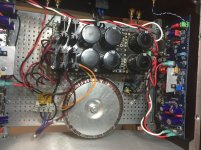

I came home Monday evening and my Honey Badger would only emit clicks after four years of faithful service. Same from both channels. Rail powered LEDs were lit. I opened it up and noticed the terminal block between the transformer and psi boards was burned. Resistance to ground as expected with capacitors in circuit, slowly rising from zero. Only the one terminal of one winding is burned.

Once disconnected from psi, secondaries to chassis shows infinite resistance. Secondary winding resistance identical. Line fuses (6A slow blow) intact.

PSU capacitors are bulging. With 40 VAC secondaries 63V caps are too close to their maximum voltage. They will be replaced.

Any ideas why only one side of the circuit would arc/burn its terminal block? Anything else I should look for?

Thanks in advance.

Once disconnected from psi, secondaries to chassis shows infinite resistance. Secondary winding resistance identical. Line fuses (6A slow blow) intact.

PSU capacitors are bulging. With 40 VAC secondaries 63V caps are too close to their maximum voltage. They will be replaced.

Any ideas why only one side of the circuit would arc/burn its terminal block? Anything else I should look for?

Thanks in advance.

Attachments

These style of terminal block are notorious for the connection coming loose. The copper wire relaxes and shrinks a bit under the clamp, then the connection is slightly loose, then it gets hot, the wire becomes annealed and shrinks more, causing a looser, hotter connection until it burns up.

When you find a defect as this one .... overheating connector ... there is only 2 possible explanations you may have ....

overcurrent in a well set connector ... or

normal current in a bad or loose connector ..... maybe dirty ??

since there is only one connector overheating ... where is the return ??

I think you should replace the connector an then start investigating to see if there is another problem ...

overcurrent in a well set connector ... or

normal current in a bad or loose connector ..... maybe dirty ??

since there is only one connector overheating ... where is the return ??

I think you should replace the connector an then start investigating to see if there is another problem ...

Thanks for the replies. I suspected it was arcing. The terminal just to the right/above the burnt one is the other side of the circuit. No significant discoloration. I'm happy to have other opinions.

I'm thinking the caps are just running too close to their limits. New PSU in the works. I have a Leach amp of similar vintage and voltage showing the same bulging. I bought a big batch of surplus caps not realizing how hard I'd be pushing them. Guess I'm going to make Digikey happy with an order for 30 big caps.

I'm thinking the caps are just running too close to their limits. New PSU in the works. I have a Leach amp of similar vintage and voltage showing the same bulging. I bought a big batch of surplus caps not realizing how hard I'd be pushing them. Guess I'm going to make Digikey happy with an order for 30 big caps.

I have not had any problem with running 63V smoothing capacitors at voltages up to 60V.

I did replace one capacitor (during a long and extended assmebly) that had a bulge before I powered the amp on for the first time.

Since then I have reused that capacitor since it appeared to perform as well as any of the others.

The rating on the capacitor is the maximum working voltage.

All ratings will have a factor of safety (FoS). They don't instantly blow up because they have 63.1V across them. Reliability gets worse the higher the over voltage above the rated working voltage.

I did replace one capacitor (during a long and extended assmebly) that had a bulge before I powered the amp on for the first time.

Since then I have reused that capacitor since it appeared to perform as well as any of the others.

The rating on the capacitor is the maximum working voltage.

All ratings will have a factor of safety (FoS). They don't instantly blow up because they have 63.1V across them. Reliability gets worse the higher the over voltage above the rated working voltage.

Thanks, Andrew. I know rated voltage isn't a break point, but I've got a dozen caps and 11 are bulging. They were flat topped when installed four years ago. My Leach amp has another 16, 14 of which are bulging. Bulging meaning I can feel the scoring in the top through the paper cap. Both amps use the same transformer and have similar usage history. The Leach powered subwoofers while the Honey Badger took care of the mains.

The caps were surplus at a very good price, so they don't owe me anything. I might get away with continuing to use them, but that exploded electrolytic cap smell wouldn't endear me to my sweetheart. I'll swap them out for new. Maybe I'll use the caps in a workshop amp to see how they last.

The caps were surplus at a very good price, so they don't owe me anything. I might get away with continuing to use them, but that exploded electrolytic cap smell wouldn't endear me to my sweetheart. I'll swap them out for new. Maybe I'll use the caps in a workshop amp to see how they last.

It's in a store 4U chassis using the baseplate. There seems to be plenty of ventilation and the sinks rarely get above 30° C. You'd think that would be plenty, but I'm guessing that the surplus stock was really old. Nichicon LQ(M) have been obsolete for a while. What I've been able to find suggests they are a 2000 hour cap. I'd think that they have much more time on them than that. Not at max temperature, though.

Here's the layout.

Here's the layout.

Attachments

Last edited:

Hi Bob,

I'd also suggest you to replace these terminal blocks. You just clamped the litz ends into it, or soldered the ends right before clamping, didn't you? So the screw with that burned isolating stuff around it's head perhaps wasn't fastened enough, or did become loose, or the litz wires, or the solder was screeping - as the others yet mentioned.

When using screw terminal blocks to connect litz wires, I'd strongly recommend to crimp these to the litz ends and then securely screw that into the blocks:

or these:

(Sorry, I don't know the English word for them...)

In Germany, administered by VDE, these are obligate with litz wire - for the reason you were observing. You can really call yourself a lucky man, 'cause your unit didn't catch fire!

Your slightly bulging caps do not have anything to do with your burned termination block. As they were from a surplus distibutor, you don't exactly know their age - and the condition they were used or stored in before.

Best regards!

I'd also suggest you to replace these terminal blocks. You just clamped the litz ends into it, or soldered the ends right before clamping, didn't you? So the screw with that burned isolating stuff around it's head perhaps wasn't fastened enough, or did become loose, or the litz wires, or the solder was screeping - as the others yet mentioned.

When using screw terminal blocks to connect litz wires, I'd strongly recommend to crimp these to the litz ends and then securely screw that into the blocks:

or these:

(Sorry, I don't know the English word for them...)

In Germany, administered by VDE, these are obligate with litz wire - for the reason you were observing. You can really call yourself a lucky man, 'cause your unit didn't catch fire!

Your slightly bulging caps do not have anything to do with your burned termination block. As they were from a surplus distibutor, you don't exactly know their age - and the condition they were used or stored in before.

Best regards!

Were the wires tinned before being inserted into the terminal blocks? If so this will explain the failure. The solder will crystallize when placed under pressure and eventually cause a high resistance joint. Its best to crimp a ferrule into the wire before inserting and clamping it into the terminal block. And yes, check it after a few weeks of running.

I was thinking the same thing.. loose connection. I have seen it in the wiring to household sockets. The thing that made me unsure is the bulging power supply capacitors.

Many new homes in America require a special type of circuit breaker called a AFCI. Arc Fault Circuit Interrupter.

120V AC arcing can reach 10,000* F. Not a typo 10,000*F.

Very common cause of house fires, lamp / clock plugged into socket near bed, bed bumps plug, plug almost comes out but arcs. Poof.

I don't like those block connections simply because their flimsy, now I have a second reason. Thanks Bob.

Ron

I didn't know such a breaker existed.Many new homes in America require a special type of circuit breaker called a AFCI. Arc Fault Circuit Interrupter. ...........

from the wiki:

I have not heard of it being required in the UK. Maybe I'm just out of date.AFCI breakers have been required for circuits feeding electrical outlets in bedrooms of homes by the electrical codes of Canada and the United States since the beginning of the 21st century; since 2014, U.S. code has required them for outlets in most rooms in houses.

Anyone know of the UK requirement?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Honey Badger troubleshooting