agree, nice work bob. I also like the 55-2421 build.

Tapped Horn build

I see a spl meter in one pic, maybe some measurements to share?

Tapped Horn build

I see a spl meter in one pic, maybe some measurements to share?

agree, nice work bob. I also like the 55-2421 build.

Tapped Horn build

I see a spl meter in one pic, maybe some measurements to share?

yes those are both my builds.

the thread for the 55-2421 with measurements can be found here.

the build of my 8 x SS15 can be found here.

i still have not found time to take measurements of my SS15s.

bob

Last edited:

Here is another driver that might be worth looking into ...AP-1526-8

Has the right specs , 40hz fs , QTS and VAS in the right range ..... Looks like it should work well in an Jim's SS15 and the cost puts it well under the Single Sheet Challenge limit ...

I have seen the Klippel report for this driver and it shows potential ... Around 9mm xmax at 70% BL if i am reading it correctly .... Its also my understanding that the 350w rms rating is very conservative ...

Mark at Audiopile provided some values in surprisingly good drivers in the past from what i understand ...

Has the right specs , 40hz fs , QTS and VAS in the right range ..... Looks like it should work well in an Jim's SS15 and the cost puts it well under the Single Sheet Challenge limit ...

I have seen the Klippel report for this driver and it shows potential ... Around 9mm xmax at 70% BL if i am reading it correctly .... Its also my understanding that the 350w rms rating is very conservative ...

Mark at Audiopile provided some values in surprisingly good drivers in the past from what i understand ...

Thanks.

I went to check it out and had a snake in my cart! I had forgot about that driver and need to get those m/fing snakes.

Here is another driver that might be worth looking into ...AP-1526-8

Has the right specs , 40hz fs , QTS and VAS in the right range ..... Looks like it should work well in an Jim's SS15 and the cost puts it well under the Single Sheet Challenge limit ...

I have seen the Klippel report for this driver and it shows potential ... Around 9mm xmax at 70% BL if i am reading it correctly .... Its also my understanding that the 350w rms rating is very conservative ...

Mark at Audiopile provided some values in surprisingly good drivers in the past from what i understand ...

I went to check it out and had a snake in my cart! I had forgot about that driver and need to get those m/fing snakes.

Hi All,

The AP-1526-8 looks like the PAS-1507 from the Chinese Wave Audio. Also it is described on the Audiopile website as quote: "Good mid range loudspeaker for PA or instrument applications." which doesn't suggest it has a high Xmax.

It's relative low VAS, low power and relative high sensitivity figures are all signs of a relative high BL combined with a low moving mass, which are not good specs for the SS15.

The AP-1526-8 looks like the PAS-1507 from the Chinese Wave Audio. Also it is described on the Audiopile website as quote: "Good mid range loudspeaker for PA or instrument applications." which doesn't suggest it has a high Xmax.

It's relative low VAS, low power and relative high sensitivity figures are all signs of a relative high BL combined with a low moving mass, which are not good specs for the SS15.

I went to check it out and had a snake in my cart! I had forgot about that driver and need to get those m/fing snakes.

Mr Doom, when you saw the snake did you jump back and say "EEEEEK!"

Let me know how good that snake is when you get it, the pricing on some of their cabling seems reasonable ... Their cables look like they might be well built and heavier when compared to some of the similarly priced lower end stuff from PE.

Hi All,

The AP-1526-8 looks like the PAS-1507 from the Chinese Wave Audio. Also it is described on the Audiopile website as quote: "Good mid range loudspeaker for PA or instrument applications." which doesn't suggest it has a high Xmax.

It's relative low VAS, low power and relative high sensitivity figures are all signs of a relative high BL combined with a low moving mass, which are not good specs for the SS15.

Hey there Djim ,

I'm not sure if this is the best method but i used hornresponse to calculate the moving mass of the Audiopile driver, and the moving mass looks like it might be very close to that of the Definimax 4015, which makes it significantly heavier than the 3015LF's moving mass .... BL factor is probably around 21 ..

Perhaps not ideal, but apparently workable if the other specs are close enough (based upon the popularity of the 4015LF and 3015LF in these designs) ..

However, i do realize that even though the cone is just as heavy as the Definimax's cone that it doesn't necessarily mean that it is just as strong, and failures such as tearing or cone folding may occur if used in a cabinet that has some compression (S2 area less than driver's SD) ... Its probably just one of those situations where someone will have to give it a shot to see if the cone holds up to some abuse ...

So I spent the past week at work reading through this thread in my (ample) spare time at work... woah there's a lot to take in, some great discussions along the way!

I've convinced myself that building a bunch of SS15s is the way to go, but I want to see if this makes sense to those in the know:

I have 6x Delta 12LFA on hand, bought for dirt cheap after coming accross plans for some tall horns starting with T. After procrastinating for a while and reading around, I've been swayed away for a few reasons, and my goals have changed a bit.

The new plan is to build a battery-powered sound system, that is moderately portable and versatile. A couple of hand trolleys/sack trucks, with a stack of batteries (low for balance), a few subs, then tops above head height, would make the stereo pair that can be used as portable system on the move for parades and the like. When stopped and set up, the subs can be lumped together and the trolleys are kept as speaker stands for the tops.

Probably sounds silly, but we have some pretty good street/laneway/park parties here (Newtown/Marrickville) every year, Reclaim The Lanes being the biggest and that's in February - giving me a goal to work towards...

I'm set on the SS15, not because it's the "best" for my purpose as a few reflex boxes would probably work really well for my bass duty... but how cheap, light and simple this design is makes sense for expanding the system in the future when it becomes more than just a rig on wheels.

The gains from "barn door" additions as made by r23d (posted here) is a big appeal, the panels could strap on the sides of the system when it's being wheeled around and when it's parked in a park, they can be bolted together for something bigger and louder again.

The limitations of working with 24V battery power outdoors means I'll only be putting 24V max (probably ~22V) in to the drivers, and only need response from 60ish up, pursuing anything lower is futile.

When I modelled the D12LFA using DJIMs numbers shows the driver seems to perform OK in an unmodded box, and runs out of xmax at 22V. Happy coincidence!

It all seems to be a good idea so far...

Long winded intro, sorry, I'm bored at work and full of ideas... the point this post is to ask:

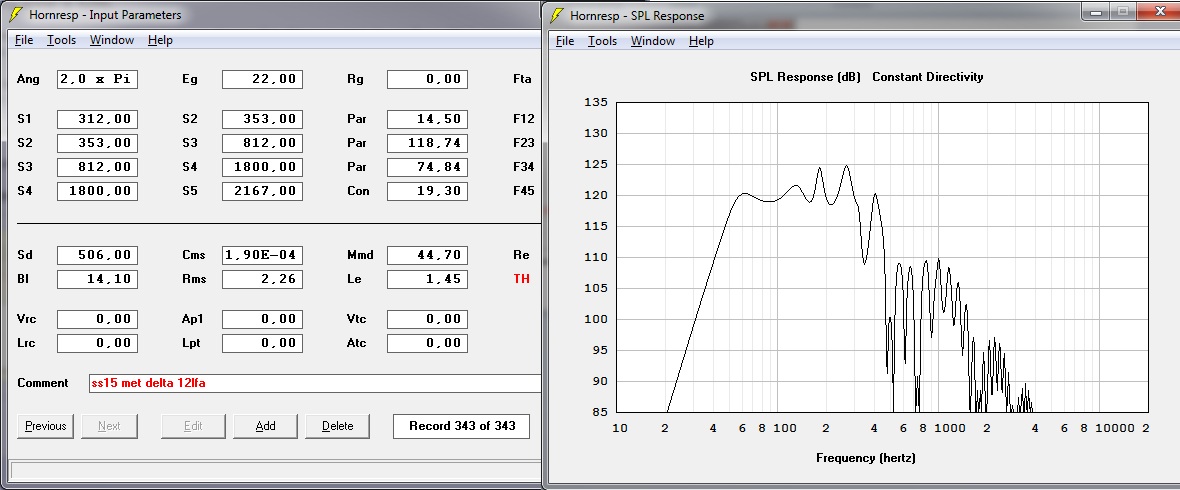

Are my numbers for simming the D12LFA close to accurate? It's the first time I've used HornResp

Would I gain/lose anything by making the box slightly narrower, perhaps 19.5"?

And are there any other mods to the box needed for running the 12" instead of 15", ie, does the driver mount off centre on the baffle or anything like that?

I'll try and build a test box in the next month or so to see if it works out, and if there are any small changes to make I'd like to factor them in...

I've convinced myself that building a bunch of SS15s is the way to go, but I want to see if this makes sense to those in the know:

I have 6x Delta 12LFA on hand, bought for dirt cheap after coming accross plans for some tall horns starting with T. After procrastinating for a while and reading around, I've been swayed away for a few reasons, and my goals have changed a bit.

The new plan is to build a battery-powered sound system, that is moderately portable and versatile. A couple of hand trolleys/sack trucks, with a stack of batteries (low for balance), a few subs, then tops above head height, would make the stereo pair that can be used as portable system on the move for parades and the like. When stopped and set up, the subs can be lumped together and the trolleys are kept as speaker stands for the tops.

Probably sounds silly, but we have some pretty good street/laneway/park parties here (Newtown/Marrickville) every year, Reclaim The Lanes being the biggest and that's in February - giving me a goal to work towards...

I'm set on the SS15, not because it's the "best" for my purpose as a few reflex boxes would probably work really well for my bass duty... but how cheap, light and simple this design is makes sense for expanding the system in the future when it becomes more than just a rig on wheels.

The gains from "barn door" additions as made by r23d (posted here) is a big appeal, the panels could strap on the sides of the system when it's being wheeled around and when it's parked in a park, they can be bolted together for something bigger and louder again.

The limitations of working with 24V battery power outdoors means I'll only be putting 24V max (probably ~22V) in to the drivers, and only need response from 60ish up, pursuing anything lower is futile.

When I modelled the D12LFA using DJIMs numbers shows the driver seems to perform OK in an unmodded box, and runs out of xmax at 22V. Happy coincidence!

It all seems to be a good idea so far...

Long winded intro, sorry, I'm bored at work and full of ideas... the point this post is to ask:

Are my numbers for simming the D12LFA close to accurate? It's the first time I've used HornResp

Would I gain/lose anything by making the box slightly narrower, perhaps 19.5"?

And are there any other mods to the box needed for running the 12" instead of 15", ie, does the driver mount off centre on the baffle or anything like that?

I'll try and build a test box in the next month or so to see if it works out, and if there are any small changes to make I'd like to factor them in...

Attachments

...The Fs is 64hz and vas is higher btw.

And I'm wondering how the heck you can get a 4" VC driver to have such a low BL.....

Even though this is an international crowd i still want to wish everyone a happy thanksgiving! How is this pertinent you may ask?

Big thanks to Mr Jbell for initiating and nurturing this excellent discussion and all of the other great minds for their contributions! ... Such fantastic examples of innovation and collaboration should be celebrated !..

I have some questions for Mr Bell, and actually Bitsmasher has already sort of beat me to the first question, its about hornresponse inputs ... Are the inputs in Bitsmasher's example (in the above post) the most current inputs? Because i also use those very same numbers to simulate the SS15 cabinet and i want to make sure that i am up to date

Excellent design by the way, so small, lightweight, affordable and great output covering the most important portion of the bass range when it comes to reproducing the majority of music ..... The most adept of hornresponse jockeys could push pixels all day long and never come up with an improvement to your box, at least not without having to make some major sacrifice in one area or another...... Did the SS15 version 2 with the cone compensation improve upon your original design at all? I never did hear much about the results or see any charts ...

Jim, i have seen you mention in this discussion that you would like to see a little more output at 40hz.. It would be like adding a giant cherry on top of an already superb product...

Adding a little extra bass extension to this box has been the focus of a few of my recent hornresponse tinkerings... I'm a novice but i did observe something interesting that might be useful ... When i was plugging a few different drivers into the SS15 i spotted a pattern .. I noticed that a few drivers that had very low VAS values, lower QTS values and higher BL values such as the RCF LF15G400 and the B&C 15tbx100 would allow the SS15 to play lower .... You have to add "LE" to smooth out the response (totals of 4 or 5 millihenries including driver inductance) ... The end result being a sacrifice of a few DBs at 65hz to gain 3 decibels at 40hz , but i think the best part is that the "knee" point at which the response drops off sharply shifts down by 10hz!

Forgive me if someone in this forum has already mentioned this...

I have to wonder if this is the same method that Mr Danley uses in some of his boxes because i have heard that large inductors are used in some of his TH cabinets and he also seems to use some drivers with high BL factors ...

Big thanks to Mr Jbell for initiating and nurturing this excellent discussion and all of the other great minds for their contributions! ... Such fantastic examples of innovation and collaboration should be celebrated !..

I have some questions for Mr Bell, and actually Bitsmasher has already sort of beat me to the first question, its about hornresponse inputs ... Are the inputs in Bitsmasher's example (in the above post) the most current inputs? Because i also use those very same numbers to simulate the SS15 cabinet and i want to make sure that i am up to date

Excellent design by the way, so small, lightweight, affordable and great output covering the most important portion of the bass range when it comes to reproducing the majority of music ..... The most adept of hornresponse jockeys could push pixels all day long and never come up with an improvement to your box, at least not without having to make some major sacrifice in one area or another...... Did the SS15 version 2 with the cone compensation improve upon your original design at all? I never did hear much about the results or see any charts ...

Jim, i have seen you mention in this discussion that you would like to see a little more output at 40hz.. It would be like adding a giant cherry on top of an already superb product...

Adding a little extra bass extension to this box has been the focus of a few of my recent hornresponse tinkerings... I'm a novice but i did observe something interesting that might be useful ... When i was plugging a few different drivers into the SS15 i spotted a pattern .. I noticed that a few drivers that had very low VAS values, lower QTS values and higher BL values such as the RCF LF15G400 and the B&C 15tbx100 would allow the SS15 to play lower .... You have to add "LE" to smooth out the response (totals of 4 or 5 millihenries including driver inductance) ... The end result being a sacrifice of a few DBs at 65hz to gain 3 decibels at 40hz , but i think the best part is that the "knee" point at which the response drops off sharply shifts down by 10hz!

Forgive me if someone in this forum has already mentioned this...

I have to wonder if this is the same method that Mr Danley uses in some of his boxes because i have heard that large inductors are used in some of his TH cabinets and he also seems to use some drivers with high BL factors ...

the data looks okAre my numbers for simming the D12LFA close to accurate? It's the first time I've used HornResp

Would I gain/lose anything by making the box slightly narrower, perhaps 19.5"?

And are there any other mods to the box needed for running the 12" instead of 15", ie, does the driver mount off centre on the baffle or anything like that?

I'll try and build a test box in the next month or so to see if it works out, and if there are any small changes to make I'd like to factor them in...

if you narrow the box you wil always lose low end and/or efficiency.

mods are not needed ,but you wil gain a bit round 60 hz by making s2 a bit smaler.

(try s1 300 and s2 350)

i would put the driver as far back as posible (shorter s1>s2 and longer s4>s5)

When I'm building subs like this, it's all a matter of how fast and how well can I build.... speed is the name of the game, and expanding PL is part of what allows that speed. Torx head deck screws and pl allow me to build a quad of these in a day -- no clamps, no waiting for glue to dry, just go. When it's done it's air tight, square, and ready for finish and install.

So, I guess for my purposes, this is the way I choose to do subs. Pocket hole jig/screws and/or brad nailer with pva gets excessive use in other construction projects of mine -- but not subs.

J,

Can you elaborate a bit on how you use the torx head deck screws to assemble the wood,

also...

is it better to use torx than hex head screws or why you gravitate towards torx?

do you use a power tool like a cordless drill with the screw attachment to secure the panels ?

i do not have those clamps and if i can build without clamps it would be a plus

Thanks

Max.

Last edited:

can you paste some links of the actual partsThey don't snap like drywall screws

They don't strip as easily as Philips head screws

Most boxes come with the correct torx bit to use.

screws and boxes

i googled but there are sooo many flavours

i dont want to get the wrong ones

I have had good luck with deckmate brand from Home Depot.

Deck Mate, #7 x 1-1/4 in. Coarse Green Coated Steel Flat Head Exterior Wood Screws 1 lb. Pack, 12125 at The Home Depot - Mobile

Deck Mate, #7 x 1-1/4 in. Coarse Green Coated Steel Flat Head Exterior Wood Screws 1 lb. Pack, 12125 at The Home Depot - Mobile

ic,I have had good luck with deckmate brand from Home Depot.

Deck Mate, #7 x 1-1/4 in. Coarse Green Coated Steel Flat Head Exterior Wood Screws 1 lb. Pack, 12125 at The Home Depot - Mobile

so you just use the screws to make the "box" and the insides panels are just glued

or you screw all parts in then super PL all joints

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge