Remember your own words 🙂 :

Now I am pretty sure that the point of this design was for 4 cabinets to be Flat to 35hz.....

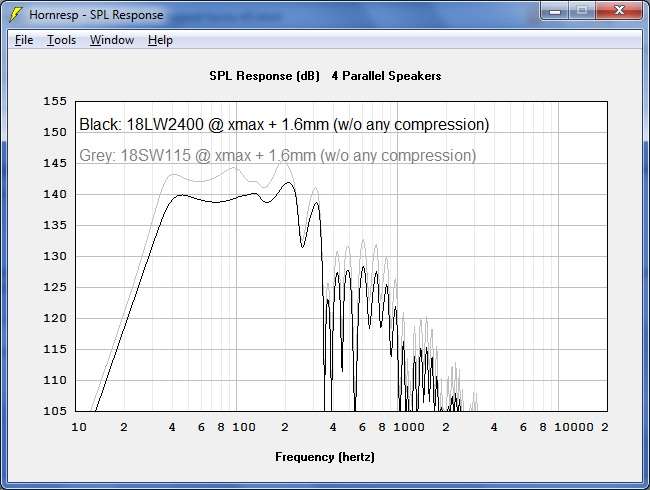

Here is a sim for 4 cabs at xmax + with the 18 sound 2400 drivers...

I am doing it because I do want that extra 10hz that the ss15 doesn't have.

Last edited:

Hi Djim,

Thanks for this - looks like i will have to try a pair of these..

Presume if these are run in close pairs this should improve the response below 40hz? Excuse the basic questions but how well do tapped horns take to eq being applied to extend response a little - do they unload the driver below tuning and x max will be the problem?

Thanks again,

Luke

Thanks for this - looks like i will have to try a pair of these..

Presume if these are run in close pairs this should improve the response below 40hz? Excuse the basic questions but how well do tapped horns take to eq being applied to extend response a little - do they unload the driver below tuning and x max will be the problem?

Thanks again,

Luke

Hi Luke,Hi Djim,

Thanks for this - looks like i will have to try a pair of these..

Presume if these are run in close pairs this should improve the response below 40hz? Excuse the basic questions but how well do tapped horns take to eq being applied to extend response a little - do they unload the driver below tuning and x max will be the problem?

Thanks again, Luke

I'll try to explain as good as I can. Stacking multiple Tapped Horns will not lower the resonance of the design as HornResp predicts. But in this case the design limit (1/3 wavelength) is set out on 38Hz. So the response in stacks will get a boost at all frequencies above 38Hz but the 'knee' (point were the response drops) will never go below 38Hz in reality like some predictions suggest. So, there is no need to worry about Xmax. However, you will need a low-cut filter (same as high-pass) to prevent extreme excursion. The settings for this low-cut filter haven't been modelled yet.

Sorry luke, forgot to mention that EQ-ing doesn't make your amp grow bigger. I mean if you use a power amplifier that is able to produce 1500W you can boost whatever you like because the amp will never produce more than 1500Watts. Therefore in combination with the right settings for the low-cut filter the excursion will never get above safety levels.how well do tapped horns take to eq being applied to extend response a little - do they unload the driver below tuning and x max will be the problem?

The Xoc1 TH18 is compatible with many 15" drivers as well. The disadvantage of using 15's is a slightly higher group delay. The BMS 15N840 (old model) seems to model well in a Xoc1 TH18. Of course you will need some eq (and low-cut filtering)

Thanks for the info Djim, it all makes sense.

Looking fwd to creating some saw dust.. Will go for routed rebate contruction and brace as suggested.

Looking fwd to creating some saw dust.. Will go for routed rebate contruction and brace as suggested.

Hi Xoc1,

Just would like to say that I appreciate your efforts very much, and hope that you can provide more insights into box behaviour as in the Ansys pictures in Post #6/11. It looks like the bottom board was used as reference in the FEA simulation, and it would be interesting to see what it looks like turned (referenced) upside down, so that the whole mouth perimeter would be able to flex.

Anyway, great work, thanks.

Regards,

Just would like to say that I appreciate your efforts very much, and hope that you can provide more insights into box behaviour as in the Ansys pictures in Post #6/11. It looks like the bottom board was used as reference in the FEA simulation, and it would be interesting to see what it looks like turned (referenced) upside down, so that the whole mouth perimeter would be able to flex.

Anyway, great work, thanks.

Regards,

Hi Xoc1,....

it would be interesting to see what it looks like turned (referenced) upside down, so that the whole mouth perimeter would be able to flex. Anyway, great work, thanks.

Regards,

Hi there: If I remember correctly, JBELL uses his live sound TH's on their sides, in pairs mouth to mouth. (For the Xoc1, this orientation would place the 535 dimension vertical) ...regards, Michael

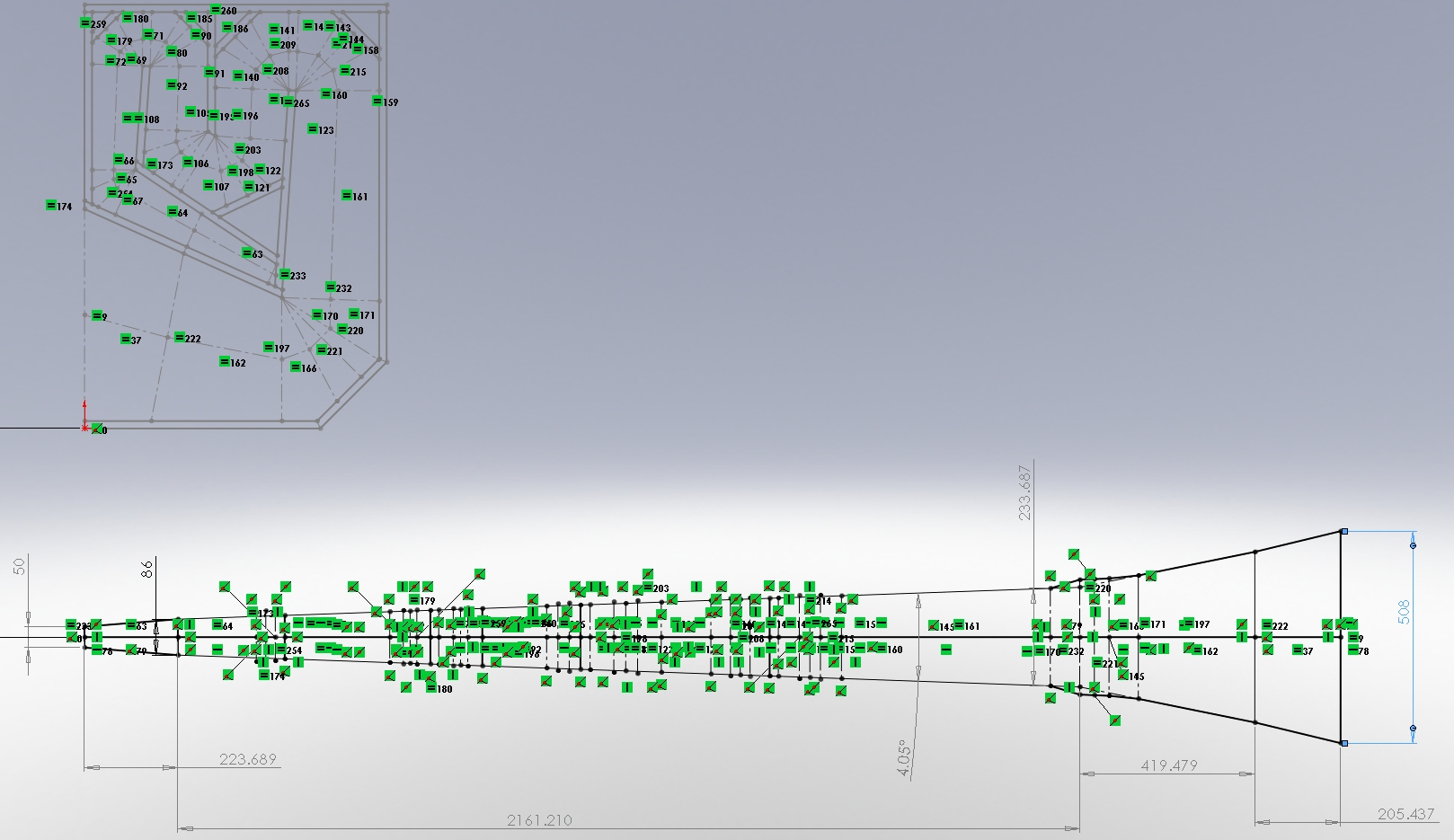

...the exit mouth internal dimension is 508 not 526. (Adjust S4 from 2814.1 to 2717.8)

Fortunately the effect on the sim is very minimal.

Could you post the current value for S4? I'm trying to follow along 🙂

Attachments

Could you post the current value for S4? I'm trying to follow along :)[/QUOTE]

Apologies s4 should read s5:o Adjust [B]S5[/B] from 2814.1 to 2717.8

s4 is 409 x 5.35 = 2188.5 sq cm

Use the dimensions in the PDF in post 6 to get the hornresp sizes

Multiply the heights by 5.35 to go from mm to sq cm..

Regards

Martin

would a peavey lowrider or one of the eminence 18" drivers work in this cabinet. i was getting ready to cut 2 of jbell's SS15, but i saw this thread. i am just looking for a cabinet to use for live band application only. so i will never need anything below say 45hz.

Things are not quite lining up, am I missing something?

You are using the dimensions from my sketch screengrab showing the parametric sketch relations. Thats OK apart from S3 which does not line up with the dimension shown in the screengrab S3 is 238.67 mm not 233.7

So s3 is about 1277 sq cm.

Some drivers sim lower and others sim flatter - But the actual response is still unknown untill cabs get built.😉

Great responses from everyone!😀

To surmise.

The horn mouth would benefit from having a removable steel grille – Preferably with a metal frame. (Cross braced?????) Many metal grilles have percentage open area below 50% so the material should be chosen with care. Maybe maximum performance might be a reinforcing steel frame with no grille!

The bracing should be more or less like Djims sketch. But a decision needs to be made on the thickness of the bracing to make sure that the performance of the horn is not degraded too much.

A pair of speakers can be made from 5 sheets of 5’x 5’ birch ply.

The base panel of the speaker could possibly benefit from doubling to increase its stiffness.There is enough spare material within a 5 sheet cut pair to cut a second pair of bases, as long as the bracing is not cut from the birch ply. The doubling panel could be external to the given cabinet dimensions.

To surmise.

The horn mouth would benefit from having a removable steel grille – Preferably with a metal frame. (Cross braced?????) Many metal grilles have percentage open area below 50% so the material should be chosen with care. Maybe maximum performance might be a reinforcing steel frame with no grille!

The bracing should be more or less like Djims sketch. But a decision needs to be made on the thickness of the bracing to make sure that the performance of the horn is not degraded too much.

A pair of speakers can be made from 5 sheets of 5’x 5’ birch ply.

The base panel of the speaker could possibly benefit from doubling to increase its stiffness.There is enough spare material within a 5 sheet cut pair to cut a second pair of bases, as long as the bracing is not cut from the birch ply. The doubling panel could be external to the given cabinet dimensions.

Only one in middle (horizontal) would be enough.Cross braced?????

In case you want an extra 'broomstick' or removable (metal) bar, place it under the magnet.

3x Bracing in the most outside corners 18mm (or same as the cabinet), everything else minimum 9mm.But a decision needs to be made on the thickness of the bracing

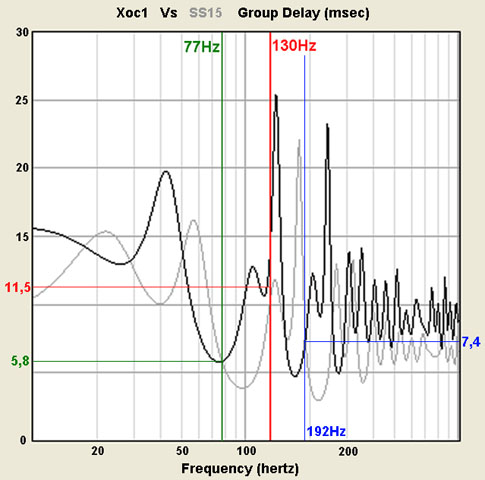

Theoretical Comparison between SS15 (3015lf) and TH18 (18LW2400)

4 x SS15 Vs 4 x TH18 (2,83V)

Group Delay

In case you want to use SS15's and TH18's in the same time, crossover suggestions:

Xover @ 77Hz (top delay time alignment = 5,8mS)

Xover @ 192Hz (top delay time alignment = 7,4mS)

Also possible but not exact:

Xover @ 130Hz (top delay time alignment = 11,5mS)

4 x SS15 Vs 4 x TH18 (2,83V)

Group Delay

In case you want to use SS15's and TH18's in the same time, crossover suggestions:

Xover @ 77Hz (top delay time alignment = 5,8mS)

Xover @ 192Hz (top delay time alignment = 7,4mS)

Also possible but not exact:

Xover @ 130Hz (top delay time alignment = 11,5mS)

Last edited:

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)