Hi Djim,

Just to make sure I got it right with your suggestions on cone correction.

1. The first suggestion (post 1611) is for strong drivers only, and the second (post 1612) is a more versatile version for both strong and week drivers?

2. CRESCENDO is using two layers of wood plus the cutout from the baffle. So that is too much in your opinion?

3. What influence will the different types of cone correction and the volume of the cone corretion have in your opinion?

- I read that it can result in higher output in the low end of the pass band?

- And it can reduce excursion?

4. I have not yet done any measurements, but it seems that the most excursion is in the 50-60 HZ region?

Thanks again,

Just to make sure I got it right with your suggestions on cone correction.

1. The first suggestion (post 1611) is for strong drivers only, and the second (post 1612) is a more versatile version for both strong and week drivers?

2. CRESCENDO is using two layers of wood plus the cutout from the baffle. So that is too much in your opinion?

3. What influence will the different types of cone correction and the volume of the cone corretion have in your opinion?

- I read that it can result in higher output in the low end of the pass band?

- And it can reduce excursion?

4. I have not yet done any measurements, but it seems that the most excursion is in the 50-60 HZ region?

Thanks again,

Hi Andy1967,

1.) The difference isn’t big between the two, but for 'weaker' drivers I would recommend the smaller version from post#1612. Another advantage is that this 'smaller' version allows more building deviation.

2.) CRESCENDO used the 'trail & error' method to find his 'ideal' setting for his 18NW100’s. The examples I post here on diy are usually somewhat smaller so they work with a wider range of drivers. I expect the 18SW100 can handle an even higher compression ratio, something that looks like the design in NEO Dan’s post#1587.

3 & 4) The excursion maximum/minimum usually doesn’t shift much (if any) in frequency. The excursion 'height' is also similar at low level signals. If you increase the compression ratio considerably, things can change of course.

The problem is that predictions (something that looks like low level signals) are limited. Models don’t suffer from losses or drivers that change in BL and suspension (force) curves that you can find in Klippel measurements. At this point one gains most from cone corrections. Nevertheless, there is also a small improvement at low signals which can be modelled.

If you want the best results it needs time and experimentation until you find the best solution for your specific driver.

1.) The difference isn’t big between the two, but for 'weaker' drivers I would recommend the smaller version from post#1612. Another advantage is that this 'smaller' version allows more building deviation.

2.) CRESCENDO used the 'trail & error' method to find his 'ideal' setting for his 18NW100’s. The examples I post here on diy are usually somewhat smaller so they work with a wider range of drivers. I expect the 18SW100 can handle an even higher compression ratio, something that looks like the design in NEO Dan’s post#1587.

3 & 4) The excursion maximum/minimum usually doesn’t shift much (if any) in frequency. The excursion 'height' is also similar at low level signals. If you increase the compression ratio considerably, things can change of course.

The problem is that predictions (something that looks like low level signals) are limited. Models don’t suffer from losses or drivers that change in BL and suspension (force) curves that you can find in Klippel measurements. At this point one gains most from cone corrections. Nevertheless, there is also a small improvement at low signals which can be modelled.

If you want the best results it needs time and experimentation until you find the best solution for your specific driver.

I'm catching up from p.161, so before I forget when I get to the current post:

Correction: They are identical, since I am also using the 18SW100

The above photo was before they were glued in place. Before those were glued in place, the baffle cut-out was first centered (the edge had to be cut flat to prevent hang-over at the first turn into the horn/tap) and glued, then the above (pictured) pieces (the wider piece totaling 6.75-7", the smaller totaling 2.5") glued on top of the baffle cut out (not shown in above pic).

The above piece that has an angled cut was just from a leftover piece from the cabinet build. The width measurement was taken from the centerline of the wood. It only seemed natural to mount it with the angle "going with the flow"

I've attached Djim's suggestion back when I was in the construction process:

In practice, cone correction in 18” loaded TH’s only need two 18mm sheet-strips. Crescendo’s cone correction is a good example of that method.

The cone-volume of your B&C 18SW100 is almost identical to Crescendo’s 18NW100’s, so you can use his work as guideline.

Correction: They are identical, since I am also using the 18SW100

Hi Djim, with the cone correction, simple enough solution, however what are the dimensions of each 18mm piece used in the photo? Am I correct to assume an angle on one piece? (looking at the photo)

Regards

The above photo was before they were glued in place. Before those were glued in place, the baffle cut-out was first centered (the edge had to be cut flat to prevent hang-over at the first turn into the horn/tap) and glued, then the above (pictured) pieces (the wider piece totaling 6.75-7", the smaller totaling 2.5") glued on top of the baffle cut out (not shown in above pic).

The above piece that has an angled cut was just from a leftover piece from the cabinet build. The width measurement was taken from the centerline of the wood. It only seemed natural to mount it with the angle "going with the flow"

I've attached Djim's suggestion back when I was in the construction process:

Attachments

Last edited:

Just curious, as I am still thinking about doing Xoc1's version where the correction is built in with a slightly longer path length, but why do these horn corrections always have a rectangular shape as opposed to the circulr shape of the cone. Wouldnt the edges of the cone still have more pressure and possibly be the weak point?

Just seems like the cone correction being rectangular is only correcting from a 2d area instead of it being 3d as in circular. I dont know the science behind it so I am only asking. I plan on building my pair of TH18's in about a month. Still trying to learn all I can before saw dust.

Just seems like the cone correction being rectangular is only correcting from a 2d area instead of it being 3d as in circular. I dont know the science behind it so I am only asking. I plan on building my pair of TH18's in about a month. Still trying to learn all I can before saw dust.

Correction: They are identical, since I am also using the 18SW100

Oops, and I now remember that it wasn't the first time... Sorry Justin

Oops, and I now remember that it wasn't the first time... Sorry Justin

Hi chrapladm,....why do these horn corrections always have a rectangular shape as opposed to the circulr shape of the cone. Wouldnt the edges of the cone still have more pressure and possibly be the weak point?

Just seems like the cone correction being rectangular is only correcting from a 2d area instead of it being 3d as in circular....

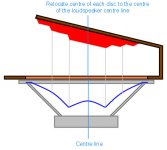

The pressure is everywhere equal at that point in the 'horn'. Therefore shapes do not matter as long they don't become obstructive. Even sideway corrections work.

Last edited:

Hi CRESCENDO,

So the final cone correction for your 18SW100 was as you kindly shared in post 1144?

And then I can use Djim suggestion for the week drivers post#1612 in my second pair with 18PS100 temporarily until I get my second pair of 18SW100?

CRESCENDO, can I ask in what configuration you are using your TH18? Crossover settings, Max input and such? And what you are using them for?

Thanks a lot,

Andy

The above photo was before they were glued in place. Before those were glued in place, the baffle cut-out was first centered (the edge had to be cut flat to prevent hang-over at the first turn into the horn/tap) and glued, then the above (pictured) pieces (the wider piece totaling 6.75-7", the smaller totaling 2.5") glued on top of the baffle cut out (not shown in above pic).

So the final cone correction for your 18SW100 was as you kindly shared in post 1144?

And then I can use Djim suggestion for the week drivers post#1612 in my second pair with 18PS100 temporarily until I get my second pair of 18SW100?

CRESCENDO, can I ask in what configuration you are using your TH18? Crossover settings, Max input and such? And what you are using them for?

Thanks a lot,

Andy

Last edited:

MMD or MMS as a stiffness indicator is also dependent on Xmax, drivers with less Xmax don't require as much MMS since less pressure is encountered with less excursion.MMD is usually a good indicator. obviously this is highly dependant on the diameter of the cone (larger diameter is more material, means more mmd), so you should only compare mmd of similar diameter drivers.

Horn loading subjects the cone to more stress for a given excursion than porting, so drivers used in horn loaded applications need more MMS to keep cone flex (and distortion) from being a problem.

Art

MMS makes sense. I was confused by the MMD comment. The 2400 has a MMS of about 190. So

18 Sound LW2400 Mms 192

18 Sound NLW9601 Mms 270

18 Sound NLW9000 Mms 218

BC TBX100 Mms 209

BC TBW100 Mms 245

BC SW115 Mms 275

Seems like the 2400 is the weakest cone. Although it has the least excursion but not by much less than the 100. 115, 9000 and 9601 have the same excursion capabilities though. Considering all these are safe in the TH18 are we just saying the 270g class can just take more punishment compared to a woofer that has the same abilities but lighter cone?

18 Sound LW2400 Mms 192

18 Sound NLW9601 Mms 270

18 Sound NLW9000 Mms 218

BC TBX100 Mms 209

BC TBW100 Mms 245

BC SW115 Mms 275

Seems like the 2400 is the weakest cone. Although it has the least excursion but not by much less than the 100. 115, 9000 and 9601 have the same excursion capabilities though. Considering all these are safe in the TH18 are we just saying the 270g class can just take more punishment compared to a woofer that has the same abilities but lighter cone?

Hi Andy1967,So the final cone correction for your 18SW100 was as you kindly shared in post 1144?

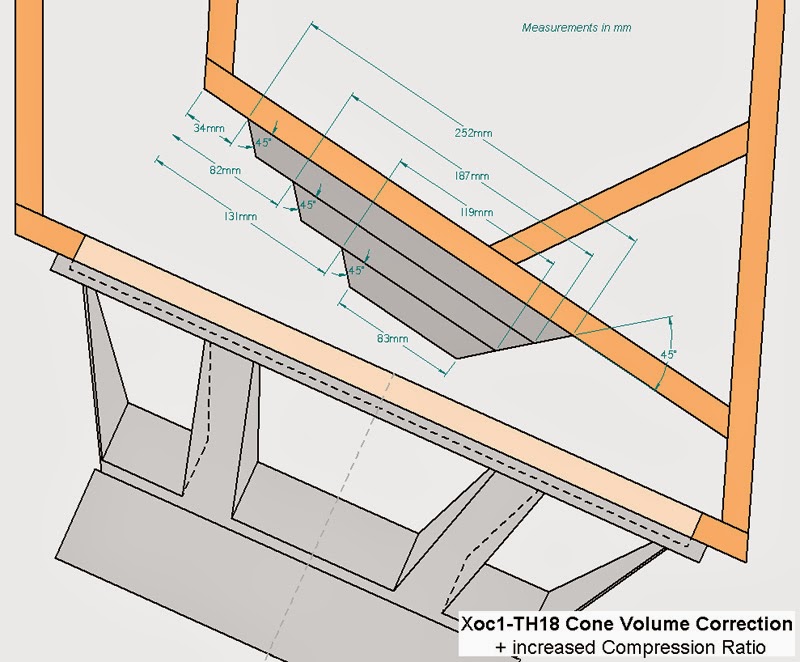

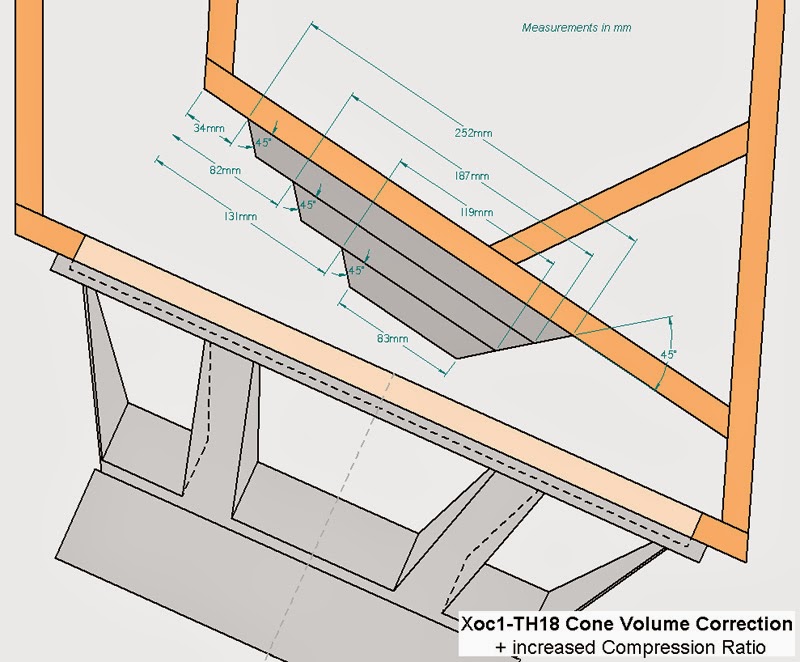

This one is cone correction + an increase of the compression ratio similar (but optimised this time and no longer uses round disks but sheet strips) to what I recommended for CRESCENDO's 18SW100.

Last edited:

What determines a weak cone?

I will be using the 18 Sound LW2400 in mine.

fyi

the 18sound 18lw2400 are used a few times in the xoc1 cab,with good results.

dont know wich post's .there was even a youtube clip somewhere here.

recently had a few in my hands and they are resonably strong cones.

Wow huge help. ThanksHi Andy1967,

This one is cone correction + an increase of the compression ratio similar (but optimised this time and no longer uses round disks but sheet strips) to what I recommended for CRESCENDO's 18SW100.

Thanks for this also. I know they have been used and wasnt really stressing using it. I am trying to decide if I want to spend the extra money for the 9000 right now anyways. Although I am thinking I will stick with the 2400.fyi

the 18sound 18lw2400 are used a few times in the xoc1 cab,with good results.

dont know wich post's .there was even a youtube clip somewhere here.

recently had a few in my hands and they are resonably strong cones.

Quote:

Originally Posted by Andy1967

So the final cone correction for your 18SW100 was as you kindly shared in post 1144?

Hi Andy1967,

This one is cone correction + an increase of the compression ratio similar (but optimised this time and no longer uses round disks but sheet strips) to what I recommended for CRESCENDO's 18SW100.

Hi Djim,

Thanks a lot for your suggestion for cone correction in Post 1633.

I was hoping for something like this, that seems to work both as part of the throat(?), and also aims for the right compression.

The nice thing about CRESCENDOs solution is that he has documentation that he has more output with his correction. Your correction might even add something on top of that, like cone control?

I am still aiming to do some type of excursion testing when i get my SPL meter and when it gets a bit warmer outside here in Denmark

Thanks again

/ Andy

Hi Andy 1967,and also aims for the right compression.

....and when it gets a bit warmer outside here in Denmark

YW

What is "the right compression"?

That kind of weather will arrive soon...

Last edited:

Hi Andy 1967,

YW

What is "the right compression"?

That kind of weather will arrive soon...

Hi Djim,

Good question, but I am hoping that the right compression will have impact on the output and cone control. Except from bracing the mouth I recon this type of adjustment is all we are left with when the cab is glued

We are still below zero Celsius at night and short of a SPL meter

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)