Hi,

I've had a browse of the forum where there are similar threads and I'll continue to look through but I'm considering a project to build a new amp from an existing one and have fairly specific parameters so wanted to ask for ideas.

I have an amp. I've been a little indiscreet in the past and named it but I'll try to avoid that this time. It's a cinema amp, of the variety which cost thousands new. I bought it on the cheap, broken and had it fixed / restored, intending to use it as a high quality stereo amp with the option to go active. It doesn't sound good to me. Every time we find an issue and fix it there's another two behind that. I'm now over two years and a thousand pounds in and my engineer (I'm just a beginner) has given up. I don't blame him, he's a saint to have gotten this far. We could keep chasing problems for another two years and end up finding there's not a decent amp in there after all, and it's a bastard to work on.

What the tech is up for is throwing out the circuit boards and using the thing as the basis for a new build. This seems like a good idea to me as it would give us the following most excellent platform:

- 2 x 800VA 60V toroidals

- 10 x 10k uF capacitors (I'm sure we could fit a few more in

- 10 pairs of 2SC5200 / 2SA1943

- Big, heavy, fan cooled internal heatsink

- Very sexy case of 3U(ish) size

I presently have 8 ohm 300W speakers (ATC SCM19) and a belief that headroom is very desirable. I'm a hifi buff and looking for best possible quality but also want at least 300W into 8, ideally with the flexibility to handle trickier loads to cover possible speaker changes in the future (you never know). We'd like to use all 10 pairs (so 5 per channel). First instinct is just to copy a Krell or Bryston design but they might not match the transistors and the first Krell we looked at was too complex / esoteric. I only mention them to give an idea of the sort of thing which would be ideal. Because this isn't just a fun project but rather will end up as my main amp in a quality system and can't be just chucked out I'm trying to avoid the build it and see if it's any good thing and get it right first time.

Any suggestions to throw into the mix would be greatly appreciated

I've had a browse of the forum where there are similar threads and I'll continue to look through but I'm considering a project to build a new amp from an existing one and have fairly specific parameters so wanted to ask for ideas.

I have an amp. I've been a little indiscreet in the past and named it but I'll try to avoid that this time. It's a cinema amp, of the variety which cost thousands new. I bought it on the cheap, broken and had it fixed / restored, intending to use it as a high quality stereo amp with the option to go active. It doesn't sound good to me. Every time we find an issue and fix it there's another two behind that. I'm now over two years and a thousand pounds in and my engineer (I'm just a beginner) has given up. I don't blame him, he's a saint to have gotten this far. We could keep chasing problems for another two years and end up finding there's not a decent amp in there after all, and it's a bastard to work on.

What the tech is up for is throwing out the circuit boards and using the thing as the basis for a new build. This seems like a good idea to me as it would give us the following most excellent platform:

- 2 x 800VA 60V toroidals

- 10 x 10k uF capacitors (I'm sure we could fit a few more in

- 10 pairs of 2SC5200 / 2SA1943

- Big, heavy, fan cooled internal heatsink

- Very sexy case of 3U(ish) size

I presently have 8 ohm 300W speakers (ATC SCM19) and a belief that headroom is very desirable. I'm a hifi buff and looking for best possible quality but also want at least 300W into 8, ideally with the flexibility to handle trickier loads to cover possible speaker changes in the future (you never know). We'd like to use all 10 pairs (so 5 per channel). First instinct is just to copy a Krell or Bryston design but they might not match the transistors and the first Krell we looked at was too complex / esoteric. I only mention them to give an idea of the sort of thing which would be ideal. Because this isn't just a fun project but rather will end up as my main amp in a quality system and can't be just chucked out I'm trying to avoid the build it and see if it's any good thing and get it right first time.

Any suggestions to throw into the mix would be greatly appreciated

Last edited:

Approximately 400 x 80 x 120. It's comprised of two sections which bolt together in the middle but probably can't be split in practice because combined they're the entire height and width of the case, with a little gap for cable routing etc. It has mountings for two fans at the moment (120mm IIRC).

Last edited:

what transformers have you got?2 x 800VA 60V toroidals

60Vac single secondary,

or 60Vac centre tapped secondary,

or dual 60Vac secondaries?

You have to supply information that can be understood, if you want some help.

Forget ClassA.

If it needs a fan assisted cooler for it's former duty, there is no way you can copy, or clone a ClassA.

I would not recommend cloning a Bryston either. It's output stage is quite complex and without good debugging capabilities you may never get a clone to run.

If it needs a fan assisted cooler for it's former duty, there is no way you can copy, or clone a ClassA.

I would not recommend cloning a Bryston either. It's output stage is quite complex and without good debugging capabilities you may never get a clone to run.

Last edited:

what transformers have you got?

60Vac single secondary,

or 60Vac centre tapped secondary,

or dual 60Vac secondaries?

You have to supply information that can be understood, if you want some help.

Thanks for taking an interest. I do apologise for any ambiguity. I'm trying not to casually use any terms I'm only 90% confident of and lead people up the garden path without spending a little time reading up but do ask if I miss something and I'll check it out. Also, I don't have the unit here to check right now. I'm in the early stages of kicking ideas around and seeing what sort of options are available before deciding whether to commit to the project.

At present the transformers are wired in parallel and putting out +60 and -60 (AC) so I'm fairly confident that is available from each but I want to physically check and read up a little rather than assume before I talk about centre taps and dual / single. I shall respond on that as soon as I'm able.

Forget ClassA.

If it needs a fan assisted cooler for it's former duty, there is no way you can copy, or clone a ClassA.

I would not recommend cloning a Bryston either. It's output stage is quite complex and without good debugging capabilities you may never get a clone to run.

For sure, I'm not looking at class-A. I know I don't have the cooling or the electric bill budget for 300W of that.

Thanks for the Bryston advice, it may save some time ruling it out. I mainly mention those to give an idea of the kind of application / spec I'm chasing. Cloning one is probably a little pie in the sky even if I hadn't already determined the transistors.

What is the dimensions of the mounting surfaces of the heatsinks? Is there one mounting surface of two?

At the moment the transistors are all mounted on one surface running almost the entire width of the heat sink. There doesn't seem to be a lot of flexibility to change that. The heat sink provides a flat surface top to bottom of the case on the side it connects with nothing in the way.

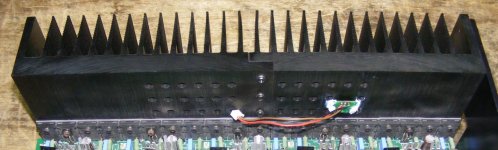

In fact, I think I can sufficiently redact a picture of it, sec...

I can't give exact dimensions because the unit is in the workshop at the moment and dimensions are not in the service manual but that should give you an idea. It sits about half way back in the amp separating the power and display sections from the rest of the circuitry.

I must stress that boards can be made, metal can be drilled etc and I'm really at the early stages of seeing what circuits are around which might fit the bill.

Thanks for taking an interest. I do apologise for any ambiguity. I'm trying not to casually use any terms I'm only 90% confident of and lead people up the garden path without spending a little time reading up but do ask if I miss something and I'll check it out. Also, I don't have the unit here to check right now. I'm in the early stages of kicking ideas around and seeing what sort of options are available before deciding whether to commit to the project.

At present the transformers are wired in parallel and putting out +60 and -60 (AC) so I'm fairly confident that is available from each but I want to physically check and read up a little rather than assume before I talk about centre taps and dual / single. I shall respond on that as soon as I'm able.

That's not great either is it. I am fumbling a little on this. I'm pretty confident that there's no regulation and they hook to smoothing caps and a rectifier and result in two rails, one +60V DC and one -60V DC. Hope that a little more clear / less rubbish.

Last edited:

60 VAC output from the transformer will give you +/- 85V rails. Judging by the way those transistors are mounted, it's unlikely this amplifier was running at that high rail voltages. This looks like a 5 channel 100W design. Can you post some pictures or specs on the transformer(s)?

That heat sink surface would be good for a single 300W channel of one of VZaichenko's NS series amplifier channels. In a high power design the transistors normally are spaced farther apart for cooling. With them mounted like that, the center ones can run hotter and current hog, causing self destruction.

With the modern day low cost of output devices, it's not worth bothering to try to reuse old output devices. The power supply and chassis are the majority of the cost of the amplifier. If you want to build a high power amplifier, do yourself a favor and start with all new parts in the amplifier channels themselves.

That heat sink surface would be good for a single 300W channel of one of VZaichenko's NS series amplifier channels. In a high power design the transistors normally are spaced farther apart for cooling. With them mounted like that, the center ones can run hotter and current hog, causing self destruction.

With the modern day low cost of output devices, it's not worth bothering to try to reuse old output devices. The power supply and chassis are the majority of the cost of the amplifier. If you want to build a high power amplifier, do yourself a favor and start with all new parts in the amplifier channels themselves.

"60 VAC output from the transformer will give you +/- 85V rails. Judging by the way those transistors are mounted, it's unlikely this amplifier was running at that high rail voltages. This looks like a 5 channel 100W design. Can you post some pictures or specs on the transformer(s)?

That heat sink surface would be good for a single 300W channel of one of VZaichenko's NS series amplifier channels. In a high power design the transistors normally are spaced farther apart for cooling. With them mounted like that, the center ones can run hotter and current hog, causing self destruction.

With the modern day low cost of output devices, it's not worth bothering to try to reuse old output devices. The power supply and chassis are the majority of the cost of the amplifier. If you want to build a high power amplifier, do yourself a favor and start with all new parts in the amplifier channels themselves. "

Thank you, that's all very helpful. I posted that last comment because I clicked that +/- 60V rails weren't 60V AC so was trying to clear it up. I think until I can get further info let's just say I can produce + and - 60V DC rails.

I did rather grit my teeth when I reviewed that picture and saw the transistors all huddled together. It may be possible to split it and mount half at the top and half at the bottom. It probably makes more sense for board layout anyway.

You may be on to something with the transistors. It would be nice to have the thing reborn with it's existing chips but there's no point being too precious about that so comments definitely taken on board.

I'd still be interested to hear of any circuits which would work with these output devices and potentially produce the kind of power and quality I'm after but there's no harm in throwing it open to other transistors I guess

That heat sink surface would be good for a single 300W channel of one of VZaichenko's NS series amplifier channels. In a high power design the transistors normally are spaced farther apart for cooling. With them mounted like that, the center ones can run hotter and current hog, causing self destruction.

With the modern day low cost of output devices, it's not worth bothering to try to reuse old output devices. The power supply and chassis are the majority of the cost of the amplifier. If you want to build a high power amplifier, do yourself a favor and start with all new parts in the amplifier channels themselves. "

Thank you, that's all very helpful. I posted that last comment because I clicked that +/- 60V rails weren't 60V AC so was trying to clear it up. I think until I can get further info let's just say I can produce + and - 60V DC rails.

I did rather grit my teeth when I reviewed that picture and saw the transistors all huddled together. It may be possible to split it and mount half at the top and half at the bottom. It probably makes more sense for board layout anyway.

You may be on to something with the transistors. It would be nice to have the thing reborn with it's existing chips but there's no point being too precious about that so comments definitely taken on board.

I'd still be interested to hear of any circuits which would work with these output devices and potentially produce the kind of power and quality I'm after but there's no harm in throwing it open to other transistors I guess

Last edited:

+/-60Vdc rails will get you close to 200W average into 8 ohms.

Thank you, that's interesting. I really need to get more info on the config of the transformers.

From your photo it looks like you want to share both channels with the one heatsink? In this case my previous temperature calc is incorrect.

If your rails are +/-60Vdc you are looking at a max of 200W/channel avg, or 400W average total. At class B efficiency this would mean your heatsink has to dissipate 200W. Heatsink T=200*.25+25=75C. Add 20% for error T=90C.

90C is too hot.

Re: existing trannies. There is a lot of work involved in replacing 20 power transistors as well as cost. If they aren't damaged I'd keep 'em.

If your rails are +/-60Vdc you are looking at a max of 200W/channel avg, or 400W average total. At class B efficiency this would mean your heatsink has to dissipate 200W. Heatsink T=200*.25+25=75C. Add 20% for error T=90C.

90C is too hot.

Re: existing trannies. There is a lot of work involved in replacing 20 power transistors as well as cost. If they aren't damaged I'd keep 'em.

From your photo it looks like you want to share both channels with the one heatsink? In this case my previous temperature calc is incorrect.

If your rails are +/-60Vdc you are looking at a max of 200W/channel avg, or 400W average total. At class B efficiency this would mean your heatsink has to dissipate 200W. Heatsink T=200*.25+25=75C. Add 20% for error T=90C.

90C is too hot.

Re: existing trannies. There is a lot of work involved in replacing 20 power transistors as well as cost. If they aren't damaged I'd keep 'em.

Yeah, it's shared between all channels, which were originally specced as 5 x 100W (with not much additional detail). After servicing an AP test rig showed 150W with one channel driven into 8 ohms at 1% THD+N. I can't say I spent a lot of time running all five channels flat out as I mainly listen two channel but I can say that the main heat sink never got very hot. The fans probably helped.

Re: existing trannies. There is a lot of work involved in replacing 20 power transistors as well as cost. If they aren't damaged I'd keep 'em.

He's planning to junk the amplifier boards and install new. It's less work to throw out the old transistors at the same time.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Circuit Suggestions Wanted for 2SC5200 / 2SA1943