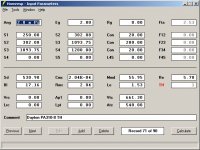

Well, I'm finally taking the plunge - gonna build me a TH based on the new Dayton 12" PA driver - the PA310-8. Specs will be similar to the ones indicated below (I'm still doing some fine-tuning). I haven't finished the folding yet, but I'm looking to fit everything into a box that's approximately 3'x2'x1' (ok, slightly wider, as the driver has to be accomodated). It's destined to be used in a small bar (the rest of the spectrum will be provided by EV ZXA1s installed in various locations). I'll probably end up using four of them, or more, depending on how much output I get from this initial build. As DJs tend to be silly with the volume knob here, I'm trying to split the load across multiple cheap subs rather than one or two more expensive ones  .

.

Attachments

Well, I'm finally taking the plunge - gonna build me a TH based on the new Dayton 12" PA driver - the PA310-8. Specs will be similar to the ones indicated below (I'm still doing some fine-tuning). I haven't finished the folding yet, but I'm looking to fit everything into a box that's approximately 3'x2'x1' (ok, slightly wider, as the driver has to be accomodated). It's destined to be used in a small bar (the rest of the spectrum will be provided by EV ZXA1s installed in various locations). I'll probably end up using four of them, or more, depending on how much output I get from this initial build. As DJs tend to be silly with the volume knob here, I'm trying to split the load across multiple cheap subs rather than one or two more expensive ones.

Clone the TH-Mini...

I've built a LOT of subwoofers, and I'd probably have to say that I've never been happier with a subwoofer than I am with my TH-Mini clone.

The usual caveats apply - for serious prosound use, the 'real' TH-Mini has more output than what I am using, and the drivers that Danley uses are known to be more durable. Seems to be a great little sub.

Also, if you're going to purchase four drivers, why not do push-pull? I've used that on the last two I built, and the difference is NOT subtle. I actually ripped apart my "Triple8" sub from diymobileaudio and flipped one of the woofers, and that made a big difference.

Last but not least, aren't you in another country? Faital Pro is more expensive than Dayton, but the shipping will cost less. Not sure what distributor you'd use, but this gives you an idea of the pricing:

http://cgi.ebay.com/FAITAL-PRO-W12N...ultDomain_0&hash=item45f29139ba#ht_2392wt_801

Last edited:

Clone the TH-Mini...

This design is probably going to a look a bit like the TH-Mini, maybe slightly thinner

Also, if you're going to purchase four drivers, why not do push-pull?

Box size. Smaller single-driver multiple boxes rather than bigger boxes with multiple drivers will serve this particular requirement (bass for a small bar) better.

Last but not least, aren't you in another country? Faital Pro is more expensive than Dayton, but the shipping will cost less.

Yup, shipping is a b*tch. I'm not sure that I will save much by going with the Faital Pro - shipping will still be high.

This design is probably going to a look a bit like the TH-Mini, maybe slightly thinner.

Box size. Smaller single-driver multiple boxes rather than bigger boxes with multiple drivers will serve this particular requirement (bass for a small bar) better.

Yup, shipping is a b*tch. I'm not sure that I will save much by going with the Faital Pro - shipping will still be high.

An externally hosted image should be here but it was not working when we last tested it.

I'd read that Faital is manufactured in Mexico, and their website indicates that they have a factory in Puebla, so it seems like they'd offer a good value to folks in South America. But I just checked the box on the woofers that I purchased from them this week, and it says "Made in Italy." Hmmm.

I'd read that Faital is manufactured in Mexico, and their website indicates that they have a factory in Puebla, so it seems like they'd offer a good value to folks in South America.

It would probably be just as expensive to ship it to me, LOL.

I might have more luck with Selenium stuff (I believe Brazil is the source for that). In fact, one of my friends built an entire PA rig (tops, midbass and horns) using Selenium components and plans they provided a few years ago and used it to provide the sounds for my brother's Carnival band. It was easily the clearest, cleanest and loudest rig on the road. OTOH, most of the competition basically seemed to be of the "what else can we fit on the truck" type.

Maybe I should give their bass drivers another look...

Hmmm...

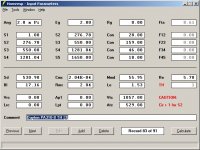

Published specs:

Vas: 2.89 cu.ft.

Fs: 44.4 Hz

Qes: 0.34

Qms: 8.63

Qts: 0.32

Le: 1.5 mH

Re: 5.7 Ohms

Measured specs:

Vas: 3.30 cu.ft. (need to confirm)

Fs: 39.0 Hz

Qes: 0.31

Qms: 7.50

Qts: 0.30

Le: 0.37 mH (!!)

Re: 5.2 Ohms

The low Le came as a big surprise. It's significantly different to the published spec. So much so that I measured the parameters of another driver with the WT3 just to ensure that it was still working (and measuring Le) properly (I got the expected Le for the test driver during those measurements). 0.37 it is.

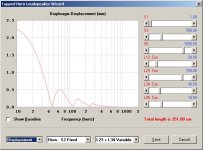

Published Xmax for the PA310-8 is 5mm, but some quick tests suggest that might be a bit on the generous side - the suspension seems to be applying the brakes quite a bit before 10mm p-p is reached and distortion quickly rises. On the plus side, I was unable to get it to bottom while driving it free air with low frequency test tones.

I'm rethinking my TH idea. Maybe I should just go with a simple EBS alignment...

Nah.

Published specs:

Vas: 2.89 cu.ft.

Fs: 44.4 Hz

Qes: 0.34

Qms: 8.63

Qts: 0.32

Le: 1.5 mH

Re: 5.7 Ohms

Measured specs:

Vas: 3.30 cu.ft. (need to confirm)

Fs: 39.0 Hz

Qes: 0.31

Qms: 7.50

Qts: 0.30

Le: 0.37 mH (!!)

Re: 5.2 Ohms

The low Le came as a big surprise. It's significantly different to the published spec. So much so that I measured the parameters of another driver with the WT3 just to ensure that it was still working (and measuring Le) properly (I got the expected Le for the test driver during those measurements). 0.37 it is.

Published Xmax for the PA310-8 is 5mm, but some quick tests suggest that might be a bit on the generous side - the suspension seems to be applying the brakes quite a bit before 10mm p-p is reached and distortion quickly rises. On the plus side, I was unable to get it to bottom while driving it free air with low frequency test tones.

I'm rethinking my TH idea. Maybe I should just go with a simple EBS alignment...

Nah.

The coil is much shorter (and less x-max) with a low value of Le.

LOL - perhaps Xmax is really 0.5mm instead of 5.0 mm?

Seriously I took a look at the coil (shone a flashlight through the spider), and it looks like there's what could be about 5mm sitting above the gap. Also, when I pushed the cone outwards, there was still a bit of coil in the gap at the point where the suspension brought the cone to a halt.

More about the PA310-8 can be seen here: Dayton PA310-8 12" Pro Woofer | Parts-Express.com

The specs claim a "Low distortion motor system w/copper cap." Perhaps that has something to do with the low measured Le.

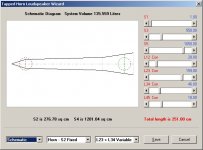

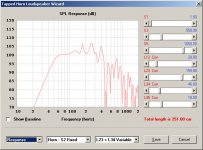

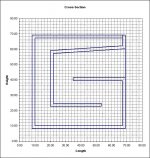

Here's the latest iteration I'm working with. It's a combination stepped and tapered TH. The cross-section drawing is the output from an Excel spreadsheet (still being tweaked) that I'm using to try to optimize the layout (using Excel's "goal-seek" function). Basically I put in a few parameters, select the "goal-seek" option, and it chucks out the cross-section in a chart. I could probably modify it to do a full-tapered cross-section, but that might end up in the path length being shortened a bit.

The question though is how should the path length around the corners be determined? At one time I thought that a simple arc would do it, but my measurements with POC #1 suggests otherwise, that actual path length lies somewhere between the arc length and the centerline (and closer to the latter).

The question though is how should the path length around the corners be determined? At one time I thought that a simple arc would do it, but my measurements with POC #1 suggests otherwise, that actual path length lies somewhere between the arc length and the centerline (and closer to the latter).

Attachments

Corners

Hi Brian,

I use the arc (center of bend) around the corner:

http://www.diyaudio.com/forums/subw...ecific-tapped-horn-thread-58.html#post1833856

This should get you close.

Regards,

Hi Brian,

I use the arc (center of bend) around the corner:

http://www.diyaudio.com/forums/subw...ecific-tapped-horn-thread-58.html#post1833856

This should get you close.

Regards,

Hi Brian,

I use the arc (center of bend) around the corner:

http://www.diyaudio.com/forums/subw...ecific-tapped-horn-thread-58.html#post1833856

This should get you close.

Regards,

I did some quick checks with my POC #1 and it seems that the "arc" approach results in an effective length measurement that's lower than what is suggested by the measured lower resonant frequency. I'll repeat the measurements this afternoon in a bit more detail to confirm this.

Path Length

Hi Brian,

The arc method arrives at a slightly shorter path than the actual box measurements indicate. But the difference is not significant, that's why I send you the reference. Maybe you can provide more accurate numbers/measurements. That would be great.

Regards,

Hi Brian,

The arc method arrives at a slightly shorter path than the actual box measurements indicate. But the difference is not significant, that's why I send you the reference. Maybe you can provide more accurate numbers/measurements. That would be great.

Regards,

Hi Brian,

The arc method arrives at a slightly shorter path than the actual box measurements indicate. But the difference is not significant, that's why I send you the reference. Maybe you can provide more accurate numbers/measurements. That would be great.

Regards,

I repeated my measurements, using my POC#1. Here's a summary:

Design: tapped-pipe, c-section 290cm^2, split into four equal lengths of 51 cm, built using 0.75 in thick ply.

Design path length = 204 cm

Design Fb (from HornResp impedance data) = 41.5 Hz

Calculated path length = 199 cm (using arcs rather than center line)

Measured Fb (from WT3 impedance data) = 43 Hz

Hard to draw conclusions. I'm not sure what value HornResp is using for c, and it doesn't provide the option to adjust this. It should be about 347.8 m/s here, if this is different to what's built in to HornResp, then that's going to skew things a bit as well.

I'm going to switch my optimization calcs to use arcs, just in case

I'm going to switch my optimization calcs to use arcs, just in case.

I made the switch. Calculated horn length is reduced by a whopping 3%, resulting in enormous 2% increase in Fc. I'm not going to worry too much about it.

I'm not sure what value HornResp is using for c.

Hi Brian,

Hornresp assumes that the velocity of sound in air is 344 metres per second, and that the density of air is 1.205 kilograms per cubic metre. Note 1 on page 17 of the Help file refers.

Kind regards,

David

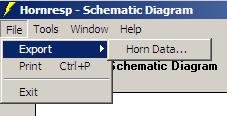

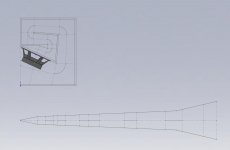

Brian

Regards the folding of you TH

Here is a possible layout that might suit.

This is a cabinet I am working on that has a horn that is a similar shape to the one in your first post.

I have used the small S1 dimension to make more room for the flared mouth, and have tried to minimise any wasted space.

Regards the folding of you TH

Here is a possible layout that might suit.

This is a cabinet I am working on that has a horn that is a similar shape to the one in your first post.

I have used the small S1 dimension to make more room for the flared mouth, and have tried to minimise any wasted space.

Attachments

Effect of Inductance on TH passband...

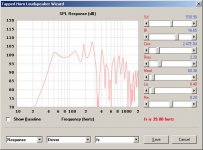

The first image is a TH alignment with no inductor in series.

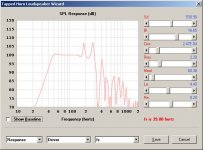

The second is the same TH alignment with a 4mH inductor in series.

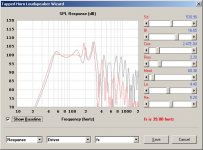

The last compares the two responses.

Of interest here is the flattening of the TH's passband, particularly the apparent increase in SPL between the two main peaks.

In theory, based on the other TH observations made on this forum, the peaks and dips will likely be a lot less than predicted, which suggests that a lot less than 4mH of inductance will be needed to flatten the passband.

The first image is a TH alignment with no inductor in series.

The second is the same TH alignment with a 4mH inductor in series.

The last compares the two responses.

Of interest here is the flattening of the TH's passband, particularly the apparent increase in SPL between the two main peaks.

In theory, based on the other TH observations made on this forum, the peaks and dips will likely be a lot less than predicted, which suggests that a lot less than 4mH of inductance will be needed to flatten the passband.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Finally taking the plunge (Dayton PA310-8 TH)