Hmm. New to blogs. But I have to say I read a bunch as I designed my latest project. The latest build was a PA style sub with very specific objectives; A PA sub that I could carry with one hand.

The best commercial options I could find all seemed to me to have flaws. The primary one being that they were not lightweight... At least by my definition.

I built a 6+ cubic foot enclosure out of common foam board insulation with beveled latex glue joints and many reinforceing cross braces. I covered that with thin aluminum commonly used for roof valleys/gutters ( did I mention that controlling cost was also an objective).

1/2 inch by 1/16 aluminum angle to protect the corners, and a leather dogbone handle and the cabinet is complete. Oh yeah... painted it with truck bed liner from the hardware store.. Carefull, nothing will remove that without also removing the skin from your fingers...

JBL 268G (at an amazing 6 1/2 lbs) and an inexpensive bash 300 watt amp brings the whole thing to finish.

I am sure that it is not the most amazing sub ever... Win-Isobeta specs it as -14 at 20 hz. But I bet it is close to the best per pound at 28.5 lbs for an 18" self powered PA sub...

Thoughts? Comments? It's OK I can take it.

Steve

The best commercial options I could find all seemed to me to have flaws. The primary one being that they were not lightweight... At least by my definition.

I built a 6+ cubic foot enclosure out of common foam board insulation with beveled latex glue joints and many reinforceing cross braces. I covered that with thin aluminum commonly used for roof valleys/gutters ( did I mention that controlling cost was also an objective).

1/2 inch by 1/16 aluminum angle to protect the corners, and a leather dogbone handle and the cabinet is complete. Oh yeah... painted it with truck bed liner from the hardware store.. Carefull, nothing will remove that without also removing the skin from your fingers...

JBL 268G (at an amazing 6 1/2 lbs) and an inexpensive bash 300 watt amp brings the whole thing to finish.

I am sure that it is not the most amazing sub ever... Win-Isobeta specs it as -14 at 20 hz. But I bet it is close to the best per pound at 28.5 lbs for an 18" self powered PA sub...

Thoughts? Comments? It's OK I can take it.

Steve

On the origional test - signal sweeep 10 to 200 hz (when it was bare aluminum with no feet) it did vibrate across the floor at random - mostly around 40 hz. With 4 heavy duty rubber feet on it, it stays in place well.

As for panel flex, yes it's a problem. Let's just say you don't want to set your beer on it while it's playing. Only way I can think to get around that is to totally rebuild it with honeycomb aluminum. Don't have the spare cash for that right now.

Still it sounds pretty good for a total price under $500.

Steve<a href="http://www.freeimagehosting.net/92067"><img src="http://www.freeimagehosting.net/t/92067.jpg"></a>

As for panel flex, yes it's a problem. Let's just say you don't want to set your beer on it while it's playing. Only way I can think to get around that is to totally rebuild it with honeycomb aluminum. Don't have the spare cash for that right now.

Still it sounds pretty good for a total price under $500.

Steve<a href="http://www.freeimagehosting.net/92067"><img src="http://www.freeimagehosting.net/t/92067.jpg"></a>

Enlighten me. I understand that with midbass, midrange and treble flexing of the cabinet reduces spl by allowing the sound to travel in full space or at least half space. The cabinet direct the sound functionally making it 1/8 space increasing spl in front of the speakers.

Having spent long hours sitting behind various DJ setups I can only say that if you think your wood cabinets direct the low bass forward you are dreaming (at least with any cabinet that is 'portable')....

A ridigid cabinet in a sub controlls the sub cone/coil preventing it from overexcursion... However, JBL differential drives have a breaking coil in the center and I powered it below the max power because I knew the box would flex...

Ok. So my true dream enclosure would be steel lined reinforced concrete, which could come close to making subs perform like 1/8 space spl... but the point is I don't want to pack that around.

This is an experiment in trade offs. If I have to pack 2 of these to match 1 concrete bunker style so be it.

Steve

Having spent long hours sitting behind various DJ setups I can only say that if you think your wood cabinets direct the low bass forward you are dreaming (at least with any cabinet that is 'portable')....

A ridigid cabinet in a sub controlls the sub cone/coil preventing it from overexcursion... However, JBL differential drives have a breaking coil in the center and I powered it below the max power because I knew the box would flex...

Ok. So my true dream enclosure would be steel lined reinforced concrete, which could come close to making subs perform like 1/8 space spl... but the point is I don't want to pack that around.

This is an experiment in trade offs. If I have to pack 2 of these to match 1 concrete bunker style so be it.

Steve

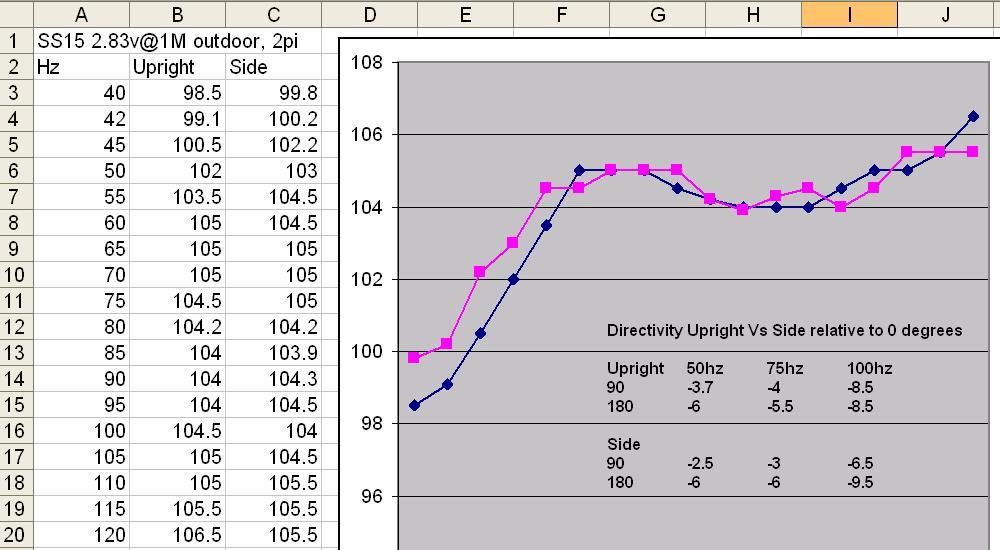

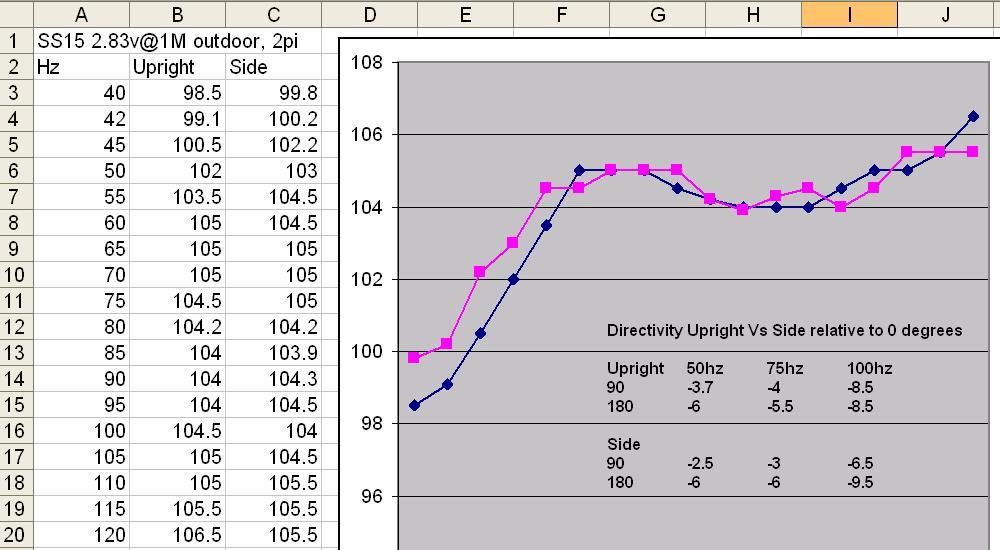

There are some sub designs that are NOT omnidirectional... the attached measurements of my ss15 show that. (It's a 50lb sub... so a bit heavier than yours, but has REALLY good output.)

However in the panel flex department, additional bracing internal with adhesive/foam board, etc should help alot.

My appreciation for something 'out of the ordinary' that seems to fit your needs. Just a thought -- For future builds you can approximate what you get with 'honeycomb' board by adhering 1/8" ply to inside/outside of the foam board.

However in the panel flex department, additional bracing internal with adhesive/foam board, etc should help alot.

My appreciation for something 'out of the ordinary' that seems to fit your needs. Just a thought -- For future builds you can approximate what you get with 'honeycomb' board by adhering 1/8" ply to inside/outside of the foam board.

Enlighten me. I understand that with midbass, midrange and treble flexing of the cabinet reduces spl by allowing the sound to travel in full space or at least half space. The cabinet direct the sound functionally making it 1/8 space increasing spl in front of the speakers.

Having spent long hours sitting behind various DJ setups I can only say that if you think your wood cabinets direct the low bass forward you are dreaming (at least with any cabinet that is 'portable')....

A ridigid cabinet in a sub controlls the sub cone/coil preventing it from overexcursion... However, JBL differential drives have a breaking coil in the center and I powered it below the max power because I knew the box would flex... Steve

sorry, bad quip, the back-wave energy is contained within and damped by panel treatments so that the box does not turn into a distortion generator. You can conceivably make a very light but highly damped box out of carbon fiber with fractal lattice dampers.

Attachments

Last edited:

I've spent quite some time thinking about this since i saw this thread. Now I want to make just such a box using a lattice made of Tinker-toys or something similar and the thinest material possible. I spent about three hours yesterday trying to figure out how to make a carbon fiber sphere... I figured it out but would need 3500$ in carbon fiber...

I've used this for projection screens.... would probably be one of the few economical choices for lightweight panel if you really wanted ultralight sub cabinets.

You can get it at screen printing shops.

Ultra Plus: Foam Board for Outdoor Use | United Industries

You can get it at screen printing shops.

Ultra Plus: Foam Board for Outdoor Use | United Industries

First off thanks Revboden, jbell, I wanted input when I started this post. And for the record I understand the problems of flex, wave canecelation, and distortion. P.S. in the middle of the script I should have started by saying that this was the starting point for the ultralight sub. I plan to to work more on both the low weight/low cost concept. Yep, in the end this cabinet probably ends up scrapped.

Having the general an unfocussed approch to the origional design I built the cabinet an reinforcece everywhere I could feel flex. Here is a pic of how the reinforcement came out (close to random)...

The foam board in 1x1 strips obviously expands more sideways than lenthwise....

dc5cf.jpg at Free Image Hosting

With my wife's help... see if your brain wraps around this: a 28 lb sub cab;

e0108.jpg at Free Image Hosting

and the box...

94544.jpg at Free Image Hosting

So rethink.

But like I said this is Version 1. All help/comments appreciated...

Steve

Having the general an unfocussed approch to the origional design I built the cabinet an reinforcece everywhere I could feel flex. Here is a pic of how the reinforcement came out (close to random)...

The foam board in 1x1 strips obviously expands more sideways than lenthwise....

dc5cf.jpg at Free Image Hosting

With my wife's help... see if your brain wraps around this: a 28 lb sub cab;

e0108.jpg at Free Image Hosting

and the box...

94544.jpg at Free Image Hosting

So rethink.

But like I said this is Version 1. All help/comments appreciated...

Steve

That Ultra Plus looks interesting. Not available in normal retail outlets I suppose. How does the price compare to plywood and MDF?

I suppose I should explain my interest. I am building a portable (luggable) system and intend to use inserts for the main speakers which will then be installed in the main solid wood console. Some thing light and ridged would be good as the cabinet itself and the KT88 amplifier are already going to be rather heavy. I guess I could use regular foam board as it will be braced on all but one or two sides by the cabinet (interior volume will be on the order of 0.5ft^3).

I suppose I should explain my interest. I am building a portable (luggable) system and intend to use inserts for the main speakers which will then be installed in the main solid wood console. Some thing light and ridged would be good as the cabinet itself and the KT88 amplifier are already going to be rather heavy. I guess I could use regular foam board as it will be braced on all but one or two sides by the cabinet (interior volume will be on the order of 0.5ft^3).

Last edited:

It's about $85 bucks a sheet. You really need to find a local screen printing place to buy it, as shipping is not really a good option from places like this: Ultra Board

I realize that's double the going rate for auroco 1/2" ply from lowes, but it's not ridiculous priced like honeycomb board for RV's.

You could always do what kenworth does for the floors of their semi's.... balsa wood with a bonded skin on both sides. (balsa wood in a semi... no, I'm not kidding... look it up.)

I realize that's double the going rate for auroco 1/2" ply from lowes, but it's not ridiculous priced like honeycomb board for RV's.

You could always do what kenworth does for the floors of their semi's.... balsa wood with a bonded skin on both sides. (balsa wood in a semi... no, I'm not kidding... look it up.)

First off thanks Revboden, jbell, I wanted input when I started this post. And for the record I understand the problems of flex, wave canecelation, and distortion. P.S. in the middle of the script I should have started by saying that this was the starting point for the ultralight sub. I plan to to work more on both the low weight/low cost concept. Yep, in the end this cabinet probably ends up scrapped.

Having the general an unfocussed approch to the origional design I built the cabinet an reinforcece everywhere I could feel flex. Here is a pic of how the reinforcement came out (close to random)...

The foam board in 1x1 strips obviously expands more sideways than lenthwise....

An externally hosted image should be here but it was not working when we last tested it.

With my wife's help... see if your brain wraps around this: a 28 lb sub cab;

An externally hosted image should be here but it was not working when we last tested it.

and the box...

An externally hosted image should be here but it was not working when we last tested it.

So rethink.

But like I said this is Version 1. All help/comments appreciated...

Steve

Impressive!

I'm thinking poplar plywood Lightweight plywoods (poplar plywood) :: Winwood Products -- even with bracing, comes in right at the same weight... without all of the complexity.

I vote for poplar.

I vote for poplar.

Hi, Looked into the poplar light plywoood. Just the outside, no cross bracing still calculates to over 70 lbs for the end result with no cross bracing (driver and amp included). Still a far cry from the current 28 lb weight...

PS me on the subwoofer is not a macho statement... I was trying to show that foam board covered with aluminum isn't flimsy.... I tilt the scale at 225 so the cabinet is fairly solid.

Me holding up the sub with my pinky isn't a macho statement either... The point is the sub weights 28 lbs.

I do like the idea of using the aluminum over foam board and using something like the poplar for the cross bracing.... way more ridgid for the bracing than the foam board bracing.

Steve

PS me on the subwoofer is not a macho statement... I was trying to show that foam board covered with aluminum isn't flimsy.... I tilt the scale at 225 so the cabinet is fairly solid.

Me holding up the sub with my pinky isn't a macho statement either... The point is the sub weights 28 lbs.

I do like the idea of using the aluminum over foam board and using something like the poplar for the cross bracing.... way more ridgid for the bracing than the foam board bracing.

Steve

Hi, Looked into the poplar light plywoood. Just the outside, no cross bracing still calculates to over 70 lbs for the end result with no cross bracing (driver and amp included). Still a far cry from the current 28 lb weight...

Redo your math.... The popular plywood comes in right at 28lbs with driver.

Just a sanity check, a 22" cube is about 3/4 of a 4x8 sheet of ply... even with 42lbs per sheet auroco, that's no where close to 70lbs....

I understand your desire to do something different and applaud it. However there are easier ways to get to 28lbs.

My bad.

The only website I could find listed poplar plywood weight in terms cubic feet and I obviously screwed up the calculations.

From the link you posted a 3/4 sheet comes in at around 21 lbs per sheet. The current design is 24x24x27 so the wiegnt of the wood would come in around 23 lbs (the amp has a seperate internal enclosusre to prevent vibration).

With everything else added I guess the total weight around 33 lbs without crossbracing. Having said that I would have gone with the poplar had I known how light it is.

My other option was honeycomb aluminum at $400 plus per sheet. Now I know there is no way I would pay that with poplar as an option.

Thanks

Steve

The only website I could find listed poplar plywood weight in terms cubic feet and I obviously screwed up the calculations.

From the link you posted a 3/4 sheet comes in at around 21 lbs per sheet. The current design is 24x24x27 so the wiegnt of the wood would come in around 23 lbs (the amp has a seperate internal enclosusre to prevent vibration).

With everything else added I guess the total weight around 33 lbs without crossbracing. Having said that I would have gone with the poplar had I known how light it is.

My other option was honeycomb aluminum at $400 plus per sheet. Now I know there is no way I would pay that with poplar as an option.

Thanks

Steve

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Ultralight PA Sub with 268G