I've published a guide on how to build transmission lines with hornresp.

An Improved Transmission Line Alignment.

Thanks PB, for doing this.

You will notice that I have posted a few comments on the linked thread

PH-4220 and TD2001

I have been trying to model the P-Audio PH-4220 horn to possibly use to make a low cost multiple entry horn. The first stage of this was to trace the the horn from the data sheet. To do this I approximated the horn as conical with an exponential flare near the mouth. I then needed a compression driver model to drive the horn an found this:

Hornresp and TD2001 simulation - Jmmlc - High Efficiency Speaker Asylum

I am actually planning on using a P-Audio BMD-440 but the TAD seemed like a good starting point to see if I had entered values correctly. The problem I am having is that the efficiency is very low, I should be seeing ~106 dB/1W but I instead get about 94dB/1W. Any ideas?

I have been trying to model the P-Audio PH-4220 horn to possibly use to make a low cost multiple entry horn. The first stage of this was to trace the the horn from the data sheet. To do this I approximated the horn as conical with an exponential flare near the mouth. I then needed a compression driver model to drive the horn an found this:

Hornresp and TD2001 simulation - Jmmlc - High Efficiency Speaker Asylum

I am actually planning on using a P-Audio BMD-440 but the TAD seemed like a good starting point to see if I had entered values correctly. The problem I am having is that the efficiency is very low, I should be seeing ~106 dB/1W but I instead get about 94dB/1W. Any ideas?

Attachments

Hmm, first thing is the driver is incomplete in that it has a short internal conical horn defined as "a first element a conical element with S1 = 2,26 cm² ; S2 = 5,07cm² and a length of 6,50cm."

So make/save a new record labelled 'TAD TD2001 1" exit' [not throat as so many mislabel all the W.E./Lansing copycats] with just this horn segment. Now you have a complete driver to sim with.

The second problem is you have the horn throat larger than the 1" exit that it actually has and third, unless the horn is on a huge baffle/box, need to set ANG = 4 pi/free space.

Don't know why you think it should be ~106 dB/W on a conical WG since these vintage spec drivers were designed to load large expo horns, so more like ~96-98 dB on a conical WG.

Bottom line, not the best driver for designing a WG unless extremely long, large or just terminating its internal horn to make a super tweeter at the other extreme.

GM

So make/save a new record labelled 'TAD TD2001 1" exit' [not throat as so many mislabel all the W.E./Lansing copycats] with just this horn segment. Now you have a complete driver to sim with.

The second problem is you have the horn throat larger than the 1" exit that it actually has and third, unless the horn is on a huge baffle/box, need to set ANG = 4 pi/free space.

Don't know why you think it should be ~106 dB/W on a conical WG since these vintage spec drivers were designed to load large expo horns, so more like ~96-98 dB on a conical WG.

Bottom line, not the best driver for designing a WG unless extremely long, large or just terminating its internal horn to make a super tweeter at the other extreme.

GM

I mark the contents of the S1 box, change the value, hit enter or tab, can now edit the first S2, hit enter/tab, can enter L12 values, hit enter/tab, go directly to the first S3 segment completely skipping the last S2. Looks exactly like the old sequence.I don't understand. The tab sequence has been changed for stepped segments as shown in Attachment 2. What issue is still present?

I doubt it is my computer at fault, at least for tab/enter keyboard stroke functionality.

That may be, but last time I was interested in offset closed boxes was a few years ago, could well be that I did not comprehend the proper way to do it.There was nothing to prevent you from specifying a closed box with an offset driver before the latest release. It's just that the enclosure type has now been included as an option in the Input Wizard.

Edit:

Not seeing anything newer than v 49.10, which is what I have.

Last edited:

Hmm, first thing is the driver is incomplete in that it has a short internal conical horn defined as "a first element a conical element with S1 = 2,26 cm² ; S2 = 5,07cm² and a length of 6,50cm."

So make/save a new record labelled 'TAD TD2001 1" exit' [not throat as so many mislabel all the W.E./Lansing copycats] with just this horn segment. Now you have a complete driver to sim with.

The second problem is you have the horn throat larger than the 1" exit that it actually has and third, unless the horn is on a huge baffle/box, need to set ANG = 4 pi/free space.

Don't know why you think it should be ~106 dB/W on a conical WG since these vintage spec drivers were designed to load large expo horns, so more like ~96-98 dB on a conical WG.

Bottom line, not the best driver for designing a WG unless extremely long, large or just terminating its internal horn to make a super tweeter at the other extreme.

GM

Thanks for your help. I though the TD2001 was a pretty normal compression driver not realising it had such an inbuilt horn. Once the horn is added you can see that it is a bad match for this horn. (attached)

Any ideas on something I can use to represent the BM-D446?

Product - Pro Audio Components

My main concern is not accurately predicting the compression driver output but to incorporate its internal path length into the midrange simulation such that I get a prediction of the first cancellation null.

Regarding angles etc. I think I'm seeing less than I expected sensitivity as Hornresp is not including the effect of the horns 90x40 directivity.

Attachments

That may be, but last time I was interested in offset closed boxes was a few years ago, could well be that I did not comprehend the proper way to do it.

Edit:

Not seeing anything newer than v 49.10, which is what I have.

Plum evaded me too, so settled on minimum vent area/length since in the real world I've found it's extremely hard to get a sealed alignment that didn't bleed down fairly quick even with only a psi or two of pulled vacuum.

Me too, though haven't checked out your scenario yet.

GM

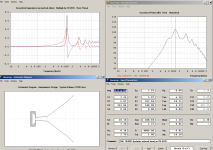

Hello everyone, I am simulating the behavior of a bandpass 6th order and I ended up finding some differences between the hornresp and other softwares, which can be checked in the attached images. I wonder if I'm entering data incorrectly or if that difference between programs is the way they simulate it. I think, as many know, the bassbox pro simulates a cone excursion rms and not a peak excursion, so the voltage used on the graphic was 39.18 volts, which is found doing 27.7 / 0.707, resulting in a graphic of peak excursion. used only in this graphic. in other graphs the voltage used is 27.7 volts.

I mark the contents of the S1 box, change the value, hit enter or tab, can now edit the first S2, hit enter/tab, can enter L12 values, hit enter/tab, go directly to the first S3 segment completely skipping the last S2. Looks exactly like the old sequence.

This is very strange indeed - it works perfectly for me!

As far as the Hornresp code is concerned, if stepped segments have been specified it should be impossible for the action you describe to occur. Just to confirm - are all the segment area labels red when you are doing this? If so, then pressing the Enter or Tab key should navigate you through the segment input boxes in the order shown in the attachment, starting at S1 and finishing at L45.

* * * Is anyone else experiencing the same problem as KaffiMann, when using stepped segments? * * *

Attachments

I am simulating the behavior of a bandpass 6th order and I ended up finding some differences between the hornresp and other softwares,

Without full details of the input data used in each program it is not possible to make a definitive comment, except to say that the results will always be different because Hornresp takes chamber depth into account, whereas most other programs treat the chambers as simple acoustical compliances. The Hornresp model is the more rigorous one.

Hi Everyone,

CHANGE 1

The Loudspeaker Wizard now works with stepped segments.

Fantastic feature! Thank you.

This is very strange indeed - it works perfectly for me!

...

* * * Is anyone else experiencing the same problem as KaffiMann, when using stepped segments? * * *

Allright, n00b alert!

I did not realize I had to actually activate this function by double clicking the S1/S2/S3/S4 area...

But there is one thing, if the stepped segment function is NOT activated, should not Hornresp behave like the good 'ol times?

Because the way it is right now the secondary S2/S3/S4 areas, do not change to the same as the new values in the primary S2/S3/S4 areas.

Bug or feature?

GM, yes exactly!

But if you double click the gray area OUTSIDE the boxes where the S1/S2/S3/S4 text is, then you activate the new stepped segments function.

The new stepped function works great, but it seems to have come at the cost of the regular vanilla flavor of entering data.

But if you double click the gray area OUTSIDE the boxes where the S1/S2/S3/S4 text is, then you activate the new stepped segments function.

The new stepped function works great, but it seems to have come at the cost of the regular vanilla flavor of entering data.

Thanks for your help. I though the TD2001 was a pretty normal compression driver not realising it had such an inbuilt horn.

Any ideas on something I can use to represent the BM-D446?

My main concern is not accurately predicting the compression driver output but to incorporate its internal path length into the midrange simulation such that I get a prediction of the first cancellation null.

Regarding angles etc. I think I'm seeing less than I expected sensitivity as Hornresp is not including the effect of the horns 90x40 directivity.

You're welcome!

It is, but it's designed for a 500 Hz-up XO horn, so design one of those and it will look quite nice and probably will perform better overall than the sim.

Not really, I don't keep up with what's available, plus not real easy to measure what you have/want, so at the mercy of whatever works on someone else's similar alignment.

Dunno, I assume HR uses the mean [90*40]^0.5 = 60 deg, just know conical doesn't load other than via directivity.

You'll have to find the depth from the face of the phase plug to the driver mounting face + any gasket thickness and subtract it from the calculated length to get the distance from the horn throat to the port centerline.

GM

Hmm, I have to double click on the S1, etc., text to get the stepped function, nothing happens clicking on any background area.

GM

Yeah, seems to depend on where you click. On the left side is a broader area that is clickable, seems to be the text + a bit to the right of the text?

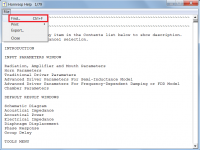

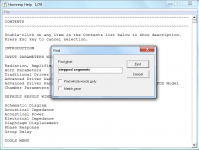

How the stepped segments are enabled?

Double-click on any segment area label in edit mode.

All features are documented in the Help file. In this case, to get the answer you could have simply searched for stepped segments using the Find tool, as shown in the attachments.

Attachments

But there is one thing, if the stepped segment function is NOT activated, should not Hornresp behave like the good 'ol times?

Nothing has changed - when the stepped segment functionality is not activated and the area labels are black, the auto-copy feature works exactly the same as before. This is to ensure that the mouth area of one segment is equal to the throat area of the next.

- Home

- Loudspeakers

- Subwoofers

- Hornresp