Björnö very grateful for your remembrance.

I see you're an enlightened person.

Well, regarding HR.

Were the same as you posted.

What are these:

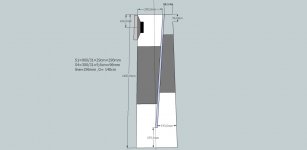

Ok,but this simulation show a T-TQWT that best would be folded at least two times and not one time as your last layout depicts.I will test if the given numbers would work in a 2-fold, my time tomorrow..

b

3 o'clock in the morning:Time to get some sleep.

Again, I thank you!

Good sleeps!

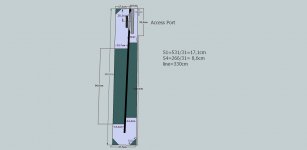

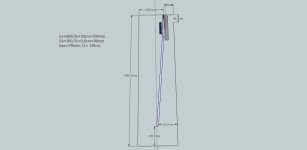

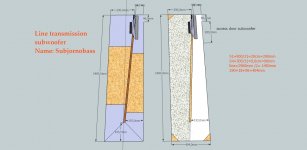

Here are two pictures again:

The first is the consequences of turning my suggested ODT-TQWT into a single-folded T-TQWT,the second is an optimisation of the latter using an optimal BR box as the starting point.

b

Attachments

finished!

I just want his endorsement.

Can I cut the MDF?

Yes...good work! Looking forward for your pictures? when finished.

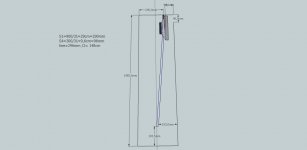

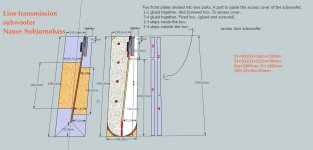

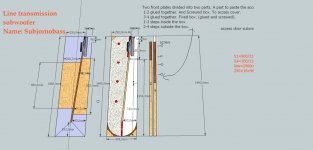

Here are some more hints:

b

Attachments

more photos

It is not easy!

A week working right, that measures be exact.

But it is very rewarding.

Björnö.

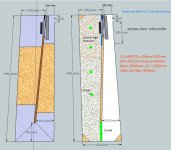

I just wanted an idea of the position of foams.

It is not easy!

A week working right, that measures be exact.

But it is very rewarding.

Björnö.

I just wanted an idea of the position of foams.

Attachments

It is not easy!

A week working right, that measures be exact.

But it is very rewarding.

Björnö.

I just wanted an idea of the position of foams.

Good work Nelnar!

I never use foams to lime the walls in a TL but instead different felt= dense types up to an inch of thickness. The given material for damping the enclosure should be of ordinary polyester type that can be adjusted to different densities.

b

Attachments

It is very gratifying a compliment coming from you.

Thank you!

But, you are responsible for my success.

Then take half of the TL, what do you think of fiberglass filler?

Fiberglass will work too. but when used for bulk volume stuffing, leave at least 25-50 % of this volume without, i.e. e.g.:Use 2inch battens in parallel with a 1-2 inch free air passage until paralleled with more battens.The arrangement should look like an soundproofed ventilation air duct.

b

PS: I my previous post I wrote: ' never use foams to lime the walls'. Should be: I never use foams glued to the walls.

Last edited:

more photos!!

almost done.

interior finishing and coating.

almost done.

interior finishing and coating.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- SUBWOOFER LT