It would seem that your new laptop just doesn't like Hornresp.

Greets!

Hmm, it was working fine since Christmas till the last two updates........ Hope the latest update proves a 'keeper'.

GM

Hmm, it was working fine since Christmas till the last two updates........

Hi GM,

Interesting. Could you please let me know if "freezing" still occurs with the latest release.

As an experiment, perhaps try archiving your existing Hornresp.dat file somewhere and allow Hornresp to automatically create a new data file, and see if that helps.

Kind regards,

David

Attachments

Hi GM,

Interesting. Could you please let me know if "freezing" still occurs with the latest release.

As an experiment, perhaps try archiving your existing Hornresp.dat file somewhere and allow Hornresp to automatically create a new data file, and see if that helps.

Kind regards,

David

Greets!

Of course!

Will do, though FWIW it's a new one that began back at Christmas and only has [155] files with none more complex than some offset driver reflex alignments [MLTL].

GM

Has anyone ever requested passive radiators as an option?

Hi Mark,

Not that I can recall.

Just as well - it wouldn't happen anyway

Kind regards,

David

Greets!

Of course!

Will do, though FWIW it's a new one that began back at Christmas and only has [155] files with none more complex than some offset driver reflex alignments [MLTL].

GM

Thanks GM.

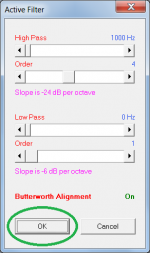

The concern I have is that perhaps the filter data in some of your records may have been corrupted, causing Hornresp to freeze up under certain conditions. The corruption could have been caused by the "save data" bugs that I hope have now all been eradicated

Creating a new Hornresp.dat file will remove the possibility of corrupted filter data being the cause of the "freezing" problem.

Kind regards,

David

Hi Mark,

Not that I can recall.

Just as well - it wouldn't happen anyway.

Kind regards,

David

Never say never!

You have pulled off some minor miracles as of late.

A PR capability would be the cherry on top of the sundae in terms of what this program is capable of simulating.

A PR capability would be the cherry on top of the sundae

Since you put it like that, I guess I will have to give it some consideration...

A chocolate or strawberry flavoured Hornresp - now that would be something!

Since you put it like that, I guess I will have to give it some consideration...

A chocolate or strawberry flavoured Hornresp - now that would be something!.

Perhaps a tool to calculate the PR that is equivalent to the vent that has been defined, where the use can enter the Sd, Mmd, and other relevant parameters of his PR and the tool can calculate much mass has to be added to it to achieve the same tune.

Perhaps a tool to calculate the PR that is equivalent to the vent that has been defined, where the use can enter the Sd, Mmd, and other relevant parameters of his PR and the tool can calculate much mass has to be added to it to achieve the same tune.

Exactly.

Klippel has quite an application note detailing the math behind most of the calculations.

As much as I don't like them in small box high mass loadings, they do have a purpose and a position is the arsenal of design choices we face.

At times I have to design sub cabinets that are so small there is pretty much no other way to get it done.

Another feature request...

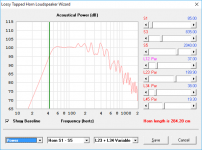

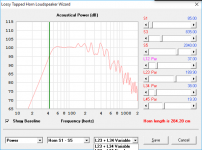

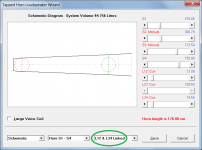

See in the attached image where the horn length is indicated? Is it also possible to have another line of text below there that shows the resonance frequency? The green line on the graph shows the resonance frequency, but it's difficult to determine what it actually is unless you exit the Wizard and run the Calculate option (where it can be identified by looking at the displacement graph and clicking on the graph near to the lowest minimum excursion point). An alternative might be to have the text placed on the graph itself, to the bottom right of the green line showing the resonance frequency.

See in the attached image where the horn length is indicated? Is it also possible to have another line of text below there that shows the resonance frequency? The green line on the graph shows the resonance frequency, but it's difficult to determine what it actually is unless you exit the Wizard and run the Calculate option (where it can be identified by looking at the displacement graph and clicking on the graph near to the lowest minimum excursion point). An alternative might be to have the text placed on the graph itself, to the bottom right of the green line showing the resonance frequency.

Attachments

Perhaps a tool to calculate the PR that is equivalent to the vent that has been defined

What would be the size (expressed in terms of Ap and Lpt) of a typical port tube that would be considered suitable for replacement with a passive radiator?

See in the attached image where the horn length is indicated? Is it also possible to have another line of text below there that shows the resonance frequency? The green line on the graph shows the resonance frequency, but it's difficult to determine what it actually is unless you exit the Wizard and run the Calculate option (where it can be identified by looking at the displacement graph and clicking on the graph near to the lowest minimum excursion point). An alternative might be to have the text placed on the graph itself, to the bottom right of the green line showing the resonance frequency.

I'm intrigued - why it is so important to know the precise frequency (particularly for a tapped horn) and how is the information then used in practice? The setting of the green line in the example given is about 42 to 43 Hz. Isn't this close enough?

An option to link L12 to L34 rather than L45.

The TH1 tapped horn configuration has an option to link L12 to L34. I would rather not have to include it in the TH configuration as well, unless there is a compelling reason to do so. Your "minor" request would require major work to implement.

Attachments

What would be the size (expressed in terms of Ap and Lpt) of a typical port tube that would be considered suitable for replacement with a passive radiator?

I don't know if I can quantify that; maybe MarkK can. I think the PRs we will use are anywhere from 4" to 18" dia., perhaps multiples. I don't know about the length; when it becomes impractically long we consider PRs

JphnJ at AE says the following:

"The PR can be considered equivalent to a port with a surface area equal to the Sd of the passive radiator. The PR Mms is then equivalent to the mass of air volume that would be in the length of the port. They are so similar that you can tune them the same as a port with these simple calculations found here." unfortunately, the link to the equations is broken.

- Home

- Loudspeakers

- Subwoofers

- Hornresp