Some responses

If you mean because one driver is inverted... no, I didn't forget. I measured each driver by itself before i paralleled them, and amazingly enough- both

vent tunings were at 50 Hz. It's a moot point, because I intend to dis-assemble these failures. Even after 38 years of speaker building- it seems I am still very capable of a total blunder

As far as addressing the mid-bass- yes DJK, you are correct: I have been using a single PRO 15" driver in a sealed enclosure, and it sounds pretty good.

Pretty good, but not awesum sounding like Les'. Next summer, or when ever speaker building season starts up again, I'll seriously think about dual 15" ppsl's again. In a common enclosure, and everything as close to the design as what I can make out, without knowing any exact design details.

Next up- it's time to design/ build an awesum midrange section- which is beyond the scope of this thread. I better get on it soon, as it's getting colder and colder as the weeks pass by. Happy listening to everyone!

Sorry to interrupt but it can work Norman, as long the tolerances of the TS parameters between the two drivers are very close and the boxes behind the drivers have exact the same volume...

But realistically, only top (expensive) drivers have such small tolerances and Scott seems to have 'forgotten' to make up the volume differences made by the drivers...

If you mean because one driver is inverted... no, I didn't forget. I measured each driver by itself before i paralleled them, and amazingly enough- both

vent tunings were at 50 Hz. It's a moot point, because I intend to dis-assemble these failures. Even after 38 years of speaker building- it seems I am still very capable of a total blunder

As far as addressing the mid-bass- yes DJK, you are correct: I have been using a single PRO 15" driver in a sealed enclosure, and it sounds pretty good.

Pretty good, but not awesum sounding like Les'. Next summer, or when ever speaker building season starts up again, I'll seriously think about dual 15" ppsl's again. In a common enclosure, and everything as close to the design as what I can make out, without knowing any exact design details.

Next up- it's time to design/ build an awesum midrange section- which is beyond the scope of this thread. I better get on it soon, as it's getting colder and colder as the weeks pass by. Happy listening to everyone!

Well so far so good. I have one cabinet ready for the speakers which should be arriving any day. I have a question regarding mounting the speakers. I assume I will need to remove some wood so the speakers will mount flush. Is that called rabbeting? Anyway how wide? How deep? Just enough for the speakers or allow for a little space? What about rounding the corners? Anyone know a site which will give some pointers?

As for the mounting I am planning on using some kind of insert to screw into. I may have two studs on each speaker just to hold it in place while screw the rest in.

For wire I was planning on using some solid core cat wire. Good enough?

Thanks!

As for the mounting I am planning on using some kind of insert to screw into. I may have two studs on each speaker just to hold it in place while screw the rest in.

For wire I was planning on using some solid core cat wire. Good enough?

Thanks!

I have a question regarding mounting the speakers. I assume I will need to remove some wood so the speakers will mount flush. Is that called rabbeting? Anyway how wide? How deep? Just enough for the speakers or allow for a little space?

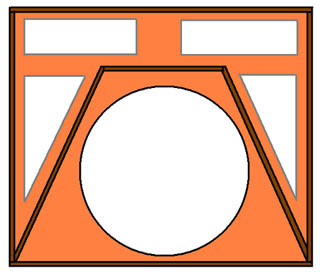

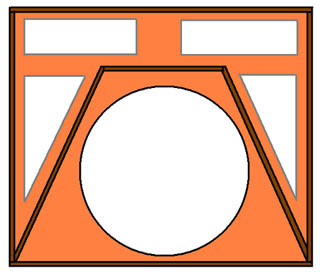

This

I only make the plenum the total height of the inverted driver, add the frame thickness of the other, plus about 1/4" to spare.

As for the mounting I am planning on using some kind of insert to screw into. I may have two studs on each speaker just to hold it in place while screw the rest in.

These might be of help.

Two suggestions:

These work much better than T or Hurricane Nuts: McMaster-Carr

Rotating the inserts 1/8 turn gives you knuckle room

And instead of studs, why don't you flip the enclosure on its side so the inverted driver is facing down so gravity is helping you; and on the other side so the normal driver is facing up. That should help w/mounting.

djk:

I'm going with the same layout concept as you posted:

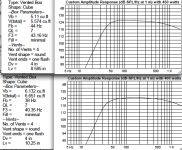

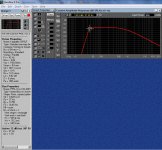

(This was designed for (2) Kappalite 3015LF w/an F3 of 31.86 Hz)

(A) 45 x 22.5

(B) 43.5 x 21

(C) 22.5 x 21

(D) 21 x 17.75

(E) 21 x 14.9125

(F) 21 x 9

With my layout, there is a 4" distance between the back (B) and (F). Is this acceptable?

Also, I was unaware that the wider a port is, the longer it would have to be - the opposite of what I was thinking. The inside height in my to-be enclosure is 21". I entered a 3" width and BB6 gave me a 9" length. If 4" width is entered, BB6 suggests 12.6" length. Just making sure this is correct. If so, I'm thinking of going with the 3" width option.

Any thoughts/suggestions before I start making saw dust? Also, any objections to Arauco (3/4")?

I'm going with the same layout concept as you posted:

(This was designed for (2) Kappalite 3015LF w/an F3 of 31.86 Hz)

(A) 45 x 22.5

(B) 43.5 x 21

(C) 22.5 x 21

(D) 21 x 17.75

(E) 21 x 14.9125

(F) 21 x 9

With my layout, there is a 4" distance between the back (B) and (F). Is this acceptable?

Also, I was unaware that the wider a port is, the longer it would have to be - the opposite of what I was thinking. The inside height in my to-be enclosure is 21". I entered a 3" width and BB6 gave me a 9" length. If 4" width is entered, BB6 suggests 12.6" length. Just making sure this is correct. If so, I'm thinking of going with the 3" width option.

Any thoughts/suggestions before I start making saw dust? Also, any objections to Arauco (3/4")?

Last edited:

Four inch for the back area is a bit on the small side, you could make the D parts almost 4 inches smaller, reducing the plenum area (good) and expanding the cabinet volume, reducing the restriction between chambers, also good as it allows for a bigger port .djk:

I'm going with the same layout concept as you posted:

(This was designed for (2) Kappalite 3015LF w/an F3 of 31.86 Hz)

(A) 45 x 22.5

(B) 43.5 x 21

(C) 22.5 x 21

(D) 21 x 17.75

(E) 21 x 14.9125

(F) 21 x 9

With my layout, there is a 4" distance between the back (B) and (F). Is this acceptable?

Also, I was unaware that the wider a port is, the longer it would have to be - the opposite of what I was thinking. The inside height in my to-be enclosure is 21". I entered a 3" width and BB6 gave me a 9" length. If 4" width is entered, BB6 suggests 12.6" length. Just making sure this is correct. If so, I'm thinking of going with the 3" width option.

Any thoughts/suggestions before I start making saw dust? Also, any objections to Arauco (3/4")?

Longer ports tune lower, bigger volume ports require more depth to tune as low.

High aspect ratio (long, thin) ports have more surface area to enclosed volume by ratio, they will chuff at a lower volume than a more square or circular shape.

They also tune lower than the volume /length predictions of a circular duct.

Remember to deduct the port area from the cabinet volume, and round over all the port and plenum entrances and exits.

Arauco is a decent choice, the last birch plywood I purchased turned out to use a filler wood and was not as stiff (or heavy) as Arauco.

Art

Thanks for the quick informative reply, Art!

"you could make the D parts almost 4 inches smaller"

With almost 15.5" overall diameter of the driver and taking the thickness of panel (F) into account, I only have .75" to work with inside the plenum (without screwing the drivers into panel E).

"also good as it allows for a bigger port"

Should I go wider than 3"?

"Remember to deduct the port area from the cabinet volume"

Do I just deduct the volume of panel G? Or the volume of panel G + the volume between G and C?

"and round over all the port and plenum entrances and exits"

I don't remember which test I read, but they compared a completely smooth enclosure to an enclosure w/sharp edges and the smooth enclosure didn't show any significant improvements. Thought it to be very interesting. I like how Bowers & Wilkins puts the "golf ball dimples" in their ports. I wonder how close one could get with drill bits & a steady hand.

"you could make the D parts almost 4 inches smaller"

With almost 15.5" overall diameter of the driver and taking the thickness of panel (F) into account, I only have .75" to work with inside the plenum (without screwing the drivers into panel E).

"also good as it allows for a bigger port"

Should I go wider than 3"?

"Remember to deduct the port area from the cabinet volume"

Do I just deduct the volume of panel G? Or the volume of panel G + the volume between G and C?

"and round over all the port and plenum entrances and exits"

I don't remember which test I read, but they compared a completely smooth enclosure to an enclosure w/sharp edges and the smooth enclosure didn't show any significant improvements. Thought it to be very interesting. I like how Bowers & Wilkins puts the "golf ball dimples" in their ports. I wonder how close one could get with drill bits & a steady hand.

Diffraction effects (rounded corners) are different (and more subjective, and harder to test) than port chuffing. Rounding the ports reduces chuffing.Thanks for the quick informative reply, Art!

"you could make the D parts almost 4 inches smaller"

With almost 15.5" overall diameter of the driver and taking the thickness of panel (F) into account, I only have .75" to work with inside the plenum (without screwing the drivers into panel E).

"also good as it allows for a bigger port"

Should I go wider than 3"?

"Remember to deduct the port area from the cabinet volume"

Do I just deduct the volume of panel G? Or the volume of panel G + the volume between G and C?

"and round over all the port and plenum entrances and exits"

I don't remember which test I read, but they compared a completely smooth enclosure to an enclosure w/sharp edges and the smooth enclosure didn't show any significant improvements. Thought it to be very interesting. I like how Bowers & Wilkins puts the "golf ball dimples" in their ports. I wonder how close one could get with drill bits & a steady hand.

Make part D as small as you can and still fit the drivers in and still leave room for a grill, I'll leave you to figure out 3.5 or 4.25 or whatever :^).

The port volume (that slug of air that wiggles back and forth, and does not blow out if big enough) is not part of the cabinet volume, deduct it and panel G, and the volume of the speakers intruding in to the cabinet, and the plenum. And deduct handle volume, and jacks, and braces, and paint drips...

Other than the fact that big ports reduce cabinet volume, within reason it is hard to make them too big, seat of my pants says go 4", and put a brace in the middle of the port.

And make the port too long, do a dry fit and then cut it down after you confirm it tunes FB too low, easier than adding on.

P.S. Why are you planning to tune the cabinet more than 10 Hz below the driver FS ?

Art

Last edited:

For a 9.6mm x-max driver the 4" port width would be the minimum, as far as I'm concerned.

I run a brace down the middle of the port, across the back, and up the other side.

I would also run a brace on part 'B', about 21" x 3". I don't normally brace this part, but I make mine smaller than this.

Tests of large-radius flared ports vs non-flared ports showed the large-radius port could play about 1.5dB louder before the onset of 'chuffing', I would just make the port a little bigger and don't worry about it. I always make the port as big as will fit in the box.

I run a brace down the middle of the port, across the back, and up the other side.

I would also run a brace on part 'B', about 21" x 3". I don't normally brace this part, but I make mine smaller than this.

Tests of large-radius flared ports vs non-flared ports showed the large-radius port could play about 1.5dB louder before the onset of 'chuffing', I would just make the port a little bigger and don't worry about it. I always make the port as big as will fit in the box.

and paint drips...

Great, made me LOL when out to dinner! Thanks!

P.S. Why are you planning to tune the cabinet more than 10 Hz below the driver FS ?

Art

Because I already have 2 extra new 3015LF dirvers that I haven't taken out of the box for over 6 months. This enclosure will be smaller than 2 T48s or 2 stadiumhorns (I have 2 T48s and 2 SS15s already) and as it sims, I can get flat to 30, louder, w/a smaller footprint. The T48s are large for the little spl you get and the SS15s don't play low enough for me. Heard great things about the PPSL design from djk and some others. Thought I'd try it w/what I've got. Bad idea? What should I expect from this enclosure w/these drivers? Should I just sell the drivers and build some TH18's?

For a 9.6mm x-max driver the 4" port width would be the minimum, as far as I'm concerned.

I run a brace down the middle of the port, across the back, and up the other side.

I would also run a brace on part 'B', about 21" x 3". I don't normally brace this part, but I make mine smaller than this.

Tests of large-radius flared ports vs non-flared ports showed the large-radius port could play about 1.5dB louder before the onset of 'chuffing', I would just make the port a little bigger and don't worry about it. I always make the port as big as will fit in the box.

Cool, thanks. I was planning on bracing any section 12" or longer.

Good to know about 'the larger, the better' for the port. Thx guys.

Hi Crescendo, going 30ties flat with two 3015LF's, I wish you luck... Your PPSL is a basreflex and pushing the driver 14Hz below it’s Fs isn’t healthy in these type of enclosures. Speaking for myself, I prefer expanding plenums for high excursion drivers in PPSL’s because for the reasons already mentioned. With an expanding plenum the pressure inside is everywhere a little different and is lowest at the 'mouth' of the plenum.and as it sims, I can get flat to 30, louder, w/a smaller footprint. The T48s are large for the little spl you get and the SS15s don't play low enough for me. Heard great things about the PPSL design from djk and some others. Thought I'd try it w/what I've got. Bad idea?

"Flat" is a relative term. The low corner will drop below Fb, but tuning so low will cause a rolloff above Fb.Because I already have 2 extra new 3015LF dirvers that I haven't taken out of the box for over 6 months. This enclosure will be smaller than 2 T48s or 2 stadiumhorns (I have 2 T48s and 2 SS15s already) and as it sims, I can get flat to 30, louder, w/a smaller footprint. The T48s are large for the little spl you get and the SS15s don't play low enough for me. Heard great things about the PPSL design from djk and some others. Thought I'd try it w/what I've got. Bad idea? What should I expect from this enclosure w/these drivers? Should I just sell the drivers and build some TH18's?

Good to know about 'the larger, the better' for the port. Thx guys.

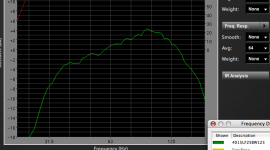

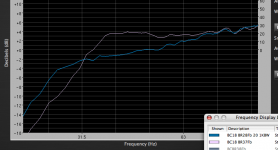

Note in the sims below that a larger box is required to get basically the same output at 40 Hz when Fb is lowered.

Your box is roughly the size (per speaker) of the 44Fb, tuning it to 30 Hz will lower the low corner at the expense of upper output.

It will have a knee around 30 Hz, but will droop from the upper response down to that point. You will sacrifice a lot of 40 Hz level to achieve the lower corner.

The 36 Fb example below is a 4015LF with a 36 Fb "too small" box, your response will look something like that tuned low.

Anyway, it's all a tradeoff, and you can always shorten the port if you find the rolloff above Fb is not worth the extension.

Using the speaker you have, I'd probably tune no lower than 36 Hz as a compromise between extension and kick.

Edit: just added charts of a 37Fb and 28Fb in the same box size to better illustrate the choice: loose 4 dB at 40 Hz for the same response at 31.5, but gain about 4 dB at 28 Hz.

For the music I work with, the 37 Hz tuning works better.

Art

Attachments

Last edited:

IMO an idea worth investigating.

Speaking for myself, I prefer expanding plenums for high excursion drivers in PPSL’s because for the reasons already mentioned. With an expanding plenum the pressure inside is everywhere a little different and is lowest at the 'mouth' of the plenum.

I think that's a great idea; I was going to try just that in my next (quasi)

ppsl attempt. I must have missed your post where it was mentioned before.

Do you have any pictures of your project ?

Hi Crescendo, going 30ties flat with two 3015LF's, I wish you luck... Your PPSL is a basreflex and pushing the driver 14Hz below it’s Fs isn’t healthy in these type of enclosures. Speaking for myself, I prefer expanding plenums for high excursion drivers in PPSL’s because for the reasons already mentioned. With an expanding plenum the pressure inside is everywhere a little different and is lowest at the 'mouth' of the plenum.

Speaking for myself, I prefer expanding plenums for high excursion drivers in PPSL’s because for the reasons already mentioned. With an expanding plenum the pressure inside is everywhere a little different and is lowest at the 'mouth' of the plenum.

I think that's a great idea; I was going to try just that in my next (quasi)

ppsl attempt. I must have missed your post where it was mentioned before.

Do you have any pictures of your project ?

Hi Oliver,

That example can make the mouth area of the plenum critical low and makes the building a little more complex. Just two expanding side walls that end at both sides of the enclosure will do the trick without risking a too small mouth area.

The importance is not just too lower the internal volume of the plenum but also make the mouth area in relation to displaced volume.

From the PP principle point of view it's more important to place the drivers as close as possible to each other. So my advice, lower the hight of the plenums and expand the width. If the driver doesn't fit trough the mouth any longer (exceptional high drivers like those with a dual magnet system for instance) you always can install it by building an accessible top or bottom plate.

The top plate and bottom plate of the plenum self, I prefer to make them as big as the inside cab dimensions. Cut out wholes for connecting the air of the two sides of the cab and you wont have to brace it in the middle any longer (since it already is).

That example can make the mouth area of the plenum critical low and makes the building a little more complex. Just two expanding side walls that end at both sides of the enclosure will do the trick without risking a too small mouth area.

The importance is not just too lower the internal volume of the plenum but also make the mouth area in relation to displaced volume.

From the PP principle point of view it's more important to place the drivers as close as possible to each other. So my advice, lower the hight of the plenums and expand the width. If the driver doesn't fit trough the mouth any longer (exceptional high drivers like those with a dual magnet system for instance) you always can install it by building an accessible top or bottom plate.

The top plate and bottom plate of the plenum self, I prefer to make them as big as the inside cab dimensions. Cut out wholes for connecting the air of the two sides of the cab and you wont have to brace it in the middle any longer (since it already is).

Last edited:

Thanks Oliver, I guess enough old school 'American Projecting Drawings' does help me out here  . It is just a fraction more simple to build and gives a wider mouth opening/area. The advantage is that you can place the drivers even closer together although you can't fit the drivers trough the mouth opening any longer. Just make sure that the distance between the two drivers is at least Xlim (in other words the magnet of one driver falls into the cone of the second driver).

. It is just a fraction more simple to build and gives a wider mouth opening/area. The advantage is that you can place the drivers even closer together although you can't fit the drivers trough the mouth opening any longer. Just make sure that the distance between the two drivers is at least Xlim (in other words the magnet of one driver falls into the cone of the second driver).

Our cabs are 70cm x 70cm x 70cm for dual 15 inch. This gives the advantage of stacking four cabs vertically if needed (or 4 high and 4 width to get a ridiculous stack if needed) to get the right pattern and acoustic couple from 32Hz.

Our cabs are 70cm x 70cm x 70cm for dual 15 inch. This gives the advantage of stacking four cabs vertically if needed (or 4 high and 4 width to get a ridiculous stack if needed) to get the right pattern and acoustic couple from 32Hz.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- A Thread for those interested in PPSL enclosures