jakelm3075 said:...a Dh-200 with a bad on\off switch. I went to radio shack and bought another 3 prong switch. Replaced the switch the exact same way the bad switch was. Plugged the amp in and blow the main fuse. The switch I bought is a 3 prong switch similar to the original, different look but same 3 prong. I'm lost as to what went wrong.

.....

I also plan on bridging this amp for a sub amp. Is this a good idea? Does Hafler still make the bidgeing kit? Also, is there a way to bridge it without the kit?

There may be a reason the switch was burned out. The amp could have serious problems that cause it to draw lots of juice and blow the fuse. Or the cheapo switch from RS might not be able to handle the load. Or you might have hooked up the switch wrong. Switches are not standard in their pinouts, sorry to say.

You can tell if the amp is OK or not by just bypassing the switch, and seeing if the fuse blows again. People do this when the switch fails, and just plug and unplug the power cord instead. If fuses blow again, leave it for a tech, it's probably more than you can fix.

If not, figure out which two pins on the switch connect together when you close the switch. Those are the lugs to connect to. You should be able to figure out what two lugs to use by measuring the switch resistance with an ohmmeter as you move it on and off.

I have a hunch your RS switch can't take the load. It's a 15A rating demanded. I wrote up a fixit list for this amp two years ago here, and the first thing I mentioned is the switch is bad on most of the amps I see. Anyway, you need a beefy 15A switch, and it will still fail in a few years again, sorry about that. My patch for the switch is a thermistor, but I don't recommend you put this in unless you really know what you are doing.

Here is what I wrote about this in Feb 2004:

"First, here is my list of the most common failures in these amps, with causes. The power switch fails, due to excessive inrush currents (see fix below). The output transistors do burn out, probably due to insufficient cooling coupled with oversized fuses on power. The input pairs go leaky due to overdriven inputs. When the outputs fail, they generally take out drivers and possibly inputs, as you would expect. That's what I see most often, so those are the areas I check first.

There is not a lot you can do to hugely improve the sound of this amp, in my opinion. Here are some small mods that preserve the essential character of the design while adding reliability.

The first mod is simply an NTC thermistor (5 ohm cold) on the AC power. This is needed to prevent the switch from failing due to high inrush current. On most of the amps I see, the power switch is toast and has to be replaced, but it will just fail again unless you do this mod. If you do nothing else, do this mod!"

I don't know if your amp is seriously blown or just the switch is toast, you will have to do the switch bypass to see. If the fuses blow again, quit while you are ahead and turn this over to a tech. Probably the outputs MOSFETs are shorted, but there is no sense in you causing a fire trying to chase it down. You're dealing with a 30 year old amp that could have other issues, so walk softly.

As far as bridging this, once you get it working it's easy if you are a competent tech. A couple of wire pairs have to be connected in a particular way from each board to a new switch on the back. I do it all the time to the amps I modify. I put it in, and bingo, a monoblock is born. I get the feeling most people use these for subs, but they are still good amps in my book. Just no frills, which I like. Anyway, good luck!

Thanks slow. I'm trying another switch tonight. But if that doesn't work, what wires do I hook together to bypass the switch? There is a small wire from the fuse, a large black wire from the plug, another small black wire to the light and another blue wire from the right channel board.

jakelm3075 said:Thanks slow. I'm trying another switch tonight. But if that doesn't work, what wires do I hook together to bypass the switch? There is a small wire from the fuse, a large black wire from the plug, another small black wire to the light and another blue wire from the right channel board.

I will probably regret this, but...

To see if it is just the switch, connect the two wires together that do not go to the light. In other words, connect the wire from the fuse to the wire from the plug. This is just temporary. If it works, use the new switch when you get it.

If the fuse blows again, it's not just the switch. You have a big problem somewhere else. Quit while you are ahead and have a tech finish the job.

slowhands said:

I will probably regret this, but...

I will take full responsibility for my actions..

Lets hope the fuse blows before my house...lol

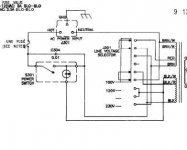

You need to get up close and personal with the Hafler DH-200 schematic and wiring diagrams. You can get these at WWW.HAFLER.COM. Go to the Archive library and download the pdf file for your amp.

The switch has three prongs. Two are to switch the AC, the 3rd is to light the pilot light. The proper switch has the numbers 1, 2, 3 embossed on its back side. The Hafler wiring diagram shows the switch wiring complete with the numbers 1, 2, 3. If you study the diagrams and get the proper switch and match up the 1, 2, 3 connections installing the switch is as simple as "1, 2, 3."

Install a ceramic cap across the AC connections and make it a .01 uF cap as previously suggested.

The other stuff you referred to, the resistor, etc., are part of a little circuit that makes the yellow indicator lamp blink if the amp overheats and one of the thermal switches opens up. Again, study the schematic and wiring diagrams and firgure it out. It is a simple circuit.

Don't even think about bridging the DH-200. Reports from those who did said the amp did not really like being bridged. To bridge it requires a special add on circuit card that no longer is available. Any amp channel has distortion and when you bridge an amp you add up the distortion from each channel together so the mono output has twice the normal amount of distortion. This, plus the impedance load limitations, make bridging a very poor solution. If you need more watts, get a larger amp.

When you get the Mouser switch, tell us about it. The Carling variety I purchase locally has the 1, 2, 3 numbers molded in. Does the Mouser switch have the numbers?

Good luck.

The switch has three prongs. Two are to switch the AC, the 3rd is to light the pilot light. The proper switch has the numbers 1, 2, 3 embossed on its back side. The Hafler wiring diagram shows the switch wiring complete with the numbers 1, 2, 3. If you study the diagrams and get the proper switch and match up the 1, 2, 3 connections installing the switch is as simple as "1, 2, 3."

Install a ceramic cap across the AC connections and make it a .01 uF cap as previously suggested.

The other stuff you referred to, the resistor, etc., are part of a little circuit that makes the yellow indicator lamp blink if the amp overheats and one of the thermal switches opens up. Again, study the schematic and wiring diagrams and firgure it out. It is a simple circuit.

Don't even think about bridging the DH-200. Reports from those who did said the amp did not really like being bridged. To bridge it requires a special add on circuit card that no longer is available. Any amp channel has distortion and when you bridge an amp you add up the distortion from each channel together so the mono output has twice the normal amount of distortion. This, plus the impedance load limitations, make bridging a very poor solution. If you need more watts, get a larger amp.

When you get the Mouser switch, tell us about it. The Carling variety I purchase locally has the 1, 2, 3 numbers molded in. Does the Mouser switch have the numbers?

Good luck.

I do have the technical schematics manual for the amp. The amp seems to be a pretty easy design. I just want , with the help from you guys, to make sure I do things right, the first time (or second time in this case).

I take this project as the perfect oportunity to learn more about circuits and schematics. I am good at part changing but I do have alot to learn on how everything works. That was the main reason for joining up here. Hopefully I can learn alittle, then give my opinion to someone in the future who is in the same boat as I am right now.

I am more familiar with speaker design and audio\video calibration than actual hands on repairs. So I appreciate everyones patients and help.

Jake

P.s. I will let you know on the switch

I take this project as the perfect oportunity to learn more about circuits and schematics. I am good at part changing but I do have alot to learn on how everything works. That was the main reason for joining up here. Hopefully I can learn alittle, then give my opinion to someone in the future who is in the same boat as I am right now.

I am more familiar with speaker design and audio\video calibration than actual hands on repairs. So I appreciate everyones patients and help.

Jake

P.s. I will let you know on the switch

Hi Jake,

The last comment I made was not aimed at anyone, but rather intended to keep you from making an error.

To test the amplifier, I have a real problem with just shorting the wires and juicing it up. At least use a variac or light bulb in series.

For a permanent inrush limiter, consider using a 2~4 ohm resistor in series that is shorted out by relay contacts, coil energized by the secondary DC supply. That will give you the best solution and lowest supply impedance in the "run" state. This method is used in many large amplifiers.

-Chris

The last comment I made was not aimed at anyone, but rather intended to keep you from making an error.

To test the amplifier, I have a real problem with just shorting the wires and juicing it up. At least use a variac or light bulb in series.

For a permanent inrush limiter, consider using a 2~4 ohm resistor in series that is shorted out by relay contacts, coil energized by the secondary DC supply. That will give you the best solution and lowest supply impedance in the "run" state. This method is used in many large amplifiers.

-Chris

I find it difficult to believe this thread has gone on this long. It's really a very simple fix.

Oh, well. I'm having a bad day so I'm grumpy. Ignore me if I fuss too much.

The Mouser part number I gave earlier is the Carling Mini-Tippette (or whatever they call the silly thing) direct replacement for the original switch, albeit with a 50% higher current rating than the early version of the switch. Jeez, guys, did you think I'd send you off on a wild goose chase? I've rebuilt four or five of these things in the past eight months or so and have yet another lying open on the floor behind my workbench, ready for Evil Experiments of a JFET nature. I also sold scads of the things back when I was in retail.

Yes, the switch will come in with the 1 2 3 connections stamped on the side. DO NOT IGNORE THE NUMBERS. Connect it as per the original Hafler schematic and you'll be fine.

If you want to upgrade the thing, go through and replace all the electrolytics with film caps. People did so for years. Then Hafler finally got smart and started a production version that did the same thing called the DH-220. It's relatively cheap (assuming that you don't use really, really expensive caps) and very effective, sound quality-wise. That said, the stock units still sound decent. As I detailed in another thread, they beat the pants off my la-di-dah Pioneer Elite receiver in my AV system, and that's without any updates, mods, increasing of bias, etc. Shameful, the sound that AV people think is acceptable, but there it is.

As I believe I mentioned earlier, the power switches in the DH-200 were prone to failure. They usually failed in the closed (i.e. "on") position, but every once in a while you'd get one that froze open. They don't like being hit, either. The red plastic rocker will break if you bump it against a table or shelf. The one booger is that you're going to be working in a tight space getting the new one put in. Be patient and it will work out okay. When doing repairs on these things I would sometimes use push-on connectors so as to make switch replacement faster and easier. The idea is worth what it cost you. If you get some bozo who has managed to kill three switches during the course of a year, it starts sounding like a good idea.

Regarding bridging:

--As I believe someone mentioned earlier, it's not a good idea to use a bridged DH-200 for low impedance loads. In this case, interpret low impedance as anything below 8 Ohms.

--The bridging boards may be unavailable, but that's not a problem. All the add-on board did was serve as a phase splitter. Nothing fancy. It was, as I recall, just a simple differential on a circuit board about an inch or two square. It's trivial to whip up something like that. Use, say, MPSA42s or ZTX453s. This would be a good time to use a current source, although a resistor will do nearly as well and be a lot simpler. Might even sound better. Something like a 15k 1/2W (or 1W if you want to be more conservative) would give you 2mA per side bias.

--For those who believe in opamps, it would be simple enough to use opamps to do the phase splitting, but remember that the Hafler rails are on the order of 60V. You're going to need to drop the voltage so that the opamp doesn't pop.

Regarding gain: There are far too many variables to guess about something like that. Try it. If it works, fine. If not, then we'll talk about possible solutions.

Grey

Oh, well. I'm having a bad day so I'm grumpy. Ignore me if I fuss too much.

The Mouser part number I gave earlier is the Carling Mini-Tippette (or whatever they call the silly thing) direct replacement for the original switch, albeit with a 50% higher current rating than the early version of the switch. Jeez, guys, did you think I'd send you off on a wild goose chase? I've rebuilt four or five of these things in the past eight months or so and have yet another lying open on the floor behind my workbench, ready for Evil Experiments of a JFET nature. I also sold scads of the things back when I was in retail.

Yes, the switch will come in with the 1 2 3 connections stamped on the side. DO NOT IGNORE THE NUMBERS. Connect it as per the original Hafler schematic and you'll be fine.

If you want to upgrade the thing, go through and replace all the electrolytics with film caps. People did so for years. Then Hafler finally got smart and started a production version that did the same thing called the DH-220. It's relatively cheap (assuming that you don't use really, really expensive caps) and very effective, sound quality-wise. That said, the stock units still sound decent. As I detailed in another thread, they beat the pants off my la-di-dah Pioneer Elite receiver in my AV system, and that's without any updates, mods, increasing of bias, etc. Shameful, the sound that AV people think is acceptable, but there it is.

As I believe I mentioned earlier, the power switches in the DH-200 were prone to failure. They usually failed in the closed (i.e. "on") position, but every once in a while you'd get one that froze open. They don't like being hit, either. The red plastic rocker will break if you bump it against a table or shelf. The one booger is that you're going to be working in a tight space getting the new one put in. Be patient and it will work out okay. When doing repairs on these things I would sometimes use push-on connectors so as to make switch replacement faster and easier. The idea is worth what it cost you. If you get some bozo who has managed to kill three switches during the course of a year, it starts sounding like a good idea.

Regarding bridging:

--As I believe someone mentioned earlier, it's not a good idea to use a bridged DH-200 for low impedance loads. In this case, interpret low impedance as anything below 8 Ohms.

--The bridging boards may be unavailable, but that's not a problem. All the add-on board did was serve as a phase splitter. Nothing fancy. It was, as I recall, just a simple differential on a circuit board about an inch or two square. It's trivial to whip up something like that. Use, say, MPSA42s or ZTX453s. This would be a good time to use a current source, although a resistor will do nearly as well and be a lot simpler. Might even sound better. Something like a 15k 1/2W (or 1W if you want to be more conservative) would give you 2mA per side bias.

--For those who believe in opamps, it would be simple enough to use opamps to do the phase splitting, but remember that the Hafler rails are on the order of 60V. You're going to need to drop the voltage so that the opamp doesn't pop.

Regarding gain: There are far too many variables to guess about something like that. Try it. If it works, fine. If not, then we'll talk about possible solutions.

Grey

For the inrush limiter I picked up a small box of .01uF disk. I'm not too thrilled about "hard" wiring this amp either. I wont. I will just wait a couple of days for the Carling switch to come in. Tonight I'll go ahead and try my other switch again. If I blow a fuse, I blow a fuse. I looked at the switch again last night. Its not the switch I posted. That switch was for something else. The switch I bought from RS but is a much bigger toggle switch. The only difference in the switch I bought from RS and the Carling I bought was (becides the light) I believe the amps are different and the style.

My dad had this amp driving 2pairs of Polk Monitor 7a's stacked. Which stacked dropped the ohms down to 3, this amp did a wonderfull job. Thats why I'm so excited to get it workign again. I have only one pair of Monitor 7b's I would love take them off of my Onkyo tx-502 and hook them up to the Hafler, use my onkyo as preamp. But for the long run, I am rebuilding two seperate subs and would use this amp to drive them. It has to be 10 times better than that little plate amp the subs came with.

Some conversations have more meat on their bones than others. Speaking purely for myself, unless we're due for tornadoes, hurricanes, and blizzards, all on the same day, I get bored with conversations about the weather. What's tomorrow's high going to be and is it going to rain? Mid-70s and 0% chance of rain. Conversation over. Move on to other things. Alcohol, naked ladies, you know...the usual. Given the choice, I prefer them 'nekkid' to 'nude.' As the humorist Lewis Grizzard used to say, "nude" is art--"nekkid" means you're up to something.

I regard inrush limiting as about the same sort of thing. You can use an active circuit, thermistors, relays, or lightbulbs, your choice. Will it make the switch last longer? Presumably. But my experience has been that the 15A version of the switch is pretty reliable as long as it's got the spark suppression caps on it and you don't bash it mechanically. Next topic.

The bridging thing is potentially more interesting, but to take it much further than "not lower than 6-8 Ohms or so" would get into questions of bias current, heatsinking, and whether the DH-200 power supply could handle that sort of thing. However, that seems to have been settled fairly efficiently and that's all to the good.

Jake, I'm not bothered by your posts. They're completely understandable--particularly when faced with some rather random and contradictory responses to your original questions. It's just that I wonder whether some of the posters in this thread really bothered to think about what they wrote, hence my somewhat less-than-cheerful tone (aside from the fact that I had a lousy afternoon, which is certainly not the fault of anyone here--those following the power JFET story will not be at all surprised to hear that I had another run-in with the USPS whilst trying to take care of some of our Canadian members).

Oh, and for the record, I'm not particularly wild about hot-wiring the power switch. Not necessarily for any reason that might first occur to anyone, though. My main objection is the spark you get when the plug first makes contact with the socket. It's an arc. It will pit the plug and the contacts in the socket, which will lead to poor contact in the future. That interface wasn't designed to handle a hot make/break current flow.

Me grumbly? Certainly. It's this unrequited wish to strangle certain nitwits at the post office that keeps bubbling over.

Grey

I regard inrush limiting as about the same sort of thing. You can use an active circuit, thermistors, relays, or lightbulbs, your choice. Will it make the switch last longer? Presumably. But my experience has been that the 15A version of the switch is pretty reliable as long as it's got the spark suppression caps on it and you don't bash it mechanically. Next topic.

The bridging thing is potentially more interesting, but to take it much further than "not lower than 6-8 Ohms or so" would get into questions of bias current, heatsinking, and whether the DH-200 power supply could handle that sort of thing. However, that seems to have been settled fairly efficiently and that's all to the good.

Jake, I'm not bothered by your posts. They're completely understandable--particularly when faced with some rather random and contradictory responses to your original questions. It's just that I wonder whether some of the posters in this thread really bothered to think about what they wrote, hence my somewhat less-than-cheerful tone (aside from the fact that I had a lousy afternoon, which is certainly not the fault of anyone here--those following the power JFET story will not be at all surprised to hear that I had another run-in with the USPS whilst trying to take care of some of our Canadian members).

Oh, and for the record, I'm not particularly wild about hot-wiring the power switch. Not necessarily for any reason that might first occur to anyone, though. My main objection is the spark you get when the plug first makes contact with the socket. It's an arc. It will pit the plug and the contacts in the socket, which will lead to poor contact in the future. That interface wasn't designed to handle a hot make/break current flow.

Me grumbly? Certainly. It's this unrequited wish to strangle certain nitwits at the post office that keeps bubbling over.

Grey

- Home

- Amplifiers

- Solid State

- Hafler DH-200 switch