Hi rpowell,

I have heard a rumor that a new design will be put up,but no you haven't missed it ,This cab I built I did with some help from everyone here's Ideas ,I am learning hornresp ,I used a protractor and made the curves,each turn gets about 10% bigger,I used 400mm lenght for the part#10 ,If someone would like to run it in hornresp I would like to see how close it is,

It got to Play music tonight but the cone is stiff ,but it sounded good ,I am new to rew but what I did run looked reasonably flat and no big bumps or dips,I was happy with it ,bass filled the room EZ,I have 2 more stiffeners and the broom stick to put in tomorrow,

Regards

NS

I have heard a rumor that a new design will be put up,but no you haven't missed it ,This cab I built I did with some help from everyone here's Ideas ,I am learning hornresp ,I used a protractor and made the curves,each turn gets about 10% bigger,I used 400mm lenght for the part#10 ,If someone would like to run it in hornresp I would like to see how close it is,

It got to Play music tonight but the cone is stiff ,but it sounded good ,I am new to rew but what I did run looked reasonably flat and no big bumps or dips,I was happy with it ,bass filled the room EZ,I have 2 more stiffeners and the broom stick to put in tomorrow,

Regards

NS

Last edited:

Hi CRESCENDO,

I think that is correct,I didn't do these in hornresp,Trail and error,Djim helped me along with those he might be able to give some more exact figures on hows and whys,

The first one is breaking in and starts coming on at 20HZ or so,The second one is not broke in and starts about 40 hz but I think that will change as it loosens up some ,

I was wondering if you would post what you did for horn correction,I would like to see! I hope to make some measurements with REW tomorrow ,I don't have any plans but to run them,,,I hope ,lol.

Regards,

NS

I think that is correct,I didn't do these in hornresp,Trail and error,Djim helped me along with those he might be able to give some more exact figures on hows and whys,

The first one is breaking in and starts coming on at 20HZ or so,The second one is not broke in and starts about 40 hz but I think that will change as it loosens up some ,

I was wondering if you would post what you did for horn correction,I would like to see! I hope to make some measurements with REW tomorrow ,I don't have any plans but to run them,,,I hope ,lol.

Regards,

NS

Last edited:

I was wondering if you would post what you did for horn correction

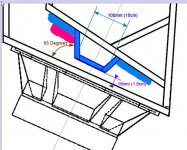

I took the baffle cut-out, a 3/4" piece 6.75" wide on top of it and a 3/4" piece 2.5" wide on top of that, glued & screwed to the opposing wall centered over the driver.

Attachments

Hi guys,Djim helped me along with those he might be able to give some more exact figures on hows and whys

How can I give "more exact figures" when I don't have any dimensions

Hi,

I will get the deminions to him,

CRENSENDO looks like what I did too but I did cut another a smaller piece for the left side or the out side and that did the trick,I had also put 2 layers 1 was 80% of the cut out and the top layer was about 60% ,I put both layers in and I think it choked it off,Volume was low and bass wasn't there,immediate effect.lol. so took out one top piece from the small side of the throat,and it was on then sound and bass returned, I'll have to look for the pic I think I have one of it.

Regards

NS

I will get the deminions to him,

CRENSENDO looks like what I did too but I did cut another a smaller piece for the left side or the out side and that did the trick,I had also put 2 layers 1 was 80% of the cut out and the top layer was about 60% ,I put both layers in and I think it choked it off,Volume was low and bass wasn't there,immediate effect.lol. so took out one top piece from the small side of the throat,and it was on then sound and bass returned, I'll have to look for the pic I think I have one of it.

Regards

NS

Hi,

If anyone would like to help me out with a sim or hornresp here is what I change all the other measurements are the same,THANKS in advance,any help I can offer just ask!

Thanks alot,

NS

If anyone would like to help me out with a sim or hornresp here is what I change all the other measurements are the same,THANKS in advance,any help I can offer just ask!

Thanks alot,

NS

Attachments

Hi All

Just trying to keep up with developments. Good to see all the effort that people are putting in to developing this design.

Crescendo - Both mk 1 and Mk2 speakers were eventually simmed with a 2.5:1S2 compression ratio. The difference being that the Mk1 does not take into account the volume of the cone while the mk 2 does. in practical terms this means the mk2 has a higher compression ratio.

I see you have modded your Mk1 speakers throat with a coule of layers of 18mm timber

Did you ever manage any measurements?

What would you say was the subjective result of the throat mods?

No Smoking . Really good to see your build pics Are you saying you have a Mk1 speaker which you have now added a fairly radical throat mod which is now giving you improved results, and a second cab which is a Mk2 style cab which is still pending measurement?

Rpowell - I have not posted any detailled drawings of a Mk2 cab yet. I have not had the time to get on with it recently.

Also I am not confident yet that we have really nailed which is the best way to impliment the throat changes. it really does take the time and effort of people like Nosmoking and Crescendo who are prepared to put their resources into building and testing these cabs to push this design forward.

Regards

Xoc1

Just trying to keep up with developments. Good to see all the effort that people are putting in to developing this design.

Crescendo - Both mk 1 and Mk2 speakers were eventually simmed with a 2.5:1S2 compression ratio. The difference being that the Mk1 does not take into account the volume of the cone while the mk 2 does. in practical terms this means the mk2 has a higher compression ratio.

I see you have modded your Mk1 speakers throat with a coule of layers of 18mm timber

Did you ever manage any measurements?

What would you say was the subjective result of the throat mods?

No Smoking . Really good to see your build pics Are you saying you have a Mk1 speaker which you have now added a fairly radical throat mod which is now giving you improved results, and a second cab which is a Mk2 style cab which is still pending measurement?

Rpowell - I have not posted any detailled drawings of a Mk2 cab yet. I have not had the time to get on with it recently.

Also I am not confident yet that we have really nailed which is the best way to impliment the throat changes. it really does take the time and effort of people like Nosmoking and Crescendo who are prepared to put their resources into building and testing these cabs to push this design forward.

Regards

Xoc1

Hi Xoc1,

I do need some help and I realize time is precious to all of us,Now I built the 1st box acording to #6 thread plans is this a mk1? I also built a second box I call it #2 it has cone correction incoporated in the folds,did this with a big protractor and followed the flow of the folds,My question is could I get you to model it and tell me where I'm at at S1 as far as I know right now both sides are equal ,I would think S1 needs to be smaller but I am not a cad or hornresp designer,I'm learning but neither are quick learning curves ,lol. I wished, but alot of varibles,so any suggestion,I am listening,I have the first box running good with the additions to the stubs with rings ,pics in the earlier threads,

I hope you are recovering well,I would have asked you earlier but I know first hand about recoveries and didn't want to burden you ! Glad you're Better!Email if you like!

Regards,

NS

I do need some help and I realize time is precious to all of us,Now I built the 1st box acording to #6 thread plans is this a mk1? I also built a second box I call it #2 it has cone correction incoporated in the folds,did this with a big protractor and followed the flow of the folds,My question is could I get you to model it and tell me where I'm at at S1 as far as I know right now both sides are equal ,I would think S1 needs to be smaller but I am not a cad or hornresp designer,I'm learning but neither are quick learning curves ,lol. I wished, but alot of varibles,so any suggestion,I am listening,I have the first box running good with the additions to the stubs with rings ,pics in the earlier threads,

I hope you are recovering well,I would have asked you earlier but I know first hand about recoveries and didn't want to burden you ! Glad you're Better!Email if you like!

Regards,

NS

.

I see you have modded your Mk1 speakers throat with a coule of layers of 18mm timber

Did you ever manage any measurements?

What would you say was the subjective result of the throat mods?

POST #744

These measurements were taken as the amplifier just illuminated the limit light, which is WELL under the rated output power. My voltmeter does not climb quickly enough with 'Rec' engaged and caused it to go "Over" many times, so exact voltage values are unknown for that night of testing. I just used this info for comparison sake and hope to figure out my REW issue soon.

I only played/measured test tones without and with cone correction.

It appears the difference from 35Hz to 45Hz bettered (response dipped less) by 0.5dB with correction. As 45-50Hz did by 0.2dB and the 0.7dB dip @ 75Hz disappeared with correction as well.

So, we see response drops off a (small) bit more gradually while also 'fixing' very slight response issues with cone correction (I used roughly HALF of the 18SW100's cone volume for this test). For a few pieces of extra/spare timber? I'll take it!

Unless you are in an open field the meter and sine waves method is not accurate.

It would be great to get an anechoic measurement.

So what is the plan of action to get that done?

Looking back at the post, you mention it was over grass. But how far away are the closest objects that can be sources of reflection? Anything bigger than a phone booth?

Does the MBP have two 1/8" audio jacks? The newer ones have only one

It would be great to get an anechoic measurement.

So what is the plan of action to get that done?

Looking back at the post, you mention it was over grass. But how far away are the closest objects that can be sources of reflection? Anything bigger than a phone booth?

Does the MBP have two 1/8" audio jacks? The newer ones have only one

Unless you are in an open field the meter and sine waves method is not accurate.

It would be great to get an anechoic measurement.

So what is the plan of action to get that done?

Looking back at the post, you mention it was over grass. But how far away are the closest objects that can be sources of reflection? Anything bigger than a phone booth?

I've attached an image of the same testing configuration I used for SS15 measuring.

But, again, this was for comparison sake - cone correction vs without. Not highest-most-accurate-super-scientific-ness

Does the MBP have two 1/8" audio jacks? The newer ones have only one

It has 1/8" headphone out and 1/8" mic in.

Attachments

nice movie.

nice movie.

Thanks! I think it's pretty cool... I made it in part because you can give a video link to the Massachusetts Institute of Technology, which is my top choice college that I'm applying to.

I tested the 3 of these that I have done a tiny bit today. I maxed out my SPL meter at 130 dB

I was hitting 100 dB peaks from approx 200 ft. I did the testing at lunch, and people all over the school heard it. Turns out when you hit 130dB at lunch you draw a crowd, and people tend to notice who you are haha

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)