short version? Nope

Long version? REALLY nope.

You'd get a ton of rocking mode distortion from the extended pivot point, and the suspension isn't meant for the type of stress you'd be placing on it.

Better to get woofers more purpose designed for your app. What's wrong with a few Acoustic Elegance IB15s?

Long version? REALLY nope.

You'd get a ton of rocking mode distortion from the extended pivot point, and the suspension isn't meant for the type of stress you'd be placing on it.

Better to get woofers more purpose designed for your app. What's wrong with a few Acoustic Elegance IB15s?

Tinitus, have a look at this thread: http://www.diyaudio.com/forums/showthread.php?t=133711&page=37. They're going full range there, but I'm thinking like you, just try it for the bass. some day, I'm thinking of filling the cones of some old drivers with polystyrene foam and coupling then to a large sheet of something, just to see what happens

I have similar idea to make huge dipole sub.

get pro woofer with strong motor, remove its cone, leave spider and coil in place. then build and attach your own cone and frame.

then you'll have subwoofer bigger than 31" fostex for much less money.

flat panel cone is a bad idea, it will resonate way too much.

I actually plan to make deep profile, corrugated cone.

get pro woofer with strong motor, remove its cone, leave spider and coil in place. then build and attach your own cone and frame.

then you'll have subwoofer bigger than 31" fostex for much less money.

flat panel cone is a bad idea, it will resonate way too much.

I actually plan to make deep profile, corrugated cone.

Attachments

Thanks for the valuable input

You nailed down some of the obvious benefits

Update

"Cone" might be a 1/2" thick polystyrene sheet, about a square meter

No thread surround, but instead use the flexibility of the polystyrene

Corners are cut away to increase flexibility

Which woofer?

I dont expect this to be a high power speaker

I want a refined sub to be used solely at "normal" SPL

But stilll need a woofer driver with a strong motor and fairly good Xmax, if this thing goes really deep

Beyma SM212 might work, and cost is avarage around 100EUR

Or maybe even a carfi woofer would work fine

You nailed down some of the obvious benefits

Update

"Cone" might be a 1/2" thick polystyrene sheet, about a square meter

No thread surround, but instead use the flexibility of the polystyrene

Corners are cut away to increase flexibility

Which woofer?

I dont expect this to be a high power speaker

I want a refined sub to be used solely at "normal" SPL

But stilll need a woofer driver with a strong motor and fairly good Xmax, if this thing goes really deep

Beyma SM212 might work, and cost is avarage around 100EUR

Or maybe even a carfi woofer would work fine

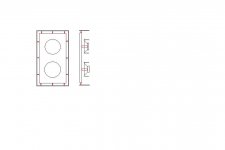

Attachments

That 'felt' surround can be noisy I guess, no? I like the one with thread suspension better

And the motor should be secured in some way, so I think the skectch by MisterTwister make more sense to me.

As to the membrance, how about honeycomb cardboard? Quite light and rigid related to given area. If more than one motors can be used, then it can be driven more evenly.

And the motor should be secured in some way, so I think the skectch by MisterTwister make more sense to me.

As to the membrance, how about honeycomb cardboard? Quite light and rigid related to given area. If more than one motors can be used, then it can be driven more evenly.

I can see quite a few problems with this. Firstly, two motors driving one cone seems like asking for trouble! Also having no baffle at all makes is horrendously efficient, so you are working uphill negating your gains.

I think you'd be better off starting with some large 15" drivers with a powerful magnet and low Qts. Now remove the surround and simply extend the cone so that it's bigger. Cones are better because they combine stiffness and low mass. Any flat panel will be inferior. So you might turn that 15" driver into a 21" and perhaps use a few of them. Now put it in a H frame to get the best efficiency you can from a dipole.

I think you'd be better off starting with some large 15" drivers with a powerful magnet and low Qts. Now remove the surround and simply extend the cone so that it's bigger. Cones are better because they combine stiffness and low mass. Any flat panel will be inferior. So you might turn that 15" driver into a 21" and perhaps use a few of them. Now put it in a H frame to get the best efficiency you can from a dipole.

Tinitus,

Why don't use a shaker as motor for some sort of rigid panel? Like this one: http://www.smarthome.com/8249P/Bass-Shaker-Pro-50-Watt-RMS-Pair-Bass-Transducers/p.aspx

Why don't use a shaker as motor for some sort of rigid panel? Like this one: http://www.smarthome.com/8249P/Bass-Shaker-Pro-50-Watt-RMS-Pair-Bass-Transducers/p.aspx

Tinitus,

Why don't use a shaker as motor for some sort of rigid panel? [/url]

It did cross my mind

But I have no idea about how shakers work

Dont you think it would be like "one-note" bass ?

Small update

There have been some misunderstanding about mounting the woofer driver

Ofcourse it will be fixed on a chassis connected to the main frame

I was just too lazy to draw it, or thought the drawing would look simpler

I have looked a bit backwards and was close to decide on the the first suggestion with a stiff thick "cone" with some sort of "surround"

But as mentioned earlier theres a huge risk it will be "rocking" badly putting too much strain on the woofer drivers voicecoil, and lead to distortion

Another option( I think it has mentioned earlier as well)

Fill the woofer cone with a carefully shaped block of polystyrene

With a bigger plate of polytyrene in front

Like say 400x400x40 mm

And no additional surround, just the woofer

Some benefits are still there

Like a bigger cone that equals 2x 15", using just relatively cheap 12" with a strong quality motor

Lowered Fs and raised Qts, fit for OB

And pure pistonic motion

And certainly NO high FR peaking

Maybe nothing but low frequency

Makes me wonder how high it rolls off, about how much low pass filtering is needed

The previous suggestion with a big thinner sheet polystyrene

Flexible, and dont need additional surround

Doesnt put much strain on the woofer driver

Lower Fs is based on size, more than weight

Kind of like a very big ringradiator

Concerns with a big flexible "cone" ( 800x800x12 mm)

The ressonance of a big polystyrene "cone" could be a problem, and also lead to one-note bass

And there would probably be lots of other spurious concentric ressonaces

On the other hand, what are chances of winning in a lottery

But its getting closer to the dumpster

Last edited:

Perhaps you could fashion a more typical type of surround from bicycle inner tube rubber? You could then mount to a baffle for better efficiency. I'd have thought if you used the flexibility of the material to act as excursion, you'd push the resonance back up from the springyness?

I'd expect flat polystyrene to perform very poorly. It is light, but it has no strength or stiffness. A cone with the same mass will be a lot stiffer and stronger. Aluminium subwoofer cones have enough strength for you to stand on them! Just think how thick and heavy the polystyrene would have to be to support your weight!

A cone wouldn't be extremely difficult to make. You could try paper combined with fibreglass/carbon fibre/kevlar. You might use paper to create the shape first, then apply the matting and resin. You could even create ribs for extra stiffness so the cone can remain thin. You could use balsa wood ribs - it has little strength of its own but as the matting wraps around it you then get the strength.

The real challenge is the suspension system. Have you ever heard what a driver sounds like once the surround is damaged? It's not pretty! You can buy rubber surrounds for re-cone kits, but the ones I've seen are small and not cheap. You may have some success with an accordion style surround, but to me this sounds like one of the most difficult parts.

If you leave it out you need a very stiff spider.

A cone wouldn't be extremely difficult to make. You could try paper combined with fibreglass/carbon fibre/kevlar. You might use paper to create the shape first, then apply the matting and resin. You could even create ribs for extra stiffness so the cone can remain thin. You could use balsa wood ribs - it has little strength of its own but as the matting wraps around it you then get the strength.

The real challenge is the suspension system. Have you ever heard what a driver sounds like once the surround is damaged? It's not pretty! You can buy rubber surrounds for re-cone kits, but the ones I've seen are small and not cheap. You may have some success with an accordion style surround, but to me this sounds like one of the most difficult parts.

If you leave it out you need a very stiff spider.

Perhaps you could fashion a more typical type of surround from bicycle inner tube rubber?

Might have a good idea there

I didnt know how to

Maybe I do now

Polystyrene

They come in all sorts of density and strenght

Here we use it below concrete floors

Anayway

I have decided to order a Beyma SM212 because of its relatively low cost and good 15mm Xmax(p-p),

Along with a 15" woofer I need for my bassguitar

I reckon a wheel for a racebike is 28"

A fine size for a woofer

Tuck in the tube

Pump it up

And its moving

Makes me wonder how much such a thing moves

Attachments

Last edited:

There were some speakers called Poly-Planar back about 1970 that used a relatively thin 1/8" polystyrene membrane and no outer suspension. The diaphragm worked in bending mode. They sounded pretty good; the 8" and 14" x 20" versions had decent bass. Their weak points were a cheap motor (voice coils fell apart > 5W or so) and an aluminum foil whizzer which resonated nastily, fortunately easily removed.

Yamaha also did a bending polystyrene diaphragm design shaped like a human ear with the motor mounted off-center. Theirs was impressive (huge cast aluminum frame made of recycled motorcycles?) but strange sounding to my western ears.

I've wondered what a big styrene foam sheet driven by a stout motor would sound like. Might be pretty good, based on the Poly-Planar array I built.

Yamaha also did a bending polystyrene diaphragm design shaped like a human ear with the motor mounted off-center. Theirs was impressive (huge cast aluminum frame made of recycled motorcycles?) but strange sounding to my western ears.

I've wondered what a big styrene foam sheet driven by a stout motor would sound like. Might be pretty good, based on the Poly-Planar array I built.

I've wondered what a big styrene foam sheet driven by a stout motor would sound like. Might be pretty good, based on the Poly-Planar array I built.

Nice info, thanks

I have thought about the next step

Tall planar using RUBANOIDE "motor"

But man, those big neos cost more than quality woofers

The project was supposed to be big AND cheap

One step at a time I guess

Seems I cant let it go now

Stiffness of the foam panel can be controlled and the strength could be huge if a good quality epoxy/fiberglass mat was used on both sides.

But I think the problem here is that surely you will be limited to the original woofers X-Max and efficiency will be going down as the mass increases.

Great idea tho.

Bicycle tubes for surround--- just like "Myth-Busters"

But I think the problem here is that surely you will be limited to the original woofers X-Max and efficiency will be going down as the mass increases.

Great idea tho.

Bicycle tubes for surround--- just like "Myth-Busters"

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- BIG diy woofer for OB