Hello I am new to this Forum and would like to know if anyone else is using a Arc Welder Transformer to power their projects.

mine is rated at 3000VA and is centre tapped with 28v/28v after rectification om the lower setting or 40v/40v on the higher setting.

i have been using the transformer for 5 months with no problems.

I driven class A's with it and it doesn't get hot only warm even after 8 hours of use.

mine is rated at 3000VA and is centre tapped with 28v/28v after rectification om the lower setting or 40v/40v on the higher setting.

i have been using the transformer for 5 months with no problems.

I driven class A's with it and it doesn't get hot only warm even after 8 hours of use.

i can carry the transformer myself and i do all my testing away from the family and when i finally put the transformer into my home cinema amplifier project i am building, it will be well shielded and insulated as the last thing i want to do is kill myself or one of my family.

I've also been tempted to this also,

since welding arcs have larger output voltages and currents as high as

300 amperes.

though very impractical......

and, just what Guru says welding arcs are not properly shielded and

some poor and maybe ineffecient cores that are used.

well, very tempting....... but not very recommendable

rgds,

hienrich

since welding arcs have larger output voltages and currents as high as

300 amperes.

though very impractical......

and, just what Guru says welding arcs are not properly shielded and

some poor and maybe ineffecient cores that are used.

well, very tempting....... but not very recommendable

rgds,

hienrich

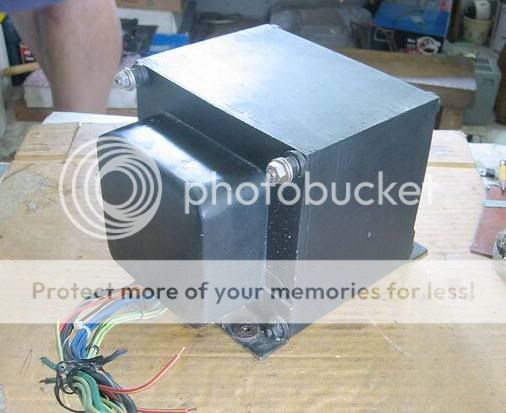

the Transformer I am using actually came from a small gasless MIG Welder I Made the mistake of buying as it wasn't really up to the job of doing the welding i wanted to do and when i lent it to my brother, he wrecked it burning out the drive motor and it sat in the shed for along time until i decided to see what voltage it would be giving out at the secondarys.

As for hum appearing at the speakers, there's no more ( Very Little you only hear it when the volume is turned all the way up and you place your ear next to a speaker.) hum when using the amplifier with a normal transformer.

As for hum appearing at the speakers, there's no more ( Very Little you only hear it when the volume is turned all the way up and you place your ear next to a speaker.) hum when using the amplifier with a normal transformer.

And what vattage is your amp?

If you put a 200W amp on 3000W transformer, It will surely behave very well indeed, despite it is a welding one.

But you probably will have nearly the same results with 300-400W well made toroidal transformer made for this purpose, not welding.

Welding transformers usualy have a gap in their magnetic path, because when you weld with 300A, the putput voltage must be considerably lower then when not welding. On the other side, for the arc to start more easy the output voltage must be 40-60V.

Simple arithmetics 3000W/300A=10V.

If you put a 200W amp on 3000W transformer, It will surely behave very well indeed, despite it is a welding one.

But you probably will have nearly the same results with 300-400W well made toroidal transformer made for this purpose, not welding.

Welding transformers usualy have a gap in their magnetic path, because when you weld with 300A, the putput voltage must be considerably lower then when not welding. On the other side, for the arc to start more easy the output voltage must be 40-60V.

Simple arithmetics 3000W/300A=10V.

the hum is there only when you are within half a metre from the transformer.

as for the voltage drop it's only about 1.5volts underload.

as this is a mig welding transformer designed to weld only 0.8mm mig wire, not 3mm arc rods its not being placed under the same stress, maybe this is the reason it only has a voltage drop of 1.5volts.

as for the voltage drop it's only about 1.5volts underload.

as this is a mig welding transformer designed to weld only 0.8mm mig wire, not 3mm arc rods its not being placed under the same stress, maybe this is the reason it only has a voltage drop of 1.5volts.

is this the output power or electrical power.

For 45W class B or AB you need about 80-90VA transformer

for 5.1 system 5*90=450VA.

It is 5.1 system, so a 250-300VA would be enough.

Add to this the 200-300VA for the woofer and here you are.

600VA transformer is enough for class AB or B for 5.1 system.

as for class A - It strongly depends on amp topology. but I think 3-5 times the output power will be enough. (this is my thought. I've never made class A transistor amp, and maybe will not make any in the future. The tube amps are another thing.)

But... If you feel happy with this transformer then it doesn't matter anyway. Right?

But if I make such a thing I will go and get 600-700VA toroid. It will be more compact, will not have acoustical hum,will create less EMI, will weight less, and will have less voltage fluctuation on the output if made the right way.

Cheers

And be happy.

For 45W class B or AB you need about 80-90VA transformer

for 5.1 system 5*90=450VA.

It is 5.1 system, so a 250-300VA would be enough.

Add to this the 200-300VA for the woofer and here you are.

600VA transformer is enough for class AB or B for 5.1 system.

as for class A - It strongly depends on amp topology. but I think 3-5 times the output power will be enough. (this is my thought. I've never made class A transistor amp, and maybe will not make any in the future. The tube amps are another thing.)

But... If you feel happy with this transformer then it doesn't matter anyway. Right?

But if I make such a thing I will go and get 600-700VA toroid. It will be more compact, will not have acoustical hum,will create less EMI, will weight less, and will have less voltage fluctuation on the output if made the right way.

Cheers

And be happy.

That's a great idea!

Everyone keeps mentioning the voltage drop under load, but think about it, if you have big caps, and the amplifier(s) uses nowhere near 300A transformer rating, but maybe like 20 or 30A or so, the transformer would be more than suitable.

Holy ****, there's probably enough current available to run several amps from one transformer.

*Now I wonder if there's a good way to use a large transformer that's NOT Center tapped to run an amplifier.

Everyone keeps mentioning the voltage drop under load, but think about it, if you have big caps, and the amplifier(s) uses nowhere near 300A transformer rating, but maybe like 20 or 30A or so, the transformer would be more than suitable.

Holy ****, there's probably enough current available to run several amps from one transformer.

*Now I wonder if there's a good way to use a large transformer that's NOT Center tapped to run an amplifier.

The Main reason i decided to see how a welder transformer would go powering a amplifier was the cost.

as i had an almost new transformer that had only done about 5 hours of work before my brother stuffed the drive motor just sitting in the garage doing nothing, i decided that if it worked i would have more than enough power to drive any of my projects.

as for power usage isn't it the rule that a tranformer only draws

current / voltage from the primary side in relation to what is being drawn from the secondary side. so small load small current flow, large load large current flow.

as i had an almost new transformer that had only done about 5 hours of work before my brother stuffed the drive motor just sitting in the garage doing nothing, i decided that if it worked i would have more than enough power to drive any of my projects.

as for power usage isn't it the rule that a tranformer only draws

current / voltage from the primary side in relation to what is being drawn from the secondary side. so small load small current flow, large load large current flow.

Yes that's correct John.

You can always build bridge amps if you have only one winding, low voltage and high current ability. Or with centre tap/twin windings lots of amps for a 5.1 plus sub.

Just dont let the kids sit on it when it's on. Better to sit on a sub.

Cheers,

Greg

You can always build bridge amps if you have only one winding, low voltage and high current ability. Or with centre tap/twin windings lots of amps for a 5.1 plus sub.

Just dont let the kids sit on it when it's on. Better to sit on a sub.

Cheers,

Greg

Salamat, Tony from the Philipines, i like you transformer, you shouldn't run out of current with that one.

It's Good to hear from someone fron the Philipines as my wife was born in Manilla and i have found Filipino people to be some of the friendliest people around and that's why i married my wife.

As will most woman she doesn't care much for my electronics hobby.

It's Good to hear from someone fron the Philipines as my wife was born in Manilla and i have found Filipino people to be some of the friendliest people around and that's why i married my wife.

As will most woman she doesn't care much for my electronics hobby.

- Home

- Amplifiers

- Solid State

- Arc Welder Transformer used to power Amplifier