The Datasheet doesn´t provide Sd (I simply don´t get why TC Sounds always does that, but.. oh well..... It´s just the way it is..). The Diameter is NOT the exakt effective area which would be Sd.... This is something TC Sounds is doing the wrong way, honresp can´t be blamed for incomplete datasheets.

The discrepance comes from the way the diameter is derived... If simply measured from the middle of the surrounding, you get a slightly different value compared to calculating it from other parameters. Often datasheets are "mixed", resulting in some slight shifts in the values. In fact, most manufacturers have slight irregularities in theyr datasheets.

One moment, doing some math...

Asuming all the other values in the datasheet are allright, I get Sd=1186,5 cm², which results in Cms=1.25E-04, close enough to the datasheet.

Slight abberations still occur, but thats "normal".

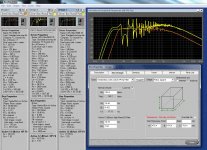

To derive some unknown parameters, you can crosscalc with some tools. I recall WiniSD PRO, LSPCad or TSPCheck, there are probably many more, but these three worked fine for me in the last years. WINISD PRO is free.

So your saying the Cms figure is likely to be more accurate then the diameter they provided? Can you work back from Cms to get Sd?

Hard to tell how they got the data. I don´t know the used measruement system, so I don´t know which method is used to get the data. Most of the paramteres can be calculated from a set of others...

Some parameters are rocksolid most of the times... But then I´ve even found measruement differences in Re when using DAAS, MLSSA and others.... Not by a noticable dimension, but enough to get a datasheet which almost looks like a different driver at first glance... Many manufacturers have slight improvemts on the drivers over the years and not everytime all the data in the datasheet gets updated at once... When Eminence changed the glue on the 3015LF and added some epoxy, MMD certainly went up slightly, but first datasheets around only showed different Qts Values (resulting in "not suitable for ported boxes anymore" statements on the web, since Qts then was 0.45 rather then 0.39 before...). Of course, the driver performed the same (we used a lot of them, I can tell....) and simulations differed only slightly, but there were many people on the web having a completeley different view on this driver than before (all that was changed, was 1,5g of epoxy more...)..

What I am trying to say: On Paper, it sometimes looks like a big difference - but in Reality or simulation, it often is only a small one, if any... TSP-Sets from different measruement-methods even can look very different but still represent the same driver.

Using WinISDPro, you can calculate missing parameters, as long as you have the ones leading to the missing one (assuming they are correct....).

My guess is, that the diameter provided is simply measured with a ruler. Which is ok, if the rest is done afterwards on this basis.. Obviously, it´s not

Some parameters are rocksolid most of the times... But then I´ve even found measruement differences in Re when using DAAS, MLSSA and others.... Not by a noticable dimension, but enough to get a datasheet which almost looks like a different driver at first glance... Many manufacturers have slight improvemts on the drivers over the years and not everytime all the data in the datasheet gets updated at once... When Eminence changed the glue on the 3015LF and added some epoxy, MMD certainly went up slightly, but first datasheets around only showed different Qts Values (resulting in "not suitable for ported boxes anymore" statements on the web, since Qts then was 0.45 rather then 0.39 before...). Of course, the driver performed the same (we used a lot of them, I can tell....) and simulations differed only slightly, but there were many people on the web having a completeley different view on this driver than before (all that was changed, was 1,5g of epoxy more...)..

What I am trying to say: On Paper, it sometimes looks like a big difference - but in Reality or simulation, it often is only a small one, if any... TSP-Sets from different measruement-methods even can look very different but still represent the same driver.

Using WinISDPro, you can calculate missing parameters, as long as you have the ones leading to the missing one (assuming they are correct....).

My guess is, that the diameter provided is simply measured with a ruler. Which is ok, if the rest is done afterwards on this basis.. Obviously, it´s not

Last edited:

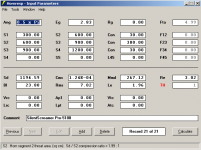

That didn't work... I put in 1194.59 for the Sd and 1125.4 for Cms (which turns into 1.13E+03) I double click Cms and add a Vas of 251.4 and the Cms turns into 1.24E-04, so something isn't right.

I have attached the TS Parameters can you please see what is wrong.

Notice that Cms in the datasheet is in um/N (micrometer per Newton), the units used in Hornresp is m/N. So the value in the datasheet is actually 1125.4E-06 = 1.13E-03.

-Bjørn

The only bit of software I can get to make any kind of sense in Bass Box Pro.

When you use the driver picker it loads a different Cms to the one in the data sheet suggesting a typo in the data sheet.

The Cms in BBP is the same as HR after you double click and it alters the Cms.

When you use the driver picker it loads a different Cms to the one in the data sheet suggesting a typo in the data sheet.

The Cms in BBP is the same as HR after you double click and it alters the Cms.

Attachments

Tolerance and Sensitivity

Derived and Measured TSPs will always be at variance, because those that are measured represent averages over a statistical sample. Expect [CMS] and its derivatives to vary widely from driver to driver and over time as well. Unfortunately, driver manufactures do not publish TSP tolerances because they do not want to warrant them or reveal how little they may be controlling them. For any particular enclosure design, analysis of its sensitivity to driver TSP variance is recommended.

Regards,

WHG

Derived and Measured TSPs will always be at variance, because those that are measured represent averages over a statistical sample. Expect [CMS] and its derivatives to vary widely from driver to driver and over time as well. Unfortunately, driver manufactures do not publish TSP tolerances because they do not want to warrant them or reveal how little they may be controlling them. For any particular enclosure design, analysis of its sensitivity to driver TSP variance is recommended.

Regards,

WHG

Got it sort of working, but it wants to make the cabinet several thousand litres, can anyone make this smaller as the wizard only want to make it big.

You can try a different set of starting parameters. It seems from the resulting horn desing that you want to build a 40Hz-600Hz bass horn for use in a large, open field. (2Pi = halfspace). Two problems with that:

1) you probably do not plan to use the horn out on a large field, so you shoudl specify Ang of either 0.5 (corner) or 1.0 (floor/wall intersection). However, if you do plan to use the horn outdoors, you actually need a large mouth.

2) the driver is a subwoofer driver with a heavy cone, and will not go high in a horn. Hornresp tries to compensate by reducing the throat area, which makes the horn longer and increases throat distortion.

Try setting Ang to 0.5 and reduce the upper cutoff, and the horn becomes much smaller. Efficiency increases too.

-Bjørn

No I was planning to use two of them as home theatre sub woofers.... but cant get the box size down below room size. This program seems to have potential but is completely useless for a novice. The help file is not user friendly enough to be of use and is too vauge for a novice, the wizards which a novice needs to use to get in the ball park suggest boxes the size of football fields.

I treid using 0.5 but still facing 2700 litres which is not practical. So I think I will go back to Bass Box Pro and do a BR box in that. Pity I really wanted to try a folded horn.

I might follow the progress of this one leonardaudio.co.uk mentioned on this website, and see if it is a bit more user friendly.

I treid using 0.5 but still facing 2700 litres which is not practical. So I think I will go back to Bass Box Pro and do a BR box in that. Pity I really wanted to try a folded horn.

I might follow the progress of this one leonardaudio.co.uk mentioned on this website, and see if it is a bit more user friendly.

There is a nice hornresp tutorial on avs forums, google hornresp tutorial.

That will get you started using the general feature set of hornresp.

Once you have a feel for how the input side works you can noodle with the sliders in the output sim windows and get that driver into a horn that will fit your room.

Took me about 3 hrs of noodling to integrate it.

Incedentally that lead to a quantum understanding of how Akabak works without even having used the program. Cool eh?

That will get you started using the general feature set of hornresp.

Once you have a feel for how the input side works you can noodle with the sliders in the output sim windows and get that driver into a horn that will fit your room.

Took me about 3 hrs of noodling to integrate it.

Incedentally that lead to a quantum understanding of how Akabak works without even having used the program. Cool eh?

Its funny, i see this response alot in these type of situations.

are you aware that you judge as "inferior" the abilities of someone who created an amazing tool and the tool itself as inferior, based on the fact that they couldn't build a tutorial.

One of the things we must be aware of is that some people are task oriented and some are are people oriented.

Judging a task oriented person for not being people oriented shows that you are not aware of the difference, ignorance will be a limitation on your experience in general and more acutely in this area.

i hope you find time to learn hornresp, its an INCREDIBLE tool.

Nice box you simmed, ill have to look into that software, can it sim horns as well?

are you aware that you judge as "inferior" the abilities of someone who created an amazing tool and the tool itself as inferior, based on the fact that they couldn't build a tutorial.

One of the things we must be aware of is that some people are task oriented and some are are people oriented.

Judging a task oriented person for not being people oriented shows that you are not aware of the difference, ignorance will be a limitation on your experience in general and more acutely in this area.

i hope you find time to learn hornresp, its an INCREDIBLE tool.

Nice box you simmed, ill have to look into that software, can it sim horns as well?

I wish it could sim horns... It is a very simple program to use and even gives you material cuts.

From my clicking around, I don't for a moment think HR is anything less than brilliant, but it is akin to having a 1000 channel EQ board and not knowing where the power button is located, because the manufacturer assumes you will know how to turn it on.

Confidence in a program is directly proportional to your ability to use it. I am not the only one that doesn't know how to get started, for instance if it shipped with a few example boxes at least we could reverse engineer it and try make a driver we intend to use fit something that has already been included that is close, but not being able to get the box under several thousand litres is pretty much useless to anyone, because we don't know what the right measurements look like to start with.

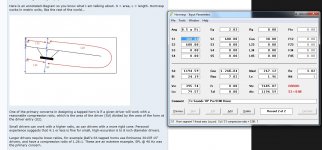

The attached picture is a classic reason why the software needs to include extremely clear instructions. In the tutorial it appears to calculate the compression ratio based on S2, yet when you hover over S1 in the app it appears that it is using S1 as the means to calucate it, when you hover over S2 in the app nothing to do with compression comes up.

So now I am faced with the delima of knowing to trust a self proclaimed novice, or the person who wrote the software, of course I naturally trust the person who wrote the software, but logic also tells me that calculating it off S1 is wrong.

Common sense would dictate that if I am working out a ratio of an angled board I would use the S2 mid point because the high and low either side would even out... but what do I know I dont even understand why I am calculating in the first place so now I am well and truely confused who to trust and what value to put in there...

From my clicking around, I don't for a moment think HR is anything less than brilliant, but it is akin to having a 1000 channel EQ board and not knowing where the power button is located, because the manufacturer assumes you will know how to turn it on.

Confidence in a program is directly proportional to your ability to use it. I am not the only one that doesn't know how to get started, for instance if it shipped with a few example boxes at least we could reverse engineer it and try make a driver we intend to use fit something that has already been included that is close, but not being able to get the box under several thousand litres is pretty much useless to anyone, because we don't know what the right measurements look like to start with.

The attached picture is a classic reason why the software needs to include extremely clear instructions. In the tutorial it appears to calculate the compression ratio based on S2, yet when you hover over S1 in the app it appears that it is using S1 as the means to calucate it, when you hover over S2 in the app nothing to do with compression comes up.

So now I am faced with the delima of knowing to trust a self proclaimed novice, or the person who wrote the software, of course I naturally trust the person who wrote the software, but logic also tells me that calculating it off S1 is wrong.

Common sense would dictate that if I am working out a ratio of an angled board I would use the S2 mid point because the high and low either side would even out... but what do I know I dont even understand why I am calculating in the first place so now I am well and truely confused who to trust and what value to put in there...

Attachments

Your problem is that you are calculating a front loaded horn, where the driver is attached at S1. You need to tell Hornresp that you want a tapped horn, where the driver is attached at S2 and S3. The help tells you how to do this (on page 20, note 8 in my version of HR). When you do this, hovering over S2 gives the compression ratio.

A sample is attached:

A sample is attached:

Attachments

Last edited:

The help tells you how to do this (on page 20, note 8 in my version of HR).

Sorry where do I find this i.e. a thread you have started?

Edit:

Found it at the very bottom of the help file (not sure what it was talking about after that..)

Last edited:

I treid using 0.5 but still facing 2700 litres which is not practical.

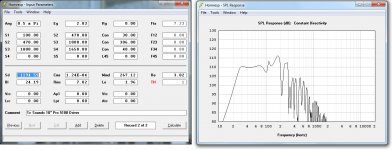

If I set Ang to 0.5, and run "System design with driver", setting the frequency limits to 40Hz and 200Hz, I end up with a total volume of 532 litres. Perhaps you forgot to set the lower frequency to 40Hz? Because using the default values gives you a 2700 litres box.

As you understand, if you want low bass with a horn, they get BIG. But the beauty of a simulation program like Hornresp is that you can truncate the horn and see the effect on the response. And then see if you are willing to accept the compromise (also keep in mind that room modes make the low frequency response very uneven and location dependent).

Once you learn how to use Hornresp, it is very quick to set up a simulation there. But the learning curve can be a little steep, like it can be with many sophisitcated programs. If you accept that, you have at your hands a program that can do things very few other programs can do. And for tapped horns, the only other available program that can simulate them (that I know of) is AkAbak, where you have to enter a script in a text editor.

-Bjørn

Actually I plan to use the two 5100 as bass drivers in OB, I plan on buying another two Ultra 5400's for subs, but needed to work out if the 5400 were the right choice over the 5100's in TH cabinets.

As per the Bass Box pic with both the 5100 and 5400, I should be able to get the 5400 to go lower in TH now.

As per the Bass Box pic with both the 5100 and 5400, I should be able to get the 5400 to go lower in TH now.

- Home

- Loudspeakers

- Subwoofers

- Hornresp