usekgb said:If anyone is feeling daring, you could use two woofers with center vented pole pieces. Carefuly cut away the dust cover, and you have a hole ready to accept a rod. Run the rod through the center of both pole pieces, and secure the rod with locking washers or nuts. If you wish, you can re-attach the dust cap to make everything look pretty. This would also work with the solid aluminum spacer between the magnets as was posted earlier. You wouldn't need any speacial driver for this configuration, as vented pole piece drivers are very common.

Any comments folks?

Just that if you do this you have to be careful that you have the spacers the right size. If you have any gaps there exists the possibility of cranking things down to the point where you pull a magnet off. You also loose any cooling or venting effect of the vented pole piece (althou some find that plugging up the pole piece is a good thing sonically anyway.

dave

Sorry for not posting earlier, but things have gotten busy for me. Thanks to all for the info! (Just as an FYI, yes, all-thread is the same as a threaded rod)

Now, I just have to sit down and think about some designs to build. I'm still pretty busy until June, but the money for the amp showed up the other day, so I should be ordering that in the next couple of days. (Then I can play and experiment a little with the existing setup!)

I'll post more details after I have a design and start construction!

Now, I just have to sit down and think about some designs to build. I'm still pretty busy until June, but the money for the amp showed up the other day, so I should be ordering that in the next couple of days. (Then I can play and experiment a little with the existing setup!)

I'll post more details after I have a design and start construction!

Just that if you do this you have to be careful that you have the spacers the right size. If you have any gaps there exists the possibility of cranking things down to the point where you pull a magnet off. You also loose any cooling or venting effect of the vented pole piece (althou some find that plugging up the pole piece is a good thing sonically anyway.

So guess what, my woofers came today, and they have vented polepieces.

Since I was just planning to cut a wooden donut and epoxy two of them to this donut back to back, this comes as a surprise.

Does plugging up the vent affect the T/S parameters significantly? I have no measuring equipment, so I'm using the manufacturer's specs to determine crossover point, and have to play it safe to avoid changing them too much. Would it be safer to cut vent holes in the donut, or maybe use a thick donut?

Blocking up the vents will change the compliance of the speaker a little, but more importantly, if you are running the sub at high levels, the cooling will be greatly compromised. If you can cut some vents in your doughnut, then I think it would be worthwhile. You could always block them up later if you want to experiment, but if you don't have them and you find they are needed, you're stuffed

Thanks pinkmouse.

Would the type of wood for the donut actually make any difference in the effect of the push-push? Would a non-dimensional wood such as MDF be required, because a grained wood would take one woofer's vibration and impart a directional vector to it along the grain when pushing against the other woofer? Or is even something much less elastic than wood like metal required? Or is this just insane overkill because I'm using $14 woofers?

Would the type of wood for the donut actually make any difference in the effect of the push-push? Would a non-dimensional wood such as MDF be required, because a grained wood would take one woofer's vibration and impart a directional vector to it along the grain when pushing against the other woofer? Or is even something much less elastic than wood like metal required? Or is this just insane overkill because I'm using $14 woofers?

leadbelly said:Would the type of wood for the donut actually make any difference in the effect of the push-push? Would a non-dimensional wood such as MDF be required, because a grained wood would take one woofer's vibration and impart a directional vector to it along the grain when pushing against the other woofer? Or is even something much less elastic than wood like metal required? Or is this just insane overkill because I'm using $14 woofers?

Insane overkill...Nah...This is DIY!

However, strangely enough, I have no experience of this, I am going on guesswork.

Natural wood is most resistant to compression along the grain, so you could just chop a round slice out of a treetrunk, such as Maple, Beech, or Iroko, and use that. Metal, unless you have the tools to work big chunks of it accurately, is probably too difficult, so I suspect it comes down to MDF. Just make sure it is never under tension as it will peel right apart...

BTW, the directional vector that MDF imparts is to that of artistic taste, which it sends into the fourth dimension, as can be seen on many tacky TV makeover programmes that use the stuff all over the place!

leadbelly said:Would the type of wood for the donut actually make any difference in the effect of the push-push?

Yes. A hard-wood is recommended... the more accurately the material passes the vibration in-tact from one woofer to the other the better. I wouldn't use MDF -- it's too squishy.

dave

Thanks Dave.

So, the widest sonotube I can find is an 18" at UFA for $36, which seems not worth it to me, since there's all that work stabilizing for a cut and the radius is not all that great for 12" woofers either. Still considering it as a maybe.

So, for the push-push dipole, are there any special geometry issues to worry about, or can I make an H-frame baffle and be done with it?

So, the widest sonotube I can find is an 18" at UFA for $36, which seems not worth it to me, since there's all that work stabilizing for a cut and the radius is not all that great for 12" woofers either. Still considering it as a maybe.

So, for the push-push dipole, are there any special geometry issues to worry about, or can I make an H-frame baffle and be done with it?

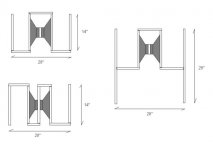

The south-east one wouldn't be push-push... if i were doing one i'd be thinking along the lines of the NE one -- I don't like the idea of the parallel sides on the front facing portiom. There would be lots of variations. Of course -- bigger the better. One could use plexi for the wings. Don't forget that the shortest path could also be over the top.

dave

dave

Attachments

planet10 said:The south-east one wouldn't be push-push

dave

south east? Now I'm confused. Which one is south-east?

Dave

kneadle said:south east? Now I'm confused. Which one is south-east?

Bottom-left.

dave

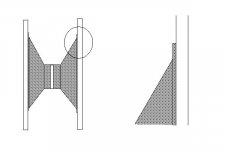

leadbelly said:As I understand Dave, it's not push-push because the driver's rear forces are transferred to the enclosure without being cancelled by the other driver.

Yep... it would be push-pull, tending to cancel non-linearities in the way the driver moves in vrs how it moves out.

dave

OK, well your answer has really made me rethink what I had planned to do.

I had planned to just epoxy 2 woofers magnet to magnet, making 1 unit, and then just screw the 2 flanges to the rear surface of two pieces of wood, as shown in the drawing, to begin making the baffle.

Is this technique still push-push?

If it is, would threaded rod bolted through the entire assembly from 1 wood surface to the other be necessary? Or else a threaded sleeve cut to length to fit tightly between the woofer flanges, bolted through from the baffle.

I had planned to just epoxy 2 woofers magnet to magnet, making 1 unit, and then just screw the 2 flanges to the rear surface of two pieces of wood, as shown in the drawing, to begin making the baffle.

Is this technique still push-push?

If it is, would threaded rod bolted through the entire assembly from 1 wood surface to the other be necessary? Or else a threaded sleeve cut to length to fit tightly between the woofer flanges, bolted through from the baffle.

Attachments

leadbelly said:OK, well your answer has really made me rethink what I had planned to do.

I had planned to just epoxy 2 woofers magnet to magnet, making 1 unit, and then just screw the 2 flanges to the rear surface of two pieces of wood, as shown in the drawing, to begin making the baffle.

Is this technique still push-push?

If it is, would threaded rod bolted through the entire assembly from 1 wood surface to the other be necessary? Or else a threaded sleeve cut to length to fit tightly between the woofer flanges, bolted through from the baffle.

yes it is push-push. With the magnets touching, any force thru the magnet and pushing against the other speaker is cancelled to a high degree. When the force is pulling the driver away it is much less effective. By gluing the magnets together you have a greater effect when the drivers pull apart. The threaded rod -- with bolts inside and out, are effective for both push towards & pull-away plus they spread the load over a larger part of the driver -- it is all a matter of how nuts you want to go.

dave

Well, here's hoping an old thread will wake up:

I never built the above designs because I just can't live with the footprint of any significantly-sized-baffle dipole. But it is warm in my garage workshop now and I already have the drivers, so it just a matter of time before I build something with them.

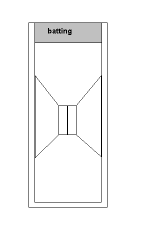

Dave's comment about adding stuffing made me think about the following design shown. Much nicer footprint for my needs.

My question is, what happens to the reponse as compared to a plain dipole? In other words, I can punch in this smaller baffle size into the same response calculator I was using to estimate the base case (no stuffing) response. More important is how the reponse curve shifts as the stuffing is increased.

I never built the above designs because I just can't live with the footprint of any significantly-sized-baffle dipole. But it is warm in my garage workshop now and I already have the drivers, so it just a matter of time before I build something with them.

Dave's comment about adding stuffing made me think about the following design shown. Much nicer footprint for my needs.

My question is, what happens to the reponse as compared to a plain dipole? In other words, I can punch in this smaller baffle size into the same response calculator I was using to estimate the base case (no stuffing) response. More important is how the reponse curve shifts as the stuffing is increased.

Attachments

I was just running some Vector Mech and still don't know why you need to "tie" the woofers back-to-back. All of the mechanical forces are applied symmetrically about a baffle and is transferred to the sides and top and bottom. The enclosure is essentially a dictionary definition for Newton's Third Law.

I did figure that the magnets would have to mounted perfectly within their regions...i.e, center of drivers coplanar.

I did figure that the magnets would have to mounted perfectly within their regions...i.e, center of drivers coplanar.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Questions on push-push subs...