When it comes to subwoofers, there are two things I hate. I hate waiting for my subs to arrive from Parts Express. And I hate it when someone publishes a sub design, only to find that the woofer is discontinued.

Over on my forum I published a version of Mike's Insubnia sub that uses an Alpine car audio woofer. While working on the design, I noticed that nearly all of Alpine's car audio subs have been heavily optimized on the Klippel, and you guys could probably make some serious subs with 'em. They're practically perfect for a tapped horn because they have a high FS and tons of XMAX, which is exactly what you want for a TH.

Check out this BL curve:

Those folks at Alpine have been doing their homework.

If anyone wants to pop this one into a tapped horn, this subwoofer is available at thousands of Best Buy locations nationwide. It's also at Car Toys. I usually dismiss anything that I see over the counter. Most subs you buy over the counter have pretty baskets and crummy motors. Or they're middle-of-the-road designs that sell for four or five hundred bucks. This Alpine woofer seems to be The Real Deal. It's under $180 over-the-counter, and it's specs are competitive with what you'd find at that price from most online retailers. And if you have the patience to wait a few days, there are tons of places selling it for under $150 delivered.

I'm curious what you guys can come up with - all of my designs tend to be hideously complex. Would be nice to build something simple.

here's the T/S:

http://support.alpine-usa.com/products/documents/OM_SWR_S06212011.pdf

Over on my forum I published a version of Mike's Insubnia sub that uses an Alpine car audio woofer. While working on the design, I noticed that nearly all of Alpine's car audio subs have been heavily optimized on the Klippel, and you guys could probably make some serious subs with 'em. They're practically perfect for a tapped horn because they have a high FS and tons of XMAX, which is exactly what you want for a TH.

Check out this BL curve:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Those folks at Alpine have been doing their homework.

If anyone wants to pop this one into a tapped horn, this subwoofer is available at thousands of Best Buy locations nationwide. It's also at Car Toys. I usually dismiss anything that I see over the counter. Most subs you buy over the counter have pretty baskets and crummy motors. Or they're middle-of-the-road designs that sell for four or five hundred bucks. This Alpine woofer seems to be The Real Deal. It's under $180 over-the-counter, and it's specs are competitive with what you'd find at that price from most online retailers. And if you have the patience to wait a few days, there are tons of places selling it for under $150 delivered.

I'm curious what you guys can come up with - all of my designs tend to be hideously complex. Would be nice to build something simple.

here's the T/S:

http://support.alpine-usa.com/products/documents/OM_SWR_S06212011.pdf

Last edited:

Yep those are good bang for the buck...I was skeptical at first but I just kept seeing positive reviews and hard data like the klippel report. Then you look at the price and factor in that they are available everywhere and backed by a huge company, so they are not going to suddenly vanish from the market... Their more expensive X series appears to use a full copper pole sleeve judging from a few pictures that I saw.

Edit: A quick Google price check shows the 15" version available shipped to your door for under $180 with full warranty. Might be worth looking into if you need something with a bit more low end and heavier duty than the Dayton 15's.

Edit: A quick Google price check shows the 15" version available shipped to your door for under $180 with full warranty. Might be worth looking into if you need something with a bit more low end and heavier duty than the Dayton 15's.

Last edited:

Nice subs, but Qts on the 12" is just a little too high for my liking.

OTOH, it's difficult to find a car audio sub with a Qts between 0.3~0.4 these days...

Yep those are good bang for the buck...I was skeptical at first but I just kept seeing positive reviews and hard data like the klippel report. Then you look at the price and factor in that they are available everywhere and backed by a huge company, so they are not going to suddenly vanish from the market... Their more expensive X series appears to use a full copper pole sleeve judging from a few pictures that I saw.

Edit: A quick Google price check shows the 15" version available shipped to your door for under $180 with full warranty. Might be worth looking into if you need something with a bit more low end and heavier duty than the Dayton 15's.

According to Jim Walter from Alpine, the tens and the twelves were the first to get this motor, and the eights got it a few months ago. Looks like the fifteens are still using the old motor. Here's his quote:

"There a 6 magnets, radially segmented and aligned around the shorting ring/frame/heatsink. The shorting ring is connected to the frame via three legs that allow the entire frame to act as a heatsink. We intro'd this design with our 2010 Type R 10" and 12" and we've carried this into the new 8"s as well …. it’s a pain in the butt to tool and assembly but the results are worth it. Check out the cut-view model, you can see on the left side, the shorting ring is directly connected to the exo-skeleton of the frame with one of three radial ribs the fit through the segments in the magnets."

He's been doing a Q&A on these over at Diyma.

Not saying the fifteens aren't a good deal, but something to consider.

I played with a couple of these in hornresp, and didn't see anything I liked in terms of using for tapped horn.

Anyone else come up with anything of interest?

Here's a comparison of the Alpine Type-R 8" versus Exodus Audio Anarchy, 250watts into 2ohms:

I used Mike's "Insubnia" as the baseline, and widened the box to 9.5" to accomodate the woofer. Everything else is identical. (Height, Length, etc.)

Here's what the insubnia looks like (not my pics)

Here's additional info:

Audio Psychosis • View topic - Cheap and Different Sub

I think you could get similar results with the dual four ohm 10" woofer, which is stocked at Best Buy. Would have to make the line a bit longer of course.

Here's a comparison of the Alpine Type-R 8" versus Exodus Audio Anarchy, 250watts into 2ohms:

I used Mike's "Insubnia" as the baseline, and widened the box to 9.5" to accomodate the woofer. Everything else is identical. (Height, Length, etc.)

Here's what the insubnia looks like (not my pics)

Here's additional info:

Audio Psychosis • View topic - Cheap and Different Sub

I think you could get similar results with the dual four ohm 10" woofer, which is stocked at Best Buy. Would have to make the line a bit longer of course.

I've got an evolution of that cabinet in the works as well.

It is nice to see that there are some more excellent driver choices out there. My cabinet wound up a bit larger, but I added 2 more flare rates, as well as widened it for use with 8s and 10s, and gave myself a bit more room for larger drivers.

Will have to have a play with these drivers. Nice find.

Last edited:

I played with a couple of these in hornresp, and didn't see anything I liked in terms of using for tapped horn.

Anyone else come up with anything of interest?

Mini DTS-10? A couple of ~6.5-7 ft^3 cabs in 1pi space theoretically should handle most music, HT apps:

GM

Attachments

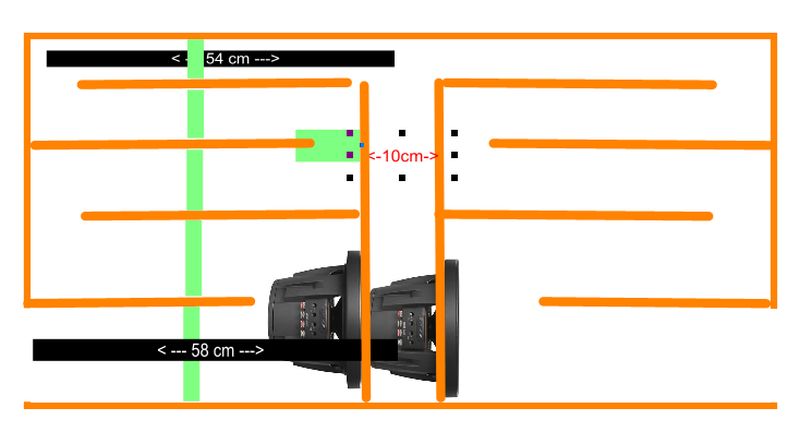

After going to one dubstep show too many, I've decided to build the biggest sub I've ever attempted to shoehorn into my car.

If you got the need for bass, here's some reasons you might consider building this:

1) if you want to make bass, it's really tough to beat a big box with a lot of power

2) while I am only using eights, I am using eights with a lot of displacement in a tapped horn, so my sims indicate it should get loud and clean

3) All of my best projects have been knockoffs of existing designs. My th-mini clone and my Unity horn projects were all based on Danley's work. This sub is in the same vein, as it's based on the TH-Spud

4) This project is not expensive. All of the wood, two subs, and the wiring costs less than $300. I think the Alpine eights are a screaming deal, with lots of displacement, a well thought out design, distortion reducing shorting rings, and a flat BL curve. You could spend a lot more and get less.

5) One of the more unusual aspects of this sub box is where it's designed to be located. It's designed to go in the back seat of a car, not the trunk. I'm doing this for a number of reasons:

a) I've kept the stereo 'stock' in this car because it's better for the resale value

b) I think that it's more difficult to get the midbass 'correct in a car than the subs. In this design, the subs are going to be run well up into the midbass freuencies, possibly as high as 300hz.

c) I believe that subs in the cabin have the potential to play a lot louder than subs in the trunk. This is due to standing waves. (Basically the ideal location for SPL in a car is to have a sub in the center of a vehicle IMHO.)

Anyways, stay tuned, should get interesting. As time permits I will publish a diagram that's easier to follow. The one above is very rough.

Here's some pics of Volvotreters clone of the TH-Spud. My sub design uses a similar folding, with a couple changes:

1) mine is a basically a th-spud that's mirrored. By mirroring the sub, we get the mouths farther apart, which should improve imaging since I intend to run these as high as 300hz

2) mine is tuned higher, which allows for a shorter line and a smaller footprint

3) I'm using a pair of Alpine SWR-843Ds, which have a couple nice features for a tapped horn. They have shorting rings, a flat BL curve, and an FS which is much higher. (allows for a smaller box.)

Here's the measured response of Volvotreters TH-Spud clone. Note that the bandwidth is much wider than what you'd expect from the hornresp sims. This is consistent with what I've found with my TH projects, which is that you can get about an extra octave more than you'd expect if you use dual woofers and if you use some EQ to tame the first peak. (above the peak it gets pretty crazy, probably wouldn't want to use a TH for more than 2-3 octaves.)

some pics of the sub coming together:

not much to look at (yet)

I used 3/8" plywood for this box - because it's designed to be placed on the back seat of a car. And I didn't want it to be so heavy that it would screw up my seats. But you can see the 'bowing' of the plywood will create some challenges.

At every step in the build process, I'm using weights to flatten and straighten the boards. It's a bit of a hassle, but I'm hoping that it will pay off with a light rigid subwoofer enclosure.

In this picture, I'm STANDING on the center tunnel of the sub box. I did this to demonstrate how rigid/strong it is. Due to the very thin plywood I am using, I believe a lot of cross braces are a pre-requisite for this thing to work properly. (IE, if I'd used 3/4" plywood instead of 3/8" plywood these types of braces wouldn't be as important.)

An externally hosted image should be here but it was not working when we last tested it.

not much to look at (yet)

I used 3/8" plywood for this box - because it's designed to be placed on the back seat of a car. And I didn't want it to be so heavy that it would screw up my seats. But you can see the 'bowing' of the plywood will create some challenges.

An externally hosted image should be here but it was not working when we last tested it.

At every step in the build process, I'm using weights to flatten and straighten the boards. It's a bit of a hassle, but I'm hoping that it will pay off with a light rigid subwoofer enclosure.

In this picture, I'm STANDING on the center tunnel of the sub box. I did this to demonstrate how rigid/strong it is. Due to the very thin plywood I am using, I believe a lot of cross braces are a pre-requisite for this thing to work properly. (IE, if I'd used 3/4" plywood instead of 3/8" plywood these types of braces wouldn't be as important.)

I used 3/8" plywood for this box - because it's designed to be placed on the back seat of a car.

On the back seat??

Hmm.. it looks like aesthetics and safety are not high on your priority list

Pat I thought you gave up on tapped horns for cars and wanted to use monopoles?

yes, I think sealed boxes are the way to go in a small room or in a car IF you want the most output per liter. In fact, one of the ideas I'd considered instead of this box was using a pile of small woofers in a sealed box.

There were a few things that tipped me towards a tapped horn again:

1) as long as you have plenty of power, output will be mostly dictated by woofer displacement.

2) a tapped horn has very low displacement at the tuning frequency

3) while a sealed box is 'theoretically' superior for a car, if you combine the low excursion of a tapped horn with a highpass filter to lower excursion below fb, a tapped horn can handle a crapload of power

Bottom line - six or eight of the Alpine woofers in a box that's about the same size will likely get louder. But the box, woofers and amplifier will cost about $1000, versus less than half that much for the tapped horn.

Also, I'd actually come *really* close to doing a front loaded horn for the Alpines, but they don't work so hot because their QTS is so high.

On the back seat??

Hmm.. it looks like aesthetics and safety are not high on your priority list

Something I wrote in rec.audio.car about 8 years ago:

... forces of 40 to 50 G are routinely recorded during the standard 30 MPH crash tests. Your sub box weighs, for example, 50 pounds. Multiply that by 50: 50 x 50 = 2500 pounds.

That's well over a ton. If you were to suspend your car nose down, then stack over a ton of weights onto the back of the seat, do you think the seat locks would hold? Would you be prepared to be buckled into the driver's seat while the weights were stacked? What do you think would happen to you if more than a ton of weights landed on you? It'd be ironic if you were to hit something, be saved by the seat belt and airbag, then be mashed to strawberry jam by your sub box.

Bolt that sub box to the vehicle frame. NOW.

It needs to be bolted down as securely as a trailer hitch would be mounted. This means high-tensile bolts and big load spreading washers. The bolts should run right through the box- it's no use just bolting the bottom down, the rest of the box will likely rip off it and go flying.

If you doubt that, just take a sledge hammer to an old sub box sometime.(*) I'll wager that it'll only take one big swing to break out the bottom or a side if you hit it from the inside near one edge (puts the joint under maximum tension). The sledge head weighs 20 pounds or less and is moving less than 30 MPH. I'll bet your sub drivers weigh 20 pounds or more, and they will be moving faster in even a moderate collison.

(*) Yes, I have done this. They were water and smoke damaged and had to be written off. We broke them up so they'd pack flat in the dumpster.

In Patrick's case, I would suggest designing the box so it can be restrained by the rear seat belts. It's not ideal, but it's better then nothing. If the belts are too short to fit around the box, consider using (safety approved) seat belt extenders.

Something I wrote in rec.audio.car about 8 years ago:

... forces of 40 to 50 G are routinely recorded during the standard 30 MPH crash tests. Your sub box weighs, for example, 50 pounds. Multiply that by 50: 50 x 50 = 2500 pounds.

That's well over a ton. If you were to suspend your car nose down, then stack over a ton of weights onto the back of the seat, do you think the seat locks would hold? Would you be prepared to be buckled into the driver's seat while the weights were stacked? What do you think would happen to you if more than a ton of weights landed on you? It'd be ironic if you were to hit something, be saved by the seat belt and airbag, then be mashed to strawberry jam by your sub box.

Bolt that sub box to the vehicle frame. NOW.

It needs to be bolted down as securely as a trailer hitch would be mounted. This means high-tensile bolts and big load spreading washers. The bolts should run right through the box- it's no use just bolting the bottom down, the rest of the box will likely rip off it and go flying.

If you doubt that, just take a sledge hammer to an old sub box sometime.(*) I'll wager that it'll only take one big swing to break out the bottom or a side if you hit it from the inside near one edge (puts the joint under maximum tension). The sledge head weighs 20 pounds or less and is moving less than 30 MPH. I'll bet your sub drivers weigh 20 pounds or more, and they will be moving faster in even a moderate collison.

(*) Yes, I have done this. They were water and smoke damaged and had to be written off. We broke them up so they'd pack flat in the dumpster.

In Patrick's case, I would suggest designing the box so it can be restrained by the rear seat belts. It's not ideal, but it's better then nothing. If the belts are too short to fit around the box, consider using (safety approved) seat belt extenders.

So you're saying that Unity horns on the dash and tapped horns on the back seat are a recipe for disaster?

:O :O :O

LinkSo you're saying that Unity horns on the dash and tapped horns on the back seat are a recipe for disaster?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Tapped Horn for the Lazy and Impatient