Hi Art,

Post #1079: "...it will be good to smell sawdust and be a wood butcher again!"

Easy on the woodworking, get lifting help. My stepson didn't adhere to the advice he got, and the result is not pretty, and this time it's permanent. Follow the recommendations by the letter, take it easy!

Get well soon!.

Regards,

Post #1079: "...it will be good to smell sawdust and be a wood butcher again!"

Easy on the woodworking, get lifting help. My stepson didn't adhere to the advice he got, and the result is not pretty, and this time it's permanent. Follow the recommendations by the letter, take it easy!

Get well soon!.

Regards,

Attachments

Wow Art...Best wishes on a fast recovery. Should be fun going through airport scanners now. Any upgrades while they were in there? Maybe a bit of overclocking and a few extra gigs of ram? [emoji14]

Radelescu,

You have 2 18sw115 based TH's in an apartment?! LOL.

Josh,Wow Art...Best wishes on a fast recovery. Should be fun going through airport scanners now. Any upgrades while they were in there? Maybe a bit of overclocking and a few extra gigs of ram?

When my brain was pushed almost 30mm left of center it may have increased my comprehension of the metric system ;^). I do actually feel generally more aware than prior to the beating. Eating like crazy though, healing takes calories, I'm back to my hang gliding "flying weight" of under 64.5 kilos fully clothed.

Other than the scratched cornea (done in the operating room...) don't seem to have any problems I didn't have before, other than even a small hit to the head seems to hurt.

Cheers,

Art

Josh,

When my brain was pushed almost 30mm left of center it may have increased my comprehension of the metric system ;^). I do actually feel generally more aware than prior to the beating. Eating like crazy though, healing takes calories, I'm back to my hang gliding "flying weight" of under 64.5 kilos fully clothed.

Other than the scratched cornea (done in the operating room...) don't seem to have any problems I didn't have before, other than even a small hit to the head seems to hurt.

Cheers,

Art

I bet food tastes a bit better now...I may have missed it but what happened? Car wreck?

Jeremy,Just saw this. I hope the cops get whomever beat on you. That's awful. I'm glad to see you're alright.

I hope to buy some plans from you for the keystone in the near future.

I wish you the best for a full recovery.

The location of the free plans for the Keystone are still listed on page one of this thread.

I may charge a small fee for the Keystone "B-Low" plans to go towards my $10,000.00 deductible medical insurance costs, which unfortunately are only a small fraction of the total costs.

The Sheriff's department has told me that since I was "intoxicated" and did not press charges against the felon, Anthony Hill (mug shot below) that night, I can't now. Anthony had told the deputies that his "elderly neighbor was drunk and fell and hit his head, and I helped him off the road".

He didn't mention the part about the hit to my left temple and second hit to the jaw, and then kicking me under my jaw and in the left gut while I was unconscious, laying on Montgomery Avenue.

And no word of any of the items that David Myers and his stepson stole from me while I was in the hospital.

But on the upside, I always wanted some titanium jewelry, and now have some permanently mounted in my cranium, one piece looks like a snowflake, but unlike real snowflakes, this one is probably not unique ;^).

Cheers,

Art (fell of the turnip truck on my head in DeLand of plenty of felons) Welter

P.S.-Anthony Hill now sports tattoos on his neck and head, and his lower four front teeth are one piece of gold.

David Myers and son were still doing their confidence scams on Super Bowl Sunday, when they tried to sell a "church group" scented candle to a friend a few blocks from my house- needless to say, the $12 I spent for my candle has not resulted in any light or scent other than that of bull crap.

But "that's the way the cookie crumbles", can't help bad luck ;^).

Attachments

Last edited:

What I was meaning was that in my view, you have created something and spent the time to make it right.

I would feel crappy snatching the plans just to build it without having acknowledged your effort.

When I finally decide to build, I will pm you for an address I can send a cheque to. I don't use paypal or credit cards.

Thank you for your excellent contribution to the diy field.

Ps: I would be proud to be able to have a product logo imprint of yours that I could incorporate onto the boxes.(looks more official)

I would feel crappy snatching the plans just to build it without having acknowledged your effort.

When I finally decide to build, I will pm you for an address I can send a cheque to. I don't use paypal or credit cards.

Thank you for your excellent contribution to the diy field.

Ps: I would be proud to be able to have a product logo imprint of yours that I could incorporate onto the boxes.(looks more official)

Last edited:

hey all

Been reading my way through this thread with much interest over the last month or two and am planning to build myself a pair of these, hopefully over the summer.

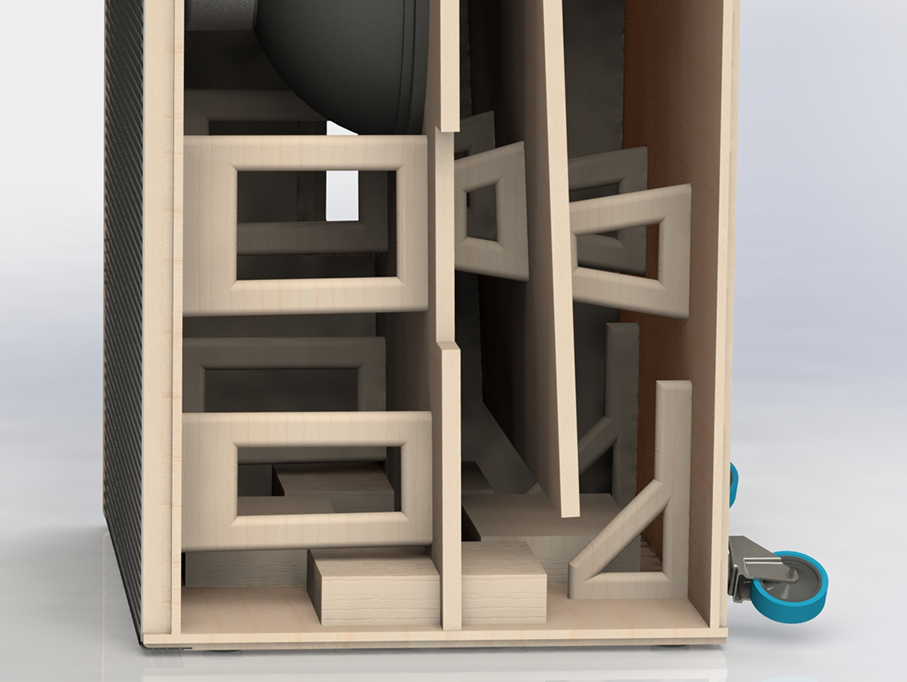

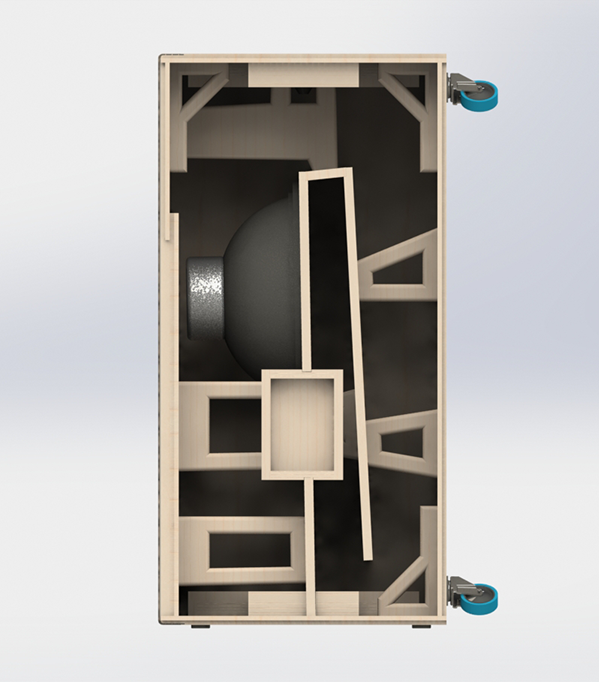

However I'm lucky enough to have a maker space near me and access to CNC machining facilities, and so have been drawing the design up in Solidworks over the last couple of days to get things ready. The advantage of the CNC machine is that I can do a fair bit of complex rebating to make the box much more secure an solid, can cut complex shapes for bracing, and can add handles to make it much easier to manage and move about.

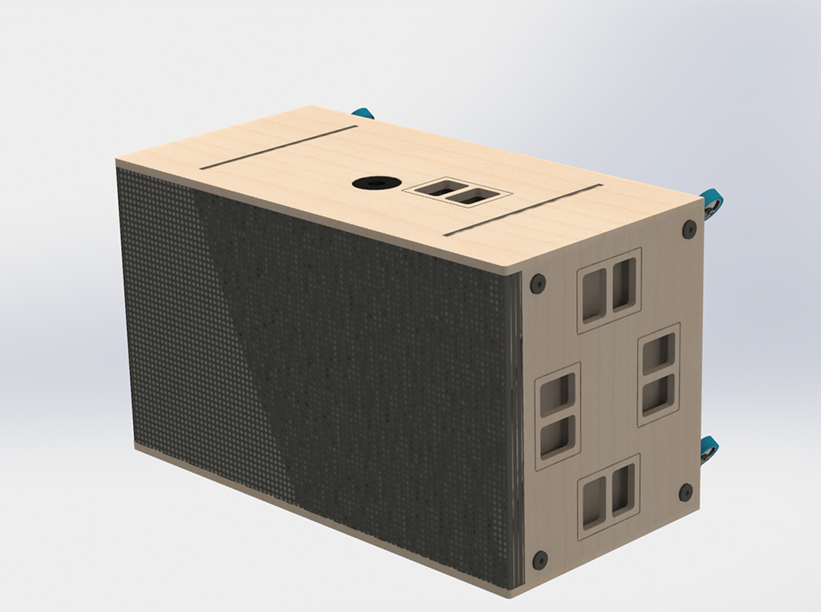

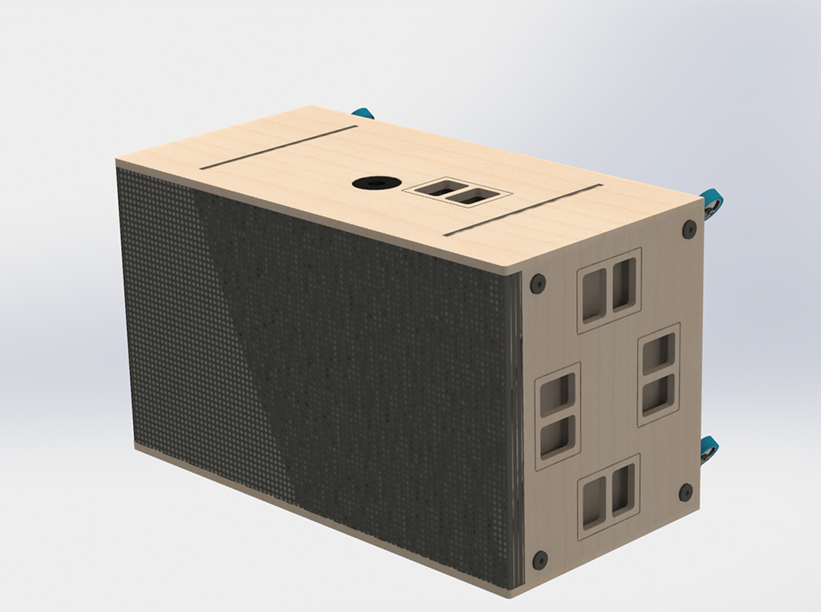

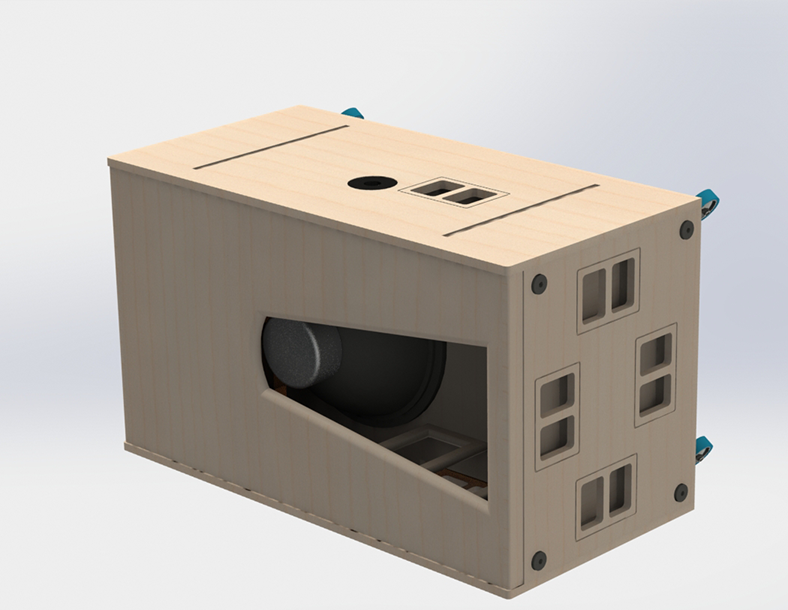

So here is what I've came up with so far......

As you can see, it has a full face grill (which I always thinks looks a bit more professional for the work I do) and has handles routed in most faces. There are two handles routed into the long faces so that when you have it stood up vertically you have some handles to lift and move it with, and in this orientation it has some rubber feet on the bottom (which you can see in other angles) and has a pole mount on the top for your top speaker.

If your planning to use a few together, it can be stacked horizontally and has plastic runners on the bottom and matching mating groves on the top to locate the cabs and lock them together.....

In that orientation it has two handles on each end to allow you to lift it up and stack it, three on top of each other would give a nice height to stack some powerful horn tops on top of for a large crowd.

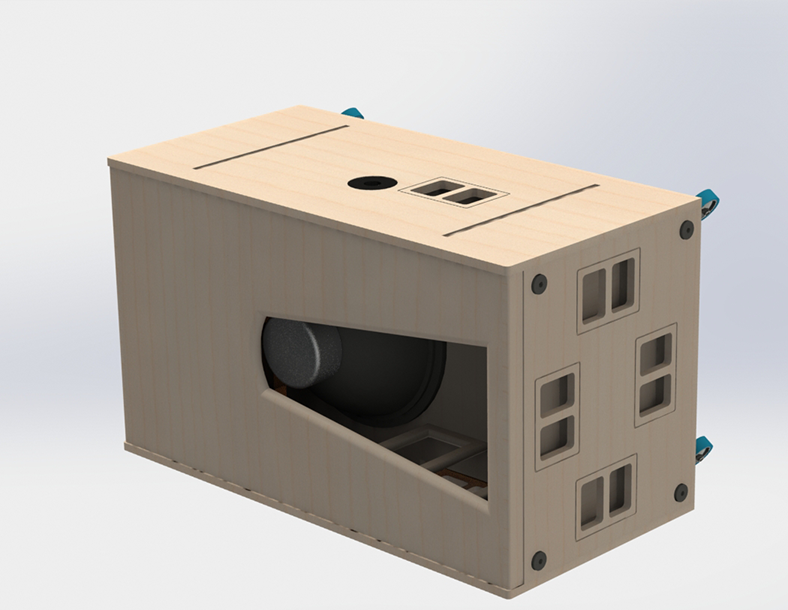

For transport it has castors on the back, and so two more handles allow it to be lifted and moved in this orientation.....

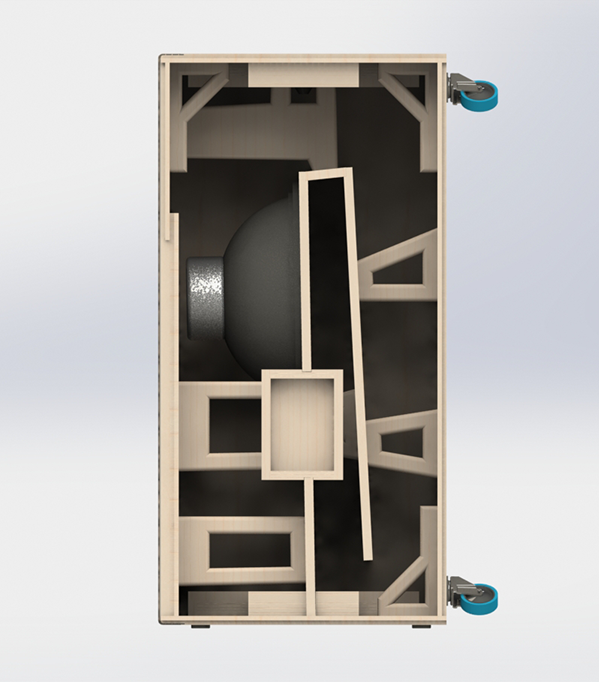

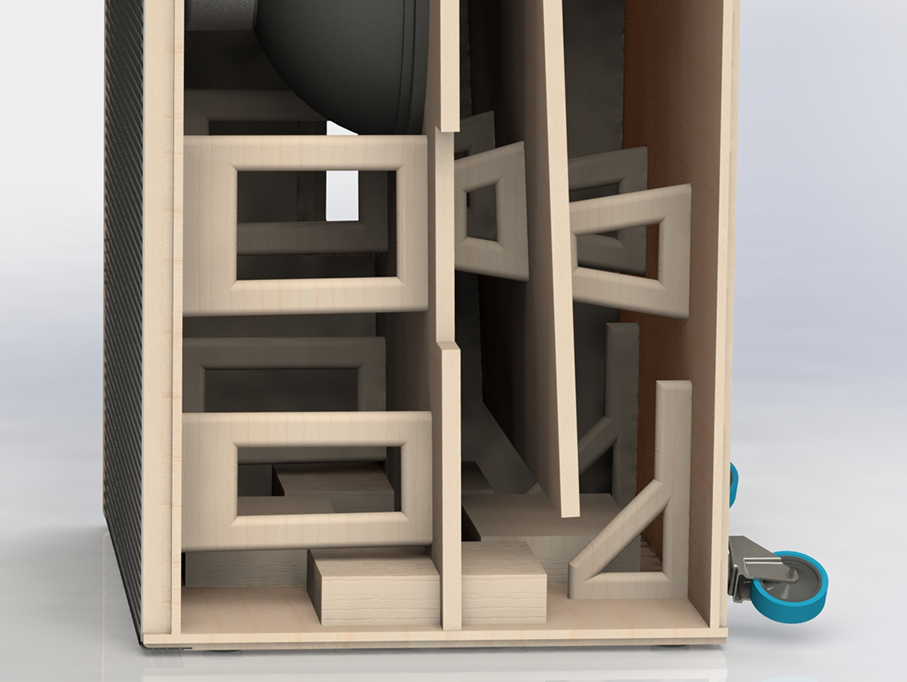

Inside it has some extensive bracing to make the cab rock solid, though that also does reveal my one concern with this design.

I originally looked at using metal Penn Elcom bar handles, but it was very hard to place them sensibly and usefully without crossing over the main pieces of wood that make up the horn path. Its almost impossible to create a proper seal around these and maintain the hornpath's air tightness.

Using handles routed into the wood, with square back boxes, eliminates this as the pieces of wood that makes up the baffle can have square notches cut out to go around these and the joins can be sealed easily. They also aid in bracing a fair bit and make those end panels pretty immovable.

However they take up a bit more room, and especially around the first horn bend I'm not sure if it'll be a little too much volume taken away and it might affect the response. A test cab will really need to be built and measured first to see, and maybe a few little modifications made to even that out again.

As I said it'll be the summer before I'm able to make any sawdust with these but in the mean time, once I have it all finished and fully drawn up I'd be happy to make these solidworks models (or 2d DXF files of all of the wooden panels) available to anyone else who has access to CNC machinery.

Been reading my way through this thread with much interest over the last month or two and am planning to build myself a pair of these, hopefully over the summer.

However I'm lucky enough to have a maker space near me and access to CNC machining facilities, and so have been drawing the design up in Solidworks over the last couple of days to get things ready. The advantage of the CNC machine is that I can do a fair bit of complex rebating to make the box much more secure an solid, can cut complex shapes for bracing, and can add handles to make it much easier to manage and move about.

So here is what I've came up with so far......

As you can see, it has a full face grill (which I always thinks looks a bit more professional for the work I do) and has handles routed in most faces. There are two handles routed into the long faces so that when you have it stood up vertically you have some handles to lift and move it with, and in this orientation it has some rubber feet on the bottom (which you can see in other angles) and has a pole mount on the top for your top speaker.

If your planning to use a few together, it can be stacked horizontally and has plastic runners on the bottom and matching mating groves on the top to locate the cabs and lock them together.....

In that orientation it has two handles on each end to allow you to lift it up and stack it, three on top of each other would give a nice height to stack some powerful horn tops on top of for a large crowd.

For transport it has castors on the back, and so two more handles allow it to be lifted and moved in this orientation.....

Inside it has some extensive bracing to make the cab rock solid, though that also does reveal my one concern with this design.

I originally looked at using metal Penn Elcom bar handles, but it was very hard to place them sensibly and usefully without crossing over the main pieces of wood that make up the horn path. Its almost impossible to create a proper seal around these and maintain the hornpath's air tightness.

Using handles routed into the wood, with square back boxes, eliminates this as the pieces of wood that makes up the baffle can have square notches cut out to go around these and the joins can be sealed easily. They also aid in bracing a fair bit and make those end panels pretty immovable.

However they take up a bit more room, and especially around the first horn bend I'm not sure if it'll be a little too much volume taken away and it might affect the response. A test cab will really need to be built and measured first to see, and maybe a few little modifications made to even that out again.

As I said it'll be the summer before I'm able to make any sawdust with these but in the mean time, once I have it all finished and fully drawn up I'd be happy to make these solidworks models (or 2d DXF files of all of the wooden panels) available to anyone else who has access to CNC machinery.

Kevin,For transport it has castors on the back, and so two more handles allow it to be lifted and moved in this orientation.....

Inside it has some extensive bracing to make the cab rock solid, though that also does reveal my one concern with this design.

Using handles routed into the wood, with square back boxes, eliminates this as the pieces of wood that makes up the baffle can have square notches cut out to go around these and the joins can be sealed easily.

However they take up a bit more room, and especially around the first horn bend I'm not sure if it'll be a little too much volume taken away and it might affect the response.

The handle population you propose will definitely reduce output level, and the constriction to the horn path won't do anything positive to the response. If you really think you need that many handles I'd suggest spring handles, they won't reduce the interior space at all if they are flush mounted on the surface. The units with the fat rubber over the handle don't rattle.

As far as casters on the back- make sure they don't rattle, there are a few types of casters that don't but most have a resonant rattle frequency. I personally hate transporting cabinets grill up, as it makes them a rain barrel, and also a tempting spot for heavy objects to be placed, which tends to mess the grill up.

Since you plan to make the cabinets interlock, I'd suggest making a separate casterboard with the same skid pattern, you could wheel in two or three subs at once, saves money on wheels and reduces wasted truck space.

If you put casters on the back of two cabinets they occupy about the same truck space as a good two wheel dolly, and a dolly's big inflatable tires roll over bumps a lot easier than casters.

An exterior grill also chews up trailer space, and eliminates the truck integer depth dimension of 22.5".

Cheers,

Art

Last edited:

Kevin,

The handle population you propose will definitely reduce output level, and the constriction to the horn path won't do anything positive to the response. If you really think you need that many handles I'd suggest spring handles, they won't reduce the interior space at all if they are flush mounted on the surface. The units with the fat rubber over the handle don't rattle.

As far as casters on the back- make sure they don't rattle, there are a few types of casters that don't but most have a resonant rattle frequency. I personally hate transporting cabinets grill up, as it makes them a rain barrel, and also a tempting spot for heavy objects to be placed, which tends to mess the grill up.

Since you plan to make the cabinets interlock, I'd suggest making a separate casterboard with the same skid pattern, you could wheel in two or three subs at once, saves money on wheels and reduces wasted truck space.

If you put casters on the back of two cabinets they occupy about the same truck space as a good two wheel dolly, and a dolly's big inflatable tires roll over bumps a lot easier than casters.

An exterior grill also chews up trailer space, and eliminates the truck integer depth dimension of 22.5".

Cheers,

Art

Thank you for your thoughts Art

In terms of the grill, I'm only adding 5mm onto the design, a wrap around grill with a thin layer of foam to stop the metal vibrating against the wood, and I feel that's a worthwhile compromise to achieve a full face grill.

In terms of the casters, a dolly of three would be very quick if all of the venues we played in had proper loading docks and facilities, it's a big heavy lump to try and wheel into some of the ones we would play in that have less than ideal get-ins, so the extra truck space taken up by the castors is worth the compromise to allow them to be wheeled and moved as singles. They'd be tipped and stacked much like our flight cases which also have permanent wheels so giving up that little space an d finding ways to stack things with the wheels towards each other bit offset slightly to nest them together is something that's common.

However yes, as I look more at the handle situation it does seem as if it'll need looking at. While spring handles would be an ideal solution from a practical point of view, it does look very DIY when used on a speaker, and as much as any reasonable sound person would know it makes no difference to the actual sound, it would detract from the visuals that are always considered by promoters and bands that generally hire me and pay my wages. Just like the need to often use small line arrays in less than ideal conditions (that point source would work better for), just because it's what the promoter wants visually, it's something that I unfortunately need to factor in. I've built smaller tapped horns before (THAM15) and in that case rather than building handles into the cabinet and taking away too much volume, I built out the way instead and extended the length a little to give a place for handles (in that design a large bar handle) that didn't detract from the cab volume and horn path, and I'll probably look at adjusting my model for that.

K

To makeup for the lost path 'space' you could widen the cabinet a cm. Ditch the long side handles, I think you don not need those. Instead of 4 handles on the bottom/top make two 4,5 inch round ones. This way you can pick it from any angle or use the holes for straps pick-point. I do it this way on all my builds and its awesome.

I Agree with the front wheel plate, you can do butterfly locks on them. you can stack two per plate with straps. Or you can do some rubberband around the wheels to prevent noise.

Anyway.... nice work on converting to solidworks. I am trying to convert from Hornresp to solid but still learning how, I have most of the parts for my CNC build in, waiting for the 1500x1500mm framework to arrive. Hopefully starting building in the spring.

I Agree with the front wheel plate, you can do butterfly locks on them. you can stack two per plate with straps. Or you can do some rubberband around the wheels to prevent noise.

Anyway.... nice work on converting to solidworks. I am trying to convert from Hornresp to solid but still learning how, I have most of the parts for my CNC build in, waiting for the 1500x1500mm framework to arrive. Hopefully starting building in the spring.

- Home

- Loudspeakers

- Subwoofers

- Keystone Sub Using 18, 15, & 12 Inch Speakers