Yes, yes, not cheap, but interesting...

http://www.mcmaster.com/ctlg/DisplC...6109805973&ScreenWidth=1600&McMMainWidth=1230

(just the cold plate)

http://www.mcmaster.com/ctlg/DisplC...6109805973&ScreenWidth=1600&McMMainWidth=1230

(just the cold plate)

I'd say if you have a thick piece of alloy lying around, a residual copper pipe, and you have a column drill the 30 is a quick save.

I suppose something like that could be made of alloy segments.

Drill depth could be sized to the kind of column drill, and one can build huge cooling plates.

I suppose something like that could be made of alloy segments.

Drill depth could be sized to the kind of column drill, and one can build huge cooling plates.

There was only one mention of oil submerging. Well, if its good enough for PC, its good enough for amp  :

:

http://calypshuile.chez.tiscali.fr/fabhi.htm

Keyword to search is transformer oil cooling. There are more examples.

http://www.dowcorning.com/content/p...d Utilities&DCWSS=Fire-safe Transformer Fluid

I imagine that servicing is, um, interesting...

http://calypshuile.chez.tiscali.fr/fabhi.htm

Keyword to search is transformer oil cooling. There are more examples.

http://www.dowcorning.com/content/p...d Utilities&DCWSS=Fire-safe Transformer Fluid

I imagine that servicing is, um, interesting...

Those guys are Froggies, i am sure they use Olive oil.

They even flooded the ventilator panel.

Probably Cousteau family members too

Thank you for posting, WIMMS, that Dow article on silicone fluid is really extensive.

Funny, dont you think, transformer fluids have been used for so long and still many regard the idea exotic.

They even flooded the ventilator panel.

Probably Cousteau family members too

Thank you for posting, WIMMS, that Dow article on silicone fluid is really extensive.

Funny, dont you think, transformer fluids have been used for so long and still many regard the idea exotic.

Why not mount the cold plate to your regular heat sink to augment it's performance? Just get one of the copper ones shown in the McMaster Carr catalog for $31, slap a bunch of thermal goo on and connect the cold plate to the heat sink. The copper cold plate would help spread the heat across the heatsink while augmenting it's ability to dissapate some heat. You could connect the cold plate to one of those Zalman fanless cooling towers.

There was only one mention of oil submerging. Well, if its good enough for PC, its good enough for amp :

Man, I would call that "gasket confidence."

I think one of the coldplates would probably be overkill with an existing heatsink.

Its certainly cheaper to make t he Grey version with a length of copper pipe soldered to a plate of copper as I already mentioned. I guess you have to see how much a 12" length of 1/2" pipe and a plate of copper the correct size cost. If you are doing more than one, then the cost savings would be significant.

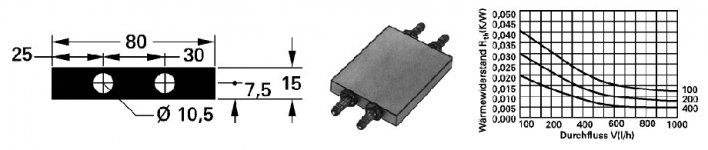

i just found this cooler, the lines are for different cooler length.

No copper pipes, only threaded holes for screw-in plugs.

For agressive fluids this one is made with pressed-in copper piping too.

Converting to US means a 16" x 3" x 0.6 " alloy plate with two 0.4" diameter holes has a thermal factor of 0.005 if the cooling fluid does a little over 2.5 gallons of water per minute.

Above that waterspeed the heat doesnt go through the alloy fast enough.

Supposing 30 degrees over ambient this little baby is able to cool 6000 Watts.

No copper pipes, only threaded holes for screw-in plugs.

For agressive fluids this one is made with pressed-in copper piping too.

Converting to US means a 16" x 3" x 0.6 " alloy plate with two 0.4" diameter holes has a thermal factor of 0.005 if the cooling fluid does a little over 2.5 gallons of water per minute.

Above that waterspeed the heat doesnt go through the alloy fast enough.

Supposing 30 degrees over ambient this little baby is able to cool 6000 Watts.

Attachments

This is actually very close to what I have been thinking about the past few days. I was looking at Peter Daniel's Patek Amp, and thinking that a similar solution (central copper bar heatsink) could be used for a liquid-cooled class A design. I wouldn't copy his design, just the copper bar backbone. That is one beautiful little amp.

So, I'm thinking a 3x6cm copper bar with 2 - 1cm (or so) holes bored through it length wise. Then press a semicircular copper return into the front, and two small threaded fitting on the back. Hook it up to an external cooler/pump and off you go.

So, I'm thinking a 3x6cm copper bar with 2 - 1cm (or so) holes bored through it length wise. Then press a semicircular copper return into the front, and two small threaded fitting on the back. Hook it up to an external cooler/pump and off you go.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Water Cooling