Sounds like you're making a heck of a thing there- Is that all set up for some heavy jam sessions? Neighbors must love you haha.

I went with 6 foot tall arrays to take up little garage floor space, the design reduces metal garage reflections and the big sound of them works well when working in the garage. Since I'm using low power, the 96dB at one watt/one meter level makes a great party speaker. The local church wants to run the array system with the tapped horn to evaluate that design... amazing how people come out of the wood work when arrays are sitting in your garage.

They NEED bass support and considering how arrays "throw", the bass support needs to be L O U D. I'm not into pro sound anymore but the 2x12 TH would give me enough bass (at 120 watts in the garage) and it would mesh well with the arrays.

Out of all the designs, the Kraken would give me 16 Hz performance for classical music/HT sound, it has enough output to be used as a PA type bass bin (around 98 dB at one watt) it will easily handle the 600 watts RMS I would provide with my Carver amp for PA/block party use and the 6 foot height and 14" width is almost a perfect match for the arrays within an inch. It also fits nicely in one corner of my garage so as an "all-in-one" design--it's a keeper.

Normally, the garage arrays are running about 3 to 10 watt peaks when playing music...the 12" sub strains if I play classical so since I'm in MY garage, the WAF is not in play. Always wanted to get into pipe organ music but that is another league--the league that dual 12" tapped horns play in.

As far as building one, I have a table saw, Roto-Zip, jig saw and other various things. Looked at the design and noted the critical dimension: the "leaves" of the horn to include the sides. My plan is to cut them on the table saw slightly oversize and take them to a cabinet maker for planing to perfect dimension. Have two guitar playing buddies that will help assemble the beast so I'm laying out the plan at this point. The JBLs will be my Christmas present to bypass the wife objections to such a beast. "Not in the house!"

It's always encouraging when the local community is interested in your set up! Is this your church or did a random member happen to see your system and see use for it in the building?I went with 6 foot tall arrays to take up little garage floor space, the design reduces metal garage reflections and the big sound of them works well when working in the garage. Since I'm using low power, the 96dB at one watt/one meter level makes a great party speaker. The local church wants to run the array system with the tapped horn to evaluate that design... amazing how people come out of the wood work when arrays are sitting in your garage.

They NEED bass support and considering how arrays "throw", the bass support needs to be L O U D. I'm not into pro sound anymore but the 2x12 TH would give me enough bass (at 120 watts in the garage) and it would mesh well with the arrays.

Out of all the designs, the Kraken would give me 16 Hz performance for classical music/HT sound, it has enough output to be used as a PA type bass bin (around 98 dB at one watt) it will easily handle the 600 watts RMS I would provide with my Carver amp for PA/block party use and the 6 foot height and 14" width is almost a perfect match for the arrays within an inch. It also fits nicely in one corner of my garage so as an "all-in-one" design--it's a keeper.

Normally, the garage arrays are running about 3 to 10 watt peaks when playing music...the 12" sub strains if I play classical so since I'm in MY garage, the WAF is not in play. Always wanted to get into pipe organ music but that is another league--the league that dual 12" tapped horns play in.

As far as building one, I have a table saw, Roto-Zip, jig saw and other various things. Looked at the design and noted the critical dimension: the "leaves" of the horn to include the sides. My plan is to cut them on the table saw slightly oversize and take them to a cabinet maker for planing to perfect dimension. Have two guitar playing buddies that will help assemble the beast so I'm laying out the plan at this point. The JBLs will be my Christmas present to bypass the wife objections to such a beast. "Not in the house!"

Interesting how you use the word "throw" for sound distribution; While the Kraken's output doesn't seem much affected by your position in the area (it always sounds somehow "distant" despite its volume level) it certainly has the characteristic of really throwing the bass out there. I don't know if this is due to infrasonic frequencies traveling farther or something to do with the horn resonance lining up the waves, but it is every bit as loud in the theater as it is in any other part of the house. It's way too big to use as a mobile sub (you're only gonna want to haul it to the church once

) but it should match up with the arrays quite nicely for that reason.

) but it should match up with the arrays quite nicely for that reason.As far as making sure the inner "leaf" panels are all exactly the same, you should be able to do that with your table saw no problem as long as you can rely on the cut being at a consistent 90* angle to the table surface. Just make all of your length cuts first (or do them with a skill saw guided with a straight edge like I did,) and when it's time to do width, set up the table saw to the correct width (either use a fixture if you have one, or clamp a straight edge to the table if you don't) and do them all at once. As long as the saw is cutting at a 90* right angle, all of the leaves will be the same width and will be perpendicular to the face you screw them onto, lining up perfectly with the other face sheet to be installed on the other side.

Before doing that though, cut the two faces together (cut one out, put it on the next sheet, then trace it and cut the second,) then line them up as well as you can, clamp em, and drill all of your pilot holes. With the pilots drilled, unclamp the sheets and do your counter sinks, making sure they are drilled on the proper side according to which way the panels will be screwed down as a finished product. Do it right and everything will line up perfectly

It's always encouraging when the local community is interested in your set up! Is this your church or did a random member happen to see your system and see use for it in the building?

I talk to the sound guy at the church on occasion--small church and the dual JBLs on stands work. Someone told him I built these really tall speakers that look like coffins so he asked about what I was doing. He just wants to stack them to 12+ feet high, run the dual 12" TH for bass support and kill two birds with one stone...line arrays and tapped horns. They won't be used in a service, just an experiment.

I've been eyeballing the design for the dual 12" JBL for about the last year. Figure the perfect dimensions and 90 degree angles would be assured with a planer at a cabinet shop--my table saw is decent but one less thing to worry about leaking. The wood will be perfect so it might make up for my wood working skills or lack of them.

I am guessing here but am assuming the Kraken weighs around 250 pounds? If so, the hook the arrays up at the church with bass support will be a one time good deal. I'm sure after building the beast--I won't be too hip about moving it around for awhile.

So the entire sub can be built with 3 sheets of 4x8 plywood by joining the "scrap"? My plan is to use 1/2" ply for braces, Titebond II wood glue for the wood pieces and finish up by applying the expanding foam wood glue along the seams just in case.

My Christmas present will be the JBL woofers so the project starts in January. Thanks for your report on the Kraken, it pushed me over the edge and would be the perfect addition for the garage system.

@18Hurts-

While I do believe it possible to get good results with your table saw alone, it certainly doesn't hurt to have the pieces professionally sized up (especially if that will give you greater peace of mind!)

I have no idea what this thing actually weighs, but it is undoubtedly a very heavy object and was no fun moving out from my basement back door, around the house, and back inside to the theater upstairs. Good thing I did it before this happened-

(the day before Halloween, of all times!!)

Yes you can build the whole thing with 3 sheets of 4x8 3/4" void-free plywood, and in fact you can even do the bracing with remnants from said sheets, though I don't know how much that affects the internal dimensions. I personally used my 3/4" scraps for bracing and still have far more than enough wood to spare, and of course the sound quality has remained phenominal even if that did happen to affect the target internal dimensions, so it might not be a bad idea to just go that route to begin with and save a few bucks. Not to mention, since everything has to line up right when you screw the face sheet down at the end, it doesn't hurt to have an extra 1/4" width to lesson the chances of a screw missing its target (since you can't see anything more than your pilot holes at that point)

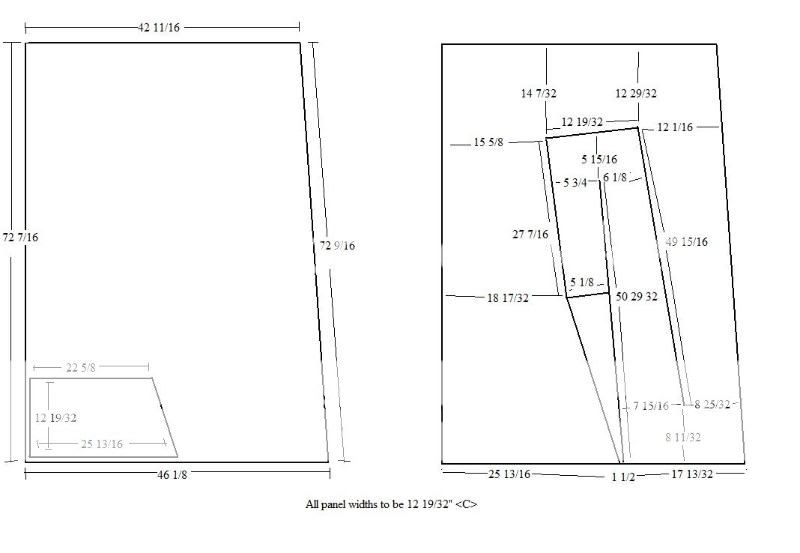

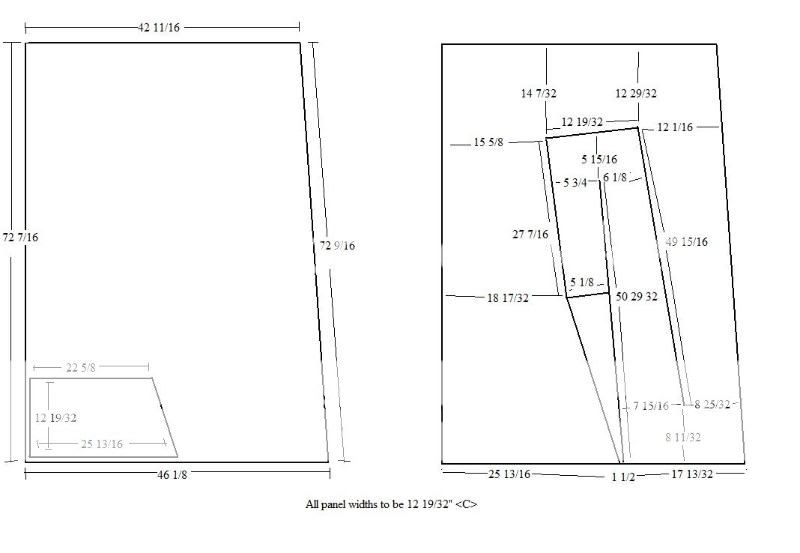

Here's my version of translating this build to inches. Double check everything as you draw it out on the plywood before diving right in, but it should be pretty accurate barring any major screw ups. Can't wait to see yours up and running!

While I do believe it possible to get good results with your table saw alone, it certainly doesn't hurt to have the pieces professionally sized up (especially if that will give you greater peace of mind!)

I have no idea what this thing actually weighs, but it is undoubtedly a very heavy object and was no fun moving out from my basement back door, around the house, and back inside to the theater upstairs. Good thing I did it before this happened-

(the day before Halloween, of all times!!)

Yes you can build the whole thing with 3 sheets of 4x8 3/4" void-free plywood, and in fact you can even do the bracing with remnants from said sheets, though I don't know how much that affects the internal dimensions. I personally used my 3/4" scraps for bracing and still have far more than enough wood to spare, and of course the sound quality has remained phenominal even if that did happen to affect the target internal dimensions, so it might not be a bad idea to just go that route to begin with and save a few bucks. Not to mention, since everything has to line up right when you screw the face sheet down at the end, it doesn't hurt to have an extra 1/4" width to lesson the chances of a screw missing its target (since you can't see anything more than your pilot holes at that point)

Here's my version of translating this build to inches. Double check everything as you draw it out on the plywood before diving right in, but it should be pretty accurate barring any major screw ups. Can't wait to see yours up and running!

@18Hurts-

While I do believe it possible to get good results with your table saw alone, it certainly doesn't hurt to have the pieces professionally sized up (especially if that will give you greater peace of mind!)

Yes you can build the whole thing with 3 sheets of 4x8 3/4" void-free plywood, and in fact you can even do the bracing with remnants from said sheets, though I don't know how much that affects the internal dimensions. Not to mention, since everything has to line up right when you screw the face sheet down at the end, it doesn't hurt to have an extra 1/4" width to lesson the chances of a screw missing its target (since you can't see anything more than your pilot holes at that point)

Good points and thank you for the conversion!

The church sound guy asked a good question, can you make it with a single JBL? I'm assuming the only change would involve the 46 1/8th depth would drop to around 24" since the width of the horn path could be cut in half? Basically, a single version would be around 14"W x 24"D x 72"H ? I'm aware that the horn path would actually be slightly longer so tuned slightly lower which is not a bad thing.

Asked him why and his reasoning is sound, the Kracken would be impossible to move around and way too deep at 46" to fit in the corner. Having four singles would fit better than two full sized Krackens and not break anyone's back.

My issues with the single version would it loses the push/pull of the duals so I'd assume the response would not be as smooth. Not sure about the tapped horn mouth either, would cutting the width in half while keeping the height the same create issues? It sounds like a simple solution on the surface but it can't be that simple--can it?

Great to know the Kracken was worth the build and now you can hide from the snow with a few movies--keep an eye on the dry wall!

I did a re-CAD drawing today. Unfortunatilly, I does not have the original any

more, Some minor changes were done but nothing that will affect the

preformance negativly. Will post that one together with a better drawing soon.

I am also making a drawing for the 10" JBL GTO 1014. Same SPL performance

but some 5 Hz less low freq. extention. About 100x160x32 cm. Will try to

translate it into inches aswell.

The advantage of push pull is reduced harmonic distorsion due to assymetrical

behavion inwards and outwards movement.

Spuddy, what did your friends say about your new build?

Is it okay to post your images and comments on a swedish forum where I also posted the Kraken?

more, Some minor changes were done but nothing that will affect the

preformance negativly. Will post that one together with a better drawing soon.

I am also making a drawing for the 10" JBL GTO 1014. Same SPL performance

but some 5 Hz less low freq. extention. About 100x160x32 cm. Will try to

translate it into inches aswell.

The advantage of push pull is reduced harmonic distorsion due to assymetrical

behavion inwards and outwards movement.

Spuddy, what did your friends say about your new build?

Is it okay to post your images and comments on a swedish forum where I also posted the Kraken?

Can have a look if a single would be possible. Mut so much weight will be saved since the internal will be almost the samt though...

Petter,

It won't be a drastic drop in weight, I calculated it would take one sheet less of plywood (32 KG or 70 pounds) and the weight of the driver (7.7 KG or 17 pounds)

A wild guess calculation is the proper dual JBL Kraken weighs around 115 KG so cutting it down to 75 KG would be quite noticeable--and considering it is half the size it can be squeezed through doors easier etc.

Looking forward to your modified drawings and the dual 10" GTO. The Kraken has me pulling out my pipe organ CDs, dusting them off and pondering what 120 dB of the big pipe firing would do to my garage.

Petter (and anyone else), You are more than welcome to post my images wherever people want to listen  I'll try to get some better ones when I can, unfortunately my camera is toast, so I'm stuck with the phone camera for now. As for my friends, the comments with this sub are more in the "weird faces" category than verbal comments- It seems like I've finally built a sub so big that they don't need words anymore, cause what's the point??? Just gotta be there and you'll understand

I'll try to get some better ones when I can, unfortunately my camera is toast, so I'm stuck with the phone camera for now. As for my friends, the comments with this sub are more in the "weird faces" category than verbal comments- It seems like I've finally built a sub so big that they don't need words anymore, cause what's the point??? Just gotta be there and you'll understand

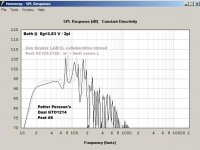

Also, I now have a video for you! Since I can't make any data charts and measurements, recording some water dancing at single digit frequencies is the least I could do. 6-7 hertz is about where you can start actually feeling bass, then around 15-16 hertz it starts getting a lot more powerful. The video shows a bit of a dead spot around 11-14 hertz, but despite the apparent calm, there's definitely still some bass being made, just no room violently shaking. My favorite is 18 hertz when it makes some beautiful ocean-style waves, as well as 23hz+ when the water starts going airborne http://www.youtube.com/watch?v=g-NRo2KMwrY

http://www.youtube.com/watch?v=g-NRo2KMwrY

18Hurts- It appears Petter has come to the rescue for your design ideas, so I'm gonna step back and leave you in his more capable hands. Let us know what you're doing though!

Also, I now have a video for you! Since I can't make any data charts and measurements, recording some water dancing at single digit frequencies is the least I could do. 6-7 hertz is about where you can start actually feeling bass, then around 15-16 hertz it starts getting a lot more powerful. The video shows a bit of a dead spot around 11-14 hertz, but despite the apparent calm, there's definitely still some bass being made, just no room violently shaking. My favorite is 18 hertz when it makes some beautiful ocean-style waves, as well as 23hz+ when the water starts going airborne

18Hurts- It appears Petter has come to the rescue for your design ideas, so I'm gonna step back and leave you in his more capable hands. Let us know what you're doing though!

As for my friends, the comments with this sub are more in the "weird faces" category than verbal comments- It seems like I've finally built a sub so big that they don't need words anymore, cause what's the point??? Just gotta be there and you'll understand

My favorite is 18 hertz when it makes some beautiful ocean-style waves, as well as 23hz+ when the water starts going airborne

18Hurts- It appears Petter has come to the rescue for your design ideas, so I'm gonna step back and leave you in his more capable hands. Let us know what you're doing though!

Kraken 2x12 looks great--no mistaking it for serious firepower--great job! So are you going to build another one for more output or would that require major room reconstruction at this point? I guess when you have the Velodyne hooked up to your computer speakers and people ask why, point at the Kraken 2x12 for the explanation. The beast has been unleashed in the east!

I do like the sound of my Isobarik face-to-face push-pull 15 inch sub with passive radiator--easy to understand why Petter designed the Kraken to use two 12's in push-pull to limit distortion. Since my use would be for pipe organs, various deep bass music and the odd "teenaged son with bass head stuff" on his phone, the Kraken should do it for me.

At this point, Petter's design is a keeper but I am curious about the single JBL version, would a pair of singles sitting next to each line array sound better trading balance for push-pull distortion reduction?

A front roared through and rain is turning into snow flakes--not a good time to build things in the garage but the time of year to get better with horn response. Eventually I'll fully understand the design concepts so will feel confident when the saw blades meet wood.

Has anyone looked at Digital Designs woofers? I use them regularly for nightclub boxes and have a killer t line dual 8" that plays to 30hz in my car. Wonderful, nearly unkillable drivers. DD Audio They make me some custom versions of the 1500 series 12" driver that suit my needs.

I took a look at the very sparse spec sheets on the DD woofers,

The JBLs have a lower resonant frequency at 28Hz VS the DD 30.3Hz which can cause issues. Also the sensitivity is 5dB lower at 85dB VS 90dB of the JBL (at 2.83 volts) Since DD did not put the sensitivity spec at one watt, I am assuming it is 2.83V. It won't go as low or be as loud as the JBL at the same power input levels.

The Kraken is tuned at 18Hz which is very low for a DD to be tuned, I'm sure it can withstand being pushed that far down but the cone travel will be used up trying to get the same SPL as the JBLs.

Another option to entertain is what would a JBL GTO 1514 do with the design as a single woofer. It has the same output as two 1214's and the 15 incher has a Fs of 25.1 Hz. Could the design of the Kraken be modified to run a 16 Hz tuning with a single 15" JBL? It would have to be wider which would help with stability but I'm worried about compression on the cone. The 15" version looks spec wise about the same as the 12" with the same voice coil diameter so the compression ratio might need to be dropped down.

One of my games with Horn Response is to play with the Kraken design--if I'm going to modify something, knowing that it works at a very high level is a great place to start. Model a single 12" and a single 15" and calculate size/weight and see if the 15" could handle a 17 or 16 Hz tuning. I was not smart enough to cut wood before the cold weather came so it's a good excuse to become proficient with Horn Response while the cold winds blow and freeze my wood working area.

The JBLs have a lower resonant frequency at 28Hz VS the DD 30.3Hz which can cause issues. Also the sensitivity is 5dB lower at 85dB VS 90dB of the JBL (at 2.83 volts) Since DD did not put the sensitivity spec at one watt, I am assuming it is 2.83V. It won't go as low or be as loud as the JBL at the same power input levels.

The Kraken is tuned at 18Hz which is very low for a DD to be tuned, I'm sure it can withstand being pushed that far down but the cone travel will be used up trying to get the same SPL as the JBLs.

Another option to entertain is what would a JBL GTO 1514 do with the design as a single woofer. It has the same output as two 1214's and the 15 incher has a Fs of 25.1 Hz. Could the design of the Kraken be modified to run a 16 Hz tuning with a single 15" JBL? It would have to be wider which would help with stability but I'm worried about compression on the cone. The 15" version looks spec wise about the same as the 12" with the same voice coil diameter so the compression ratio might need to be dropped down.

One of my games with Horn Response is to play with the Kraken design--if I'm going to modify something, knowing that it works at a very high level is a great place to start. Model a single 12" and a single 15" and calculate size/weight and see if the 15" could handle a 17 or 16 Hz tuning. I was not smart enough to cut wood before the cold weather came so it's a good excuse to become proficient with Horn Response while the cold winds blow and freeze my wood working area.

Has anyone looked at Digital Designs woofers? I use them regularly for nightclub boxes and have a killer t line dual 8" that plays to 30hz in my car. Wonderful, nearly unkillable drivers. DD Audio They make me some custom versions of the 1500 series 12" driver that suit my needs.

I had a look at their website and the qts of the drivers are far to high for horn

use. The 9500-series would work fine, but they are kind of pricy...

Spuddy, your build and word has encouraged me to develop the "Kraken 210"

and the "Kraken 112" as well. The new drawing of your "Kraken 212" will be

uploaded next week. Unfortunatilly, the space inside the throat makes it

impossible to fit the 10"-drivers in push pull configuration. On the other hand,

compared to Kraken 212, there is a significant space save (good for family

living rooms...), se images below.

The Kraken 112

The inner width and the outlet hole is 320mm wide/high. Material thickness is

22mm. I will recalculate this later on to inches and also to 3/4" but this is a

good start. The driver is the same JBL GTO 1214 as in Kraken 212. The driver

shall be placed magnet out.

The length of each board is set to the maximum length, due to the angle.

The dimensions are set from the very top of each board in the upper part of

the horn and from the very bottom of each board in the lower part of the

horn.

To cut the 177-angle, use 89 degrees on each board.

The Kraken 210

JBL GTO 1014

See notes on how to read the dimensions in the upper Kraken 112.

and the "Kraken 112" as well. The new drawing of your "Kraken 212" will be

uploaded next week. Unfortunatilly, the space inside the throat makes it

impossible to fit the 10"-drivers in push pull configuration. On the other hand,

compared to Kraken 212, there is a significant space save (good for family

living rooms...), se images below.

The Kraken 112

The inner width and the outlet hole is 320mm wide/high. Material thickness is

22mm. I will recalculate this later on to inches and also to 3/4" but this is a

good start. The driver is the same JBL GTO 1214 as in Kraken 212. The driver

shall be placed magnet out.

The length of each board is set to the maximum length, due to the angle.

The dimensions are set from the very top of each board in the upper part of

the horn and from the very bottom of each board in the lower part of the

horn.

To cut the 177-angle, use 89 degrees on each board.

The Kraken 210

JBL GTO 1014

See notes on how to read the dimensions in the upper Kraken 112.

Thank you very much for the 1x12 Kraken drawings!

It is now my winter project to build one of them with two sheets of plywood and a single GTO 12". Calculated the height, width, depth and weight, measured the corner in the garage and it is a perfect fit. It will weigh approx my body weight and with half the depth, a simple move with two people or a dolly. The plan is to eventually build a second one to go with my pair of line arrays to hold them in position and couple better as a pair.

It will weigh approx my body weight and with half the depth, a simple move with two people or a dolly. The plan is to eventually build a second one to go with my pair of line arrays to hold them in position and couple better as a pair.

I'm assuming the single 12 Kraken is tuned the same as the 2x12 original? The single GTO will be my Christmas present so it is a January/February project depending on if I can get some warm days.

What is the compression with the Kraken series? I plan on playing around with Horn Response this winter and will attempt a 16Hz tuned single 15" version. Since 12 inch woofers can handle twice as much compression, I'd like to cut that in half while playing with the Horn Response sliders. The single GTO 15 has the same efficiency as two 12's and a lower Fs--a 16Hz tuned Kraken could be possible (in theory) but I'm worried about the compression on such a large cone.

Thanks again for all your hard work and inspiration, Petter--the Kraken series are great designs.

It is now my winter project to build one of them with two sheets of plywood and a single GTO 12". Calculated the height, width, depth and weight, measured the corner in the garage and it is a perfect fit.

It will weigh approx my body weight and with half the depth, a simple move with two people or a dolly. The plan is to eventually build a second one to go with my pair of line arrays to hold them in position and couple better as a pair.

It will weigh approx my body weight and with half the depth, a simple move with two people or a dolly. The plan is to eventually build a second one to go with my pair of line arrays to hold them in position and couple better as a pair. I'm assuming the single 12 Kraken is tuned the same as the 2x12 original? The single GTO will be my Christmas present so it is a January/February project depending on if I can get some warm days.

What is the compression with the Kraken series? I plan on playing around with Horn Response this winter and will attempt a 16Hz tuned single 15" version. Since 12 inch woofers can handle twice as much compression, I'd like to cut that in half while playing with the Horn Response sliders. The single GTO 15 has the same efficiency as two 12's and a lower Fs--a 16Hz tuned Kraken could be possible (in theory) but I'm worried about the compression on such a large cone.

Thanks again for all your hard work and inspiration, Petter--the Kraken series are great designs.

How does the 1x12 Kraken compare to the Lab 12 horn? (20-25hz tuning or so...) Kraken is a few inches taller, but not as deep...

http://www.diyaudio.com/forums/subwoofers/143714-lab12-tapped-horn.html

http://www.diyaudio.com/forums/subwoofers/143714-lab12-tapped-horn.html

Nice job with all the new renderings Petter! I'd be really interested in seeing if anyone out there with more measuring equipment would like to slap one of these together and list up some actual numbers, as I'm obviously not much help in that regard.. All I can say is that the 212 is far louder and deeper (and cleaner!) than my old workhorse Velodyne, but the set ups on this forum go borderline insane, so that probably doesn't mean much around here

Build people, build! I made the biggest Kraken model there is and it was less than $500 for everything. If you're a slightly crazy bachelor like myself with no WAF to contend with, you can't go wrong! If you're married... Good luck It's easily worth a small turf war for the theater though!

It's easily worth a small turf war for the theater though!

Build people, build! I made the biggest Kraken model there is and it was less than $500 for everything. If you're a slightly crazy bachelor like myself with no WAF to contend with, you can't go wrong! If you're married... Good luck

It's easily worth a small turf war for the theater though!

It's easily worth a small turf war for the theater though!If you're a slightly crazy bachelor like myself with no WAF to contend with, you can't go wrong! If you're married... Good luckIt's easily worth a small turf war for the theater though!

The dual Kraken has the WAF = 0 so I assumed (correctly) that you don't have a ball and chain.

The single 12 version of the Kraken can fit behind a couch if you lay it down so has possibilities....heck, two of the singles will fit behind the couch if stacked on the "thin" side. Just tell your wife that it is a shelf behind the couch to hold pretty plants or something. The singles can also be used as stands to hold the surround speakers so there are ways.

The single 12 version of the Kraken can fit behind a couch if you lay it down so has possibilities....heck, two of the singles will fit behind the couch if stacked on the "thin" side. Just tell your wife that it is a shelf behind the couch to hold pretty plants or something. The singles can also be used as stands to hold the surround speakers so there are ways. I'm going to build the single version for garage use--more BAF instead of WAF. The Back Acceptance Factor comes into play since the thing will be moved when the arrays go outside for BBQs and house parties. The single would have about the same weight as me and I can see over it when moving it with a hand truck (dolly) and the 2 foot depth allows movement through door ways etc.

Calculated the "cut sheets" when using typical 4x8 3/4" plywood and the single Kraken takes less than two sheets with plenty of scrap for braces. There is one board that needs to be joined but I'd do it to the long board that faces the woofer that attaches to the "triangle". I'll glue it edge to edge and then put a overlapping brace inside the triangle to make it solid. The triangle will be filled with expanding foam so no worries about leaks.

As far as the LAB 12 VS the Kraken single, the LAB is slightly shorter but deeper and not tuned as low. It would be louder than the Kraken single but I want the lower tuning for pipe organs and the like--the LAB 12 won't do that. If I need more output, just build another Kraken single--can't tune a LAB 12 lower so I'm going low first and will add more when (if) I ever feel the need.

The Kraken single is very reasonable in price which is important for the WAF calculation. $96 for one JBL 1214, $80 for two sheets of AC rated void free 3/4" ply, $5 for glue and $7 for two pounds of screws and $6 for an input terminal or around $200 each.

In WAF math--under $100 for the speaker and nickles and dimes for wood and a few trips to the lumber yard.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Build your own 2x12" TH (The Kraken 212 TH)