So Mr r23d has finished the final pair of SS15`s and all the Unity horns...Here they are on their first outdoor outing.

We`re running the SS15`s up to 200hz at the moment which is not ideal and we`ll be working on either a third tap on the Unities or a low mid horn....

More to come!

Phil

We`re running the SS15`s up to 200hz at the moment which is not ideal and we`ll be working on either a third tap on the Unities or a low mid horn....

More to come!

Phil

i have a question regarding just my first built cab.

i built it as an SS15, but knowing i was only using a 12inch driver. this particular cab is active, so has the amp on the back, what im wondering, is that the amp has potential to drive this one cab differently to two others even with the same driver in it. so, if i do decide to keep it as a one off for smaller gigs, im thinking about leaving the 12inch hole as is, but putting a spacer ring on it so i can still fit the 15inch driver and not have the suspension slap the baffle board.

will having a 12inch hole act like a compression chamber? how would i be best to simulate this on HR??

i built it as an SS15, but knowing i was only using a 12inch driver. this particular cab is active, so has the amp on the back, what im wondering, is that the amp has potential to drive this one cab differently to two others even with the same driver in it. so, if i do decide to keep it as a one off for smaller gigs, im thinking about leaving the 12inch hole as is, but putting a spacer ring on it so i can still fit the 15inch driver and not have the suspension slap the baffle board.

will having a 12inch hole act like a compression chamber? how would i be best to simulate this on HR??

Ok, so my friend DJIM gently got me to act on this.... I haven't touched the ss15 design in months -- it just works so well.

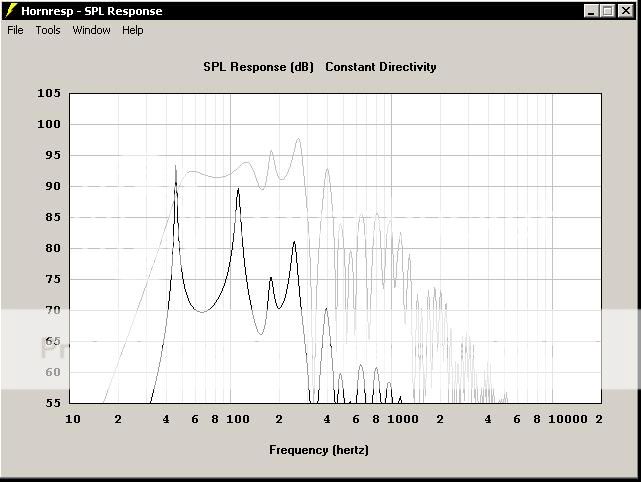

The only downside for me, is that it is not a 'flat to 40' box. And I'm big on flat to 40.

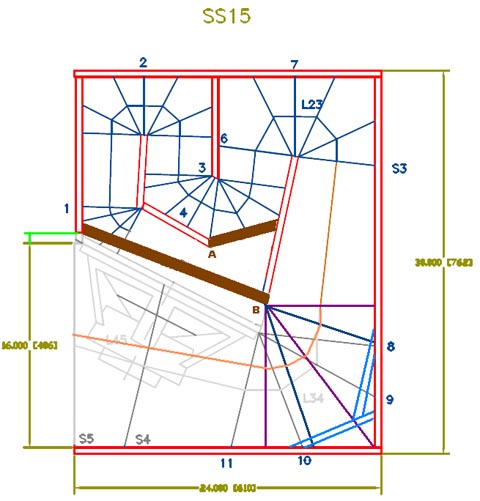

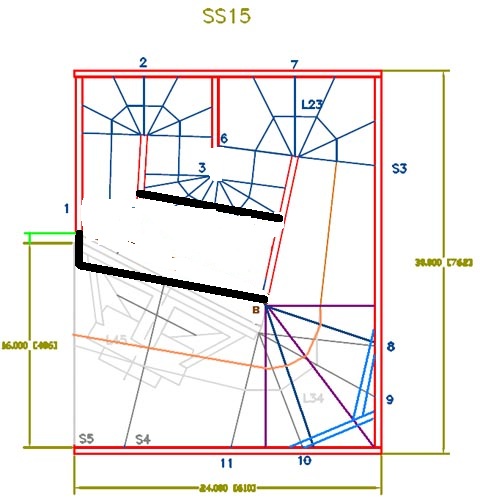

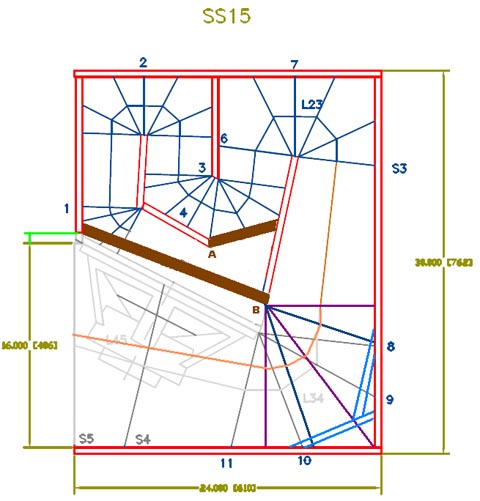

So, a bit of 'S2 cone correction' instead of a compression plate.

1" taller and 1" narrower...

and the SS15 can now hit with authority an honest to goodness 40hz.

This is still on paper and hornresp only, and it'll be a week or so before I can build/test... But I do have assembled 'original' SS15 cabinets, and I can do an A-->B comparison.

It "should" eliminate the one glaring weakness I see in the ss15. And it still does it from a single sheet, but this time you really do have nothing but sawdust left over... You even have to use the driver disk cut out from the baffle board as bracing.

Any more on this?

i was looking at this

this cone corection is only 2 dimensional

a cone has 3 dimensions.

i think creating a chamber would help to save the cone(at the expence of a dip above 100 hz)

mij new project is a conical rectangular th with chamber with the 18 sound 21nlw9000.

chamber size depending on the 8 or 4 ohm version>depending on wich amp.

probaply powersoft 3000pfc or pwr dsp1

this cone corection is only 2 dimensional

a cone has 3 dimensions.

i think creating a chamber would help to save the cone(at the expence of a dip above 100 hz)

mij new project is a conical rectangular th with chamber with the 18 sound 21nlw9000.

chamber size depending on the 8 or 4 ohm version>depending on wich amp.

probaply powersoft 3000pfc or pwr dsp1

Last edited:

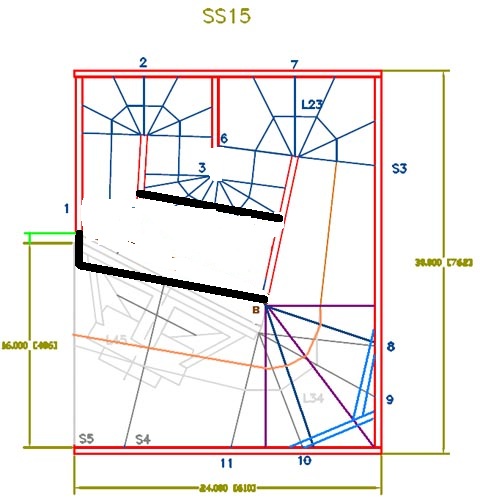

EPA or anyone else... how would I take that design and plug it into HornResp??

For example if I wanted to tweak the SS15 on paper, how do I translate the s1, s2, s3 numbers to get an estimated response?

Reason I am posting here and not in another thread is because I also want to help out with calculations while learning more about hornresp and TH Design...

For example if I wanted to tweak the SS15 on paper, how do I translate the s1, s2, s3 numbers to get an estimated response?

Reason I am posting here and not in another thread is because I also want to help out with calculations while learning more about hornresp and TH Design...

Hi Epa,this cone corection is only 2 dimensional

a cone has 3 dimensions. i think creating a chamber would help to save the cone(at the expence of a dip above 100 hz)

Cone correction doesn’t need to be three dimensional. Acoustic-air only reacts to volume in relation to its position on the horn-path. If that wasn’t the case we couldn’t use braces at all.

If you really want to use a chamber make sure you optimise the throat by a 'trumpet' shape rather than 'sharp' angled corners and if possible position the throat on the opposite side of the centre of the driver.mij new project is a conical rectangular th with chamber with the 18 sound 21nlw9000.

Never worked with that driver but it looks like a 'heftig dingetje' ;

Small correction: "Acoustic-air" should be "The cone".Acoustic-air only reacts to volume in relation to its position on the horn-path. If that wasn’t the case we couldn’t use braces at all.

Hi klampykixx,

Posts #1592/1585: "i currently have a 12inch driver in it. so it has a 12inch hole. i want to use a 15inch driver in it but dont think i can get a jigsaw in there to make it 15inch. so its either leave it as 12inch, or make a standoff ring 15inch diameter"

You should be OK with an adaptor ring: make an adaptor/standoff ring to fit the 15" with enough room to prevent the cone/surround from hitting the wood.

If you want to know what it does at low levels: enter the driver data and horn data into Hornresp, measure/calculate the throat chamber details, and enter them into Hornresp as Vtc/Atc/Ap1/Lpt.

If you have trouble working with Hornresp go here: Simple Tapped Horn Tutorial using Hornresp .

Regards,

Posts #1592/1585: "i currently have a 12inch driver in it. so it has a 12inch hole. i want to use a 15inch driver in it but dont think i can get a jigsaw in there to make it 15inch. so its either leave it as 12inch, or make a standoff ring 15inch diameter"

You should be OK with an adaptor ring: make an adaptor/standoff ring to fit the 15" with enough room to prevent the cone/surround from hitting the wood.

If you want to know what it does at low levels: enter the driver data and horn data into Hornresp, measure/calculate the throat chamber details, and enter them into Hornresp as Vtc/Atc/Ap1/Lpt.

If you have trouble working with Hornresp go here: Simple Tapped Horn Tutorial using Hornresp .

Regards,

And done (for now!).

Can't wait for the first full power field test on the weekend, then I'll finish em in texture paint if I'm happy with everything.

One SS15 and two (sort of...) HS12

Damn the Kappa Prof 15LF2 is heavy. Going to have to look at paying the 100 bucks extra for the neodymium 3015LF. I think it's worth it for the weight savings and the extra xmax.

Can't wait for the first full power field test on the weekend, then I'll finish em in texture paint if I'm happy with everything.

One SS15 and two (sort of...) HS12

Damn the Kappa Prof 15LF2 is heavy. Going to have to look at paying the 100 bucks extra for the neodymium 3015LF. I think it's worth it for the weight savings and the extra xmax.

got any more info on those top cabs? ^^

here is a trial session of my gear. just waiting for my new JB1500N drivers. ordered two. due friday 3rd august.

the center cab is an SS15 design, with a Fusion car audio sub. EncounterHD 12inch. ENSW12HD.

http://s930.photobucket.com/albums/ad150/klampykixx/?action=view¤t=02082012010.mp4

sorry about the crappy quality.

here is a trial session of my gear. just waiting for my new JB1500N drivers. ordered two. due friday 3rd august.

the center cab is an SS15 design, with a Fusion car audio sub. EncounterHD 12inch. ENSW12HD.

http://s930.photobucket.com/albums/ad150/klampykixx/?action=view¤t=02082012010.mp4

sorry about the crappy quality.

Last edited:

got my JB1500N's today

just had em pumping for a brief period at what i think was about 70% of what theyre capable of. must say, im quite pleased with them. they sound solid thats for sure.

i must admit tho first impression tells me theyre not as deep as the old china subs i had. but they should get deeper as they run in. theyre pretty stiff.

anyone recommend run in tracks?

just had em pumping for a brief period at what i think was about 70% of what theyre capable of. must say, im quite pleased with them. they sound solid thats for sure.

i must admit tho first impression tells me theyre not as deep as the old china subs i had. but they should get deeper as they run in. theyre pretty stiff.

anyone recommend run in tracks?

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge