Brian,Something really looks a bit off there. Did you do an impedance response test on your SS15 to see if it was a good match for the HornResp model?

Indoor room modes often dominate low frequency measurements. Move the microphone or the speaker around and the response will change.

The indoor warehouse response simply reflects the "boom boom room" effect, their previous outdoor tests match the "normal" SS15 response pretty closely, as can be seen in the two screen shots of the same speakers below.

Left is in the warehouse, right is outdoors.

Attachments

Last edited:

Hi

I`ll have to ask Mr Rich ( R23d) about the hornresp modelling, he plugged in most of the data and we only made some small changes to match the RCF drivers.

As for the difference between indoors and outdoors I`ll have to go back to my statement of Holm Impulse giving us some very strange readings. It seems to fill in the gaps until it gets stable enough to plot properly. The REW measurements are very good and reflect what my ears think the boxes are doing. We tried running full range sweeps with Holm on the Unities and Subs combined outdoors. It just couldn`t give us an accurate reading with all the passband gains set at relative volume, it would seem to latch onto the highs and ignore the subs / mids.

NOW I must confess I hardly know the program and was intrigued to try it out. Again if I had the time to sit down with it and work out why we getting these results I`d love to! BUT time meant we moved to REW and now have two sets of results on two different measurement programs......not ideal or helpful!!

The warehouse we measured in was VERY big but full of clutter. Also we measured from 3-4m away on initial runs. So even with the mic pointing at the floor from < 1cm we might have got some room modes.The very first measurement runs were made with temp barn doors on one box at about 2am....not too scientific!

I personally am very happy with the result the doors give. We knew the subs were never going to reach 35hz or be 6db louder with them but they have added a simple, cheap way of getting nearer to that!

Phil B

I`ll have to ask Mr Rich ( R23d) about the hornresp modelling, he plugged in most of the data and we only made some small changes to match the RCF drivers.

As for the difference between indoors and outdoors I`ll have to go back to my statement of Holm Impulse giving us some very strange readings. It seems to fill in the gaps until it gets stable enough to plot properly. The REW measurements are very good and reflect what my ears think the boxes are doing. We tried running full range sweeps with Holm on the Unities and Subs combined outdoors. It just couldn`t give us an accurate reading with all the passband gains set at relative volume, it would seem to latch onto the highs and ignore the subs / mids.

NOW I must confess I hardly know the program and was intrigued to try it out. Again if I had the time to sit down with it and work out why we getting these results I`d love to! BUT time meant we moved to REW and now have two sets of results on two different measurement programs......not ideal or helpful!!

The warehouse we measured in was VERY big but full of clutter. Also we measured from 3-4m away on initial runs. So even with the mic pointing at the floor from < 1cm we might have got some room modes.The very first measurement runs were made with temp barn doors on one box at about 2am....not too scientific!

I personally am very happy with the result the doors give. We knew the subs were never going to reach 35hz or be 6db louder with them but they have added a simple, cheap way of getting nearer to that!

Phil B

Thanks

As a new person to this site I just want to say thanks. This thread is an example of the collaboration that is the very best of the internet. I plan to build four to six of these this summer as a church youth group project. I am trying to create an initial lead booklet on the project for the kids and this thread at over 150 pages and 1500 posts has become a monster to navigate and extract the latest/best information from. Would it be possible to pull out and collect at the top of the thread:

1)The latest cutsheet

2)Recommended materials including adhesives and finishes

3)Assembly tips including where additional bracing may be wise even if they don't come out of a single sheet

4)Tips on finishing

3)Thoughts on best locations and options for handles, pole sockets, input panels.

4)Recommended drivers, response simulations for those drivers, real world measurements for those drivers

5)Recommended signal processing and amplifier power

Again this is a thread for the ages thanks to all the collaborators.

As a new person to this site I just want to say thanks. This thread is an example of the collaboration that is the very best of the internet. I plan to build four to six of these this summer as a church youth group project. I am trying to create an initial lead booklet on the project for the kids and this thread at over 150 pages and 1500 posts has become a monster to navigate and extract the latest/best information from. Would it be possible to pull out and collect at the top of the thread:

1)The latest cutsheet

2)Recommended materials including adhesives and finishes

3)Assembly tips including where additional bracing may be wise even if they don't come out of a single sheet

4)Tips on finishing

3)Thoughts on best locations and options for handles, pole sockets, input panels.

4)Recommended drivers, response simulations for those drivers, real world measurements for those drivers

5)Recommended signal processing and amplifier power

Again this is a thread for the ages thanks to all the collaborators.

I echo Dynamic's request.

An index in post1, showing links to the best bits of information would be really helpful to everyone reading this Thread.

I've pm'd mods a couple times with the same request. If we can get moderator approval, I'd sure like to edit post 1 for just exactly that.

moderator? please??

Overlaid plywood panels

Last summer we built eight homebrew microwedges and after looking at how dented and dinged they are after just one year of teenagers moving them around, I think we need something more durable than standard plywood for our subwoofer build. I am thinking http://www.olypanel.com/common/pdf/SkidGuard Prod Lit - 11-07.pdf for all external panels. My rough math indicates we could cut all the external panels for six SS15s from five panels of Skid Guard and all the remaining internal parts from two standard ply panels. We can buy Skid Guard locally from a company that uses it to build docks. I guess we will bite the bullet and use baltic birch for the internal panels as there is no more Arauco plywood available around here, pretty soon there won't be any anywhere given the factory burned down. http://www.araucoply.cl/informacion.asp?tipo=2&idq=6322&parent=0

Last summer we built eight homebrew microwedges and after looking at how dented and dinged they are after just one year of teenagers moving them around, I think we need something more durable than standard plywood for our subwoofer build. I am thinking http://www.olypanel.com/common/pdf/SkidGuard Prod Lit - 11-07.pdf for all external panels. My rough math indicates we could cut all the external panels for six SS15s from five panels of Skid Guard and all the remaining internal parts from two standard ply panels. We can buy Skid Guard locally from a company that uses it to build docks. I guess we will bite the bullet and use baltic birch for the internal panels as there is no more Arauco plywood available around here, pretty soon there won't be any anywhere given the factory burned down. http://www.araucoply.cl/informacion.asp?tipo=2&idq=6322&parent=0

PRO Audio 15" sub with Dayton (295-034)

Slideshow above with the pair I am working on the gallery will update as I finish them.

Changes

Made them 23" wide compared to the 22" wide.

I changed to 3/4" Birch Maple plywood also.A lot stronger as the use will be for a rough and tough band.

I made the PRO monitors they are using with a Kappa 15" beta Eminence 10 and a coax Selenium 2500Ti tweeter.

Hope to get the pair of subs firing in the next few days

Slideshow above with the pair I am working on the gallery will update as I finish them.

Changes

Made them 23" wide compared to the 22" wide.

I changed to 3/4" Birch Maple plywood also.A lot stronger as the use will be for a rough and tough band.

I made the PRO monitors they are using with a Kappa 15" beta Eminence 10 and a coax Selenium 2500Ti tweeter.

Hope to get the pair of subs firing in the next few days

PRO Audio 15" sub with Dayton (295-034)

Slideshow above with the pair I am working on the gallery will update as I finish them.

Changes

Made them 23" wide compared to the 22" wide.

I changed to 3/4" Birch Maple plywood also.A lot stronger as the use will be for a rough and tough band.

I made the PRO monitors they are using with a Kappa 15" beta Eminence 10 and a coax Selenium 2500Ti tweeter.

Hope to get the pair of subs firing in the next few days

A couple comments:

First the ply you chose, while it is thicker, I think you'll have issues with... The outer ply is VERY thin and will separate easily. Any place you had brads, you might think of adding screws, you don't want your cabinet coming apart. Your yellow glue is only adhered to a thin ply on all of your butt joints.

Also, It'll split and splinter on the edges. (in fact on the next to last pic in slide show, isn't the outer ply separated a bit?? To help that, put a nice 45 degree with a router bit on all of your corners. Roundovers don't help, but 45's do. It's either that, or get some aluminum/steel corner material to add some protection. If you want cheap corner material... look in the roofing section at your local lumber yard. (the corner material will look good, keep the cabinet strong, and hide the extra screws just mentioned)

Second. While the dayton has a good strong motor, it has only 5.0mm xmax. This means keep it under 200 watts in the ss15 to stay within your xmax rating.

Last, while I like yellow glue for nice tight good fitting joints... in the ss15, where the joints aren't "exact" polyurethane expanding construction adhesive (like PL premium poly) is almost a must.

Thanks for sharing, hope the above is helpful -- take measurements along with your pictures when complete.

Thanks for the comments.

Few things the plywood used is no issue I have used it on hundreds of cabinets

Yes the outer skin can peel in and around some edges. Not shown is the 1/8 round over on all edges. plus yes all joints are assembled with 2 1/8" brads along with yellow glue then PL premium poly on all joints.

Last I use PL on all plywood edges Smooth coat then let dry and sand . Final touch ups and then paint.

Smooth coat then let dry and sand . Final touch ups and then paint.

When i am building cabinets this big I use PL when ever I can.

As for the driver I am sure it will be fine

The throat will have mesh installed in the next few days.

Few things the plywood used is no issue I have used it on hundreds of cabinets

Yes the outer skin can peel in and around some edges. Not shown is the 1/8 round over on all edges. plus yes all joints are assembled with 2 1/8" brads along with yellow glue then PL premium poly on all joints.

Last I use PL on all plywood edges

When i am building cabinets this big I use PL when ever I can.

As for the driver I am sure it will be fine

The throat will have mesh installed in the next few days.

A couple comments:

First the ply you chose, while it is thicker, I think you'll have issues with... The outer ply is VERY thin and will separate easily.

I've found that a couple coats of thinned wood glue (the yellow "aliphatic resin" type) on the edges usually helps to decrease this significantly.

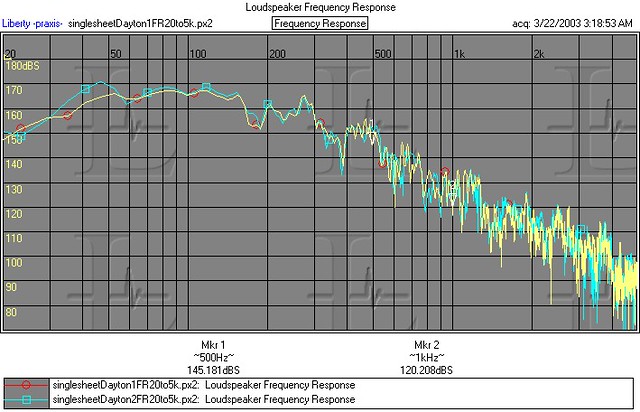

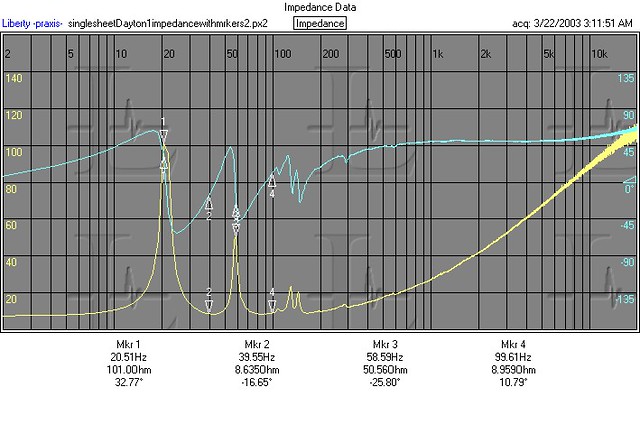

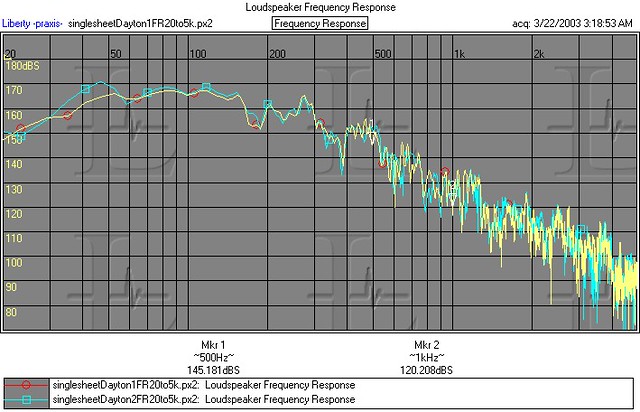

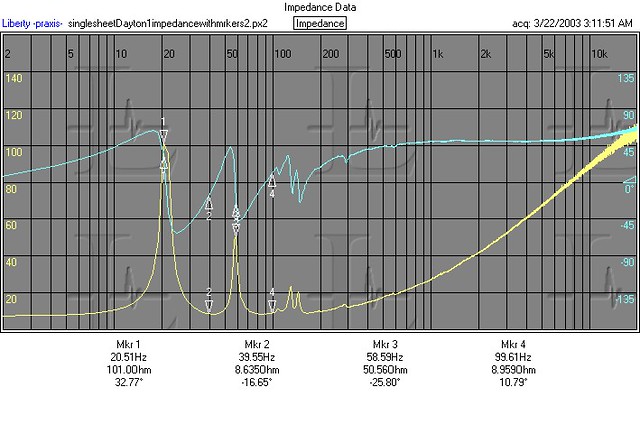

OK took a few quick measurements before the band picked them up today.

Here is a impedance of one of them.

OK on the slideshow link you will see the progress to finished speakers.The paint nothing great just rolled on Tremclad that is it.The band wanted to carpet them after the show.Time was important they would have taken them unfinished.

PRO Audio 15" sub with Dayton (295-034)

I also used the router to inset the handles without cutting threw into the cabinets.

Placement is not centered for weight reasons.This way you carry them evenly not tilted as if the handles would have been in the center.

Here is a impedance of one of them.

OK on the slideshow link you will see the progress to finished speakers.The paint nothing great just rolled on Tremclad that is it.The band wanted to carpet them after the show.Time was important they would have taken them unfinished.

PRO Audio 15" sub with Dayton (295-034)

I also used the router to inset the handles without cutting threw into the cabinets.

Placement is not centered for weight reasons.This way you carry them evenly not tilted as if the handles would have been in the center.

Hiya! I just ordered some drivers and wood for 1 SS15 and 2 HS12 (sort of...).

I wanted to ask about the PU adhesive. Since I can't get PL Premium here in Germany (as far as I can find so far), does anybody know if the Pattex PU stuff is as suitable?

PU Schaum universal 500ml - Produktinformationen - Pattex PU Schaum

Maybe Ben (salzburgsoundsystem) happens to be reading this, and can mention what kind of PU he uses....

Since there's been no feedback (as of yet) from jbell on the new design, I figured what the hell, and will be building the new (cone volume compensated) design, I hope it works out well. I'll definitely need to buy a new measurement mic and/or SPL meter once I get these done, looking forward to increasing my workshop.

Just wanted to say thanks for your design work, jim!

I wanted to ask about the PU adhesive. Since I can't get PL Premium here in Germany (as far as I can find so far), does anybody know if the Pattex PU stuff is as suitable?

PU Schaum universal 500ml - Produktinformationen - Pattex PU Schaum

Maybe Ben (salzburgsoundsystem) happens to be reading this, and can mention what kind of PU he uses....

Since there's been no feedback (as of yet) from jbell on the new design, I figured what the hell, and will be building the new (cone volume compensated) design, I hope it works out well. I'll definitely need to buy a new measurement mic and/or SPL meter once I get these done, looking forward to increasing my workshop.

Just wanted to say thanks for your design work, jim!

Hi James.

My German is rusty, but what you have a link to is not quite the same thing. The polyurethane adhesive is a thickend type that comes in caulking tubes. It has wonderful gap filling properties and expands as it cures. The catalyst is water either from the ambient air or from judicious application via a damp sponge to one side of your joinery.

My German is rusty, but what you have a link to is not quite the same thing. The polyurethane adhesive is a thickend type that comes in caulking tubes. It has wonderful gap filling properties and expands as it cures. The catalyst is water either from the ambient air or from judicious application via a damp sponge to one side of your joinery.

German Equivalent for PL Premium

Hi there (bzw. Servus Nachbar!),

Please avoid PU Schaum. This is meant for filling gaps - for example between the wall and window frame when installing doors or windows or also pipes in holes cut in walls. It expands very much - too much - and is simply not strong enough for woodworking joints.

I built my first PA system using PU Konstruktionskleber bought in an Austrian "Baumarkt". The speaker cabinets were dropped, danced on and generally abused. When I later destroyed the 1 meter cube loudspeakers it was not so easy, the glue is stronger than the wood. It is slightly different from PL Premium.

You'll be fine using this glue.

I also have a case of PL premium glue shipped in from America. I am using this for my new system (which is almost finished, the dubhorn sixpack, and kick / mid bass bins which are still being designed) PL Premium is even harder than PU Konstruktionskleber and half the price. It is a little easier to cut / trim using a Stanley knife.

This glue is also excellent.

Regards, Ben

P.S. If you take a look at the different tubes of glue, the wrong one - PU Schaum -has a long straight tube like a straw for spraying into holes.

The right glue has a pointed nozzle which you may need to cut the tip off - much like bath sealant / silicone. many have screw caps... e.g.

or

Hi there (bzw. Servus Nachbar!),

Please avoid PU Schaum. This is meant for filling gaps - for example between the wall and window frame when installing doors or windows or also pipes in holes cut in walls. It expands very much - too much - and is simply not strong enough for woodworking joints.

I built my first PA system using PU Konstruktionskleber bought in an Austrian "Baumarkt". The speaker cabinets were dropped, danced on and generally abused. When I later destroyed the 1 meter cube loudspeakers it was not so easy, the glue is stronger than the wood. It is slightly different from PL Premium.

You'll be fine using this glue.

I also have a case of PL premium glue shipped in from America. I am using this for my new system (which is almost finished, the dubhorn sixpack, and kick / mid bass bins which are still being designed) PL Premium is even harder than PU Konstruktionskleber and half the price. It is a little easier to cut / trim using a Stanley knife.

This glue is also excellent.

Regards, Ben

P.S. If you take a look at the different tubes of glue, the wrong one - PU Schaum -has a long straight tube like a straw for spraying into holes.

An externally hosted image should be here but it was not working when we last tested it.

The right glue has a pointed nozzle which you may need to cut the tip off - much like bath sealant / silicone. many have screw caps... e.g.

An externally hosted image should be here but it was not working when we last tested it.

or

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Hi there (bzw. Servus Nachbar!),

I also have a case of PL premium glue shipped in from America. I am using this for my new system (which is almost finished, the dubhorn sixpack, and kick / mid bass bins which are still being designed) PL Premium is even harder than PU Konstruktionskleber and half the price. It is a little easier to cut / trim using a Stanley knife.

This glue is also excellent.

Servas Nachbar!

Thanks a lot for your help, very fast response, wasn't sure if you'd still be lurking here, with your SS15s built so long ago.

Wow, 6 Dubhorns sounds quite impressive.... Where will one be able to hear that system? I make it out to Salzburg occasionally, have some friends living there.

Got my wood today, 127€ for 2 sheets, enough for 2 tops and 1 sub sans bracing - gonna see what I can do in way of scraps I have at home for bracing.

Now all I need to do is wait for my drivers to arrive! And maybe find a Crown XTI amp for less than 649€......

EDIT: 12mm ply feels reaaaalllyy thin - I'm going to have to trust you on this one, jim!

- Home

- Loudspeakers

- Subwoofers

- Single sheet TH challenge