It's somewhat misaligned, but your call as to whether it's off too much:

GM

it'd be a one octave bass thumper. any way to "adjust" for the CSS?

CSS sells the woofer and 2 PRs for $200, which is a pretty good deal.

it'd be a one octave bass thumper. any way to "adjust" for the CSS?

No more so than the Lab12. Not at a glance, it really 'wants' a lower tuned alignment down around 11 Hz based on Prof. Leach's math.

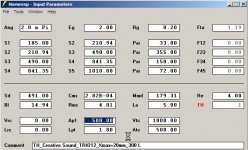

Here's what I get 'blowing up' a Prof. Leach alignment to the 'close enough' same net Vb, so import it into HR to fiddle with to see how it might can be adapted:

GM

Attachments

Hi nuconz,

When you look back at Hornresp listing in the first post, you'll see that Le is listed as 8mH. The nominal inductance for the LAB12 is 1.48mH. That means a series inductor has been added to smoothen the response. In practice that may not make much of a difference. The resistance of the inductor is added under Rg (e.g.: .1 Ohm for the supply cables, and .05 Ohm for every added mH of series inductor.)

Also, mwmkravchenko has build a nice, big FLH with the CSS TRIO12:

http://www.diyaudio.com/forums/subwoofers/168697-trio-12-front-loaded-horn-subwoofer.html

When you look back at Hornresp listing in the first post, you'll see that Le is listed as 8mH. The nominal inductance for the LAB12 is 1.48mH. That means a series inductor has been added to smoothen the response. In practice that may not make much of a difference. The resistance of the inductor is added under Rg (e.g.: .1 Ohm for the supply cables, and .05 Ohm for every added mH of series inductor.)

Also, mwmkravchenko has build a nice, big FLH with the CSS TRIO12:

http://www.diyaudio.com/forums/subwoofers/168697-trio-12-front-loaded-horn-subwoofer.html

Attachments

No more so than the Lab12. Not at a glance, it really 'wants' a lower tuned alignment down around 11 Hz based on Prof. Leach's math.

Here's what I get 'blowing up' a Prof. Leach alignment to the 'close enough' same net Vb, so import it into HR to fiddle with to see how it might can be adapted:

GM

everyone, thanks for taking the time to look at the possible "fit" for the trio 12 sw. i'm running on a linux system and don't run the cool hr sw.

Hi nuconz,

Also, mwmkravchenko has build a nice, big FLH with the CSS TRIO12:

http://www.diyaudio.com/forums/subwoofers/168697-trio-12-front-loaded-horn-subwoofer.html

thanks for this oliver. i'm confused a bit though. the project initially identifies the driver as a CSS trio 8. but throughout the project there is reference to a 12" driver. and CSS doesn't include an 8" trio driver on their product list.

Hi nuconz,

You are correct, the TRIO12 FLH thread meanders a bit (ok, maybe a lot), but it's well worth the time spend reading through it. CSS used to make a TRIO-8, it's shame that they don't have it anymore, was a great little speaker.

Regards,

ok. thanks. which was used then?

TRIO12

here's a link to something as good and that is certainly easier to build.

the SDX12 doesn't seem available any more. don't know if the trio 12 will work, but probably will. might also substitute the SDX10.

i built a prototype of this as a 1st attempt a couple years back and slapped an el cheapo "on hand" woofer in it. turned out ok in spite of some mistakes. if i did it again, and i might, i would not "side mount" the woofer as shown; i'd "front mount" it. look better and probably be louder.

perhaps scott can offer some insight?

http://homepage.mac.com/tlinespeakers/FH/download/ShadowSD12-NBVR-0v9-map.pdf

Hi nuconz,

Anyway, you might find portions of this thread interesting:

http://www.diyaudio.com/forums/subwoofers/168752-novice-stereo-subs-project-stereo-amp-4.html

Regards,

Anyway, you might find portions of this thread interesting:

http://www.diyaudio.com/forums/subwoofers/168752-novice-stereo-subs-project-stereo-amp-4.html

Regards,

MaVo did the simulation, Chris8sirhC decided to build the first one, and I did the fold for Chris. Now, Layertone has built one of the nicest Tapped Horns of this series.

Just how many have these been built by now? Does anyone have any idea? Would this still be considered a good solid build today?

The Lab12 has too soft a suspension and too low Fs. It's a good driver for the money, and available.

I'm trying to make sure I have the context correct. Is the above quote in reference to a different design? Or are we saying the Lab12 is not a good driver for the box shown in the very first post of this thread?

... anything not square is at 2.3 degrees. That includes j, h, and i as well as k. Tapped Horns require leak-proof construction. Any leak will ruin the output...

Something I like about this box is that everything is square (with respect to the other pieces it touches) except for one end of J and K. K is short and if it takes me a couple tries to cut it right, no big deal. I'm tempted to just cut both ends of J square and even if it leaks, at least the relevant end of J is accessible through the mouth of the horn. I can run a bead of construction adhesive down there if needed. Otherwise, cutting a 2.3 degree angle off the end of a 47 inch plank is going to be tricky for me. Any thoughts?

Make all the 13 inch cuts with one set-up of a well adjusted table saw, and they won't vary by more than 1/64 inch.

I've built a couple small folded horns before, but nothing on this scale. My table saw is kind small and wimpy. For some odd reason (probably bad technique) my cuts on the table saw often tend to have a small "jump" somewhere in the middle, especially if the piece with which I am working is larger than 2'x 3' or so. I'm thinking for these panels I'm going to do a much better job with a homemade sawboard and a simple circular saw. Am I headed in the wrong direction here?

...a series inductor has been added to smoothen the response. In practice that may not make much of a difference.

Has anyone tried this design without the series inductor? It would be nice to leave it out if the inductor doesn't make a significant difference in actual practice.

My last observation... I plotted the cross sectional area versus the path length. It seems to me the very first section (from the throat through to the first 180 degree bend) is just a little bit off, being larger than I think it ought to be. Is this intentional, simply a compromise of the design, or a mistake in my calculations? For what it's worth, the rest of the folding seems to have a very consistent expansion throughout all the folds.

Slight modification to Don's 30hz design

Hello Don, I am new to this and don't know a lot about the how all this works, but I was thinking of taking your 30hz tapped horn design and changing the deminsions of the box slightly. I want to lay the box flat and place my entertainment center on top of it. The change would be from 30X38 to 24x44. Seems to be the same volume so do you think it would work.

Thank you for your time.

Keith

Hello Don, I am new to this and don't know a lot about the how all this works, but I was thinking of taking your 30hz tapped horn design and changing the deminsions of the box slightly. I want to lay the box flat and place my entertainment center on top of it. The change would be from 30X38 to 24x44. Seems to be the same volume so do you think it would work.

Thank you for your time.

Keith

- Home

- Loudspeakers

- Subwoofers

- Lab12 - Tapped Horn