I just got my 18sound drivers from loudspeakersplus.com....ordered tuesday morning had them by friday evening! They are beasts!

(2) 18lw2400's which will be used in two TH-18 tapped horns, design courtesy of Xoc1 (Thanks again for all the info/effort you put into this!!) Also thanks to Djim for his help and patience through my questions with the design/corner bracing etc etc.

This thread is for anyone who builds his box. I figured I would start because I think I am one of the first to do so!

I will go pick up some good high quality 3/4" Birch tomorrow and get started on this. Pictures to follow asap!!

Here is the Sketch plus a nice cut list...

View attachment TH18 + CUT LIST.PDF

Extra bracing which Djim suggested...

Now I am pretty sure that the point of this design was for 4 cabinets to be Flat to 35hz. I am starting with only two because of cost, not just for drivers/wood but amp power needed to drive them as well. These are some powerful cabinets and depending on which driver you choose to load them with, they can take a serious amount of wattage!

There are a ton of different drivers which have been simmed for this design, I think most have been simmed for the cabinet without the corner reflectors, but still the same external volume cabinet.

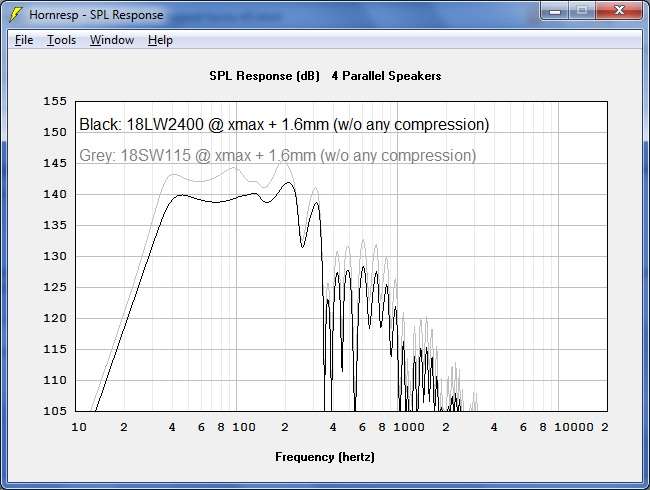

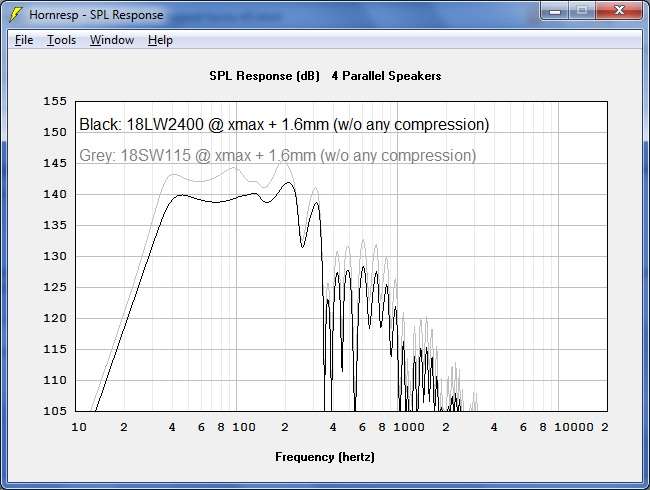

Here is a sim for 4 cabs at xmax + with the 18 sound 2400 drivers...

(2) 18lw2400's which will be used in two TH-18 tapped horns, design courtesy of Xoc1 (Thanks again for all the info/effort you put into this!!) Also thanks to Djim for his help and patience through my questions with the design/corner bracing etc etc.

This thread is for anyone who builds his box. I figured I would start because I think I am one of the first to do so!

I will go pick up some good high quality 3/4" Birch tomorrow and get started on this. Pictures to follow asap!!

Here is the Sketch plus a nice cut list...

View attachment TH18 + CUT LIST.PDF

Extra bracing which Djim suggested...

An externally hosted image should be here but it was not working when we last tested it.

Now I am pretty sure that the point of this design was for 4 cabinets to be Flat to 35hz. I am starting with only two because of cost, not just for drivers/wood but amp power needed to drive them as well. These are some powerful cabinets and depending on which driver you choose to load them with, they can take a serious amount of wattage!

There are a ton of different drivers which have been simmed for this design, I think most have been simmed for the cabinet without the corner reflectors, but still the same external volume cabinet.

Here is a sim for 4 cabs at xmax + with the 18 sound 2400 drivers...

Last edited:

Background Info & Credits

This design owes a lot to all the people who have contributed their experience and knowledge on DIYaudio.

It’s an offshoot of the thread http://www.diyaudio.com/forums/subwoofers/178029-c-e-x-pa-flat-30-ft30-pa-th-awesomeness.html. When I posted a T.H. that was more compact, and did not reach 30Hz flat, this generated a lot of interest.🙂

The objective was to design and build a T.H. using an 18” driver in a reasonably compact package, that will have decent performance without any worries about speaker excursion when driven with high power (in excess of 1000W.) An extended HF response was one of the goals.

One significant contribution was Soho54’s technique for measuring the path length of a folded horn that was discussed in the thread http://www.diyaudio.com/forums/subw...olded-horn-layouts.html?highlight=spreadsheet

This allows the path length to be measured using segmented lines rather than offset curves. This method work very well with CAD setting out. I developed the technique of using the speaker path length and widths to generate an unfolded representation of the horn path, similar to the horn schematic diagram generated by David McBeans Hornresp software.

By using Parametric Cad the lines in the folded and unfolded layout are linked. It is then possible to adjust the shape of the folded horn and rebuild the sketches to immediately see how this affects the shape of the unfolded schematic. By an iterative process it is possible to optimise the shape of the horn with very good levels of accuracy.

I produced a folding scheme based on the same layout as J Bells SS15 speaker.http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge.html. The SS15 is a very compact 15” T.H. that has been successfully built and tested by many forum members.

The overall size of the speaker I set out was rather shamefully almost a complete match of Tom Danley’s TH115 / TH118 😱– The theory being if the Danley subs work well at this size, it is ‘big enough’!😀

This design owes a lot to all the people who have contributed their experience and knowledge on DIYaudio.

It’s an offshoot of the thread http://www.diyaudio.com/forums/subwoofers/178029-c-e-x-pa-flat-30-ft30-pa-th-awesomeness.html. When I posted a T.H. that was more compact, and did not reach 30Hz flat, this generated a lot of interest.🙂

The objective was to design and build a T.H. using an 18” driver in a reasonably compact package, that will have decent performance without any worries about speaker excursion when driven with high power (in excess of 1000W.) An extended HF response was one of the goals.

One significant contribution was Soho54’s technique for measuring the path length of a folded horn that was discussed in the thread http://www.diyaudio.com/forums/subw...olded-horn-layouts.html?highlight=spreadsheet

This allows the path length to be measured using segmented lines rather than offset curves. This method work very well with CAD setting out. I developed the technique of using the speaker path length and widths to generate an unfolded representation of the horn path, similar to the horn schematic diagram generated by David McBeans Hornresp software.

By using Parametric Cad the lines in the folded and unfolded layout are linked. It is then possible to adjust the shape of the folded horn and rebuild the sketches to immediately see how this affects the shape of the unfolded schematic. By an iterative process it is possible to optimise the shape of the horn with very good levels of accuracy.

I produced a folding scheme based on the same layout as J Bells SS15 speaker.http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge.html. The SS15 is a very compact 15” T.H. that has been successfully built and tested by many forum members.

The overall size of the speaker I set out was rather shamefully almost a complete match of Tom Danley’s TH115 / TH118 😱– The theory being if the Danley subs work well at this size, it is ‘big enough’!😀

I applaud this design and effort as well.

This forum seems to be the one place that I've found with some serious thinking in terms of PA subs. No, not everyone needs pa 140db, but for those who do -- this seems to be the place where the thinking and DOING happens in regards to PA subs.

There are many forums where HT subs are the topic of the day, but very few places where PA is. Great discussions on power compression, what happens to suspensions as they approach limits, what happens in the 'real world' at 'real PA levels' as opposed to just simulations. (although we would be completely lost without David's wonderful hornresp, and for the brave... akabak for our simulations)

I look forward to the build, the testing, and eventually road show reports on how they worked in real life.

This forum seems to be the one place that I've found with some serious thinking in terms of PA subs. No, not everyone needs pa 140db, but for those who do -- this seems to be the place where the thinking and DOING happens in regards to PA subs.

There are many forums where HT subs are the topic of the day, but very few places where PA is. Great discussions on power compression, what happens to suspensions as they approach limits, what happens in the 'real world' at 'real PA levels' as opposed to just simulations. (although we would be completely lost without David's wonderful hornresp, and for the brave... akabak for our simulations)

I look forward to the build, the testing, and eventually road show reports on how they worked in real life.

The Folding Process

As outlined above the horn fold is set out and then adjusted in the CAD model to optimise it. In fact I have almost given up on modelling up a speaker from scratch in Hornresp. Instead I now prefer to lay out a basic sketch model of the horn, and unfolded speaker and adjust it to shape. The unfolded sketch is used to create a Hornresp Sim. The horn wizard is then utilised to see which way the shape of the horn can be modified to improve the performance. The modified sim can then be used to help reshape the fold.

The CAD model can be easily copied and modified, so once a folding scheme is set out the work can be reused for another speaker design.

The original design omitted 3 of the internal reflectors.

These were added at Djims suggestion. The addition of the 3 reflectors shortened the path length slightly. The reflector lengths are optimised, but the overall folding was left as the original. The largest error in the horn taper widths introduced by the extra reflectors was 0.8mm, so I left the fold as it was.

At this point it might be good to mention that I made an error in my previous drawings 😱the exit mouth internal dimension is 508 not 526. (Adjust S4 from 2814.1 to 2717.8)

Fortunately the effect on the sim is very minimal.

As outlined above the horn fold is set out and then adjusted in the CAD model to optimise it. In fact I have almost given up on modelling up a speaker from scratch in Hornresp. Instead I now prefer to lay out a basic sketch model of the horn, and unfolded speaker and adjust it to shape. The unfolded sketch is used to create a Hornresp Sim. The horn wizard is then utilised to see which way the shape of the horn can be modified to improve the performance. The modified sim can then be used to help reshape the fold.

The CAD model can be easily copied and modified, so once a folding scheme is set out the work can be reused for another speaker design.

The original design omitted 3 of the internal reflectors.

These were added at Djims suggestion. The addition of the 3 reflectors shortened the path length slightly. The reflector lengths are optimised, but the overall folding was left as the original. The largest error in the horn taper widths introduced by the extra reflectors was 0.8mm, so I left the fold as it was.

At this point it might be good to mention that I made an error in my previous drawings 😱the exit mouth internal dimension is 508 not 526. (Adjust S4 from 2814.1 to 2717.8)

Fortunately the effect on the sim is very minimal.

Attachments

Updated Drawing with Internal Reflectors

Attached PDF is the latest drawing for the TH18

I have added the internal reflectors to the cut list and details.

I have also updated the unfolded schematic with the correct exit dimension.

I am currently looking at the design of the bracing. I had the un-braced cabinet analysed for resonances. The most significant result was the resonance of the exit mouth. This wobbles from side to side at about 61Hz.😱

The bracing as suggested by Djim seem to take care of the resonances that were found in the rest of the cabinet. It might even be possible to reduce the internal bracing, if I can get some more analysis done once I have added some bracing to the CAD model.

Primary concern at the moment is the horn exit mouth. I would like to add some reinforcement to this…..

Attached PDF is the latest drawing for the TH18

I have added the internal reflectors to the cut list and details.

I have also updated the unfolded schematic with the correct exit dimension.

I am currently looking at the design of the bracing. I had the un-braced cabinet analysed for resonances. The most significant result was the resonance of the exit mouth. This wobbles from side to side at about 61Hz.😱

The bracing as suggested by Djim seem to take care of the resonances that were found in the rest of the cabinet. It might even be possible to reduce the internal bracing, if I can get some more analysis done once I have added some bracing to the CAD model.

Primary concern at the moment is the horn exit mouth. I would like to add some reinforcement to this…..

Attachments

Thanks! This is awesome! 😀

I was about to go grab the Baltic Birch from my local supplier, and they want $80 per 5x5 sheet. I was figuring out a cut sheet for 4x8 wood then I found out that the real baltic birch only comes in 5x5. Anyway, I figure it will take 3-4 (5x5') sheets of wood per cabinet. Is the baltic birch really worth the $320 per cabinet? Or can I go with a high quality domestic or canadian Birch plywood (4x8 3/4" sheet is about $60)?

Thanks!

I was about to go grab the Baltic Birch from my local supplier, and they want $80 per 5x5 sheet. I was figuring out a cut sheet for 4x8 wood then I found out that the real baltic birch only comes in 5x5. Anyway, I figure it will take 3-4 (5x5') sheets of wood per cabinet. Is the baltic birch really worth the $320 per cabinet? Or can I go with a high quality domestic or canadian Birch plywood (4x8 3/4" sheet is about $60)?

Thanks!

m R g R r

Baltic birch is the material to go for. I can't think of another material I have seen specified for decent Pro Cabs.

It is very strong - light and free from voids.

In a recent test I know of a single screw into the end of a piece of 18mm wide birch ply lifted 600kg!😉

I have put together a cut sheet and you can get 2 cabinets out of 5 off 5x5 sheets 1524 X 1524

So thats $200 per cab at your quoted price. 🙂

I checked it twice - I suggest you do the same!

Baltic birch is the material to go for. I can't think of another material I have seen specified for decent Pro Cabs.

It is very strong - light and free from voids.

In a recent test I know of a single screw into the end of a piece of 18mm wide birch ply lifted 600kg!😉

I have put together a cut sheet and you can get 2 cabinets out of 5 off 5x5 sheets 1524 X 1524

So thats $200 per cab at your quoted price. 🙂

I checked it twice - I suggest you do the same!

Attachments

Last edited:

It depends on how much bracing you want to do, as there is enough excess material in 2 & 1/2 sheets to use some of the birch ply. I,m not 100 pecent decided yet how much to brace the cab.

I may know more next week. it will take some time to get everything tested and optimised.

For example this is a resonance in the back of the cab at 274hz:😉

I may know more next week. it will take some time to get everything tested and optimised.

For example this is a resonance in the back of the cab at 274hz:😉

Attachments

Martin, I’m glad to see your PA sub concept finally got its own thread.

Although we all realise your concept is a continuation of earlier ideas, theories and concepts it is amazing to see them come together with your ideas, skills and true professionalism in modelling. Therefore I really hope the Xoc1-TH18 will get as much attention and appreciation as JBell’s SS15 and other great designs here on this forum.

Although we all realise your concept is a continuation of earlier ideas, theories and concepts it is amazing to see them come together with your ideas, skills and true professionalism in modelling. Therefore I really hope the Xoc1-TH18 will get as much attention and appreciation as JBell’s SS15 and other great designs here on this forum.

Question; the upper range harmonics as shown in your model do they also take account of the resonances of the materials selves? I mean baltic multiplx has different material resonances as Philippine hardwood ect. The reason I mention is because it also works differently in damping. I'm wondering if your modelling is able to use all these parameters that are involved.It depends on how much bracing you want to do, as there is enough excess material in 2 & 1/2 sheets to use some of the birch ply. I,m not 100 pecent decided yet how much to brace the cab.

I may know more next week. it will take some time to get everything tested and optimised.

For example this is a resonance in the back of the cab at 274hz:😉

Hi Djim

The results I have were an initial test of the unbraced cab - The material was a plywood but not Birch Ply. The results were neverless very interesting - The software is very capable. The results targeted resonances at increasing frequencies. The lowest resonance (weakest point) was the horn mouth wobble at 60Hz, Most of the other resonances involved the first vertical internal panel (part 9 Ref latest drawing), and the rear panel. Your bracing scheme would sort these out!

Some of the frequencies were higher than the passband, but would probably be present as harmonic resonances.

The 2 other internal vertical panels are quite strong. I think this is because the reflectors brace them.

The two side panels also flex around the exit of the horn. No doubt this is why even a mesh grille makes a difference to similar TH cabs.

I'm away from my CAD PC at the moment but I have added some bracing between the front and first internal (part 9), and the rear panel to the rear vertical internal panel (part 7).

I have also added 2 experimental braces to the horn mouth. These are positioned in a V shape from the centre of the base. The driver can still be removed! The bracing I will test wil be quite minimal but hopefully will be engineered to do enough to kill the major resonances in the cab without over engineering.

I know this will reduce S5 area at the horn mouth but hopefully it will cure more than it kills.😱

If I get the chance I will get this tested next week.🙂

The results I have were an initial test of the unbraced cab - The material was a plywood but not Birch Ply. The results were neverless very interesting - The software is very capable. The results targeted resonances at increasing frequencies. The lowest resonance (weakest point) was the horn mouth wobble at 60Hz, Most of the other resonances involved the first vertical internal panel (part 9 Ref latest drawing), and the rear panel. Your bracing scheme would sort these out!

Some of the frequencies were higher than the passband, but would probably be present as harmonic resonances.

The 2 other internal vertical panels are quite strong. I think this is because the reflectors brace them.

The two side panels also flex around the exit of the horn. No doubt this is why even a mesh grille makes a difference to similar TH cabs.

I'm away from my CAD PC at the moment but I have added some bracing between the front and first internal (part 9), and the rear panel to the rear vertical internal panel (part 7).

I have also added 2 experimental braces to the horn mouth. These are positioned in a V shape from the centre of the base. The driver can still be removed! The bracing I will test wil be quite minimal but hopefully will be engineered to do enough to kill the major resonances in the cab without over engineering.

I know this will reduce S5 area at the horn mouth but hopefully it will cure more than it kills.😱

If I get the chance I will get this tested next week.🙂

Attachments

I can say from experience that a metal grill like this reduces the 'walking' the sub does... (meaning much less flex)

Notice how I bent the ears inside and then bolted the top/bottom. I made sure to have enough pressure on the 'ears' on the sides that no wood/metal vibrations happen. (also dipped them in plastidip just for good measure)

Notice how I bent the ears inside and then bolted the top/bottom. I made sure to have enough pressure on the 'ears' on the sides that no wood/metal vibrations happen. (also dipped them in plastidip just for good measure)

Attachments

Hi Martin,

The corner bracing indeed makes the panel’s tuff and very roadproof (some people forget they are building PA cabs instead of Ikea kitchens 😉 ).

I see you left out the vertical bracing in the last corner that goes on over the bottom panel (my second suggestion for bracing). In our tests that extra bracing (+ ‘broomsticks’ solutions) did help allot in suppressing mouth problems without damaging the LF content to much. Also in case of Vast installation, this bracing suggestion helps very much when the cabs needs to be flying.

To be honest my eyebrows raised a little with your V-type mouth solution. Just based on my own experience it will influence the output more than you like while there are other solutions that already proved their effectiveness. Like Jbell suggested I also favour metal grills (especially with bar/solid surroundings). It suppresses the mouth problem at all places and it acts as a safety tool to keep 'unidentified objects' out.

About the high resonances, you can’t get rid of them as long you don’t tread panels over the full surface with absorbent materials such like bitumen/rubber (high elastic) based sticky layers. I doubt if (most) users have a big problem with these harmonics in the first place and those who have I suppose they already know the solutions 😀

One more question, what does the model say about the 'hollow space'? The reason I ask is that we noticed difference in measurements when we braced the inside of a similar hollow cavity.

The corner bracing indeed makes the panel’s tuff and very roadproof (some people forget they are building PA cabs instead of Ikea kitchens 😉 ).

I see you left out the vertical bracing in the last corner that goes on over the bottom panel (my second suggestion for bracing). In our tests that extra bracing (+ ‘broomsticks’ solutions) did help allot in suppressing mouth problems without damaging the LF content to much. Also in case of Vast installation, this bracing suggestion helps very much when the cabs needs to be flying.

To be honest my eyebrows raised a little with your V-type mouth solution. Just based on my own experience it will influence the output more than you like while there are other solutions that already proved their effectiveness. Like Jbell suggested I also favour metal grills (especially with bar/solid surroundings). It suppresses the mouth problem at all places and it acts as a safety tool to keep 'unidentified objects' out.

About the high resonances, you can’t get rid of them as long you don’t tread panels over the full surface with absorbent materials such like bitumen/rubber (high elastic) based sticky layers. I doubt if (most) users have a big problem with these harmonics in the first place and those who have I suppose they already know the solutions 😀

One more question, what does the model say about the 'hollow space'? The reason I ask is that we noticed difference in measurements when we braced the inside of a similar hollow cavity.

Last edited:

Great work!

Which driver was the design based on the 18 sound driver? I need to build a couple of cabs for two BMS 18N850V2 and would like to give this design a go if the driver is suitable.

Unfortunately i dont have much experience with horn design and driver matching - should i model the BMS driver in this design with hornsresp?

Any input appreciated,

Which driver was the design based on the 18 sound driver? I need to build a couple of cabs for two BMS 18N850V2 and would like to give this design a go if the driver is suitable.

Unfortunately i dont have much experience with horn design and driver matching - should i model the BMS driver in this design with hornsresp?

Any input appreciated,

I've made two models with similar bracing in the past. The difference to the picture is that the braces do no touch each other but some spacing inbetween was left, in order to get the driver out.I have also added 2 experimental braces to the horn mouth. These are positioned in a V shape from the centre of the base. The driver can still be removed! The bracing I will test wil be quite minimal but hopefully will be engineered to do enough to kill the major resonances in the cab without over engineering.

My initial impression is that it doesn't work as well as doubling the bottom panel. The panels are over the entire depth of the cabinet.

Best regards Johan

The BMS 18N850-V2 works in Xoc1's TH18.Unfortunately i dont have much experience with horn design and driver matching - should i model the BMS driver in this design with hornsresp?

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)