can you post the hr input?

An externally hosted image should be here but it was not working when we last tested it.

...what r the outside measurements?

The outside dimensions are 566 x 1008 x 716 mm (w x h x d).

...and made of 18mm birch ply.

...could you post a picture of the horn with dimensions on it?

Sorry, i dont have them on computer... just on paper. But from the section plan in my first post, and the hr input screen u can easily rebuild it... The width of the horn is constant 530 mm.

The outside dimensions are 566 x 1008 x 716 mm (w x h x d).

...and made of 18mm birch ply.

Sorry, i dont have them on computer... just on paper. But from the section plan in my first post, and the hr input screen u can easily rebuild it... The width of the horn is constant 530 mm.

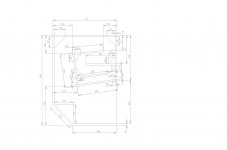

I have been reverse engineering this TH from the plan and the hornresp data.

I found that the taper varied for some of the folded sections, (the third and fourth sections are slightly shallower taper), and that the last section is stepped.

This is not meant as a criticism of what Wood1y has acheived

I think that this folding has obviously worked well.

The parallel first section has allowed extra length.

The step on the last section compensates for the area taken by the driver.

I attach a drawing of what I found, showing dimensions extrapolated from the given section plan and outside dimensions.

Attachments

I also worked it in reverse, some of the dims are a tad different. Black inches (initial guess on scale), red mm. Note that the red is the scaled dimension which has been normalized to the given external dimensions, so will be more accurate. The black inches were guessed at by looking at the woofer.

Thanks Wood1y for a great design.

Cheers, John

Thanks Wood1y for a great design.

Cheers, John

Attachments

Last edited:

Nice work guys!!

you're welcome!

Thanks Wood1y for a great design.

you're welcome!

THX

No... It is the Warnex textured lacquer... like this.

An externally hosted image should be here but it was not working when we last tested it.

Its very hard, u cant sctratch it, is waterproof and it still looks good ... I think this is the best choice for PA boxes.

Can you please share some information on the Warnex applying technique that you used?

I will have to paint a few boxes very soon.

Hey Flip. It's called Duratex here in the US. I get mine from 30 years Audio experience. Featuring Eminence speakers | Speaker Hardware. I also get wholesale prices on speakers from them. Really great service and pricing.

I use a Harbor Freight hopper gun to apply the duratex. Any other questions you have just ask, I would be glad to help you.

Mike

I use a Harbor Freight hopper gun to apply the duratex. Any other questions you have just ask, I would be glad to help you.

Mike

I know a couple of people with Rhino on rack and speaker cabs and as ute liner (tradespeople) with no chipping.I have used every type.

And it is NOT the same and also not as durable. (all have chipped)

But thanks

I have used Duratex also.

I also use the same gravity sprayer.

The Rhino lining was the best so far.

Also the one from Auto Zone worked well but both are extremely NON CLEAN UP friendly. IE don't get it on anything!

Been looking for some

different polyurea based paints and also just recently got some cement paint to test out.

I also use the same gravity sprayer.

The Rhino lining was the best so far.

Also the one from Auto Zone worked well but both are extremely NON CLEAN UP friendly. IE don't get it on anything!

Been looking for some

different polyurea based paints and also just recently got some cement paint to test out.

Any more info on applying and some pictures will be very welcomed.

Here are the brochures:

1

2

3

I think the brochures are bull****... But u can try their method if u want

First, u'll need an air compressor for this, and wil have to paint in 2 coats.

I've used 2 types of guns.

1st coat:

With a (high pressure paint gun?) (sorry, i dont know how u call it in english), its that gun, where the bottle is in the bottom...

I've used a 2mm nozzle, and 6-7 bar pressure, from 25-30 cm distance...

An externally hosted image should be here but it was not working when we last tested it.

2nd coat

With an underbody coating gun with a nozzle diameter of 8 or 9 mm, (this unerlined information isn't to find in the brochures, and cost me a lot of money.. so appreciate it

An externally hosted image should be here but it was not working when we last tested it.

... with 2-3-5 bar pressure, depends on what structure u want.

U can calculate easily with 1,2 L/m2 for the whole work.

And does anyone have a source for this stuff in the US?

Or its equivalent ?

THOMANN

They are shipping to the USA too.

Looks like a compression chamber.Compliments on a sucessful project.

I would very much like to see your input parameters for Hornresp.

Also I an very interested in the parallel horn section that is adjacent to the driver. I like how with that extra folded section you have managed to increase the length of the horn and not waste any internal space.

espacenet — Bibliographic data

Hi all!

I'm sharing here with you my tapped horn i’ve recently finished.

Nice work there!

Did you measure impedance vs. frequency? The results should indicate whether or not you achieved the 40 Hz tuning.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 15" tapped horn with RCF