This is the first eminence driver that I am aware of having an aluminum VC former.

http://www.eminence.com/pdf/lab-15.pdf

http://www.eminence.com/pdf/lab-15.pdf

This is the first eminence driver that I am aware of having an aluminum VC former.

http://www.eminence.com/pdf/lab-15.pdf

I'm all for it so long as it's wound in the USA.

I'm all for it so long as it's wound in the USA.

I would imagine that they still are, but you never know. At eminence they apply the insulation coating to the wire in house, they even make there own flat wire from round for the edge-wound coils. Although both processes are low tech. The thing about aluminum formers at eminence is the heat causing adhesive failure at the triple joint, so you see this is quite a departure for them. Mabey they are using some different adhesives nowadays, they used to use CA exclusively in the triple joint. Or more likely a new insulating wrap on the former materal for the glue joint.

At any rate there is progress in Kentucky.

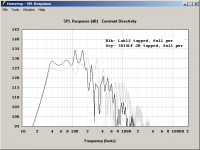

Although the sensitivity of the Lab15 is lower than the 3015LF in a tapped horn config, the Lab15 appears to go louder by 4dB until Xmax is reached. The lab15 can take a full 60V compared to the 3015LF's 40V (in a tapped horn config). The path length is a bit longer, but has less volume.

This is just a first go with it... lots of sim fun ahead.

In all honesty, I wish the resonance was higher.

This is just a first go with it... lots of sim fun ahead.

In all honesty, I wish the resonance was higher.

Attachments

Although the sensitivity of the Lab15 is lower than the 3015LF in a tapped horn config, the Lab15 appears to go louder by 4dB until Xmax is reached. The lab15 can take a full 60V compared to the 3015LF's 40V (in a tapped horn config). The path length is a bit longer, but has less volume.

This is just a first go with it... lots of sim fun ahead.

In all honesty, I wish the resonance was higher.

Or - you could just tune the horn lower, like down near 15 Hz.....

This is an interesting driver - someone must have a proper home planned for it.

can someone put the lab15 in the hornresp to see if it will be as good as the labhorn

Different drivers altogether.

Believe me, we have been playing with this driver in Hornresp since we found it.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- new lab15