SMT soldering, I know there's many who like ersa soldering workstations, if I soldered on daily basis for profit ersa i-con-v4000aicx would be a very fine station for such use. Weller good too imo. Weller wr 3000M might do it, no personal exp. with that one. "Who hasn't used a Weller"Thanks, Vunce! I just got a new hot air SMT soldering gun (more like a like pencil) and I have to say, it makes SMT soldering easier and higher quality.

If you got the technique under control, and are serious about electronics. A good solder station is mandatory or, You can design your own circuit's and the pcb factory solder for you the proto.

Reality is that the through hole components are going to

dissappear, it's quite amazing they are around from technology standpoint. Repairs needs them still.

And there's other reasons certainly.

What soldering pencil like hot air SMT are you using xrk?

I sometimes wonder why big boards, so much space few components & golden vias combo vs a smd pcb.

As I know designers went smd decades ago, schools, academys teaching electronics

So why are we here? Have schools replaced their general 2year basic transistors configuration testcircuits, banana power circuits?

I’m using a fairly inexpensive hot air gun from China. It has very precise computer controlled heat settings and is smart in that it turns on when you pick it up and turns off when you put it down. Heats up to 300C in 10 seconds. Gentle flow that doesn’t t blow SMDs out of place once they are set on paste. I also have a nice temp controlled soldering iron (Sealody brand) with Hakko compatible tips. Both make a decent soldering station for about $100. I used a Weller for the longest time and still have it for my alternate iron but prefer ergonomics and auto temp reduction when not being used of the Sealody. I just ordered an iExtruder precision solder paste dispenser that should make things even easier and more precise. These are true work tools as is O-scope and Fluke meters.

Last edited:

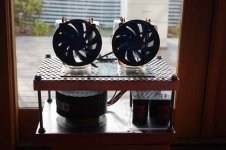

Weldings for first frame are just about done. Everything seems to fit inside, so now it's time to cut some aluminium plates inside. It really takes a lot of work to be done, but when alu sheets are cut, actual building can begin  summer vacation starts at second week of july, then I have more time to do this.

summer vacation starts at second week of july, then I have more time to do this.

Attachments

Juntuin,

Your case looks really awesome! I’ve started to plan a case of my own for the BB, but this amplifier is proving to be a challenge to fit all the necessary add-ons for a noise free and reliable class A monster. Your “multi level” idea is key for this amplifier not to take up a huge amount of shelf space.

Cheers,

Vunce

Your case looks really awesome! I’ve started to plan a case of my own for the BB, but this amplifier is proving to be a challenge to fit all the necessary add-ons for a noise free and reliable class A monster. Your “multi level” idea is key for this amplifier not to take up a huge amount of shelf space.

Cheers,

Vunce

Juntuin,

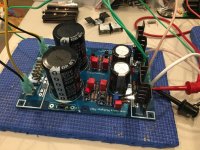

Here is where I'm at with my BB build at the layout stage.

Nowhere as Elegant as your build.

Steve.

I like it, industrial look! Like your idea about acrylic plate on top of caps. Dare to share details about psu, I see 10w resistors there so CRC or more R's or L' s?

Well aksa your doing the right thing.

I took a few beers today, it's been 2 1/2 years since.

It's amazing what you can do with exp. a few does not have a real bad influence with my bosch 18V blue, aluminum drilling.

But in the name of wisdom, a few not ok if no tolerance. More is a no no way to go.

So I'm quiting now taken 1.25l beer max. 4.5%.

I took a few beers today, it's been 2 1/2 years since.

It's amazing what you can do with exp. a few does not have a real bad influence with my bosch 18V blue, aluminum drilling.

But in the name of wisdom, a few not ok if no tolerance. More is a no no way to go.

So I'm quiting now taken 1.25l beer max. 4.5%.

? Non sequiter...

This truly is an amazing forum, I learn something new every day

....and another psu to try with the Alpha BB.

I decided to try another capMx, this one is: Simplified MrEvil / PMI Capacitance Multiplier by Jason Kuetemann. I had very good results using the Allo CM board with my Big MoFo amplifier so, when I found out the Allo was a positive rail only copy of this circuit I decided to try the full version for my BB.

So far the results are much better than the first capMx I tried. I have it adjusted to drop only 1.5vdc and the heat generated from the MosFets is very manageable. The Wakefield 272 heatsinks are reading 55°C. Im using off-board bridge rectifiers instead of T0-220 on-board rectifiers which is a nice option this board incorporated.

I decided to try another capMx, this one is: Simplified MrEvil / PMI Capacitance Multiplier by Jason Kuetemann. I had very good results using the Allo CM board with my Big MoFo amplifier so, when I found out the Allo was a positive rail only copy of this circuit I decided to try the full version for my BB.

So far the results are much better than the first capMx I tried. I have it adjusted to drop only 1.5vdc and the heat generated from the MosFets is very manageable. The Wakefield 272 heatsinks are reading 55°C. Im using off-board bridge rectifiers instead of T0-220 on-board rectifiers which is a nice option this board incorporated.

Attachments

- Home

- Amplifiers

- Solid State

- Aksa Lender P-MOS Hybrid Aleph (ALPHA) Amplifier