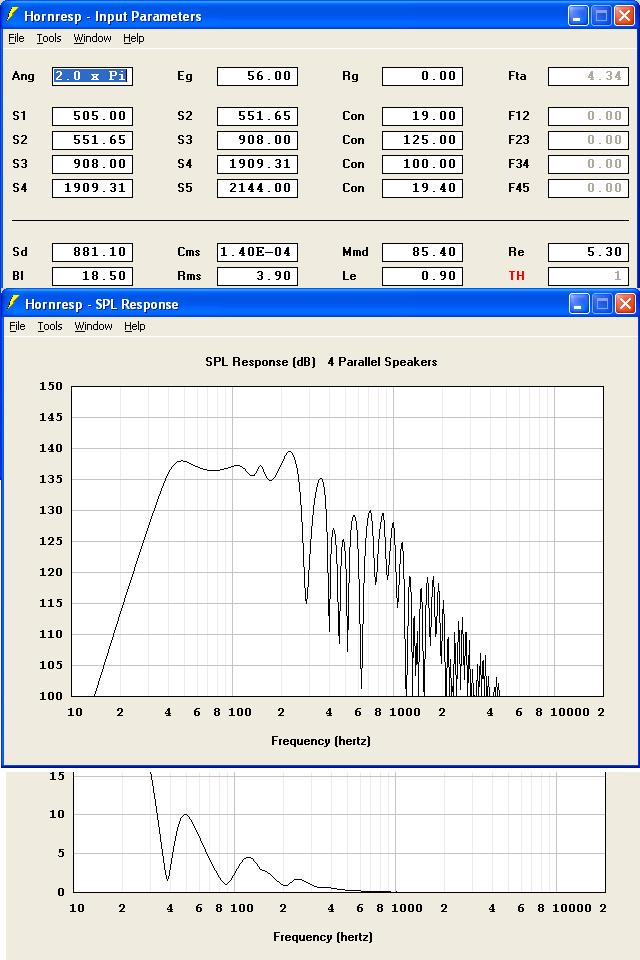

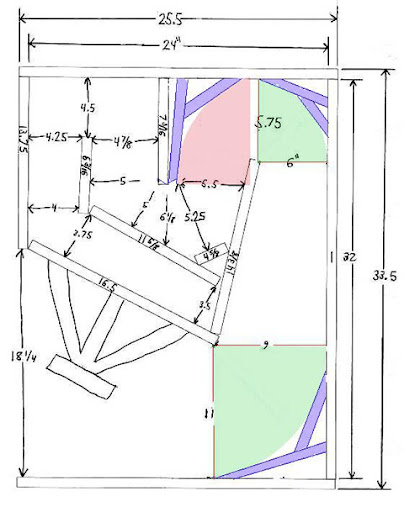

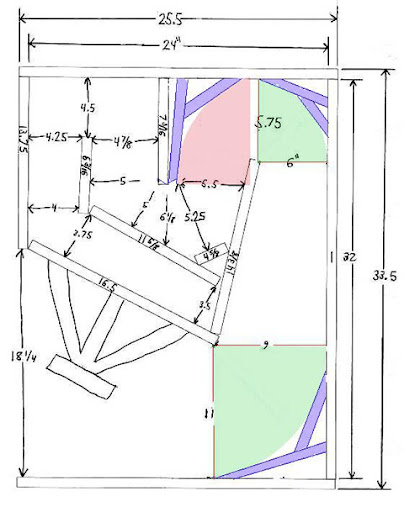

This is my rendition of Jim's SSTH15 using 3/4" ply. It sims a little better, go's lower with more SPL than the original, but uses more wood. I added an extra board in the top center to remove the restriction whare the 5.5" widths are now and dropped the bottom about 2" to remove the last restriction. When unfolded all the main lines line up almost perfectly. I did it all by hand and I think it came out pretty good. Maybe someone could draw it electronicly for me. The only other copy I have is a full scale 1 to 1 drawing I did by hand and a half hight unfolded drawing.

Andy

Andy

Attachments

Well, this answer is only....EXACTLY what I was looking for

So, with the system setup this way, will the drivers/amp not get damaged from under-powering and hitting the limiter constantly (IF the performer treats the mixer's output to do so)?

Using the SS15 as an example, how does this setup compare (other than dollars & cents) to a setup where the amp has 500W/63V to 1000W/89V rms available per driver with the brick wall limiter set to a few dB below 63V?

Last, but not least: I remember you speaking of going from the amp output to a top, that top to the subs and the subs to the other top. This is with using 12GA ext cord for speaker wire with speakons, right? Would you mind further explaining how this all works?

Regards,

Justin

Here's the bit of info I think you are looking for. The xti's have binding post or speakon's for speaker out connections. Channel 1 connection is a 2 pole speakon (has both channel 1 and 2) and channel 2 has only a single (channel 2 only) speakon.

Make up several lengths of 2 channel speakon connector cables using extension cord, White to Channel 1 +, Black to Channel 2+ and Green to Channel 1 and 2 minus. On all cabinets wire a pair of speakons with all 4 connectors in parallel, and for your tops take 1+ and 1- to your crossover/drivers, on your subs take 2+ and 2- to your sub drivers. You can then run from your amp to whatever cabinet is closest, and daisy chain your tops/subs in whatever manner works best.

One xlr connector from your mixer to your amp, one speakon connector from your amp to all of your speaker cabinets.

Chimp proof.

As to your amp question, limiting at 250watts per sub, verses limiting to 500watts is about 2db difference. (the power rating of a 3015lf is 450watts, although there is evidence in a TH that a 3015lf survives a proper setup up past the 450watt rating.) I think your question is more in line with a soft limiter and the crest available from a bigger capacity amp on a soft clip vs a brick wall limiter. My opinion -- Brick wall is brick wall. I also think that of the folks that don't like xti's for running subs -- this is exactly the issue. The xti puts out rated power, that's it. For folks that depend on a crest above the power rating of the amp to get through the evening -- they are disappointed in xti's.

If you 'really' need that 2db or more, a 3rd sub gets you slightly more output than going to a bigger amp (because of power compression), and a 3rd sub with a bigger amp gets you even more -- it's all about how much do you need. I've not seen anyone destroy a 3015lf driver by clipping/overdriving the input on an xti1000 -- it just sounds bad.

Last edited:

This is my rendition of Jim's SSTH15 using 3/4" ply. It sims a little better, go's lower with more SPL than the original, but uses more wood. I added an extra board in the top center to remove the restriction whare the 5.5" widths are now and dropped the bottom about 2" to remove the last restriction. When unfolded all the main lines line up almost perfectly. I did it all by hand and I think it came out pretty good. Maybe someone could draw it electronicly for me. The only other copy I have is a full scale 1 to 1 drawing I did by hand and a half hight unfolded drawing.

Andy

Andy:

Do yourself a favor, build one with 3/4" cdx and test before you cut into all of your beautiful expensive baltic birch.

Thanks Oliver I realy, realy appreciate it!I could put your drawing into Acad, it may take until this weekend though. What is the actual thickness of the plywood you are using, 18mm? You could take a stack of 10 pieces of scrap, and measure that. These are your final dimensions?

Yes these are the final dimensions. It looked good unfolded and simed.

I will be using 18mm thick plywood.

Can Acad do the path dimensions and the unfolded drawing too?

Andy

Jim; Wish I could but the money man wants to test two with the good plywood. We had to order 25 sheets so we sould have a few extra, if the 1st two end up only being good for bonfires. AndyDo yourself a favor, build one with 3/4" cdx and test before you cut into all of your beautiful expensive baltic birch.

hi jbell.

im a little confused about the thiele smal parameters of the 3015lf

there seems to be a lower bl factor on the fab specs?

did you measure yours?

regards erik

3015lf changed? - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

I was just using the 'old' eminence parameters in my sims... however I don't see much difference one vs the other in the ss15.

I should either measure or at least use the new 2010 build parameters.

tnx jim.3015lf changed? - Techtalk Speaker Building, Audio, Video, and Electronics Customer Discussion Forum From Parts-Express.com

I was just using the 'old' eminence parameters in my sims... however I don't see much difference one vs the other in the ss15.

I should either measure or at least use the new 2010 build parameters.

ive missed that.

thats maybe we dont use eminence as much on this side of the pond

Is this question to simple or to hard to have no replys yet?The over all path leght is about 97.875" long, but do you do the box resonance from S1 to S5 or S2 to S4 in a tapped horn.

Andy

Hi 4pyros,

If you are thinking about a resonance frequency as in a bass reflex enclosure, the tapped horn doesn't work that way. Take a look at the impedance curve in Hornresp, it may help. Otherwise, maybe these threads by Don Snyder will be of use:

http://www.diyaudio.com/forums/subwoofers/179653-elements-tapped-horn.html

http://www.diyaudio.com/forums/subwoofers/135879-evolution-tapped-horn.html

Regards,

If you are thinking about a resonance frequency as in a bass reflex enclosure, the tapped horn doesn't work that way. Take a look at the impedance curve in Hornresp, it may help. Otherwise, maybe these threads by Don Snyder will be of use:

http://www.diyaudio.com/forums/subwoofers/179653-elements-tapped-horn.html

http://www.diyaudio.com/forums/subwoofers/135879-evolution-tapped-horn.html

Regards,

Thanks Oliver I will look at that. Ya the mouth area thru me off to. AndyIf you are thinking about a resonance frequency as in a bass reflex enclosure, the tapped horn doesn't work that way. Take a look at the impedance curve in Hornresp, it may help. Otherwise, maybe these threads by Don Snyder will be of use:

OK Djim; A peeny for your thoughts. The braces in the corners were put there to stiffen the box, eliminate parallel sides and take up some of the volume in the big corners. The top one may not even be needed now that I added the extra angled board in the middle. They were not dimensioned because thay will be made from what ever is left over after the rest of the box is cut. I dont think the dimensions are critical as long as the angel is graiter than 11 degrees.I also plane on doing some central bracing from the back, across the lower part of the speaker mount piece, to the bottom. Its just not on the drawing. What are your thoughts? AndyI don’t know how accurate your drawing is but it looks like your corner corrections (corner bracing) can be improved.

Andy, a couple of months ago there were some discussions about bending in TH’s (Jbells "flute theory") Since then I have read a lot about bending in 'big' flutes/horns. Besides that I also have been talking to instrument makers and engineers that are involved with butane gas installation (high pressure) who also work a lot with bending.

Anyways, it’s not the parallel walls (resonance) you should worry about but it’s about so called ‘non-gentle-bending”. This is often represented in 90 degree bends in TH’s. Instead of resonances it’s the difference in speeds of the air molecules (high mass - low mass as result of those speed differences) that can cause errors in the output. For instance if you have two 180 degree bends in a ‘S’ form construction, they both will equalise the speed as result of the ‘S’ form (opposite bending construction). You can call such construction a gentle bending.

But many TH designs have often two 90 degree bends that are not the opposite of each other. They bend in the same direction and therefore amplify the speed differences. In that case your bends can benefit from corner corrections to optimise the pathway.

Instead of one corner brace I use at least two braces per corner to get a more ideal pathway. In realy big corners I use at least 3 bracings to come closer to the ideal path. I'll use your drawing as an example...

Anyways, it’s not the parallel walls (resonance) you should worry about but it’s about so called ‘non-gentle-bending”. This is often represented in 90 degree bends in TH’s. Instead of resonances it’s the difference in speeds of the air molecules (high mass - low mass as result of those speed differences) that can cause errors in the output. For instance if you have two 180 degree bends in a ‘S’ form construction, they both will equalise the speed as result of the ‘S’ form (opposite bending construction). You can call such construction a gentle bending.

But many TH designs have often two 90 degree bends that are not the opposite of each other. They bend in the same direction and therefore amplify the speed differences. In that case your bends can benefit from corner corrections to optimise the pathway.

Instead of one corner brace I use at least two braces per corner to get a more ideal pathway. In realy big corners I use at least 3 bracings to come closer to the ideal path. I'll use your drawing as an example...

In regards to grills, I read jbell's intention of using the Dayton square grill: http://www.parts-express.com/pe/pshowdetl.cfm?&Partnumber=262-898&scqty=1

You get 1 pair - each grill is just 2 inches shy of getting 2 SS15 grills from 1 Dayton grill for $55. You've got quite a bit left over... Looks like a bit of wasted grill..

Has anyone had success with other gill material/brand?

Justin

You get 1 pair - each grill is just 2 inches shy of getting 2 SS15 grills from 1 Dayton grill for $55. You've got quite a bit left over... Looks like a bit of wasted grill..

Has anyone had success with other gill material/brand?

Justin

Last edited:

Djim; So you are saying the additional deflectors would keep the air molecules moving faster around the outside of the bends? I read that 45 degree deflectors are no good, your thoughts? Should I do the corners of the other 180 degree bend as well? Would it be worth it to use one half of a 10" pipe in that bend?

Thanks Andy

Thanks Andy

Last edited:

Justin; I am using expanded and flattened aluminum with 1 X 3/8 slots mainly to keep the mice out. Picked up 2 4'X8' sheets from a local aluminum supplyer for $75 total. Its listed in McMasterCarr for a lot more.Has anyone had success with other gill material/brand?

Andy

Last edited:

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge