side of the baffle then that would gain an additional 43mm (19 for the MDF + 14 for the basket rim thickness), giving more like 50mm or so clearance. Just cross your fingers the driver doesnt ever pack in lol.

Ive done so much modelling with GS making sub boxes I think I'm getting pretty decent at it now, and I can usually put things together in a reasonable time. I still come up against it from time to time though, and still pick up new tricks along the way, but all in all its a great piece of software.

Would it be too hard to convert those dimensions to inches? I am sure I could make it work with them in MM's, but I would have a much easier time in building this sub if the dimensions were inches in leu of MM's.

Build will start as soon as the drivers arrived!

It wouldnt be hard to convert, but its built around 19mm because thats what the original drawing was constructed from. 19mm in inches is 0.748031496, but thats going to be of no use to you. I could easily convert all other dimensions into inches for you, but they arent going to round up to nice easy numbers unless your really lucky.

EDIT:

It seems the conversion doesnt work. As the model has been built using a template that works in mm, it wont give me dimensions in any other format. The may be a way to do it, but right now I'm not sure if thats possible. I can easily tell you what each dimension works out to be in inches. Did you get the full 3D model?

EDIT:

It seems the conversion doesnt work. As the model has been built using a template that works in mm, it wont give me dimensions in any other format. The may be a way to do it, but right now I'm not sure if thats possible. I can easily tell you what each dimension works out to be in inches. Did you get the full 3D model?

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Trying to choose which drivers to go with. Need advise