What gauge of wire?

What type of wire?

Copper clad aluminum or copper?

How many layers?

How many layers of wire in the height if the coil?

Airflow in an out at a given excursion?

Turbulence in the air flow or laminar flow?

Compression in the air entering or exiting?

These are a few of the parameters that need to be taken into account?

You could throw in coil temperature at rest?

And many of these questions require driver dis-assembly.

How many people in DIY can do this, or want to do this?

Even a spot measurement with an infrared thermometer is really only giving you an average idea of coil temperature.

This is not an easy thing to calculate.

And is extremely dependent on the driver motor engineering, not as much on the coil driving the cone.

I admit that some of this could be knocked off with a degree of probability.

And it would certainly be an interesting paper to write up.

Maybe I have a research topic?

Like I don't have enough work to do!

What type of wire?

Copper clad aluminum or copper?

How many layers?

How many layers of wire in the height if the coil?

Airflow in an out at a given excursion?

Turbulence in the air flow or laminar flow?

Compression in the air entering or exiting?

These are a few of the parameters that need to be taken into account?

You could throw in coil temperature at rest?

And many of these questions require driver dis-assembly.

How many people in DIY can do this, or want to do this?

Even a spot measurement with an infrared thermometer is really only giving you an average idea of coil temperature.

This is not an easy thing to calculate.

And is extremely dependent on the driver motor engineering, not as much on the coil driving the cone.

I admit that some of this could be knocked off with a degree of probability.

And it would certainly be an interesting paper to write up.

Maybe I have a research topic?

Like I don't have enough work to do!

Power Compression Due To Voice Coil Temperature

Hi Everyone,

Thanks for your comments.

The only thing that could realistically be done in Hornresp would be to have the user specify the voice coil temperature at Pmax input power, and to calculate the power compression based on that figure.

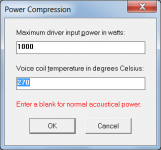

For example, user inputs might be:

Pmax = 1000 watts

Tmax = 200 degrees Celsius

Either a copper or an aluminium voice coil could be specified.

The allowable range for Tmax would be 20 deg C to 270 deg C.

Note that the problem of needing to specify the voice coil temperature still remains - there is no way of getting around this.

Would such a feature be of any practical use?

(As a general rule of thumb, simply doubling the value of Re gives a pretty good indication of the compression to be expected at high power levels).

Kind regards,

David

Hi Everyone,

Thanks for your comments.

The only thing that could realistically be done in Hornresp would be to have the user specify the voice coil temperature at Pmax input power, and to calculate the power compression based on that figure.

For example, user inputs might be:

Pmax = 1000 watts

Tmax = 200 degrees Celsius

Either a copper or an aluminium voice coil could be specified.

The allowable range for Tmax would be 20 deg C to 270 deg C.

Note that the problem of needing to specify the voice coil temperature still remains - there is no way of getting around this.

Would such a feature be of any practical use?

(As a general rule of thumb, simply doubling the value of Re gives a pretty good indication of the compression to be expected at high power levels).

Kind regards,

David

Those that need to know can use this.As a general rule of thumb, simply doubling the value of Re gives a pretty good indication of the compression to be expected at high power levels

Most of us don't use continuous levels that get anywhere near maximum voice coil dissipation limits.

It is just the transients that get close and they generally only last a few milli seconds.

@ David McBean

Hi, as it's possible to include it, albeit in the the form you mentioned, i think it's still worth having, as some designers do actually use methods to gauge temperature.

Interestingly, Any/All design software that shows max SPL, must be off by several dB, if Power Compression isn't taken into account, and/or displayed ! Not only max SPL either, as even @ half power & less Power Compression comes into play !

Hi, as it's possible to include it, albeit in the the form you mentioned, i think it's still worth having, as some designers do actually use methods to gauge temperature.

Interestingly, Any/All design software that shows max SPL, must be off by several dB, if Power Compression isn't taken into account, and/or displayed ! Not only max SPL either, as even @ half power & less Power Compression comes into play !

I have one speaker (Acoustic Energy) that quotes a power compression value. 1.5dB is stated.

All my other speakers stay silent. Even AE's non ae1 say nothing.

It was their claim that the all metal cone/dome/VCformer helped with heat dissipation and resulted in a lower compression value than equivalent domestic speakers.

All my other speakers stay silent. Even AE's non ae1 say nothing.

It was their claim that the all metal cone/dome/VCformer helped with heat dissipation and resulted in a lower compression value than equivalent domestic speakers.

Would such a feature be of any practical use?

A tool that basically raises Re by the amount that you tell it to (by specifying temp)? Not really.

If it's impossible to know the VC temp. it's all just a wild guess and I am against any tools that are based solely on guesswork as it undermines the validity of the sim and the simulator itself. There's not one currently existing feature or tool that is this likely to give wrong results based on having no choice but to guess at inputs.

Besides, opening the tool, specifiying a guessed temp, etc, is a lot more work than just raising Re, so it's a bunch of extra steps leading to a very possibly quite inaccurate sim.

Raising Re manually is also obviously guesswork but at least the user knows he/she is guessing. A tool built into the software would give the user a feeling that the subsequent sim isn't just a wild guess.

@ David McBean

Hi, as it's possible to include it, albeit in the the form you mentioned, i think it's still worth having, as some designers do actually use methods to gauge temperature.

Interestingly, Any/All design software that shows max SPL, must be off by several dB, if Power Compression isn't taken into account, and/or displayed ! Not only max SPL either, as even @ half power & less Power Compression comes into play !

Those that know about power compression already know how to deal with it and know that it takes a bit of guessing and the guesswork might not lead to accurate results. Those that don't probably shouldn't mess with it with wild guesses in a sim.

I am all for educating about power compression, I am very against having a guessing tool built into a simulator.

Design software that shows max SPL isn't necessarily off by several db. There are lots of designs (like OB woofers, but also many others) that are limited by xmax with a tiny fraction of their rated power and suffer no compression at all.

I would strongly suggest a standalone spreadsheet to help guess how much Re to add. Zero D can write it up (and I'm sure he can have plenty of help authoring it if needed) and he can share it with anyone wanting it. IMO this feature can't possibly hold up to the standard of accuracy that Hornresp is famous for and has no place as a formal feature.

I have pretty strong feelings about this. I want my simulators to give accurate results. In situations where it's impossible to give accurate results based on complex and unknown inputs I don't want my simulator guessing. I'll do that myself manually.

Last edited:

+1 ten times over.

Particulary

Particulary

Raising Re manually is also obviously guesswork but at least the user knows he/she is guessing. A tool built into the software would give the user a feeling that the subsequent sim isn't just a wild guess.

..........

Those that know about power compression already know how to deal with it and know that it takes a bit of guessing and the guesswork might not lead to accurate results.

Hi Mark,

I would be interested in having a look at a program that can do that. Is there a name you can give me so I can investigate further? Thanks.

Kind regards,

David

Hello David.

Sadly the programs I know are partly capable of doing this are way out of my reach.

But a wonderful program called FEMM can do thermal modeling. I use it for magnetics analysis. But have never tapped into it's ability to do a proper thermal analysis.

It is free and open source:

Finite Element Method Magnetics: HomePage

I'm pretty sure you know about this program anyway!

Those that need to know can use this.

Most of us don't use continuous levels that get anywhere near maximum voice coil dissipation limits.

It is just the transients that get close and they generally only last a few milli seconds.

Spot on.

Home use and professional use are very, very different.

I have consulted on a couple of very high performance driver designs. One of which pulls out every stop possible on the performance side.

The list of variables I posted previously is pretty skeletal. There are many more variables including plating type on the motor. Shinny or black, type of former, polyimide, fiberglass, aluminum. Glue ratings both on wire bond and wire to coil bond. Former to cone glue ratings. It becomes an insane amount of information to get your hands on.

Hi David,

I don't see any harm in adding an estimated average sensitivity loss figure, but as Mark and others have pointed out above it can get complicated quickly, and the accuracy will definitely be compromised.

Assuming a driver is running somewhere around a tuning point/impedance minimum (e.g.: tuning frequency of a bass reflex box) the voice coil will not be heated evenly. Only part of the voice coil will be heated severely while the rest is just slowly cooking. See Post #1399 here:

http://www.diyaudio.com/forums/subw...tive-tapped-horn-project-140.html#post1462170

Maybe a power compression figure should then also be frequency dependend, Re isn't.

Regards,

I don't see any harm in adding an estimated average sensitivity loss figure, but as Mark and others have pointed out above it can get complicated quickly, and the accuracy will definitely be compromised.

Assuming a driver is running somewhere around a tuning point/impedance minimum (e.g.: tuning frequency of a bass reflex box) the voice coil will not be heated evenly. Only part of the voice coil will be heated severely while the rest is just slowly cooking. See Post #1399 here:

http://www.diyaudio.com/forums/subw...tive-tapped-horn-project-140.html#post1462170

Maybe a power compression figure should then also be frequency dependend, Re isn't.

Regards,

Assuming a driver is running somewhere around a tuning point/impedance minimum (e.g.: tuning frequency of a bass reflex box) the voice coil will not be heated evenly. Only part of the voice coil will be heated severely while the rest is just slowly cooking. See Post #1399 here:

I think things like this are what Mark was referring to when he said "Even a spot measurement with an infrared thermometer is really only giving you an average idea of coil temperature." And it's not just frequency that determines this, it's also coil type. Overhung and underhung will vary greatly in how this type of frequency dependent heating affects temp.

There are a bunch of things that Hornresp does not account for that David could try to make it guess at in a similar way but which are also as prone to inaccuracy. Things like losses due to inadequate enclosure bracing or driver cone breakup(s). These things would require a ton of info to be able to get anywhere close, similar to properly assessing heat in a voice coil.

There's also the mystery of the disappearing peaks in high power tapped horn measurements. Data-bass.com included this hypothesis with the compression graphs:

There is a very large amount of compression shown in the top 3 sweep levels at certain frequencies. This behavior is interesting in part because there is correlation with the peaks in the tapped horns response and maximum areas of efficiency. This behavior was also noted in the tests of the DTS-10 and DTS-10 with the LMSR drivers. It appears to be some sort of output "wall" is reached where further power increases result in little or no further output. We suspect this limit occurs from either drag and or turbulence in the horn path which causes losses in loading and efficiency.

If the hypothesis is correct that sounds a lot like port compression effects which is another area that Hornresp does not account for. Should it try? I don't think so if it's based on guesswork.

In any of these cases if an accurate sim could be produced I would support adding a feature to simulate these things, they would be incredibly useful. But as long as the inputs are based on user guesswork I don't think it's appropriate.

An externally hosted image should be here but it was not working when we last tested it.

Hi Everyone,

Thanks for the additional comments. It seems that the general consensus is to not add a power compression tool to Hornresp because it could possibly mislead users.

Just for the record, the three attachments show the sort of thing that I had in mind:

The input screen is shown in Attachment 1.

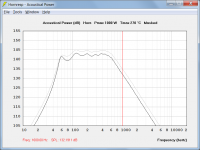

The grey trace in Attachment 2 shows the response at a voice coil temperature of 20 deg C (the given value of Re is assumed to be measured at that temperature), and the black trace shows the response at a voice coil temperature of 270 deg C.

Attachment 3 shows that the power compression at 1000 Hz is 2.787 dB.

It turns out that the difference in power compression response between a copper and an aluminium voice coil at 270 deg C is less than 0.01 dB across the whole frequency range, so there is no requirement to specify the coil material as an input.

Thanks again for the feedback - it has been an interesting discussion.

Kind regards,

David

Thanks for the additional comments. It seems that the general consensus is to not add a power compression tool to Hornresp because it could possibly mislead users.

Just for the record, the three attachments show the sort of thing that I had in mind:

The input screen is shown in Attachment 1.

The grey trace in Attachment 2 shows the response at a voice coil temperature of 20 deg C (the given value of Re is assumed to be measured at that temperature), and the black trace shows the response at a voice coil temperature of 270 deg C.

Attachment 3 shows that the power compression at 1000 Hz is 2.787 dB.

It turns out that the difference in power compression response between a copper and an aluminium voice coil at 270 deg C is less than 0.01 dB across the whole frequency range, so there is no requirement to specify the coil material as an input.

Thanks again for the feedback - it has been an interesting discussion.

Kind regards,

David

Attachments

I can't say I've read all the thermal posts, but I haven't seen anyone mention this. Typically you can monitor voice coil temp by measuring DCR during operation (or during a quick interruption of operation). So that's easy to do with an operating system with just the inclusion of a current sense resistor or current probe. If you know the coil material, you know it's resistivity vs temp characteristic so by measuring the change in DCR from ambient, you know its temperature change from ambient.

Without going through a loop of design -> build -> measure -> simulate, I don't see that thermal modeling is going to be especially useful for absolute output levels as you all have been saying - it's tough to know the relationship between voltage input to power input (depends on content and impedance) and then to temp rise without measuring the thermal time constants of the system or doing a lot of very complicated modeling to get them and then specifying your content. And even in this case, the output level is a function of time, so it's still not extremely simple to look at.

What would seem somewhat useful to me is something like David has suggested - a simulation at a range of coil temperatures. Then you could see the power compression curve shapes. You could probably estimate for most woofers that you could run up to ~200C temp rise from ambient before the coil died, so you could at least get an idea of how the frequency response would change at max power from what it is at low levels.

A possible extension of this is that you could assume a ~200C temp rise for the rated max power given for a driver by the manufacturer and get an approximate max output curve based on that which gave some indication of how power compression might contribute to long term max output. Plotting this would be fun - one possibility might be a series of SPL curves all plotted together vs temp as well as impedance and excursion curves.

Of course the next question people would be asking is what happens to the suspension at elevated temperatures and excursions...

Without going through a loop of design -> build -> measure -> simulate, I don't see that thermal modeling is going to be especially useful for absolute output levels as you all have been saying - it's tough to know the relationship between voltage input to power input (depends on content and impedance) and then to temp rise without measuring the thermal time constants of the system or doing a lot of very complicated modeling to get them and then specifying your content. And even in this case, the output level is a function of time, so it's still not extremely simple to look at.

What would seem somewhat useful to me is something like David has suggested - a simulation at a range of coil temperatures. Then you could see the power compression curve shapes. You could probably estimate for most woofers that you could run up to ~200C temp rise from ambient before the coil died, so you could at least get an idea of how the frequency response would change at max power from what it is at low levels.

A possible extension of this is that you could assume a ~200C temp rise for the rated max power given for a driver by the manufacturer and get an approximate max output curve based on that which gave some indication of how power compression might contribute to long term max output. Plotting this would be fun - one possibility might be a series of SPL curves all plotted together vs temp as well as impedance and excursion curves.

Of course the next question people would be asking is what happens to the suspension at elevated temperatures and excursions...

I can't say I've read all the thermal posts, but I haven't seen anyone mention this. Typically you can monitor voice coil temp by measuring DCR during operation (or during a quick interruption of operation). So that's easy to do with an operating system with just the inclusion of a current sense resistor or current probe. If you know the coil material, you know it's resistivity vs temp characteristic so by measuring the change in DCR from ambient, you know its temperature change from ambient.

Without going through a loop of design -> build -> measure -> simulate, I don't see that thermal modeling is going to be especially useful for absolute output levels as you all have been saying - it's tough to know the relationship between voltage input to power input (depends on content and impedance) and then to temp rise without measuring the thermal time constants of the system or doing a lot of very complicated modeling to get them and then specifying your content. And even in this case, the output level is a function of time, so it's still not extremely simple to look at.

What would seem somewhat useful to me is something like David has suggested - a simulation at a range of coil temperatures. Then you could see the power compression curve shapes. You could probably estimate for most woofers that you could run up to ~200C temp rise from ambient before the coil died, so you could at least get an idea of how the frequency response would change at max power from what it is at low levels.

A possible extension of this is that you could assume a ~200C temp rise for the rated max power given for a driver by the manufacturer and get an approximate max output curve based on that which gave some indication of how power compression might contribute to long term max output. Plotting this would be fun - one possibility might be a series of SPL curves all plotted together vs temp as well as impedance and excursion curves.

Of course the next question people would be asking is what happens to the suspension at elevated temperatures and excursions...

Hi John,

Thanks for this, haven't heard from you for quite a while - hope everything is going well.

Kind regards,

David

Thanks John.

That is a well thought out method to create an approximation of power in and heat potential. I like the balance of the considered gotchyahs to. They always get you in the end.

Hello David.

What you propose is what I have been doing for quite sometime. Many years in fact. I work into the simulation what I know from experience will be maximum power in and possible dissipation.

Coil size, layers and wire diameter all come into play.

But as just a guy pointed out power compression is nowhere linear in all drivers.

So without trying to sound to gloom and doom. I think I already threw in enough of that!

The level of simulation versus reality in hornresp as it stands is pretty close to what I actually measure. Adding in a guessed at power compression ratio is not helping me at least.

I would rather not see it as an option.

It will become an oft quoted useless addition until the people who use it understand that it is a best guess.

That is a well thought out method to create an approximation of power in and heat potential. I like the balance of the considered gotchyahs to. They always get you in the end.

Hello David.

What you propose is what I have been doing for quite sometime. Many years in fact. I work into the simulation what I know from experience will be maximum power in and possible dissipation.

Coil size, layers and wire diameter all come into play.

But as just a guy pointed out power compression is nowhere linear in all drivers.

So without trying to sound to gloom and doom. I think I already threw in enough of that!

The level of simulation versus reality in hornresp as it stands is pretty close to what I actually measure. Adding in a guessed at power compression ratio is not helping me at least.

I would rather not see it as an option.

It will become an oft quoted useless addition until the people who use it understand that it is a best guess.

@ David McBean

I understand the reasons for not including it so far. But you, & others might be interested in how Klippel are seemingly able to acheve it, Without a thermal probe etc !

The diagram in the above link, shows a I - V sensor/converter application, in which the I sense resistor is placed in an alternate position to the one in my circuit. This is the other way of measuring i alluded to. Both give the same results though.

There are lots of useful info, & also PDF's to download & persuse etc on there to.

I understand the reasons for not including it so far. But you, & others might be interested in how Klippel are seemingly able to acheve it, Without a thermal probe etc !

The voice coil temperature can be monitored without using an additional sensor by measuring the dc resistance and considering the material properties of the voice coil. The dc resistance corresponds with the electrical impedance at very low frequencies

Voice coil temperature

The diagram in the above link, shows a I - V sensor/converter application, in which the I sense resistor is placed in an alternate position to the one in my circuit. This is the other way of measuring i alluded to. Both give the same results though.

There are lots of useful info, & also PDF's to download & persuse etc on there to.

@ David McBean

I understand the reasons for not including it so far. But you, & others might be interested in how Klippel are seemingly able to acheve it, Without a thermal probe etc !

The diagram in the above link, shows a I - V sensor/converter application, in which the I sense resistor is placed in an alternate position to the one in my circuit. This is the other way of measuring i alluded to. Both give the same results though.

There are lots of useful info, & also PDF's to download & persuse etc on there to.

Both you and John mention measuring the heat with a circuit and a resistor or probe.

That brings me right back to where I started. Why not just play the driver as intended, get it hot and measure the t/s parameters while hot? That's going to give better results than just measuring the increased Re. We've always had the ability to do this.

Seems to me some of us didn't want to measure t/s parameters while hot so a "guessing" feature was proposed. Now that the guessing feature has been shown to be not too useful a temp measurement device is being proposed, but this new device is still not as useful or easy as just measuring the t/s parameters in the state that they are going to be used.

@ David McBean

I understand the reasons for not including it so far. But you, & others might be interested in how Klippel are seemingly able to acheve it, Without a thermal probe etc !

Hi Zero D,

I was not too worried about how voice coil temperate could be obtained - I was leaving that up to the user

While I understand why voice coil temperature could be considered a somewhat imprecise input parameter, like any other Hornresp input, if the value is accurate then the calculated result (in this case power compression) will be accurate. Of course if the input value is not accurate, then "garbage in, garbage out" - the same as for any other parameter.

Kind regards,

David

- Home

- Loudspeakers

- Subwoofers

- Hornresp