mhtplsh said:Is this the simplest & best?

Try it both ways and judge for yourself. I don't usually notice much difference with the drivers I have tested.

FYI, T/S theory is somewhat predicated on the driver being in a "similar acoustic environment", and free air measurements are nothing like being in a box. ....So the true test would be if the predicted response in a box is better having measured free air, laying on a surface, or mounted on a test baffle.

I have a lot of experience measuring driver parameters. I've unfortunately had to delegate hours and hours into getting a system setup to accurately measure parameters on all of our woofers. We finally have the system functioning the way it needs to for repeatability. We needed to measure the same driver on multiple passes and get the same results. A tolerance of 10% doing the same test was not an option. In reality, with running multiple passes, we need to be within no more than 1% tolerance. Nothing is changed, so the measurement shouldn't change. I've also walked several customers through things Here are some things that are very important.

The first thing I want to note is that you CANNOT fire a driver upwards. No matter what the woofer tester or any other system says, you just can't if you want accurate measurements. Several reasons. Your Bl measurement will be low. The driver instantly sags to some extent, putting it away from it's magnetic center, where Bl is low. Depending on the driver this can be up to a 10% decrease in Bl right away as you are away from the magnetic center. Firing upwards means not only is the motor working against the suspension but against gravity. Extra force to fight against makes the Bl seem even lower. Then when you add mass you are fighting even more against gravity and further sagged from center. The further you sag from center, the stiffer the compliance seems also. Now this begins to effect your measurements of Fs, Vas, Mms, etc.

The next thing is do not do the delta mass method. Use delta compliance. Adding mass to the cone means you probably have to fire it upwards, or have something sticky on the cone so you can fire vertically. With the cone firing up with added mass, you further stress the suspension into a place it isn't supposed to be and futher put the coil away from center. Bl is even more decreases, suspension seems stiffer that it is, and you can't get an accurate measurement of the shift with the added mass anyway which means your electro mechanical parameters are all off.

Then, ANY movement of the driver, mass added, or baffle holding the driver will throw off the impedance curve drastically. A door slamming, a fan blowing at the driver, truck driving by, etc can all throw it off. This doesn't mean you need a perfectly silent room, but make sure you minimize the noise. It also won't throw it off the same every time. This will show up as an irregularity in the impedance curve. Blips, bumps, dips, etc that you will see in both the magnitude and phase at and around the driver Fs will drastically throw off every possible parameter. The following are a series of measurements done by a customer. When measuring the driver he got Mms measurements that varried from 130grams up to 250grams. The mass was physically verified on a postage scale of 210grams.

Here are the images:

You can see all the bumps in both the magnitude and phase around the peak at Fs and in the one driver a double peak even. When calculating parameters a curve fit is done of the measured impedance curve. With these irregularities, the entire curve fit is thrown off.

So how do we measure accurately? First start out with the Delta Compliance method. This means you need a free air baffle, and an enclosure of known volume. We use 50L for 15" and 25L for 12" right now. Make sure to fire the driver horizontally, not up or down. You want both the coil to be centered. Make sure nothing moves. This is very critical as you have seen in the measurements above. The woofer creates and equal and opposite force on the enclosure, table, etc. We recently built our "shark cage" which is a steel structure over 250lbs bolted with 6 threaded rods into the concrete floor to be the bench for clamping our measurement enclosures down to. While you may not need to go this extreme, make sure it is well mounted. Make sure you can repeat the same impedance curve nearly identically. Praxis allows you to hold a curve, then remeasure. If the two are nearly perfectly overlaid, we realize the test is valid. If it looks different, something is wrong. If there are weird peaks, bumps, a flat top on the impedance curve, rounded top, etc, something is most likely moving.

When measuring the second step in the sealed enclosure, make sure it is perfectly sealed. If it is not, the enclosure will seem larger than it actually is, showing less shift in the given volume than it should. This throws off all your compliance related measurements. Your in box peak should be taller and narrower than the original. If it isn't, something is wrong.

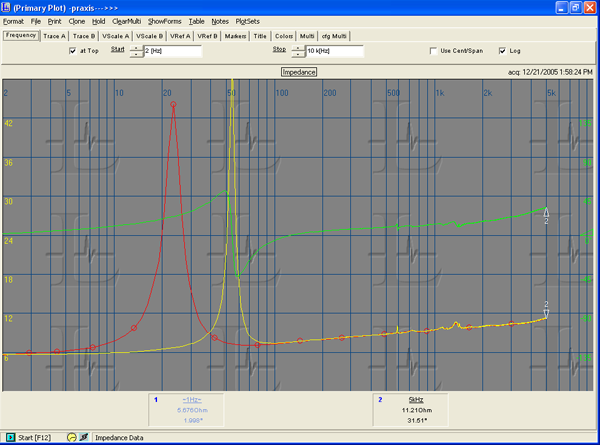

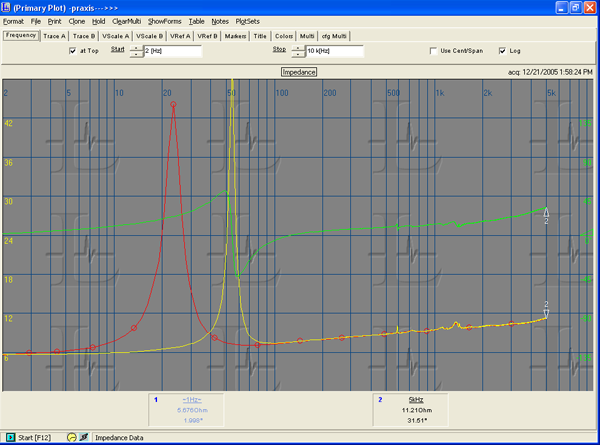

The following shows two good impedance curves that you can then withdraw accurate parameters from:

The first red peak shows the free air and the yellow shows the in box measurement. The small blips at 600hz and above are due to surround resonance, etc and are far out of the range we are concerned about for T/S parameters.

Also one final note, all the equations for Vas, Mms, Bl, etc are based on using 1/3 of the surround diameter and not 1/2. I see many software packages incorrectly stating to use 1/2 for your Vas measurements. This just doesn't work as it inflates Vas and Bl to accommodate for it. Praxis is the same way. We tried doing it, but we would get an Mms and Bl value both inflated by about 20% when doing so. Properly measuring 1/3 of the surround gave correct values. We always check our measurements based on known Mms values physically weighed on a postage scale. We then fine tune the diameter measurement until it shows the correct Mms value being measured. Then we know the rest will all fall in line as well.

John

The first thing I want to note is that you CANNOT fire a driver upwards. No matter what the woofer tester or any other system says, you just can't if you want accurate measurements. Several reasons. Your Bl measurement will be low. The driver instantly sags to some extent, putting it away from it's magnetic center, where Bl is low. Depending on the driver this can be up to a 10% decrease in Bl right away as you are away from the magnetic center. Firing upwards means not only is the motor working against the suspension but against gravity. Extra force to fight against makes the Bl seem even lower. Then when you add mass you are fighting even more against gravity and further sagged from center. The further you sag from center, the stiffer the compliance seems also. Now this begins to effect your measurements of Fs, Vas, Mms, etc.

The next thing is do not do the delta mass method. Use delta compliance. Adding mass to the cone means you probably have to fire it upwards, or have something sticky on the cone so you can fire vertically. With the cone firing up with added mass, you further stress the suspension into a place it isn't supposed to be and futher put the coil away from center. Bl is even more decreases, suspension seems stiffer that it is, and you can't get an accurate measurement of the shift with the added mass anyway which means your electro mechanical parameters are all off.

Then, ANY movement of the driver, mass added, or baffle holding the driver will throw off the impedance curve drastically. A door slamming, a fan blowing at the driver, truck driving by, etc can all throw it off. This doesn't mean you need a perfectly silent room, but make sure you minimize the noise. It also won't throw it off the same every time. This will show up as an irregularity in the impedance curve. Blips, bumps, dips, etc that you will see in both the magnitude and phase at and around the driver Fs will drastically throw off every possible parameter. The following are a series of measurements done by a customer. When measuring the driver he got Mms measurements that varried from 130grams up to 250grams. The mass was physically verified on a postage scale of 210grams.

Here are the images:

You can see all the bumps in both the magnitude and phase around the peak at Fs and in the one driver a double peak even. When calculating parameters a curve fit is done of the measured impedance curve. With these irregularities, the entire curve fit is thrown off.

So how do we measure accurately? First start out with the Delta Compliance method. This means you need a free air baffle, and an enclosure of known volume. We use 50L for 15" and 25L for 12" right now. Make sure to fire the driver horizontally, not up or down. You want both the coil to be centered. Make sure nothing moves. This is very critical as you have seen in the measurements above. The woofer creates and equal and opposite force on the enclosure, table, etc. We recently built our "shark cage" which is a steel structure over 250lbs bolted with 6 threaded rods into the concrete floor to be the bench for clamping our measurement enclosures down to. While you may not need to go this extreme, make sure it is well mounted. Make sure you can repeat the same impedance curve nearly identically. Praxis allows you to hold a curve, then remeasure. If the two are nearly perfectly overlaid, we realize the test is valid. If it looks different, something is wrong. If there are weird peaks, bumps, a flat top on the impedance curve, rounded top, etc, something is most likely moving.

When measuring the second step in the sealed enclosure, make sure it is perfectly sealed. If it is not, the enclosure will seem larger than it actually is, showing less shift in the given volume than it should. This throws off all your compliance related measurements. Your in box peak should be taller and narrower than the original. If it isn't, something is wrong.

The following shows two good impedance curves that you can then withdraw accurate parameters from:

The first red peak shows the free air and the yellow shows the in box measurement. The small blips at 600hz and above are due to surround resonance, etc and are far out of the range we are concerned about for T/S parameters.

Also one final note, all the equations for Vas, Mms, Bl, etc are based on using 1/3 of the surround diameter and not 1/2. I see many software packages incorrectly stating to use 1/2 for your Vas measurements. This just doesn't work as it inflates Vas and Bl to accommodate for it. Praxis is the same way. We tried doing it, but we would get an Mms and Bl value both inflated by about 20% when doing so. Properly measuring 1/3 of the surround gave correct values. We always check our measurements based on known Mms values physically weighed on a postage scale. We then fine tune the diameter measurement until it shows the correct Mms value being measured. Then we know the rest will all fall in line as well.

John

Thanks John_E_Janowitz,

I appreciate ur nice & informatery explanation.

Just check the following.

what i understand :

We must do the testing with Delta Compliance method.

Driver must be mouted horizontal.

Needs free airbaffle & SEALED enclosure.

Free air baffle means a sheet of plywood/mdf with driver mouted in the center.

Is this ok?

I appreciate ur nice & informatery explanation.

Just check the following.

what i understand :

We must do the testing with Delta Compliance method.

Driver must be mouted horizontal.

Needs free airbaffle & SEALED enclosure.

Free air baffle means a sheet of plywood/mdf with driver mouted in the center.

Is this ok?

The vented box method is even better as you only need one measurement, not two! -Andrews

In one of the thread i saw the above comment. Andrews hv not furnished any further info about it even after asked for.

Anybody can give details about vented box testing method?

John_E_Janowitz said:The first thing I want to note is that you CANNOT fire a driver upwards. No matter what the woofer tester or any other system says, you just can't if you want accurate measurements.

Depends on the driver. The higher the Vas or Mms, the more sag there is. I measure no difference with recent 4" and 6" woofers. Have not built a sub in a while....

John_E_Janowitz said:Firing upwards means not only is the motor working against the suspension but against gravity.

You described the change in operating point, which is due to "gravity", there is no additional effect. Also the effect is only significant for drivers with appreciable sag.

John_E_Janowitz said:The next thing is do not do the delta mass method.

Good arguments.

John_E_Janowitz said:Then, ANY movement of the driver, mass added, or baffle holding the driver will throw off the impedance curve drastically. We recently built our "shark cage" which is a steel structure over 250lbs bolted with 6 threaded rods into the concrete floor to be the bench for clamping our measurement enclosures down to.

Good info. I reserve comment on the "shark cage". If you are testing cabinets with mounted PR's, I can see the utility.

John_E_Janowitz said:We always check our measurements based on known Mms values physically weighed on a postage scale. We then fine tune the diameter measurement until it shows the correct Mms value being measured. Then we know the rest will all fall in line as well.

What you measure on the postage scale is Mmd, not Mms. Mms includes air loads which cannot be measured on a postal scale.

Geometrically, 1/2 of the surround makes more sense. Because notation varies, I cannot really argue your results without seeing them in full.

Delta compliance doesn't require diameter anyway right

mhtplsh said:In one of the thread i saw the above comment. Andrews hv not furnished any further info about it even after asked for.

Anybody can give details about vented box testing method?

You put the woofer in a vented box and measure Fl, Fh and Fb.

From this you can get Vas, Fs.

Ron E said:You described the change in operating point, which is due to "gravity", there is no additional effect. Also the effect is only significant for drivers with appreciable sag.

The additional effect is that as the cone is moving upwards it is fighting against gravity. The acceleration of gravity is 9.80665 m/s² (32.17 ft/s²). This becomes a vibes equation that gets complicated due to non-linear BL and Cms curves, but can be approximated. I'll work on that soon. The main point is that on the upward stroke the motor is fighting against gravity and on the downward stroke it is working with gravity. All in all this means your inward and outward stroke is not the same.

Good info. I reserve comment on the "shark cage". If you are testing cabinets with mounted PR's, I can see the utility.

This is just simply for T/S parameter measurements on drivers. Not full cabinets. I can show you easily how a simple chirp tone on a 12" or 15" driver can cause enough movement that even this structure cannot stop. All mounting of the driver to cabinet and cabinet to the table needs to be completely rigid. We use toggle clamps that can apply a large amount of force. Rubber ends had to be removed. Soft material behind the driver to seal the enclosure also needed to be removed. The Chirp tone is essentially a very fast sweep. Doing it quickly creates a large amount of force. Doing it slower is much less bound to movement, but then is more bound to issues due to room interaction.

What you measure on the postage scale is Mmd, not Mms. Mms includes air loads which cannot be measured on a postal scale.

Geometrically, 1/2 of the surround makes more sense. Because notation varies, I cannot really argue your results without seeing them in full.

Yes, Mms will be slightly more than the physical Mmd, but typically not by too much. It's usually no more than 1% or so. This is why you need a very open freeair baffle. As you add in more of a baffle the loading gets larger. If you look at all of the original formulas from Theil and Small, they specify that the effective moving area is 1/3 of the surround. If you were to actually be able to see a cross section of what is moved as the surround goes in and out, you'd see that it is equal to about 1/3 of the surround that is moving air.

Delta compliance doesn't require diameter anyway right

If that were the case it would make my life a lot easier. Calculating Vas, Mms and Bl does require diameter unfortunately. I had someone training on how to measure parameters. Couldn't figure out why Mms measured 100grams more than it should have been and BL was 25% too high.

John

John_E_Janowitz said:The additional effect is that as the cone is moving upwards it is fighting against gravity.

That is false, but you are correct that nonlinearities complicate things. Actually, if the cone sags appreciably it will actually be easier to move up than down

John_E_Janowitz said:This is just simply for T/S parameter measurements on drivers. Not full cabinets. I can show you easily how a simple chirp tone on a 12" or 15" driver can cause enough movement that even this structure cannot stop.

I know what a chirp is. The question: at what input level?

At what input level does it cease to be a "T/S" test and become a "proprietary" parameter test?

John_E_Janowitz said:Yes, Mms will be slightly more than the physical Mmd, but typically not by too much. It's usually no more than 1% or so. This is why you need a very open freeair baffle. As you add in more of a baffle the loading gets larger. If you look at all of the original formulas from Theil and Small, they specify that the effective moving area is 1/3 of the surround. If you were to actually be able to see a cross section of what is moved as the surround goes in and out, you'd see that it is equal to about 1/3 of the surround that is moving air.

Mms-Mmd depends on the acoustic environment, off the top of my head 20-30 grams on a 15" woofer is certainly not out of the question.

John_E_Janowitz said:If that were the case it would make my life a lot easier. Calculating Vas, Mms and Bl does require diameter unfortunately. I had someone training on how to measure parameters. Couldn't figure out why Mms measured 100grams more than it should have been and BL was 25% too high.oops.

Vas does not require Diameter when using delta compliance. You are using known Mmd, guesstimated Diameter and presumably "design Bl" and checking your T/S derived Bl and Mms against them, not something an average DIYer can do.

Bl and Cms can be measured directly.

Sd can be measured in several more accurate ways.

The "real" difference between Mms and Mmd can be determined by a vacuum resonance measurement.

T/S assumes no inductance, generally, and inductance complicates parameter measurement, making the resonance peak asymmetric. Since you are particular about accuracy, do you know how to compensate - or do you leave it to a black box?

Chocolate cheesecake...never touch the stuff

I seem to remember a time having something to do with Nick and Bassbox and PR's and when you expressed a distinct preference for not eating cheesecake when served. Then Bassbox got rewritten

Good times....

Ron E said:That is false, but you are correct that nonlinearities complicate things. Actually, if the cone sags appreciably it will actually be easier to move up than downDraw a free body diagram - remember those?

Hmm... I dropped out of school so I wouldn't have to worry about those things anymore. haha This actually goes beyond more than a simple physics problem. I never took Vibes class, but now I wish I would have. Luckily my friend did graduate and went through to get a masters in engineering mechanics. He's setting up the equations so we can work through them.

In general though, firing horizontally doesn't have the initial offset and doesn't have the nonlinear force on up and downward stroke. I never recommend up or downfiring woofers. The other problem not in measuring parameters, but in long term use, is that the driver sags and becomes permanently more biased over time due to the suspension wearing out.

I know what a chirp is. The question: at what input level?

At what input level does it cease to be a "T/S" test and become a "proprietary" parameter test?

With praxis we measure with less than 1V input. With the very short cycle chirp you can still feel the table moving. I was amazed how much force is actually applied.

Vas does not require Diameter when using delta compliance. You are using known Mmd, guesstimated Diameter and presumably "design Bl" and checking your T/S derived Bl and Mms against them, not something an average DIYer can do.

Yes, you are correct. Vas doesn't require diameter. The relationship to Bl and Mms does. looks like I messed up in the loading slightly also. I stated no more than 1%, but it looks like no more than 5% would be a more accurate number. In any case, our former build house would send us drivers specifying 375grams Mms. When physically weighing the parts, they would weigh 250grams. Obviously any loading will not the nearly that much. Bl was also equivalently inflated. they would specify motor strength as Bl^2/Re for comparison to other drivers which was obviously giving a false comparison. Vd comparisons were also inflated due to the larger Sd. Correcting diameter to 1/3 surround as the original T/S papers suggest instead of 1/2 solved the issues and makes for a fair comparison.

Obviously, calculating exactly how much air is being moved by the surround would be more correct but not a simple measurement. It's something that varies throughout the travel of the driver.

The "real" difference between Mms and Mmd can be determined by a vacuum resonance measurement.

this is a more difficult measurement though. Definitely not something a DIYer is going to do. Probably something we should be able to do at some point though.

T/S assumes no inductance, generally, and inductance complicates parameter measurement, making the resonance peak asymmetric. Since you are particular about accuracy, do you know how to compensate - or do you leave it to a black box?

Yes, the peak will be asymmetric to some extent, the higher the inductance the more it becomes an issue. I honestly don't know if our QC software takes it into account or not. I believe it will look at both sides of the peak and take an average. In general though, getting all of the other conditions out is something much more serious than compensating for the inductance as the effects are fairly minor unless you have extremely high inductance drivers.

I seem to remember a time having something to do with Nick and Bassbox and PR's and when you expressed a distinct preference for not eating cheesecake when served. Then Bassbox got rewritten

Good times....

Yeah, those were the days when I was too busy playing with speakers to go to class. Learned a few things since then. Lot more to learn yet.

John

Ron E said:That is false, but you are correct that nonlinearities complicate things. Actually, if the cone sags appreciably it will actually be easier to move up than downDraw a free body diagram - remember those?

Hi, not wanting to argue but to learn since this is a bit counterintuitive.

Is it easier to move up because you are under the gap ? So the magnet is more powerful to move up than down ?

This sag can be compensated by flowing a variable DC current from a current source. It would have the additional benefit that you could calculate Bl from the cone mass and the current (provided you could measure the zero displacement position precisely).John_E_Janowitz said:The first thing I want to note is that you CANNOT fire a driver upwards. No matter what the woofer tester or any other system says, you just can't if you want accurate measurements. Several reasons. Your Bl measurement will be low. The driver instantly sags to some extent, putting it away from it's magnetic center, where Bl is low. Depending on the driver this can be up to a 10% decrease in Bl right away as you are away from the magnetic center. Firing upwards means not only is the motor working against the suspension but against gravity. Extra force to fight against makes the Bl seem even lower. Then when you add mass you are fighting even more against gravity and further sagged from center. The further you sag from center, the stiffer the compliance seems also. Now this begins to effect your measurements of Fs, Vas, Mms, etc.

I think the major argument against firing up/down is that you can not place the speaker far enough from the floor and close reflecting surfaces may influence the measurement.

Yesterday & Today i tested the driver with woofer tester old model.

Yesterday i tested with sealed cabinet/free air & today i tested with free air/delta mass.

The driver was the same.

yesterday today

in a sealed box delta mass

Fo 41.65 hz 41.6445 hz

Re 3.5443 ohm 3.5470 ohm

Qms 6.60 6.4881

Qes 0.5584 0.5558

Qts 0.5113 0.5119

Rm in Ns/m 2.417 2.197

(Mechanical)

Cm in 260.88 268.231

micron/Newton

Mm in gms 56.00 56.4677

BL 9.64 9.54

spl 84.93 85.07

Vas .5572 cu. ft .5729 cu. ft.

Le 2..20 2.1932

I think i am getting almost similar results from both the testing methods.

In delta mass i did the weight of the modeling clay on a very presision scale 32.67gms.

When removed i weighted it as 32.65gms.

Waiting for remarks from fellow members.

Yesterday i tested with sealed cabinet/free air & today i tested with free air/delta mass.

The driver was the same.

yesterday today

in a sealed box delta mass

Fo 41.65 hz 41.6445 hz

Re 3.5443 ohm 3.5470 ohm

Qms 6.60 6.4881

Qes 0.5584 0.5558

Qts 0.5113 0.5119

Rm in Ns/m 2.417 2.197

(Mechanical)

Cm in 260.88 268.231

micron/Newton

Mm in gms 56.00 56.4677

BL 9.64 9.54

spl 84.93 85.07

Vas .5572 cu. ft .5729 cu. ft.

Le 2..20 2.1932

I think i am getting almost similar results from both the testing methods.

In delta mass i did the weight of the modeling clay on a very presision scale 32.67gms.

When removed i weighted it as 32.65gms.

Waiting for remarks from fellow members.

simon5 said:

Hi, not wanting to argue but to learn since this is a bit counterintuitive.

Is it easier to move up because you are under the gap ? So the magnet is more powerful to move up than down ?

It's easier to move up because the suspension is trying to pull the cone back up. Think of it like pulling back a crossbow.

with the help of all the fellow members i am able to get good results of thiel small. suggestion of John_E_Janowitz was very helpful in solving getting proper results in testing problem.

Now i want to know more about new USB software by three parties.

I hv posted new thread :

http://www.diyaudio.com/forums/showthread.php?s=&threadid=114228

Now i want to know more about new USB software by three parties.

I hv posted new thread :

http://www.diyaudio.com/forums/showthread.php?s=&threadid=114228

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Thiel small testing