What are you calculating?

At any rate djk has the scoop and so the coil length would need to be ~29.5mm long to get to 11mm x-max. The slice of magnet is 25mm thick, that driver better have a HUGE bump on the backplate... I doubt that it does, and I doubt that the coils is that long... It's probably like my bad math example above

The new Faital 15HP1030

can push itself to x-dammage, I gave one a good whack the other day, oops

can push itself to x-dammage, I gave one a good whack the other day, oops "Lies and damn lies seems little different from disreputable manufacturers' claims when it comes to audio product. "

Sure, if you say so.

You totally don't understand the 70% Bl specification.

The newer JBL models with the 12.7mm top plates have very low x-max by your method, but lay waste to the older models with the 8.1mm top plates.

The 70% Bl estimation with the the gap height/4 method also correlates well with how it sounds in practice.

Whatever.

Sure, if you say so.

You totally don't understand the 70% Bl specification.

The newer JBL models with the 12.7mm top plates have very low x-max by your method, but lay waste to the older models with the 8.1mm top plates.

The 70% Bl estimation with the the gap height/4 method also correlates well with how it sounds in practice.

Whatever.

Last edited:

I wanted to thank jbell and jwmbro for great advice in adapting the ss15 into a 12" driver, slimmed down version:

http://www.diyaudio.com/forums/subw...ofer-under-100-high-efficiency-low-power.html

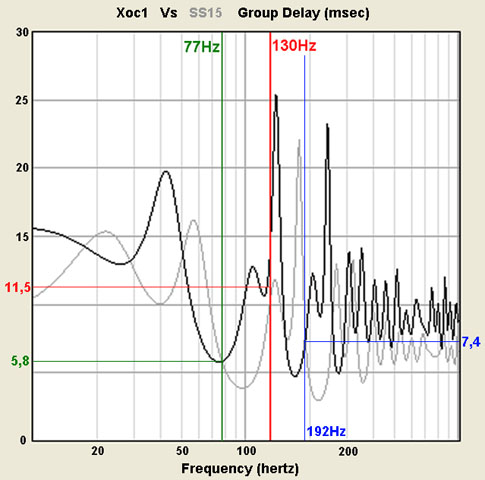

I'm usually a big advocate of time correction of bass, but it looks like I won't have time correction in the system I'm currently thinking of for this, a portable PA using a class-d car amp. Can you get away without time correction here? I found the group delay sim earlier in the thread, see below. Figure that the mains are bass reflex with a high tuning (some group delay already), and active crossover at 80 to 100 hz which could be tuned for an overlap or gap, plus a parametric EQ. Do you think the integration will be pretty clean without time correction, assuming physical alignment? Thanks!

As a side note, has anyone run FIR room correction on a horn sub...?

http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-4.html#post2604579

http://www.diyaudio.com/forums/subw...ofer-under-100-high-efficiency-low-power.html

I'm usually a big advocate of time correction of bass, but it looks like I won't have time correction in the system I'm currently thinking of for this, a portable PA using a class-d car amp. Can you get away without time correction here? I found the group delay sim earlier in the thread, see below. Figure that the mains are bass reflex with a high tuning (some group delay already), and active crossover at 80 to 100 hz which could be tuned for an overlap or gap, plus a parametric EQ. Do you think the integration will be pretty clean without time correction, assuming physical alignment? Thanks!

As a side note, has anyone run FIR room correction on a horn sub...?

http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-4.html#post2604579

Obviously I don't understand.You totally don't understand the 70% Bl specification.

I didn't know it existed, nor did I see a need to corrupt the Xmax definition.

Your explanation has helped in drawing my attention to some new standard. Does someone want to take the time to refer me to a paper or other documentation that shows what the new dimension does for us and why we need to know it?

Now it looks like there is a new definition of stroke/travel that is bigger than Xmax but which lies within a tolerable limit.

What do you call that new stroke dimension?

It can't be Xmax. It must have some other non ambiguous title.

Does it incorporate the 70 that you have mentioned?

Last edited:

Hi Andrew,

I think what Djk meant is that the BL value drops as soon displacement starts.

However, Klippel proved there is no simple relation between BL and Xmax. He also showed there is no simple relation between harmonic distortion and Xmax either. In reality this means, even when Xmax is reached it does not guarantee that the excursion is really effective in 'usable' dB's. On the other hand there are also manufacturers that produce drivers with an Xmax that can be exceeded far beyond and still having large amounts of linear displacement in the right enclosures.

Xmax figures are usually food for misconceptions. Each driver has its own specific properties and each driver responds different to their load. Therefore is Xmax nothing more than an indication. Knowing the brand and its reputation and knowing the way they measure Xmax usually helps to expect what might happen. Measuring the real thing (in dB’s instead of mm) is the only guarantee.

I think what Djk meant is that the BL value drops as soon displacement starts.

However, Klippel proved there is no simple relation between BL and Xmax. He also showed there is no simple relation between harmonic distortion and Xmax either. In reality this means, even when Xmax is reached it does not guarantee that the excursion is really effective in 'usable' dB's. On the other hand there are also manufacturers that produce drivers with an Xmax that can be exceeded far beyond and still having large amounts of linear displacement in the right enclosures.

Xmax figures are usually food for misconceptions. Each driver has its own specific properties and each driver responds different to their load. Therefore is Xmax nothing more than an indication. Knowing the brand and its reputation and knowing the way they measure Xmax usually helps to expect what might happen. Measuring the real thing (in dB’s instead of mm) is the only guarantee.

If you are referri.g to the fir plywood that has kraft paper bonded to two faces then go for it. It's good stuff. Used lots of it.

Im not sure If it is the same thing, but if it is then that's good news. Here in AUS its $80 for 2.4m X 1.2m sheet, compared to marine ply (next best aus thing to baltic birch) is $190+ for the same sized sheet. I thought the fact that its laminated may help reflecting sound through the box a bit better and may also help resonances due to probably being inferior to marine ply (maybe).

I'm guessing it is the same thing. Concrete is pretty much the same thing no matter where you work with it. The plywood is pretty much void free.

Keep in mind I have built with OSB (strand board) and cheaper poplar industrial plywoods with good effect. Keep your box well braced and you will do fine with most sheet goods.

The stiffer the box the higher the efficiency.

Keep in mind I have built with OSB (strand board) and cheaper poplar industrial plywoods with good effect. Keep your box well braced and you will do fine with most sheet goods.

The stiffer the box the higher the efficiency.

i just purchased construction ply from bunnings to do my next two SS15 cabs. its a bit crappy tho, has knots and voids all through it  but i didnt want to pay for the premium stuff so ultimately its my own problem. i do however have an issue with the sizing.

but i didnt want to pay for the premium stuff so ultimately its my own problem. i do however have an issue with the sizing.

my first cut for the side panels, had to be adjusted, which i didnt do before cutting

aus sheets are 1200x2400, not 8foot by 4foot. (1220x2440) so, ive already adjusted my cuts to suit, but where/what would you guys adjust in the plans to suit the smaller sheets? (so i can be sure i made the right educated guesses)

my first cut for the side panels, had to be adjusted, which i didnt do before cutting

aus sheets are 1200x2400, not 8foot by 4foot. (1220x2440) so, ive already adjusted my cuts to suit, but where/what would you guys adjust in the plans to suit the smaller sheets? (so i can be sure i made the right educated guesses)

when i went to get mine there was only two sheets left. So basically i got what was there. Lol. Both sheets had knots all through one layer on one side. I found more as i cut in. Thankfully i use PU glue which swells as it dries so should fill any gaps. was exactly the same with the boxes i build previously so its not a new scenario....

when i went to get mine there was only two sheets left. So basically i got what was there. Lol. Both sheets had knots all through one layer on one side. I found more as i cut in. Thankfully i use PU glue which swells as it dries so should fill any gaps. was exactly the same with the boxes i build previously so its not a new scenario....

So it does not drasticly effect sound?

....

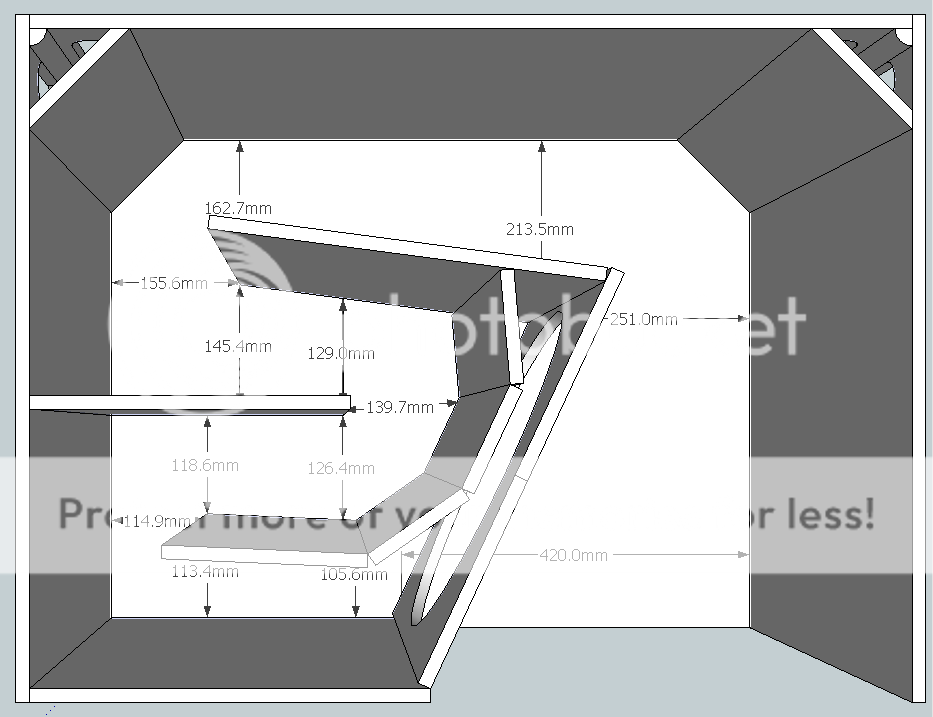

DISCLAIMER FOR ANYONE BROWSING THIS THREAD: THIS IS NOT THE OFFICIAL JBELL LAYOUT

As you can see, my path divider coming from the top of the horn is perpendicular to the top, and not angled like yours. However observing the cross sections, this seems to yield a good expansion on paper. It would be great if you could write your measurements more legibly for me

Still waiting for my Delivery of Eminences....

Oh and one more thing: what's this threads opinion on a good finish. Speaker felt, or some kind of robust paint? I already have edge rails and corner protectors on the way.

Did you test these at all? I love the idea of a lower frequency ss15?

We will have an extra sheet to use up!

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge