Any info on Hitachi 2SJ217/2SK1297 UHC-MOS devices?

Well, I was just going through some older DENON literature and it looks like their flagship mono amps (from mid 90's) are using those devices.

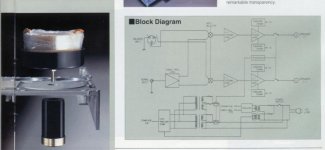

Seems like an interesting circuit with a single push-pull circuit delivering 1400W into 1 ohms.

Well, I was just going through some older DENON literature and it looks like their flagship mono amps (from mid 90's) are using those devices.

Seems like an interesting circuit with a single push-pull circuit delivering 1400W into 1 ohms.

Attachments

The booklet is dated 06094

Does that mean 1994 ? Amazing.

I never heard about it or saw it anywhere . And I travelled a lot since then! Saw quite a lot of other stuff .

Very interesting.

Wonder if we can come up with a scaled DIY version of the amp.

Thanks for posting the info Peter.

Cheers,

Ashok.

If you notice the heatsinks are probably cast and a plate of copper is placed on the whole contact area. This definitely helps with heat transfer (from devices to the sink)

Why is that so? By adding a second thermal layer you add a new thermal junction (between the copper plate and the aluminium heatsink) with its added thermal resistance. I agree that using a thick copper plate stretching all the way out to the convection fins would certainly improve heat transfer over aluminium. But that seems not to be the case here, it looks to be merely around 2 mm thick.

Looking fancy and improving heat transfer are two very different things.

Apart from the output cascode configuration, what is so impressive with this amp? For $ 20,000 i would expect more than a pamflet full of crap talk.

/Magnus

Swedish Chef said:

Why is that so? By adding a second thermal layer you add a new thermal junction (between the copper plate and the aluminium heatsink) with its added thermal resistance. I agree that using a thick copper plate stretching all the way out to the convection fins would certainly improve heat transfer over aluminium. But that seems not to be the case here, it looks to be merely around 2 mm thick.

Looking fancy and improving heat transfer are two very different things.

The copper-sheet is at least 4 or 5mm thick, and it makes a lot of sense. If you take a look at most heatsinks, the spine is waaaay too thin to spread the heat out over the entire heatsink, thus making it in-efficient. By adding a copper heat spreader you get around this problem.

It would be true that you loose it all in added thermal resistance, if you had just added a copper sheet exactly in the size of the footprint of the device in question, but that is not what they have done here. You add thermal resistance per mm2, but increase the total amount of heat transfer by adding contact area between the copper and the heatsink/device.

Magura

Really ??

Hi Magnus,

You said:

"Apart from the output cascode configuration, what is so impressive with this amp? For $ 20,000 i would expect more than a pamflet full of crap talk."

First of all the Japs aren't great with their English pamphlets . Marketing literature from any part of the world on any product can be just like this. You can't dismiss a product just based on that.

Japs work very diligently and I am quite convinced that they did their home work well. It must sound good. They would have compared it with all the other amps in that price range.

I know. I worked with them on such things for several months !

I think their engineers are great like all good engineers around the globe.

Have you seen that people are still struggling with single stage tube preamps trying to make them sound great. It takes only 8 parts at most to set it up. But it can sound from great to crap. It sometimes takes a lot of trying to get it right -- unless you just copy eaxctly a good known design. We need to appreciate everyone's effort . That leads to greater progress ...faster.

We are glad they put out some information that we can work on.

Cheers,

Ashok.

Hi Magnus,

You said:

"Apart from the output cascode configuration, what is so impressive with this amp? For $ 20,000 i would expect more than a pamflet full of crap talk."

First of all the Japs aren't great with their English pamphlets . Marketing literature from any part of the world on any product can be just like this. You can't dismiss a product just based on that.

Japs work very diligently and I am quite convinced that they did their home work well. It must sound good. They would have compared it with all the other amps in that price range.

I know. I worked with them on such things for several months !

I think their engineers are great like all good engineers around the globe.

Have you seen that people are still struggling with single stage tube preamps trying to make them sound great. It takes only 8 parts at most to set it up. But it can sound from great to crap. It sometimes takes a lot of trying to get it right -- unless you just copy eaxctly a good known design. We need to appreciate everyone's effort . That leads to greater progress ...faster.

We are glad they put out some information that we can work on.

Cheers,

Ashok.

1. Thermal issues

What it all boils down to is what thermal resistance they managed to get for the alu/copper interface and what thickness of the copper plate they are using. Facts that we will probably never have. My point was not to dismiss the whole copper-plate idea but rather to emphasize that just using copper for the interface not necessarily leads to lowered thermal resistance. In this case it probably does (otherwise it would be incredibly bad engineering

, but for other applications you really need to run the numbers to see what you end up with. Take a look at this appnote for example http://www.coolingzone.com/Guest/News/NL_FEB_2003/ATS/ATS_Feb2003.html

, but for other applications you really need to run the numbers to see what you end up with. Take a look at this appnote for example http://www.coolingzone.com/Guest/News/NL_FEB_2003/ATS/ATS_Feb2003.html

(especially the last part if you don't want to read it all!).

2. "High-End" issues

Ashok, my intention was not to critizise Japanese engineering. Most likely that amp will sound great. It better do for $20,000!

But phrases like "the superior basic characteristics of the UHC-MOS are able to realize their maximum potential, reproducing a truly natural, musical sound totally free of coloration" make me sick.

So they have designed the ideal amp. Great. How about some hard piece of evidence to back up the claim?

Cheers

/Magnus

It would be true that you loose it all in added thermal resistance, if you had just added a copper sheet exactly in the size of the footprint of the device in question, but that is not what they have done here. You add thermal resistance per mm2, but increase the total amount of heat transfer by adding contact area between the copper and the heatsink/device.

What it all boils down to is what thermal resistance they managed to get for the alu/copper interface and what thickness of the copper plate they are using. Facts that we will probably never have. My point was not to dismiss the whole copper-plate idea but rather to emphasize that just using copper for the interface not necessarily leads to lowered thermal resistance. In this case it probably does (otherwise it would be incredibly bad engineering

(especially the last part if you don't want to read it all!).

2. "High-End" issues

Ashok, my intention was not to critizise Japanese engineering. Most likely that amp will sound great. It better do for $20,000!

But phrases like "the superior basic characteristics of the UHC-MOS are able to realize their maximum potential, reproducing a truly natural, musical sound totally free of coloration" make me sick.

So they have designed the ideal amp. Great. How about some hard piece of evidence to back up the claim?

Cheers

/Magnus

If you read MJ, you'll see that the UHC Mosfets have been

the big craze recently. Myself, I just see it as more fascination

with a new device, as was the case with IGBT's. If you put

vertical (IR type) Mosfets in the middle, then the Laterals are on

one side, and the UHC's are on the other. They probably make

for great bass characteristic, but I don't have any to play with, so

that would be conjecture.

the big craze recently. Myself, I just see it as more fascination

with a new device, as was the case with IGBT's. If you put

vertical (IR type) Mosfets in the middle, then the Laterals are on

one side, and the UHC's are on the other. They probably make

for great bass characteristic, but I don't have any to play with, so

that would be conjecture.

Regarding the copper plate, the thinner gauge allows also for better flexibility and contact is improved if the flatness isn't perfect. That would be much harder to achieve with thicker plate.

And heat spreading is a definite advantage here. I've never seen this implemented in other amps, and will probably try next time I'll be building bigger amps.

PS: Disregard the price tag, after 10 years it's not an issue anymore.

And heat spreading is a definite advantage here. I've never seen this implemented in other amps, and will probably try next time I'll be building bigger amps.

PS: Disregard the price tag, after 10 years it's not an issue anymore.

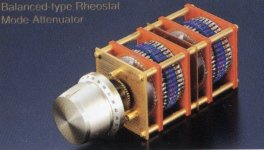

Peter Daniel said:They were using 48 position Shallco like switcher

Peter, could you make a scan of the switch alone?? I believe you know why I'm asking

Magura

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Ultra High Current Mosfets from Hitachi