Timing TH to system??

Paging DR Tom or any of his minions

Exactly how do I go about timing in a tapped horn sub to my horn loaded tops? How do I account for the phase shift caused by having the sub driver at almost 90 degrees to the mid driver.

I have two units I'm working with. One has a higher angle and seems to mesh with the tops well but doesn't have the low end response.

The other has good low end but doesn't mesh with the tops and that one has a shallower angle (almost horizontal). Ironically

that one tests the best by a couple of db over the first one.

Tips?

Paging DR Tom or any of his minions

Exactly how do I go about timing in a tapped horn sub to my horn loaded tops? How do I account for the phase shift caused by having the sub driver at almost 90 degrees to the mid driver.

I have two units I'm working with. One has a higher angle and seems to mesh with the tops well but doesn't have the low end response.

The other has good low end but doesn't mesh with the tops and that one has a shallower angle (almost horizontal). Ironically

that one tests the best by a couple of db over the first one.

Tips?

Seems like this thread belongs on the live audio board where TD and others 'hold court': http://www.prosoundweb.com/index.php/home/

GM

GM

screamersusa said:THEY DON"T LIKE DIY. For good reason.

That's hardly true. Where do you think the LAB sub hails from:

http://srforums.prosoundweb.com/index.php/f/3/0/

Even so, the focus there is really just on the LAB horn. There has been much more info on this forum regarding TH designs, including participation by Tom Danley himself.

As for integrating with tops, a crossover with delay function would seem appropriate. Most of the speaker DSP processors out there will do this, and some will automatically configure the delay between tops and bottoms for proper phase response. I'm looking at getting a Behringer DCX2496, but the DriveRack line from JBL will also handle this kind of stuff.

I too am looking towards building some compact TH subs. If you go through the huge TH thread, there is some discussion regarding the TH mini that is worth reading. I tried to model with subs I thought might be appropriate, but nothing got close to Danley's (as measured at the sub shootout). I'm thinking about either a dual 12" scaled down version of the LAB subs in TH design. More than likely, I'll probably be building single 12" boxes with more expensive, high excursion drivers.

I think it's important to state what you are trying to accomplish. In my case, I'd like extension to 30Hz. I realize this is kinda low for PA subs, and the tradeoff will be box size and sensitivity. But, as a bass player, I'd like to be able to reproduce the low B string fundamental (31 Hz). What are you looking to build?

When I was working on the BFM cabs, I got a lot of flak.

Lots of folks over there told me to just go buy xyz speakers, ignoring the stated fact that I had no funds to do so.

I've heard thier suggested boxes against both my old DIY boxes and Th modded BFM and mine won. My clients agreed. Unless I could buy some Meyers or Yorkies, I couldn't do much better than what I have.

So I stopped mentioning any DIY boxes over there.

Status

Thanks to Davids new version of horn resp, I was able to model the baffle and spacer as a chamber and found one of my problems. I think I'm having an issue figuring out folds.

The 3015LF isn't great.

I have two final boxes ready for outdoor testing.

The Bulldog has not changed from 34x34x22.5

It looks like a decent utility box. Packs well, and sounds pretty

good in pairs.

The PATH15 got bigger, 40x25.5x31. Fits through building doors fine and Van doors too, and I should be able to get 4 in the trailer easily. It's got wheels and handles like the TH-115.

It's fairly flat with a nice bump at 50 and 45, another rising slope

from 115 peaking at 120 at 107db (inside test) so it will meet up with the Omnitops. Its usable up to 130hz and down to 40 at 100db and 38 at 96 (inside test), however I would cut it hard at 38 because there is something about the 3015lf that goes bonkers below 40 and you run out of xmax with only a few watts.

It's not stiff enough.

The path is also compressed while the Bulldog is not.

The bulldog is a smaller Variant of J Bells box. It also doesn't mind 2225H drivers at all (-3db).

compression seemed to help the acoustical impedence a lot while dropping a few more hertz.

I'll pick one of these as I am out of time and am exausted.

I stopped counting at 16 builds. So one of these will have to do.

I'll post everything on there in this thread since they are intended for live use. Oh yeah, TH's couple very well

The B.I.T.C.H., is on hold as I need to get better with compression and transmission lines to make it work right and find a better driver. It got really complex

and loud but not much below 50hz. almost 4 sheets of plywood

crammed into a 40x28x21 box. I tried to get too much out of the 3015lf.

Lots of folks over there told me to just go buy xyz speakers, ignoring the stated fact that I had no funds to do so.

I've heard thier suggested boxes against both my old DIY boxes and Th modded BFM and mine won. My clients agreed. Unless I could buy some Meyers or Yorkies, I couldn't do much better than what I have.

So I stopped mentioning any DIY boxes over there.

Status

Thanks to Davids new version of horn resp, I was able to model the baffle and spacer as a chamber and found one of my problems. I think I'm having an issue figuring out folds.

The 3015LF isn't great.

I have two final boxes ready for outdoor testing.

The Bulldog has not changed from 34x34x22.5

It looks like a decent utility box. Packs well, and sounds pretty

good in pairs.

The PATH15 got bigger, 40x25.5x31. Fits through building doors fine and Van doors too, and I should be able to get 4 in the trailer easily. It's got wheels and handles like the TH-115.

It's fairly flat with a nice bump at 50 and 45, another rising slope

from 115 peaking at 120 at 107db (inside test) so it will meet up with the Omnitops. Its usable up to 130hz and down to 40 at 100db and 38 at 96 (inside test), however I would cut it hard at 38 because there is something about the 3015lf that goes bonkers below 40 and you run out of xmax with only a few watts.

It's not stiff enough.

The path is also compressed while the Bulldog is not.

The bulldog is a smaller Variant of J Bells box. It also doesn't mind 2225H drivers at all (-3db).

compression seemed to help the acoustical impedence a lot while dropping a few more hertz.

I'll pick one of these as I am out of time and am exausted.

I stopped counting at 16 builds. So one of these will have to do.

I'll post everything on there in this thread since they are intended for live use. Oh yeah, TH's couple very well

The B.I.T.C.H., is on hold as I need to get better with compression and transmission lines to make it work right and find a better driver. It got really complex

and loud but not much below 50hz. almost 4 sheets of plywood

crammed into a 40x28x21 box. I tried to get too much out of the 3015lf.

screamersusa, everything you've attempted thus far sounds good and I am pretty sure you are exhausted. 15 builds in less than a month is unimaginable!! Hats off to your persistence.

Looking forward to seeing the details of your designs.

I thought I'd mention that Don Snyder has built a fairly huge TH using the LAB12 drivers and he says that they go lower and louder than the 3015LF TH.

May be a TH using 2 x LAB12s may not be a bad idea; only have to figure out driver placement. If one chooses a compression chamber it would get very complicated.

Looking forward to seeing the details of your designs.

I thought I'd mention that Don Snyder has built a fairly huge TH using the LAB12 drivers and he says that they go lower and louder than the 3015LF TH.

May be a TH using 2 x LAB12s may not be a bad idea; only have to figure out driver placement. If one chooses a compression chamber it would get very complicated.

Samuel Jayaraj said:screamersusa, everything you've attempted thus far sounds good and I am pretty sure you are exhausted. 15 builds in less than a month is unimaginable!! Hats off to your persistence.

Looking forward to seeing the details of your designs.

I thought I'd mention that Don Snyder has built a fairly huge TH using the LAB12 drivers and he says that they go lower and louder than the 3015LF TH.

May be a TH using 2 x LAB12s may not be a bad idea; only have to figure out driver placement. If one chooses a compression chamber it would get very complicated.

Samuel:

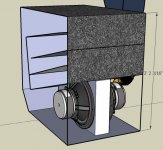

How about this configuration...

Attachments

craigwalsh, your configuration looks very promising. I installed Hornresp on my PC only last night. I need to learn how to use the program. So I'll try and make some sense of what you have posted.

In the meantime, if you or others who are inclined would take this forward, it would be a great contribution to the forum.

Thanks and regards,

In the meantime, if you or others who are inclined would take this forward, it would be a great contribution to the forum.

Thanks and regards,

It could be rewarding to find the optimum compression factor for a driver for pro sound use, since a higher compression leads to more max spl and smaller sized systems. The limiting factor would probably be the potential of cone damage at too high compression, which again seems to be related to the frequency range and excursion, since the same excursion at higher frequency equals more force on the cone. Strong motors like a higher compression value, for example the Beyma 12P1000ND seems to simulate the best for a value around 4-6, again depending on the frequency range while the BMS 18N860 favours one of around 2.

Another thing to think about in order to optimize output per box size is the ratio of cone area to mouth size. Making several small mouthed boxes with the same volume as one big mouth box with only one driver often gives more maximum spl. A good ratio seems to be around mouth size = 1 to 3 times the cone area.

Another thing to think about in order to optimize output per box size is the ratio of cone area to mouth size. Making several small mouthed boxes with the same volume as one big mouth box with only one driver often gives more maximum spl. A good ratio seems to be around mouth size = 1 to 3 times the cone area.

quote/

Oh yeah, TH's couple very well

/quote

yes they do... I'm interested in the 'smaller version of jbells box' I know for my install, size was of no consideration. However that does not apply to most, and what you've done is probably more applicable to the audience here.

Don Snyder was kind enough to draw up in cad my quick design, and double check my hornresp params.. If Don has time, I'm sure everyone would appreciate cad drawings of your efforts as well.

Also, I'll 2nd your observation of a 3015lf in a TH. If you don't have a dcx2496, or some other piece of equipment that can do a STEEP high pass at 40hz... don't build it, period.

I used a 48db/oct 40hz High Pass, and the 3015lf was happy with that.

Thanks for sharing

Oh yeah, TH's couple very well

/quote

yes they do... I'm interested in the 'smaller version of jbells box' I know for my install, size was of no consideration. However that does not apply to most, and what you've done is probably more applicable to the audience here.

Don Snyder was kind enough to draw up in cad my quick design, and double check my hornresp params.. If Don has time, I'm sure everyone would appreciate cad drawings of your efforts as well.

Also, I'll 2nd your observation of a 3015lf in a TH. If you don't have a dcx2496, or some other piece of equipment that can do a STEEP high pass at 40hz... don't build it, period.

I used a 48db/oct 40hz High Pass, and the 3015lf was happy with that.

Thanks for sharing

craigwalsh said:

Samuel:

How about this configuration...

That is a variation of a TH that I built. The only problem I see is the woofers are not configured in push-pull. This means that the non-linear suspension components will not get canceled. However, due to Sd being 2X I would say excursion should be greatly reduced anyway. I'm just saying if you are going to the trouble to build a double woofer TH you might as well go all the way and cancel non-linear distortion while you are at it. As an added benefit, I find that the chamber volume can be useful to flatten the response sometimes.

My double TH --> http://www.diyaudio.com/forums/showthread.php?postid=1627597#post1627597

Rgs, JLH

My comments on compression ratio were to illustrate that some drivers model better with higher ratios, not to indicate that they can survive such a horn in reality. One can generally say, that the smaller the driver (for example use two 12 inch instead of one 18) the more punishment it will be able to take, since the membranes are relatively more heavy compared to bigger drivers.

I dont know how real driver failing under heavy hornloading is, but i somehow it seems to be strange that the compression ratio should have something to do when the driver fails, since a closed box for example has an infinite compression ratio on one side of the driver and isnt really known as the most evil driver killer alignment or take a bandpass, which also has a very high ratio of port area to driver area and here this argument also doesnt apply. Maybe this cone failure under high compression is some kind of artefact, which is rather related to generally driving a driver out of its safe range?

I dont know how real driver failing under heavy hornloading is, but i somehow it seems to be strange that the compression ratio should have something to do when the driver fails, since a closed box for example has an infinite compression ratio on one side of the driver and isnt really known as the most evil driver killer alignment or take a bandpass, which also has a very high ratio of port area to driver area and here this argument also doesnt apply. Maybe this cone failure under high compression is some kind of artefact, which is rather related to generally driving a driver out of its safe range?

JLH said:

That is a variation of a TH that I built. The only problem I see is the woofers are not configured in push-pull. This means that the non-linear suspension components will not get canceled. However, due to Sd being 2X I would say excursion should be greatly reduced anyway. I'm just saying if you are going to the trouble to build a double woofer TH you might as well go all the way and cancel non-linear distortion while you are at it. As an added benefit, I find that the chamber volume can be useful to flatten the response sometimes.

My double TH --> http://www.diyaudio.com/forums/showthread.php?postid=1627597#post1627597

Rgs, JLH

From my perspective, this is pretty similar to the LabSub in that it's feeding a small volume throat, with roughly a 3 or 4 to 1 compression ratio. But, using push-pull might help to reduce distortion. The problem is in fitting that into a small TH. I still need to work on modeling this to find the right drivers.

MaVo said:My comments on compression ratio were to illustrate that some drivers model better with higher ratios, not to indicate that they can survive such a horn in reality. One can generally say, that the smaller the driver (for example use two 12 inch instead of one 18) the more punishment it will be able to take, since the membranes are relatively more heavy compared to bigger drivers.

I dont know how real driver failing under heavy hornloading is, but i somehow it seems to be strange that the compression ratio should have something to do when the driver fails, since a closed box for example has an infinite compression ratio on one side of the driver and isnt really known as the most evil driver killer alignment or take a bandpass, which also has a very high ratio of port area to driver area and here this argument also doesnt apply. Maybe this cone failure under high compression is some kind of artefact, which is rather related to generally driving a driver out of its safe range?

I wonder about that too. I seem to recall reading somewhere that the Lab12's have had trouble with this in the past, but that it's been fixed in the commercially available version. It does seem strange to me too that a driver would fail because it's firing into a small space in one direction, but it's certainly possible. Because of the compressibility of air, a closed box does not present itself as an infinite compression load. Indeed, you need to have a reasonable amount of air in a closed box alignment to control cone motion. I agree that smaller drivers like 12s are probably better for high compression alignments.

I wonder if others will chime in here with their experiences using high compression ratios in bass horns. Anyone had cone failures that were not due to exceeding the mechanical limits of the voice coil gap?

I'm still splitting hairs between the actual build and the original horn resp data. Amazing how a few CM make a difference.

CraigW, I was thinking about that too. I figured the box would get too big. For a moderately loud band that type of arrangement might work but I'd separate the two drivers from each other at least in the first stage. My thinking is: instead of having two drivers pounding away at each other directly, isolating the first stage or two and combining the two at a later point in the horn might take destructive pressure off both drivers. I'm thinking that high pressure at the driver and first stages will prevent damage.

Think like headers on a car, the idea is to time the exaust ports such that they are all about the same length resulting in smooth flow down the exaust pipe. I could be wrong.

While it's a pain to carry more boxes, it's safer for rental work.

If a driver fails out of 4 you disconnect it in seconds and keep going (Captain, weeve only gut thrree qwarters impulse but I think she'll hold).

With double cabs, if one driver fails in show, the whole cab is down. (Damnit Jim ,I'm an engineer not a Magician!).

A funny thing happens to horn loaded speakers as they age, the cones explode. The same pressures that help the box get louder also rip the cones apart if they get wet or dry rot. Too much compression is a bad thing.

On the 3015, try an opening 310sq cm to 600.

I think the definimax looks better but I can't afford any at the moment. I bought 3015 for another project because the 4015 would not fit....Damn!

CraigW, I was thinking about that too. I figured the box would get too big. For a moderately loud band that type of arrangement might work but I'd separate the two drivers from each other at least in the first stage. My thinking is: instead of having two drivers pounding away at each other directly, isolating the first stage or two and combining the two at a later point in the horn might take destructive pressure off both drivers. I'm thinking that high pressure at the driver and first stages will prevent damage.

Think like headers on a car, the idea is to time the exaust ports such that they are all about the same length resulting in smooth flow down the exaust pipe. I could be wrong.

While it's a pain to carry more boxes, it's safer for rental work.

If a driver fails out of 4 you disconnect it in seconds and keep going (Captain, weeve only gut thrree qwarters impulse but I think she'll hold).

With double cabs, if one driver fails in show, the whole cab is down. (Damnit Jim ,I'm an engineer not a Magician!).

A funny thing happens to horn loaded speakers as they age, the cones explode. The same pressures that help the box get louder also rip the cones apart if they get wet or dry rot. Too much compression is a bad thing.

On the 3015, try an opening 310sq cm to 600.

I think the definimax looks better but I can't afford any at the moment. I bought 3015 for another project because the 4015 would not fit....Damn!

screamersusa said:I'm still splitting hairs between the actual build and the original horn resp data. Amazing how a few CM make a difference.

CraigW, I was thinking about that too. I figured the box would get too big. For a moderately loud band that type of arrangement might work but I'd separate the two drivers from each other at least in the first stage. My thinking is: instead of having two drivers pounding away at each other directly, isolating the first stage or two and combining the two at a later point in the horn might take destructive pressure off both drivers. I'm thinking that high pressure at the driver and first stages will prevent damage.

Think like headers on a car, the idea is to time the exaust ports such that they are all about the same length resulting in smooth flow down the exaust pipe. I could be wrong.

While it's a pain to carry more boxes, it's safer for rental work.

If driver fails out of 4 you disconnect it in seconds and keep going (Captain, weeve only gut thrree qwarters impulse but I think she'll hold).

With double cabs, if one driver fails in show, the whole cab is down. (Damnit Jim ,I'm an engineer not a Magician!).

A funny thing happens to horn loaded speakers as they age, the cones explode. The same pressures that help the box get louder also rip the cones apart if they get wet or dry rot. Too much compression is a bad thing.

On the 3015, try an opening 310sq cm to 600.

I think the definimax looks better but I can't afford any at the moment. I bought 3015 for another project because the 4015 would not fit....Damn!

Actually, if wired in parallel, the dual driver box will still perform if one driver dies. But, then it will be way out of alignment! I agree with your sentiment. The other advantage, at least with typical bass horns, is that you get constructive coupling at the mouth area. I'm not sure if that works with TH's though.

JLH said:

That is a variation of a TH that I built. The only problem I see is the woofers are not configured in push-pull. This means that the non-linear suspension components will not get canceled. However, due to Sd being 2X I would say excursion should be greatly reduced anyway. I'm just saying if you are going to the trouble to build a double woofer TH you might as well go all the way and cancel non-linear distortion while you are at it. As an added benefit, I find that the chamber volume can be useful to flatten the response sometimes.

My double TH --> http://www.diyaudio.com/forums/showthread.php?postid=1627597#post1627597

Rgs, JLH

JLH:

Yes, your TH looks very nice. I bet it must sound pretty good! I'm trying to get this one into a line length of somewhere between 3 and 4m to get reasonable extension to the mid-30's. As a bass player, I'd like to get some of my 5 string's B string fundamental (about 31 Hz). But, I'd also like high output and a relatively small box size. I know, this is too much to ask. One of those 3 criteria must be thrown out.

- Home

- Loudspeakers

- Subwoofers

- Live sound specific Tapped Horn thread...