Hi reminence,

You may want to read back through Pages 10/11 of this thread as to the stuffing, etc.. Basically, what you have there looks OK, maybe a little much fiberfill (there's got to be a store in your part of the world with a scale?); try stapling a little directly to the S1 side, and staple a bit of cheesecloth (or burlap) around/behind the woofers to keep the fiberfill from working its way into the drivers, it get pretty tight there. The density should be highest in the general area behind the woofers, and become less going away from there (but even density will work too).

Looks like you filled all the corners with glue, that should keep them sealed. As to the bracing, this is a relatively narrow box, so I think you'll be just fine; it is amazing though how much flex can be introduced into these heavy panels with the pressure from the drivers.

Regards,

You may want to read back through Pages 10/11 of this thread as to the stuffing, etc.. Basically, what you have there looks OK, maybe a little much fiberfill (there's got to be a store in your part of the world with a scale?); try stapling a little directly to the S1 side, and staple a bit of cheesecloth (or burlap) around/behind the woofers to keep the fiberfill from working its way into the drivers, it get pretty tight there. The density should be highest in the general area behind the woofers, and become less going away from there (but even density will work too).

Looks like you filled all the corners with glue, that should keep them sealed. As to the bracing, this is a relatively narrow box, so I think you'll be just fine; it is amazing though how much flex can be introduced into these heavy panels with the pressure from the drivers.

Regards,

Hi reminence,

Agree with tb46..The amount of damping material should cover about half the length of the internal airways when using correct density and weight of the damping material.. I never do this in a hurry: IME, No time whatsoever is saved, if you later try to rectify a suspected bad applied stuffing.

I try to piecewise tear the wool nearly apart (~3" x 3" x 3" chunks) until the material looks having about equal volume density and the wool strands oriented as similar as possible .. then slightly compress all when placed back at the dedicated place..

When this is done correctly the CSA:s should be completely and evenly filled with tapered density but leaving a minimum of air pockets.

b

Agree with tb46..The amount of damping material should cover about half the length of the internal airways when using correct density and weight of the damping material.. I never do this in a hurry: IME, No time whatsoever is saved, if you later try to rectify a suspected bad applied stuffing.

I try to piecewise tear the wool nearly apart (~3" x 3" x 3" chunks) until the material looks having about equal volume density and the wool strands oriented as similar as possible .. then slightly compress all when placed back at the dedicated place..

When this is done correctly the CSA:s should be completely and evenly filled with tapered density but leaving a minimum of air pockets.

b

Ah, its glued now. but i should have enough room to redo it to about 1/3 (as oposed to the advised 1/2) of the throat through the driver holes if need be.

The pillow was old and rather compressed so it

took a long time to get it that fluffed up haha. I will test it tomorrow and if needed I will redo it properly with new stuffing as I think that may be an issue. Thanks for your advice.

Although I do wonder just how much of an effect stuffing vs none would be. If its huge, would the diference be in distortion, response or some other diference? I have used horn response to play with this design and cant see how changing the frequency response would make it much better since its so flat allready. Maybe more extension but that seams to me about all that could be improved. Also I wonder how this stuffing diference compares with a tapped horn the same way.

The pillow was old and rather compressed so it

took a long time to get it that fluffed up haha. I will test it tomorrow and if needed I will redo it properly with new stuffing as I think that may be an issue. Thanks for your advice.

Although I do wonder just how much of an effect stuffing vs none would be. If its huge, would the diference be in distortion, response or some other diference? I have used horn response to play with this design and cant see how changing the frequency response would make it much better since its so flat allready. Maybe more extension but that seams to me about all that could be improved. Also I wonder how this stuffing diference compares with a tapped horn the same way.

Last edited:

.. Also I wonder how this stuffing diference compares with a tapped horn the same way.

This can be modeled in MJK:s programs but what scheme did you use , the one labeled ACAD #1 or #2?

b

PS: Don't mix up you sub with a tapped one as being very different., IMO that is like comparing a Hi-Fi sub with a sub targeting PA use.

Last edited:

Hi reminence,

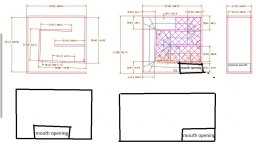

Here is my first stab at it, a simple folded T-TQWT. Gross volume is 238.7 L. It should be able to handle 500W without exceeding Xmax in its passband.

The size could be slightly modified to provide for better wood usage. The driver that sits further away from the mouth could be reversed for improved distortion cancelling, but that will require a 3/4"-1" shim, and it will restrict the duct, so it would have to be tried. When building it I would leave one side removable to get to the drivers and filling. It could also be build as a single fold.

Let me know what you think.

Regards,

Can the mouth opening of this design be remove and be place as indicate in the attach picture. If it can be done what would be the cutout size. Please see attach picture below.

Thanks

Last edited:

Hi Beat Street,

Post #38 has the Hornresp Input screen. Looking at Hornresp your mouth opening on the right hand side would work fine, keep the area the same. The other opening should be centered on the middle between the two drivers (not any further left), opening size the same.

Once you apply an active bandpass filter in the Filter Wizard it looks like you might not need any damping. Hornresp has come a long way since this was done.

Regards,

Post #38 has the Hornresp Input screen. Looking at Hornresp your mouth opening on the right hand side would work fine, keep the area the same. The other opening should be centered on the middle between the two drivers (not any further left), opening size the same.

Once you apply an active bandpass filter in the Filter Wizard it looks like you might not need any damping. Hornresp has come a long way since this was done.

Regards,

Hi Beat Street,

Post #38 has the Hornresp Input screen. Looking at Hornresp your mouth opening on the right hand side would work fine, keep the area the same. The other opening should be centered on the middle between the two drivers (not any further left), opening size the same.

Once you apply an active bandpass filter in the Filter Wizard it looks like you might not need any damping. Hornresp has come a long way since this was done.

Regards,

Tb46

What it make a big difference if I make the width of the cabinet 13.50" instead of 13.914"

Thanks for your response

Hi Beat Street,

There will be very little difference in the simulated performance when changing the external width from 13.94" to 13.5"; but the driver won't fit (see below).

The mouth particle velocity peaks around 24Hz @ about 16.8m/sec w/ Eg=63.25 V (500W into 8 Ohm). It will take a 4th order bandpass (20Hz/80Hz) to keep everything under control.

Watch out for the driver dimensions, I have the JBL GTO 1214D @ 12-5/16" 12.323"[313mm] in my drawings. If you use standard void-free plywood (23/32") you'll have only 12-1/16" left over as the internal width; you might have to go to 1/2" plywood for the side plates (at least in the driver area).

You could also make the box square, e.g.: 31-7/8" x 31-7/8" without changing the response materially.

Regards,

There will be very little difference in the simulated performance when changing the external width from 13.94" to 13.5"; but the driver won't fit (see below).

The mouth particle velocity peaks around 24Hz @ about 16.8m/sec w/ Eg=63.25 V (500W into 8 Ohm). It will take a 4th order bandpass (20Hz/80Hz) to keep everything under control.

Watch out for the driver dimensions, I have the JBL GTO 1214D @ 12-5/16" 12.323"[313mm] in my drawings. If you use standard void-free plywood (23/32") you'll have only 12-1/16" left over as the internal width; you might have to go to 1/2" plywood for the side plates (at least in the driver area).

You could also make the box square, e.g.: 31-7/8" x 31-7/8" without changing the response materially.

Regards,

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 20-30hz tapped horn for studio with ande drivers