This weekend ..

Internal panel fitted, bracing pieces ( 3/4" dowel) fitted - ready to put the lid on the first unit. Just a few small jobs to do - some wool felt in the throat, some mounting holes/bushes for screwing-on the base piece, maybe a couple of screwdriver access holes in the back panel . Should be able to play this for the first time maybe Sunday .

Pics shows 10W400 on the floor, behind. Also a few other items left as an exercise for the viewer .

Internal panel fitted, bracing pieces ( 3/4" dowel) fitted - ready to put the lid on the first unit. Just a few small jobs to do - some wool felt in the throat, some mounting holes/bushes for screwing-on the base piece, maybe a couple of screwdriver access holes in the back panel . Should be able to play this for the first time maybe Sunday .

Pics shows 10W400 on the floor, behind. Also a few other items left as an exercise for the viewer .

Attachments

Internal panel fitted, bracing pieces ( 3/4" dowel) fitted - ready to put the lid on the first unit. Just a few small jobs to do - some wool felt in the throat, some mounting holes/bushes for screwing-on the base piece, maybe a couple of screwdriver access holes in the back panel . Should be able to play this for the first time maybe Sunday .

Pics shows 10W400 on the floor, behind. Also a few other items left as an exercise for the viewer .

How are you going to access the driver after you put the last panel on? Or is that panel going to be a removable panel?

Access

Ok Brian , on the basis this unit stands upright as a tower -

The remaining side piece closes-up most of the unit. At the bottom there is ( already made ) a small base panel of 25mm birch ply about 34cm x 31cm that will screw into the side and back panels by means of M6 screws and threaded inserts that will be epoxied into those panels .

I should be able access about 4 or 5 of the speaker mounting screws from below. I will need to drill 3 or 4 small holes through the back panel to access the remainder with a long-shafted screwdriver. These can be closed-off with eg. silicone sealant when the unit is finished . The back panel will be up against a wall , or near .

Hope this makes sense.

MJ

Ok Brian , on the basis this unit stands upright as a tower -

The remaining side piece closes-up most of the unit. At the bottom there is ( already made ) a small base panel of 25mm birch ply about 34cm x 31cm that will screw into the side and back panels by means of M6 screws and threaded inserts that will be epoxied into those panels .

I should be able access about 4 or 5 of the speaker mounting screws from below. I will need to drill 3 or 4 small holes through the back panel to access the remainder with a long-shafted screwdriver. These can be closed-off with eg. silicone sealant when the unit is finished . The back panel will be up against a wall , or near .

Hope this makes sense.

MJ

One unit is now finished , edges rounded, speaker installed ; just the cosmetic finishing to complete . Here's a pic from the bottom just before I fitted the base panel . I think I will probably add a couple more of these M6 bushings into the back panel, as they worked very well on the four I fitted so far .

Attachments

Family pic

Here's a shot of the first Tapped horn unit on the left, with the odd 'family' of stuff I have currently in the living room . As you can see , I was playing with the sig generator & trying to get some early impressions. Very good so far ( I only finished this speaker about 90 mins ago ! ) .

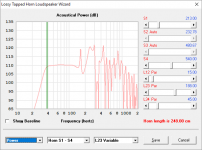

Plays solidly to 40Hz, slightly down at 35Hz but still strong, then dies-off rapidly through 34-30Hz as per the simulation .

Smooth and clean up to 105Hz ; bit of a broad peak ( room res ? ) through 110-115 Hz , then down , up again with expected peaks around 150 and 180 , but quite low-Q , not sharp . Noticeable dip around 165-170 .

Sounds reasonably clean and low-distortion up to 200Hz , this is very useful ! Above 200 it sounds like there are definite higher-harmonics in there. Plenty of dips & peaks from there upwards , as seen on the sim .

Tried to find a few records with isolated low-bass guitar notes. Sounded pretty nice & meaty on the two tracks I found .

Anyway, the speaker needs more running-in, and I will fit a proper 150Hz low-pass to one side of the amp in next 1-2 days to enable more useful listening .

Here's a shot of the first Tapped horn unit on the left, with the odd 'family' of stuff I have currently in the living room . As you can see , I was playing with the sig generator & trying to get some early impressions. Very good so far ( I only finished this speaker about 90 mins ago ! ) .

Plays solidly to 40Hz, slightly down at 35Hz but still strong, then dies-off rapidly through 34-30Hz as per the simulation .

Smooth and clean up to 105Hz ; bit of a broad peak ( room res ? ) through 110-115 Hz , then down , up again with expected peaks around 150 and 180 , but quite low-Q , not sharp . Noticeable dip around 165-170 .

Sounds reasonably clean and low-distortion up to 200Hz , this is very useful ! Above 200 it sounds like there are definite higher-harmonics in there. Plenty of dips & peaks from there upwards , as seen on the sim .

Tried to find a few records with isolated low-bass guitar notes. Sounded pretty nice & meaty on the two tracks I found .

Anyway, the speaker needs more running-in, and I will fit a proper 150Hz low-pass to one side of the amp in next 1-2 days to enable more useful listening .

Attachments

Ha ha !

Not quite, have been fettling the cosmetics a bit, and have been listening, but also working on the bass/mid horns. Sounds very promising, but need to get the SS amp finished, or buy a T-amp, to get a better impression, as my current 300B amp only has ~1.8R Zout , not ideal .

Pic attached below .

The rest of the progress is going on at this thread -

audio-talk :: View topic - Something stirs in the Undergrowth

More soon

Not quite, have been fettling the cosmetics a bit, and have been listening, but also working on the bass/mid horns. Sounds very promising, but need to get the SS amp finished, or buy a T-amp, to get a better impression, as my current 300B amp only has ~1.8R Zout , not ideal .

Pic attached below .

The rest of the progress is going on at this thread -

audio-talk :: View topic - Something stirs in the Undergrowth

More soon

Attachments

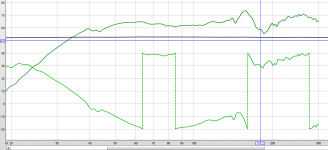

Just did a tapped horn with B&C 10CL51, it sims almost like the driver in this thread. Used the same dimensions. I attach a measurement at low volume, ignore vertical value. The measurement is taken with HP LR4@34hz applied.

Always nice to see actual measurements of these TH builds. Did you take this measurement with the mic at the TH's mouth?

At the mouth, yes.

I 'corrected' some of the S1 and S2 area by placing some material to reduce area.

Also placed some braces but don't show up in this picture. I could have used more, I feel a slight vibration when volume is pushed a little higher. MDF is 18mm thick.

I 'corrected' some of the S1 and S2 area by placing some material to reduce area.

Also placed some braces but don't show up in this picture. I could have used more, I feel a slight vibration when volume is pushed a little higher. MDF is 18mm thick.

Attachments

At the mouth, yes.

The small aberration in the FR around 40 Hz suggests that there might be a leak around the driver, if it's not being caused by the panel flex that you mentioned. Can you measure the impedance curve for the build? That should help to confirm if there is one.

The original sims for the build are not quite accurate. They are based on Conical, not Parabolic, segments, and there's no cone compensation included. Once these two things are taken into consideration, basically the same performance can be achieved by using a single-expansion TH rather than a multi-expansion one, which should make folding the TH into a box much easier - the resulting box can be a simple rectangular shape. I like the fold, as it's a pretty simple one. There's also another single-expansion fold that might be applicable that results in a shorter but deeper box that should suffer a little less from panel flex. I think I'll see if I can add optimization workbooks for them on my horn-folding page this weekend.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Ideas on 35-150(?) HiFi Tapped Horn