they care, they want business. For the time been, I would not hesitate to give them more jobs.

Then we should try to bank on this, and let them know if they are doing things right, they will get more of this to do.

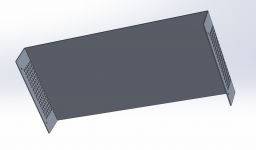

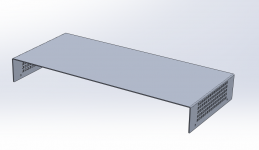

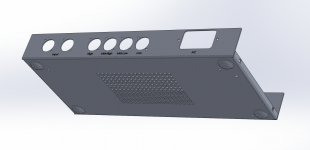

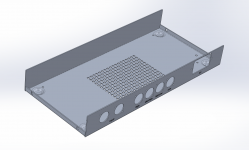

I have a small project for which I already have pcbs (not the parts yet) and that requires a case, which I have designed to be sheetmetal, preferably aluminum, to be black anodized. So if they can do this right, I'd try them out, if they're giving me a good enough pricing on it, that I can afford.

I can post visuals afterwards, since we're in this forum where everyone is posting stuff about what they build...

Yes, topology, brilliant - topology I would add !

I'm intrigued. Can you share some specifics?

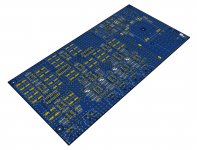

Here are some visuals for that little project I mentioned.

It's a 4way xover.

I don't have the parts, I need the get the case made, but I already do have the pcbs on hand. Looking good so far.

It's a 4way xover.

I don't have the parts, I need the get the case made, but I already do have the pcbs on hand. Looking good so far.

Attachments

^^^ Very nice !

Well, for my project the parts are big and various, so I guess a good chunk of the cost material and setup.

I am certain by the looks of it your project will be much less expensive. I am not sure how well they do with sheet metal bending as par as precision goes. I think it be more difficult to get this perfectly right so it is pleasing to look at.

I am not sure what your budget is for this, I would prefer all machined parts for the better precision, at least the side parts, top and bottom would be ok with sheet metal work.

The Technics BIAS scheme has been discussed here on the forum, I have some trouble finding it, tho.

Edit.

Found it.

It's Vzaichenko's Thread, and if I am not mistaken the Technics Synchro Bias scheme is discussed there.

Revisiting some "old" ideas from 1970's - IPS, OPS

And another Thread

New Class A, Super-A, Non-Switching : need a revival ?

Well, for my project the parts are big and various, so I guess a good chunk of the cost material and setup.

I am certain by the looks of it your project will be much less expensive. I am not sure how well they do with sheet metal bending as par as precision goes. I think it be more difficult to get this perfectly right so it is pleasing to look at.

I am not sure what your budget is for this, I would prefer all machined parts for the better precision, at least the side parts, top and bottom would be ok with sheet metal work.

The Technics BIAS scheme has been discussed here on the forum, I have some trouble finding it, tho.

Edit.

Found it.

It's Vzaichenko's Thread, and if I am not mistaken the Technics Synchro Bias scheme is discussed there.

Revisiting some "old" ideas from 1970's - IPS, OPS

And another Thread

New Class A, Super-A, Non-Switching : need a revival ?

Last edited:

Doing machined parts for something like this simple case would cost more than just plain sheet metal.

I would like to get it done black anodized, if not too costly.

There isn't a whole lot of bending to do, it's a lot more dependent on the proper cutting, to get all the holes just right, and I think laser or perhaps plasma cutting might be the best way to go to get this done right and cheap enough.

It all depends on how well equipped the shop is. I did inquire locally near a shop that I know, and they're well equipped for such things, with the laser cutting table and what's required to fold/bend the sheets. I haven't got any response yet, it's been several days, maybe they're just too busy right now, but I anticipate a hefty price from them, nobody can be economical in Europe.

So I think I'll very likely have to get this done in China, so it can be done affordably. If they can properly do the cutting, laser preferably, then do the bending without a sloppy workmanship with marks everywhere, and finally anodize, preferably in house if they can do it, which would save money...

I would like to get it done black anodized, if not too costly.

There isn't a whole lot of bending to do, it's a lot more dependent on the proper cutting, to get all the holes just right, and I think laser or perhaps plasma cutting might be the best way to go to get this done right and cheap enough.

It all depends on how well equipped the shop is. I did inquire locally near a shop that I know, and they're well equipped for such things, with the laser cutting table and what's required to fold/bend the sheets. I haven't got any response yet, it's been several days, maybe they're just too busy right now, but I anticipate a hefty price from them, nobody can be economical in Europe.

So I think I'll very likely have to get this done in China, so it can be done affordably. If they can properly do the cutting, laser preferably, then do the bending without a sloppy workmanship with marks everywhere, and finally anodize, preferably in house if they can do it, which would save money...

Attachments

In countries other than China where labour is expensive, when manufacturing sheet metal you are pretty much paying the operator to handle the sheet. 10 parts or 50 costs about the same. To be cost effective you need to fill a sheet. For CNC machining a large part of the cost is the CAD and the CAM. For 1 off parts this adds a huge expense to the job. Spread that out over 100 or 1000 parts and the price drops substantially. It's a tough go trying to get 1 off parts even quoted due to the time involved to even look at the job. They know they will be losing money on the job doing a single part due to the time it takes to do tool and fixture changes in the machines only to do one part so they quote high hoping to either scare you away are get well paid if you do go for it.

CNC machines have been around long enough to go through quite a few generations of upgrades. Modern CNC mill are turning upwards of 100000 RPM and feed rates are psychotic. Older machines that are still working fairly well are simply too slow to manufacture with any more so they are starting to become hobby machines. The trick is to find someone local that has machines that they use for a hobby. Those are the people that will manufacture one off parts reasonably.

CNC machines have been around long enough to go through quite a few generations of upgrades. Modern CNC mill are turning upwards of 100000 RPM and feed rates are psychotic. Older machines that are still working fairly well are simply too slow to manufacture with any more so they are starting to become hobby machines. The trick is to find someone local that has machines that they use for a hobby. Those are the people that will manufacture one off parts reasonably.

I wish I knew someone local with such CNC machines. That would be great.

I know someone in the usa who has easy access to a bunch of machines, and he could do this for me fairly easily, and basically at no cost. But I'm not there right now and the shipping costs would be huge enough to be significant enough to be dissuasive...

I know someone in the usa who has easy access to a bunch of machines, and he could do this for me fairly easily, and basically at no cost. But I'm not there right now and the shipping costs would be huge enough to be significant enough to be dissuasive...

I lucked out and got a nice old Fadal 4020 for Christmas last year at work. I recently bought a small Crossfire plasma table. These machines along with an old brake, shear, manual mill and lathe allow me to make just about anything now. I got tired of waiting for anodizing so I figured out how to do this myself too. The only things I outsource for my amps now is punching or laser. I send out laser engraving too, not worth buying the equipment when I can have it done for $10.

Wow, a Fadal 4020 is a serious machine, perfect for this hobby. One of my friend has something very similar to your Fadal, equipped with a Haidenhain CNC controller, in his shed in the backyard. Unfortunately he is currently fully booked making parts for a well known local company here in town that puts things into orbit.

As far as anodizing goes, I thought of it, doing it myself also, but I live within the city limits and we have signs here indicating ground water protection area so, I rather do not mess with the acidic chemicals around here, I don't want to catch a ticket if the ByLaw officer ever finds out.

I rather let a company do this messy business, it is not that expensive.

As far as anodizing goes, I thought of it, doing it myself also, but I live within the city limits and we have signs here indicating ground water protection area so, I rather do not mess with the acidic chemicals around here, I don't want to catch a ticket if the ByLaw officer ever finds out.

I rather let a company do this messy business, it is not that expensive.

The 4020's a good size for what we bought it for. I build custom vehicles so it's big enough to build parts like engine mid plate if needed. it's a bit too small for speakers though, so I'm still looking for a router to go with it.

Anodizing isn't really that messy. The acid concentration is very mild and is easily neutralized with a box of baking soda. It's not nearly as nasty as a jug of ferric chloride or the home brew board enchants people are using.

Anodizing isn't really that messy. The acid concentration is very mild and is easily neutralized with a box of baking soda. It's not nearly as nasty as a jug of ferric chloride or the home brew board enchants people are using.

Having the right tools helps with the job. I have collected some parts to build a router, they came from a pick & place machine, that was retired at work. But I doubt I would ever build a router with it as I am getting older now.

I hear ya, the etching with ferric chloride is really messy. But now that we can have professionally made boards at reasonable cost there is no need anymore to mess in the kitchen with this stuff.

I hear ya, the etching with ferric chloride is really messy. But now that we can have professionally made boards at reasonable cost there is no need anymore to mess in the kitchen with this stuff.

Almost finished.Remove rifa? funny smelll today

the guts, and the unit with the top on and a '60s linear psu with an option to double max amperage via 2 metal trannies.

Might remove the rifa located on live side of japanese power switch, funny smell today. Gotta replace the 2 volume knobs that surely have an expiry date with a stereo Alps Japanese pot.

the guts, and the unit with the top on and a '60s linear psu with an option to double max amperage via 2 metal trannies.

Might remove the rifa located on live side of japanese power switch, funny smell today. Gotta replace the 2 volume knobs that surely have an expiry date with a stereo Alps Japanese pot.

100 watt bi polar power amp.

LTP into VAS with Vbe and CCS.

Outputs are MJ15003/4

Great sounding little amp.

LTP into VAS with Vbe and CCS.

Outputs are MJ15003/4

Great sounding little amp.

An externally hosted image should be here but it was not working when we last tested it.

RIFA warning. See My thread "trannies I have tried" to find out alerted me.

One night stand with a formerly normal looking rifa "cleaning" the AC power and I woke up to a funny smell, took the top off, looked at the RIFA and removed it to find what you will see in the pic. X2 safety rating my @%$

X2 safety rating my @%$

Now I am ,

,  , love y'all FAM!

, love y'all FAM!

Sorry about blurry pic but it tells a story, and confirms many others.

Thanks to user "voltwide" for the heads up. I am wondering if he might be "time machine man" from the song by paradox

One night stand with a formerly normal looking rifa "cleaning" the AC power and I woke up to a funny smell, took the top off, looked at the RIFA and removed it to find what you will see in the pic.

Now I am

Sorry about blurry pic but it tells a story, and confirms many others.

Thanks to user "voltwide" for the heads up. I am wondering if he might be "time machine man" from the song by paradox

Last edited:

You can "rely" on these Rifas as mains bomb.One night stand with a formerly normal looking rifa "cleaning" the AC power and I woke up to a funny smell, took the top off, looked at the RIFA and removed it to find what you will see in the pic.X2 safety rating my @%$

Now I am,

, love y'all FAM! View attachment 784498

Sorry about blurry pic but it tells a story, and confirms many others.

Thanks to user "voltwide" for the heads up. I am wondering if he might be "time machine man" from the song by paradox

Some time ago I dumped all my Rifas in the X-cap box. The coating had cracked and fissures were visible everywhere. That way humidity creeps in and destroys insulation.

Last edited:

- Home

- Amplifiers

- Solid State

- Post your Solid State pics here