What is the "best" data entry order?

Hi Andrew,

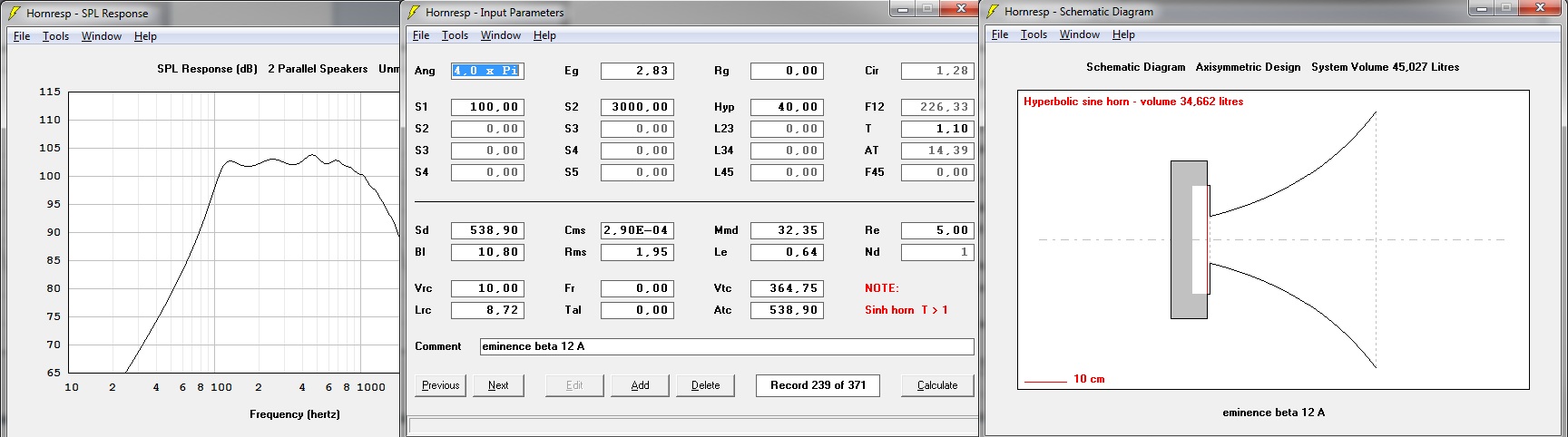

The only time that data entry order becomes important is when you wish to convert driver Thiele-Small parameter values to their electro-mechanical equivalents. In this case, the correct sequence for entering the driver T-S parameters is Sd, Cms, Mmd, Re, Bl, Rms. Use the Tab key or Enter key to automatically achieve this order.

Kind regards,

David

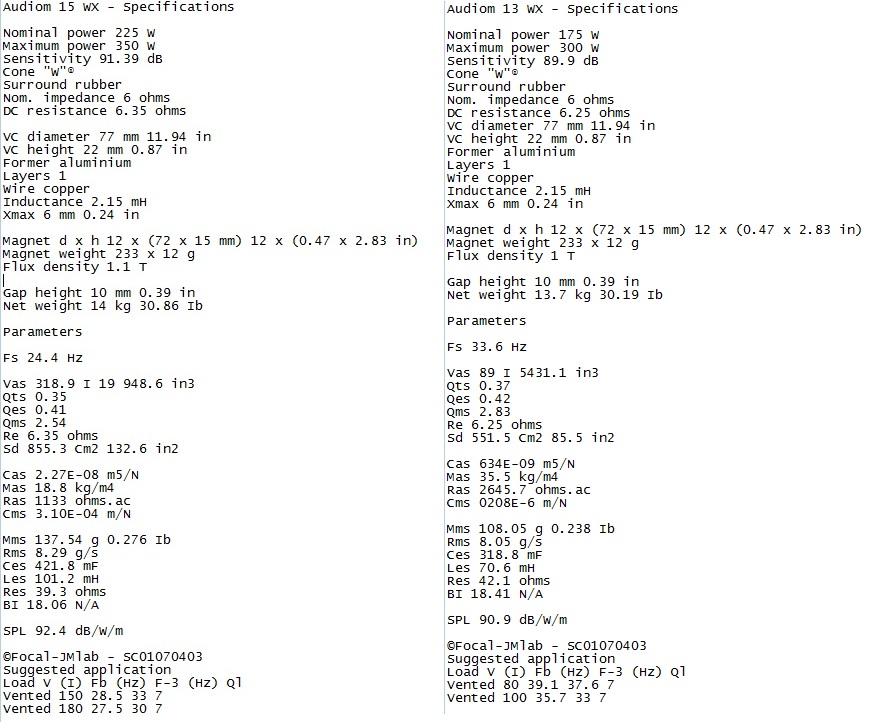

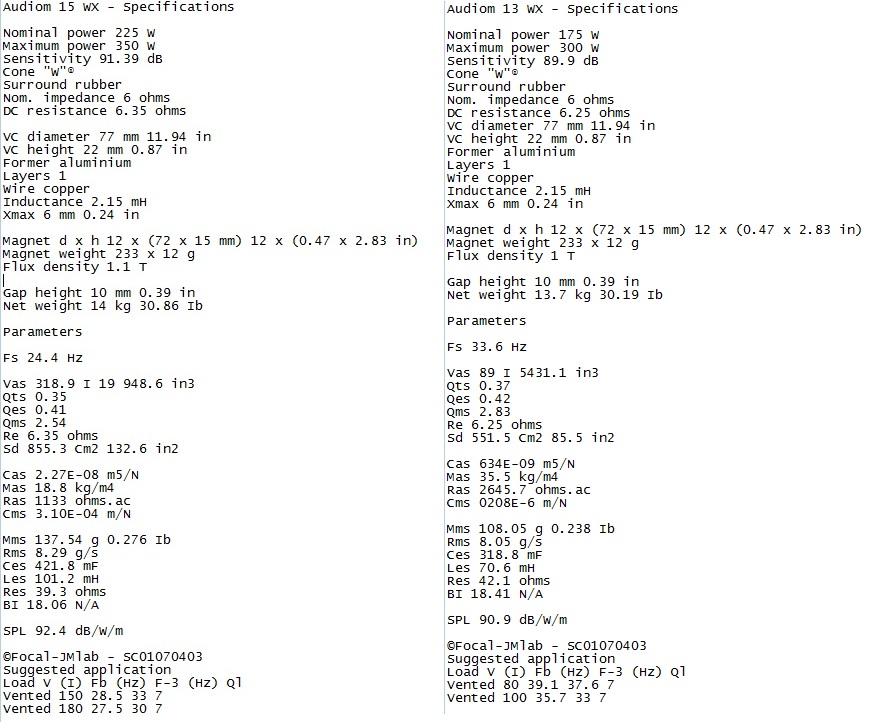

Specs were from this thread http://www.diyaudio.com/forums/subwoofers/213215-advice-required-low-frequency-bass.html

I converted the RMS 8.29 g/s to equal .83 newton.sec/m that Hornresp uses. I did a search to see what the conversion was and it said /10 so thats what I did not really knowing if that was the right conversion.

Hence my suggestion for a simple converter in the program for when the specs aren't provided in the same units, and not sure of the right conversion.

Why Rg = 4 not sure the amps I have are capable of a 4ohm load.

I converted the RMS 8.29 g/s to equal .83 newton.sec/m that Hornresp uses. I did a search to see what the conversion was and it said /10 so thats what I did not really knowing if that was the right conversion.

Hence my suggestion for a simple converter in the program for when the specs aren't provided in the same units, and not sure of the right conversion.

Why Rg = 4 not sure the amps I have are capable of a 4ohm load.

Why Rg = 4 not sure the amps I have are capable of a 4ohm load.

Rg is the output impedance of the amplifier, not what the amplifier is designed to drive. Tube amps can have high output impedances, but usually not more than a couple of ohms. For transistor amps, you can set Rg=0.

Bjørn

Hence my suggestion for a simple converter in the program for when the specs aren't provided in the same units, and not sure of the right conversion.

Hi Silent Screamer,

The existing Hornresp Calculate Parameter tool can be used to find the value of Rms as follows:

1. Set Cms = 3.10E-04 m/N as given in the specifications sheet.

2. Double-click on the Rms value in Edit mode.

3. Enter fs = 24.4 Hz as given in the specifications sheet.

4. Enter Qms = 2.54 as given in the specifications sheet.

The value of Rms is calculated by Hornresp to be 8.28 N.s/m. Note that this is very close to the numerical value given in the specifications sheet, but with entirely different units. The internationally accepted standard unit for mechanical resistance is newton.second/metre - I have no idea where g/s comes from.

Kind regards,

David

Hi David if someone like you doesn't know what hope does a newbie like me have

Funny but I kind of fell over that conclusion when I double clicked on one of the other boxes and it started asking me questions, and then it popped up 8.28, so I figured the conversion I found online must have been wrong or I interpreted it wrong.

Tried to find the website that I found previously and can't, but I did find this in my travels... Lowther PM6A In Back-Loaded Horns

5. RMS, Nm/s

So far the most confusing. Newton * sec / meter, or NS/M

For starters, many sources provide RMS in KG/S.

1 kg/s = 1000 g/s

assuming N = G * M / S^2, we get 1 G/S = 1 N * S^2 / M * S = N * S / M.

Thus, 1 kg/s = 1000 Ns/m

But this is not all yet, as some sources provide Rms in Kg/s and some - Rme in N*s/m, and these do differ, yet not by the factor of 1000. Various sources claim Lowther RMS as .4 to .5 KG/S. What to do? when RMS = 400 entered in hornresp, SPL curve is clearly bad.

So if 1 kg/s = 1000 g/s and 1 kg/s = 1000 Ns/m, then they are the same unit of measure.

Funny but I kind of fell over that conclusion when I double clicked on one of the other boxes and it started asking me questions, and then it popped up 8.28, so I figured the conversion I found online must have been wrong or I interpreted it wrong.

Tried to find the website that I found previously and can't, but I did find this in my travels... Lowther PM6A In Back-Loaded Horns

5. RMS, Nm/s

So far the most confusing. Newton * sec / meter, or NS/M

For starters, many sources provide RMS in KG/S.

1 kg/s = 1000 g/s

assuming N = G * M / S^2, we get 1 G/S = 1 N * S^2 / M * S = N * S / M.

Thus, 1 kg/s = 1000 Ns/m

But this is not all yet, as some sources provide Rms in Kg/s and some - Rme in N*s/m, and these do differ, yet not by the factor of 1000. Various sources claim Lowther RMS as .4 to .5 KG/S. What to do? when RMS = 400 entered in hornresp, SPL curve is clearly bad.

So if 1 kg/s = 1000 g/s and 1 kg/s = 1000 Ns/m, then they are the same unit of measure.

Hi David if someone like you doesn't know what hope does a newbie like me have

Hi Silent Screamer,

I was a bit careless with my wording - I should perhaps have said "I have no idea where the value of g/s comes from" rather than "I have no idea where g/s comes from"

The unit derivation itself is quite straightforward - but not quite as you have shown.

Rms = N * s / m

N = kg * m / (s ^ 2)

Therefore Rms = [ kg * m / ( s ^ 2) ] * [ s / m ]

Which can be simplified to Rms = kg / s by cancelling out m and s as appropriate.

Note that 1 kg / s = 1 N * s / m not 1000 N * s / m

It would seem that the specification sheet is in error - the 8.29 value given for Rms should be in units of kg/s, not g/s.

Kind regards,

David

It might be nice to have motor force displayed at the bottom of the screen when you hover over bl and re, I think it's BL squared /Re. From there force per area and acceleration are easy... Force per area and compression ratio could/would be an interesting metric to observe.

You have throat pressure already though.

You have throat pressure already though.

It might be nice to have motor force displayed at the bottom of the screen when you hover over bl and re, I think it's BL squared /Re. From there force per area and acceleration are easy... Force per area and compression ratio could/would be an interesting metric to observe.

You have throat pressure already though.

Hi Dan,

Making throat sound pressure data available is about as far as I am prepared to go

Kind regards,

David

Hi Dan,

Making throat sound pressure data available is about as far as I am prepared to go. Diaphragm peak velocity and acceleration values are included in the diaphragm displacement chart sample results.

Kind regards,

David

oh yes !! with a nice diagram ?

Cheers.

question about compression ratios.Hey throat pressure is your friend. Very useful when designing near the bleeding edge of efficiency.

what is a reasonable throat pressure for a mid driver.

in my model i have a 5:1 compresion ratio .throat pressure is 4500 pascal at p-max.

is this resonable for a mid pa horn?

are there other considerations?

what is a reasonable throat pressure for a mid driver.

in my model i have a 5:1 compresion ratio .throat pressure is 4500 pascal at p-max.

Seems like a lot for a paper diaphragm, but may be OK for other materials: Pascals to Pound-Forces/Square Inch Conversion Calculator

GM

Yes!

For design of a midrange compression driver the following references constitute mandatory reading. These will lead you to others that are recent and helpful as well. A phase plug should be used to form the front compression chamber.

The compression ratio of [Sd]/[St] = 5 is a good starting point. Note that [St] is the total area of the phase plug slits, not the area of the horn throat that will be larger.

Regards,

WHG

Community Light & Sound M4 Driver

[1] A White paper covering the M4 and some notable installations:

http://www.communitypro.com/files/literature/tech notes/M4_WHITE_PAPER_TECH.pdf

[2] An AES article by Bruce Howze and Clifford Henricksen is available here.

AES E-Library A High-Efficiency, One-Decade Midrange Loudspeaker

[3] Technical Notes Volume 1, Number 30

Cone Midrange Compression Drivers (CMCD)

http://www.jblpro.com/catalog/support/getfile.aspx?docid=201&doctype=3

Phase Plug Design (Smith)

[4] File: ASAJ025-0305.pdf

Date: Mar-53

Title: An Investigation of the Air Chamber of Horn Type Loudspeakers

Author: Bob H. Smith

Publication: ASA-J, Vol. 25, No. 2, Pg. 305, Mar-1953

Affiliation: Division of Electrical Engineering, University of California

URL: Cookies Required

Abstract (1): The front air chamber design is treated as a boundary value problem which yields a solution of the wave equation for the general case in which the horn throat enters the air chamber in a circumferentially symmetrical manner.

Abstract (2): The following specific cases are analyzed: (1) the case in which the horn throat enters the air chamber by means of a single orifice, (2) the horn throat enters the air chamber by means of a single annulus of radius [r] and width [w], and (3) the horn throat enters the air chamber in [m] annuli of radii [r1],[r2],...[rm] and widths [w1],[w2],...[wm].

Abstract (3): The analysis reveals that the radial perturbations caused by the horn throat excites higher order modes. At the resonant frequencies of these modes the horn throat pressure becomes zero and the loudspeaker does not radiate. By suitable choice of annulus radii and widths the first [m] modes may be suppressed and the corresponding nulls in the output pressure eliminated.

[5] File: AESP1384.pdf

Date: Nov-78

Title: An Application of Bob Smith's Phasing Plug

Author: F. M. Murray

Affiliation: Jamse B. Lansing Sound, Inc., Northridge, CA

Publication: AES-P, No. 1384, Cnv. 61 (Nov-1978)

URL: http://www.aes.org/e-lib/browse.cfm?elib=2970

e-Library:

Abstract: The war of the phasing plugs still rages after more than 25 years. Compression driver phasing plugs have vacillated between annular rings, salt shakers, teardrops, and now radial slots again. When Bob Smith provided simple design criteria for optimization of the annular ring type, little did he realize how studiously he would be ignored.

Abstract: His design is now incorporated into a large compression driver capable of operating to the high frequencies where this design is important

question about compression ratios.

what is a reasonable throat pressure for a mid driver.

in my model i have a 5:1 compresion ratio .throat pressure is 4500 pascal at p-max.

is this resonable for a mid pa horn?

are there other considerations?

For design of a midrange compression driver the following references constitute mandatory reading. These will lead you to others that are recent and helpful as well. A phase plug should be used to form the front compression chamber.

The compression ratio of [Sd]/[St] = 5 is a good starting point. Note that [St] is the total area of the phase plug slits, not the area of the horn throat that will be larger.

Regards,

WHG

Community Light & Sound M4 Driver

[1] A White paper covering the M4 and some notable installations:

http://www.communitypro.com/files/literature/tech notes/M4_WHITE_PAPER_TECH.pdf

[2] An AES article by Bruce Howze and Clifford Henricksen is available here.

AES E-Library A High-Efficiency, One-Decade Midrange Loudspeaker

[3] Technical Notes Volume 1, Number 30

Cone Midrange Compression Drivers (CMCD)

http://www.jblpro.com/catalog/support/getfile.aspx?docid=201&doctype=3

Phase Plug Design (Smith)

[4] File: ASAJ025-0305.pdf

Date: Mar-53

Title: An Investigation of the Air Chamber of Horn Type Loudspeakers

Author: Bob H. Smith

Publication: ASA-J, Vol. 25, No. 2, Pg. 305, Mar-1953

Affiliation: Division of Electrical Engineering, University of California

URL: Cookies Required

Abstract (1): The front air chamber design is treated as a boundary value problem which yields a solution of the wave equation for the general case in which the horn throat enters the air chamber in a circumferentially symmetrical manner.

Abstract (2): The following specific cases are analyzed: (1) the case in which the horn throat enters the air chamber by means of a single orifice, (2) the horn throat enters the air chamber by means of a single annulus of radius [r] and width [w], and (3) the horn throat enters the air chamber in [m] annuli of radii [r1],[r2],...[rm] and widths [w1],[w2],...[wm].

Abstract (3): The analysis reveals that the radial perturbations caused by the horn throat excites higher order modes. At the resonant frequencies of these modes the horn throat pressure becomes zero and the loudspeaker does not radiate. By suitable choice of annulus radii and widths the first [m] modes may be suppressed and the corresponding nulls in the output pressure eliminated.

[5] File: AESP1384.pdf

Date: Nov-78

Title: An Application of Bob Smith's Phasing Plug

Author: F. M. Murray

Affiliation: Jamse B. Lansing Sound, Inc., Northridge, CA

Publication: AES-P, No. 1384, Cnv. 61 (Nov-1978)

URL: http://www.aes.org/e-lib/browse.cfm?elib=2970

e-Library:

Abstract: The war of the phasing plugs still rages after more than 25 years. Compression driver phasing plugs have vacillated between annular rings, salt shakers, teardrops, and now radial slots again. When Bob Smith provided simple design criteria for optimization of the annular ring type, little did he realize how studiously he would be ignored.

Abstract: His design is now incorporated into a large compression driver capable of operating to the high frequencies where this design is important

Last edited:

oh yes !! with a nice diagram ?

Hi blo06,

I have no plans to add charts showing diaphragm velocity and/or acceleration - values can however be sampled at user-specified frequencies.

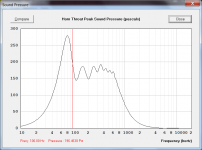

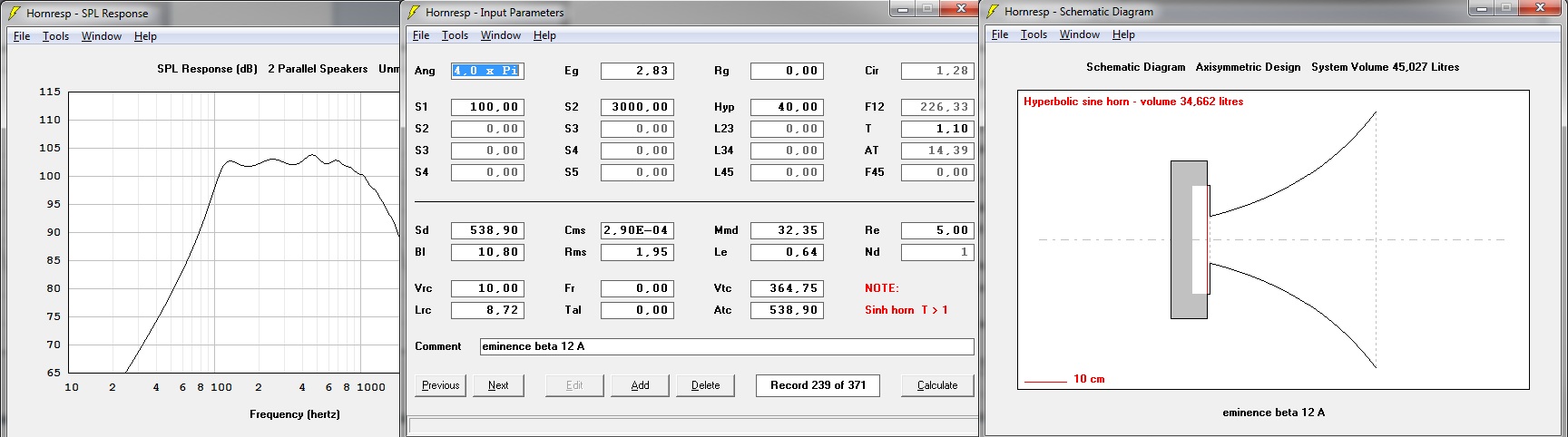

The throat sound pressure chart is displayed by selecting Tools > Sound Pressure from the SPL Response window - see attached screenprint.

Kind regards,

David

Attachments

For design of a midrange compression driver the following references constitute mandatory reading.

tnx

i gues i wil be reading for the rest of the day

I grew up with pounds/square inch (lb/in²)

and half converted to Newtons/square mm (N/mm²) in my professional career.

But Pascals have never been "natural" for me.

Would I be admitting to being lazy by asking for an easy way to "understand" or get a feel for what Pascals means in everyday terms?

Yes, I am lazy, I am asking for an easy way into Pascals.

and half converted to Newtons/square mm (N/mm²) in my professional career.

But Pascals have never been "natural" for me.

Would I be admitting to being lazy by asking for an easy way to "understand" or get a feel for what Pascals means in everyday terms?

Yes, I am lazy, I am asking for an easy way into Pascals.

I can gain read access to only two of the papers.For design of a midrange compression driver the following references constitute mandatory reading.

Is there a way to read any of the others? Without paying the AES for papers contributed by their Members !

Probably not.I guess I will be reading for the rest of the day

- Home

- Loudspeakers

- Subwoofers

- Hornresp