For my SKA project, I'm bolting together two Conrad heatsinks (flat to flat). I need them lined up and stable to do this, and was considering some method to temporarily bond them together.

I was suggested to me to use plain-ol white Elmers glue. Bond them together, drill, and toss in a pail of warm water to get them apart again after the drilling is done.

Silly idea, or might there be a better way?

I was suggested to me to use plain-ol white Elmers glue. Bond them together, drill, and toss in a pail of warm water to get them apart again after the drilling is done.

Silly idea, or might there be a better way?

Could you be a little more specific about what you want to do? Which sides of the heatsinks are you going to glue together? I'm probably misunderstanding you, but there are not THAT many holes to drill. If you measure correctly then it is quite easy to have both sides' holes line up.

Need to join the heatsink 'flats'...the machined side of each one. On one of them, after drilling, the holes will be tapped. The other will have a clearance hole - the whole point being to bolt them together to increase surface area. Would be much much easier to get holes to line up if I can join them and then drill.

EchoWars said:

Double-sided tape? Small clamps?

If you do the glue thing, a sheet of brown wrapping paper glued in between will likely make separation easier.

Regards.

Aengus

I was suggested to me to use plain-ol white Elmers glue. Bond them together, drill, and toss in a pail of warm water to get them apart again after the drilling is done.

Double-sided tape? Small clamps?

If you do the glue thing, a sheet of brown wrapping paper glued in between will likely make separation easier.

Regards.

Aengus

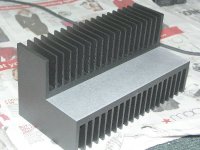

Sure...pinkmouse said:Can you post a pic?

Idea is to bolt the smaller one to the larger one. I've got a drill press, and some extra-long drill bits. Six holes get drilled through the both of them (the proper size for tapping a #6 machine screw), and then they are separated. Once apart, the holes in the smaller one get tapped for the #6 screw, and the holes in the large heatsink get drilled out to a size appropriate as a pass-through for the screw. Then they get bolted together.

Attachments

Hi EchoWars,

I think masking tape would hold them securely enough. I wouldn't bother though, just measure and drill. You have a millimeter or two give and take.

You could also make a jig and do each heatsink separately.

BTW: The gaps between the fins are not equal. The first gap at either end is a little wider, plus there seems to be a bigger gap slightly off centre. You need to check that the head of the screw fits. Forget about washers.

regards

I think masking tape would hold them securely enough. I wouldn't bother though, just measure and drill. You have a millimeter or two give and take.

You could also make a jig and do each heatsink separately.

BTW: The gaps between the fins are not equal. The first gap at either end is a little wider, plus there seems to be a bigger gap slightly off centre. You need to check that the head of the screw fits. Forget about washers.

regards

Well, my dad returned this evening with some double-sided masking tape. I have a feeling that it may do the job nicely, and probably be a lot neater than any glue.

Greg and Wavebourn...I have terrible luck getting such things right, and on these heatsinks, I have very very little room for error, as the head of a #6 Allen head screw just barely fits between the heatsink fins. If I can drill both at once, my chances for success are a hellova lot better.

Greg and Wavebourn...I have terrible luck getting such things right, and on these heatsinks, I have very very little room for error, as the head of a #6 Allen head screw just barely fits between the heatsink fins. If I can drill both at once, my chances for success are a hellova lot better.

Long thin drills can and do wobble and go off centre. I'd mark up and drill the smaller of the two with a slightly smaller bit, working on the flat face so uou can use a nice short bit for accuracy. Then, clamp the two together, and use the holes as pilots for the main hole. That will reduce wander as the drill bit is supported. When you have finished drilling, flatten both heatsinks back down on some 300 grit wet and dry taped to a sheet of glass. Oh, and a dozen or so holes might work better to spread the clamping force.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- SKA Heatsinks