The reason I recommended the batting is that in damping a line you are trying to alter the speed of sound with a fibrous tangle, it needs to fill most of the cross section but not be very dense. The blue jeans may be best used against the very end of the throat before the driver. It's not like a "regular" speaker when you want/need to absorb unwanted rear radiation.

Last edited:

I am not surprised, everything else is backwards: thinner wood, less power, smaller, low cost drivers.

Here is a thought (I'm sure this has been done) what about making small radius for the inside corners, OR a small "45" piece (which would be easier).

Finishing up the second tonight, taking them both to the HT.

Construction tip, I found that 2 1/2 degrees was fitting nicely (only a couple of places).

Here is a thought (I'm sure this has been done) what about making small radius for the inside corners, OR a small "45" piece (which would be easier).

Finishing up the second tonight, taking them both to the HT.

Construction tip, I found that 2 1/2 degrees was fitting nicely (only a couple of places).

The reason I recommended the batting is that in damping a line you are trying to alter the speed of sound with a fibrous tangle, it needs to fill most of the cross section but not be very dense. The blue jeans may be best used against the very end of the throat before the driver. It's not like a "regular" speaker when you want/need to absorb unwanted rear radiation.

Hi,

You're IMO absolutely right: It looks like the OP missed the most important measure to be taken:

Any quarter-wave design that show ripple in the passband/off-band must internally be damped to a sufficient degree, at least to below the heard ripple-threshold that SQ-wise is judged to be blameless.

b

Attachments

The 1st box is really sounds nice, full bass sound and hits really low.

The second box is finished, just need to use the flush router bit on it. I planed on building at least 1 more and try different damping technique(s).

The third build...I found a good size piece of 5/8", maybe enough for the two sides and tops and bottoms (inside would 1/2") any advantage?

Does anyone have a link, or pic, how-to damping the corners? Foam wedges?

The second box is finished, just need to use the flush router bit on it. I planed on building at least 1 more and try different damping technique(s).

The third build...I found a good size piece of 5/8", maybe enough for the two sides and tops and bottoms (inside would 1/2") any advantage?

Does anyone have a link, or pic, how-to damping the corners? Foam wedges?

Hi ODougbo,

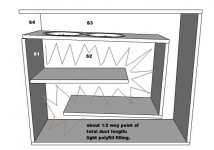

Thicker material can't hurt. It's not so much about only damping the corners, but lightly filling about 1/2 the length of the duct from S1 (end of horn below driver back side) as indicated by bjorno in Post #105.

Apparently my links didn't take in Post # 96??? Maybe this will do it:

http://www.diyaudio.com/forums/subwoofers/188283-fiddling-hornresp-peerless-831759-a-3.html

see: Post #25 by bjorno.

Regards,

Thicker material can't hurt. It's not so much about only damping the corners, but lightly filling about 1/2 the length of the duct from S1 (end of horn below driver back side) as indicated by bjorno in Post #105.

Apparently my links didn't take in Post # 96??? Maybe this will do it:

http://www.diyaudio.com/forums/subwoofers/188283-fiddling-hornresp-peerless-831759-a-3.html

see: Post #25 by bjorno.

Regards,

Last edited:

Thanks for all the advise

All,

Both boxes together was a little much, only using the 5" Fostex as satellite speakers and both subs were right next to each other.

Two together it is surprisingly poweful, but in a way one TH box was more detailed, and easier to manage then both.

A bit of a boom (with both), not terrible, so next box I'll go with thicker wood and damping.

It would be pretty easy to add a "door" right below the woofers; with the 2 existing cabs shown.

I was worried about loose fill, won't it eventually move down/out the duct?

All,

Both boxes together was a little much, only using the 5" Fostex as satellite speakers and both subs were right next to each other.

Two together it is surprisingly poweful, but in a way one TH box was more detailed, and easier to manage then both.

A bit of a boom (with both), not terrible, so next box I'll go with thicker wood and damping.

It would be pretty easy to add a "door" right below the woofers; with the 2 existing cabs shown.

I was worried about loose fill, won't it eventually move down/out the duct?

Attachments

a couple of ideas:

> Cut the base panel off, remove drivers, add stuffing, re-glue new base.

> A 4" hole on side may be an alterative

(is the highlighted pic correct?)

> Add 1/4" dowel "fingers" to keep the fill from sliding; sides & baffle.

> The black strip is home gutter material cut into strips, you can see right through it, could glue some of them in there.

> Don't have Poly fill, have a stash of damping wool, I suppose that would work.

Again, both TH boxes was nice/powerful, but it was too much - or too little, one box was easy to manage/set.

Thanks for all the info.

> Cut the base panel off, remove drivers, add stuffing, re-glue new base.

> A 4" hole on side may be an alterative

(is the highlighted pic correct?)

> Add 1/4" dowel "fingers" to keep the fill from sliding; sides & baffle.

> The black strip is home gutter material cut into strips, you can see right through it, could glue some of them in there.

> Don't have Poly fill, have a stash of damping wool, I suppose that would work.

Again, both TH boxes was nice/powerful, but it was too much - or too little, one box was easy to manage/set.

Thanks for all the info.

Attachments

- Looking at bjorno's work it looks like the stuffing will alter response below 40Hz for a leaner response.

- I would use the dowels between the free ends of B3&B4

- Very lightly fill the line from the throat down to at least the bottom corner below near S4/B3

- I don't think you need to remove the drivers.

- I'd go in through S4

MCM Part #: 50-6268 should work with the 299-114 setup, though it won't fit in the box.

Too bad the MCA2550E is NLA.

Is MCA2550E discontinued, or out of stock?

PE shows it due in on 2/9/2012.

Is MCA2550E discontinued, or out of stock?

PE shows it due in on 2/9/2012.

The PE High/Low level amp might not have the aggressive bass rolloff.

Hi ODougbo,

More like the attached side view. Also, from bjorno Post #105: "...Stuff evenly to half-ways of L counted from the S1 area: Total Amount of Stuffing = 0.461 lb = 0.209 kg."

Regards,

Hi Oliver,

I tested with progressive Stuffing too but kept the weight of the Stuffing as earlier = 0.461 lb = 0.209 kg:

b

Attachments

Hi Odougbo,

"...this is all very new and trying to catch up..."

That's why we're here, just trying to learn. By the way, when building speakers of this style with stuffing it is always good practice to leave one side plate removable until at least the initial experimenting is over. Naturally, that can get you into trouble with air leaks. So you need a good seal between the dividers and the removable side panel.

Regards,

"...this is all very new and trying to catch up..."

That's why we're here, just trying to learn. By the way, when building speakers of this style with stuffing it is always good practice to leave one side plate removable until at least the initial experimenting is over. Naturally, that can get you into trouble with air leaks. So you need a good seal between the dividers and the removable side panel.

Regards,

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Isobaric - less then $20